Parallel mechanism with three freedom degrees of twice rotation and once motion

A degree of freedom and parallel technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems such as difficult calibration and complex kinematic models, and achieve the effect of simple kinematic model, simple and reliable structure, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

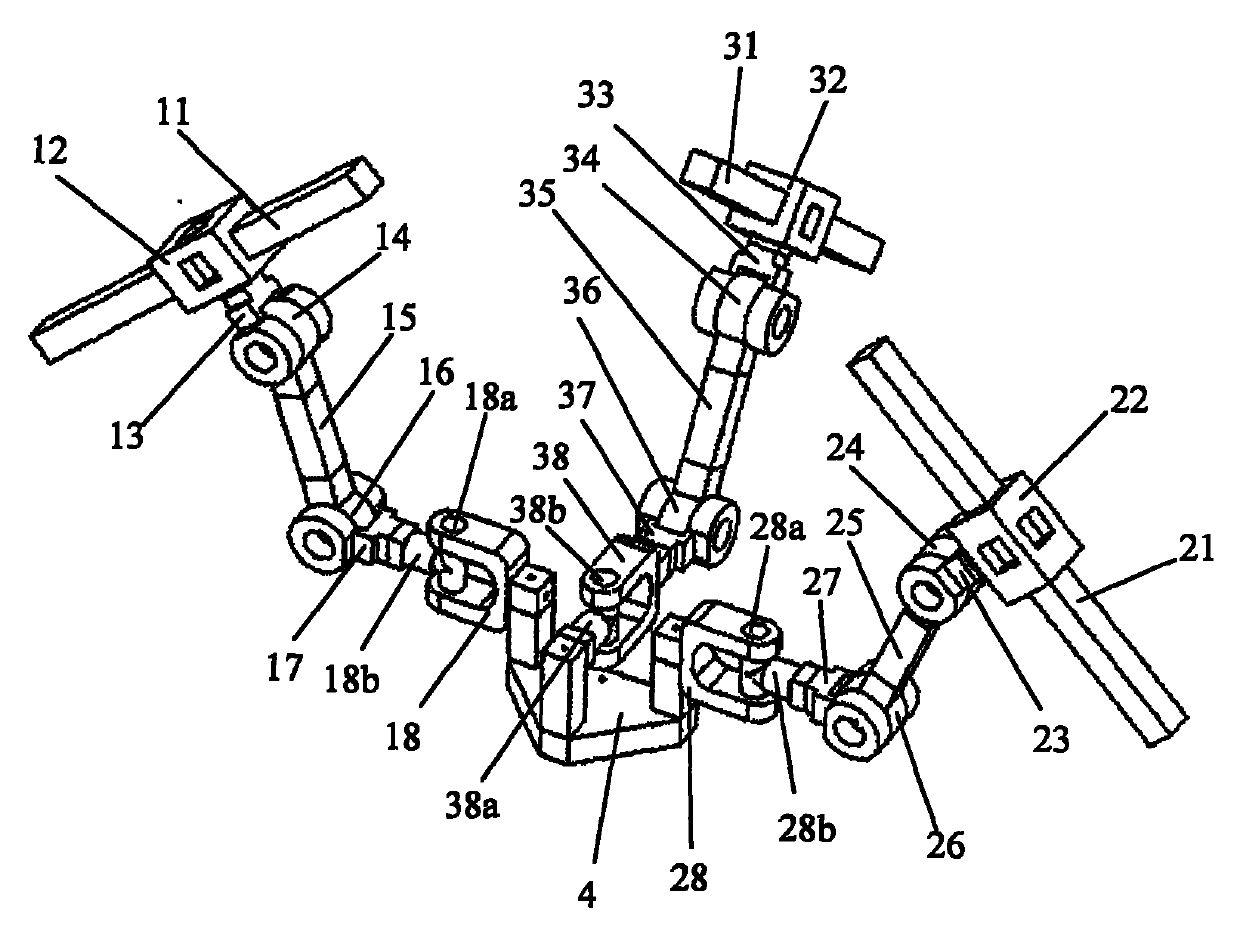

[0037] Such as figure 1 As shown, the moving platform 4 is connected with the frame 11, 21 and 31 through three branches with the same structure, and the moving pairs 12, 22, 32 in the branch are not parallel to each other and are connected with the frame 11, 21 and 31 respectively, and the connecting rod 13, One end of 23,33 is connected with moving pair 12,22,32 respectively, and the other end of connecting rod 13,23,33 is connected with rotating pair 14,24,34 respectively, and the axis of rotating pair 14,24,34 is respectively connected with moving The axes of pair 12, 22, 32 are vertical, one end of connecting rod 15, 25, 35 is respectively connected with rotating pair 14, 24, 34, and the other end of connecting rod 15, 25, 35 is connected with rotating pair 16, 26, 36 respectively , one end of the connecting rod 17, 27, 37 is connected with the revolving pair 16, 26, 36 respectively, and the other end of the connecting rod 17, 27, 37 is respectively connected with the sec...

Embodiment 2

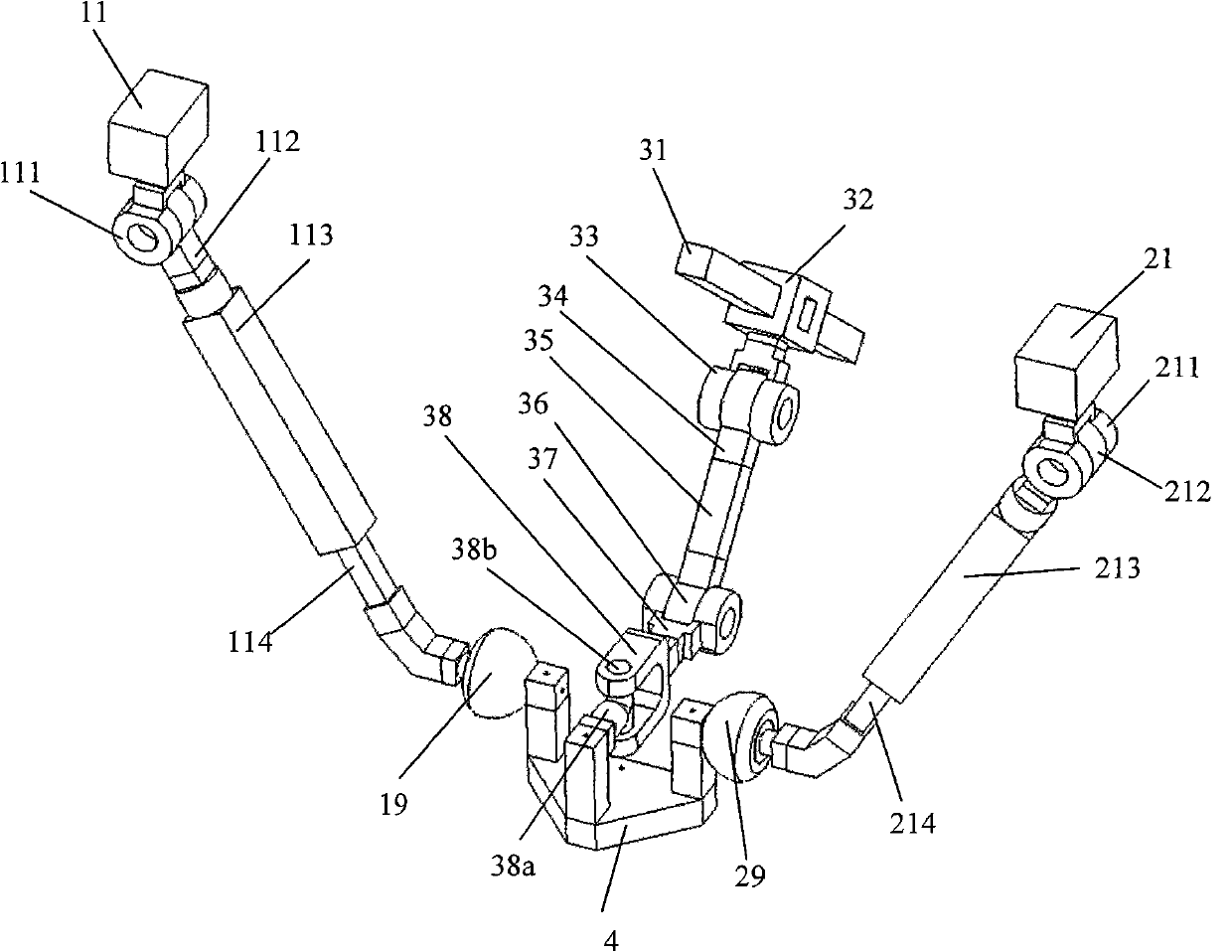

[0039] Such as figure 2 As shown, the moving platform 4 is connected to the frame 11, 21 and 31 through three branches with the same structure, the revolving pairs 111, 211, 311 are connected to the frame 11, 21 and 31 respectively, and one end of the connecting rod 112, 212, 312 is respectively It is connected with the rotating pair 111, 211, 311, the other ends of the connecting rods 112, 212, 312 are respectively connected with the moving pairs 113, 213, 313, and one end of the connecting rods 114, 214, 314 is respectively connected with the moving pairs 113, 213, 313, The other end of connecting rod 114,214,314 is connected with rotating pair 16,26,36 respectively, and one end of connecting rod 17,27,37 is connected with rotating pair 16,26,36 respectively, and the other end of connecting rod 17,27,37 One end is respectively connected with the second rotating shaft 18b, 28b, 38b of the universal joint 18, 28, 38, and the moving platform 4 is respectively connected with th...

Embodiment 3

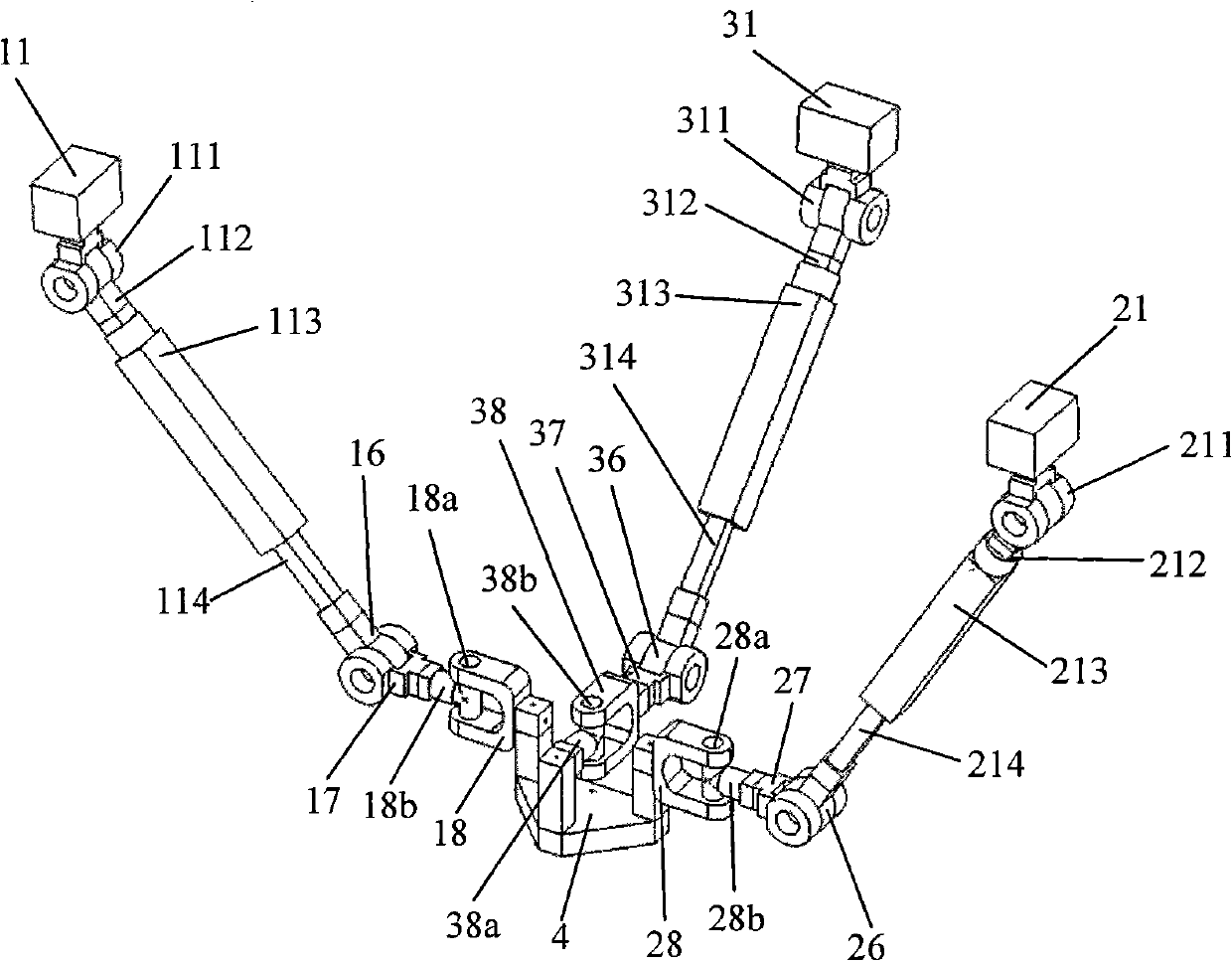

[0041] Such as image 3 As shown, the moving platform 4 is connected to the frame 11, 21 and 31 through three branches with the same structure, the revolving pairs 111, 211, 311 are connected to the frame 11, 21 and 31 respectively, and one end of the connecting rod 112, 212, 312 is respectively It is connected with the rotary pair 111, 211, 311, the other ends of the connecting rods 112, 212, 312 are respectively connected with the rotary pairs 116, 216, 316, and one end of the connecting rods 15, 25, 35 is respectively connected with the rotary pairs 116, 216, 316, The other end of connecting rod 15,25,35 is connected with rotating pair 16,26,36 respectively, and one end of connecting rod 17,27,37 is connected with rotating pair 16,26,36 respectively, and the other end of connecting rod 17,27,37 One end is respectively connected with the second rotating shaft 18b, 28b, 38b of the universal joint 18, 28, 38, and the moving platform 4 is respectively connected with the first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com