Automatic aeration system for underflow type artificial wet land

A technology of artificial wetland and automatic oxygenation, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc. Nitrogen capacity and other issues, to achieve the effect of convenient manufacture and installation, simple structure, and improved denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

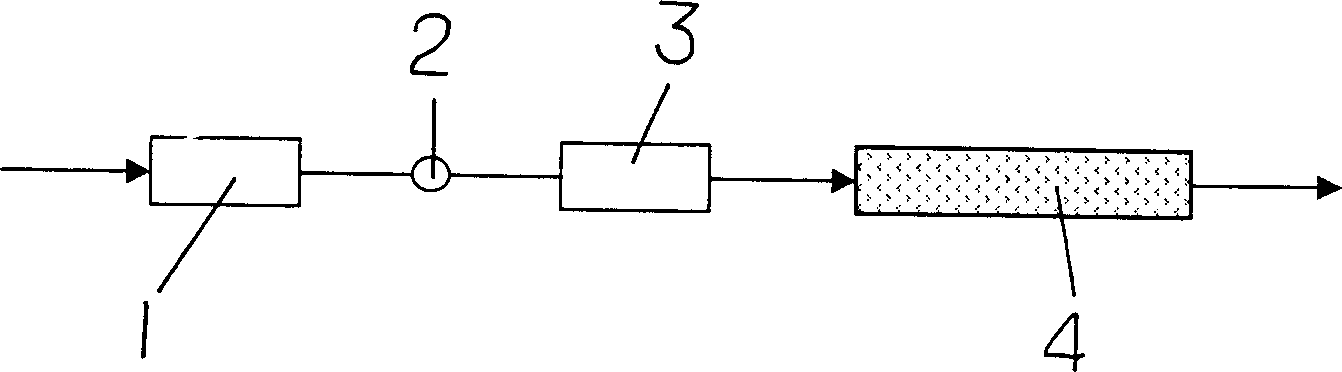

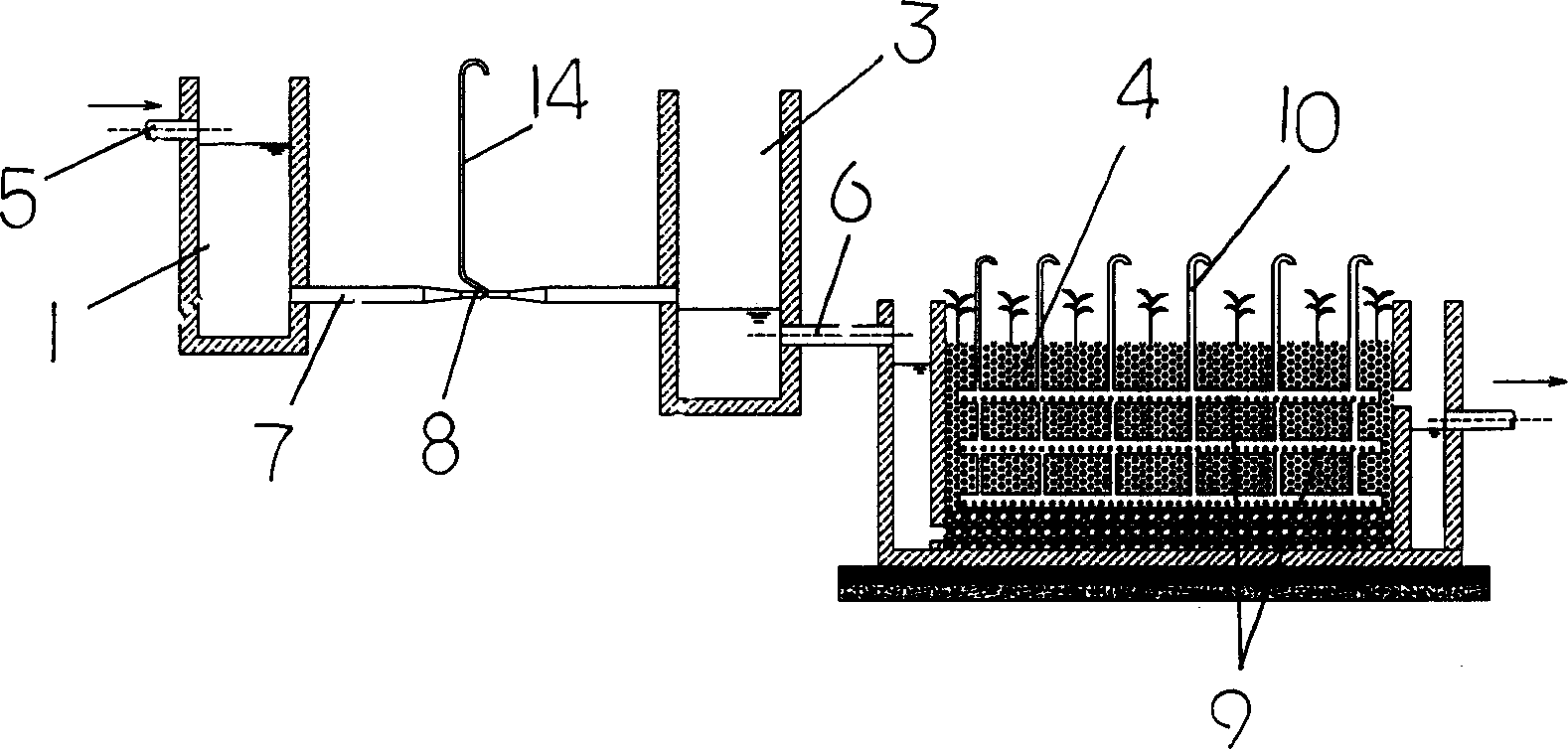

[0024] see figure 1 , figure 2 In this embodiment, No. I aerator tank 1, aerator 2 and No. II aerator tank 3 are arranged sequentially from the waste water input pipe 5 to the water inlet 6 of the submerged constructed wetland according to the drop of natural water flow. Wherein, the inlet of No. I aerator tank 1 communicates with the waste water input pipe 5, and the outlet of No. II aerator tank 3 communicates with the water inlet 6 of the submerged constructed wetland; an aeration pipeline is set in the constructed wetland 4.

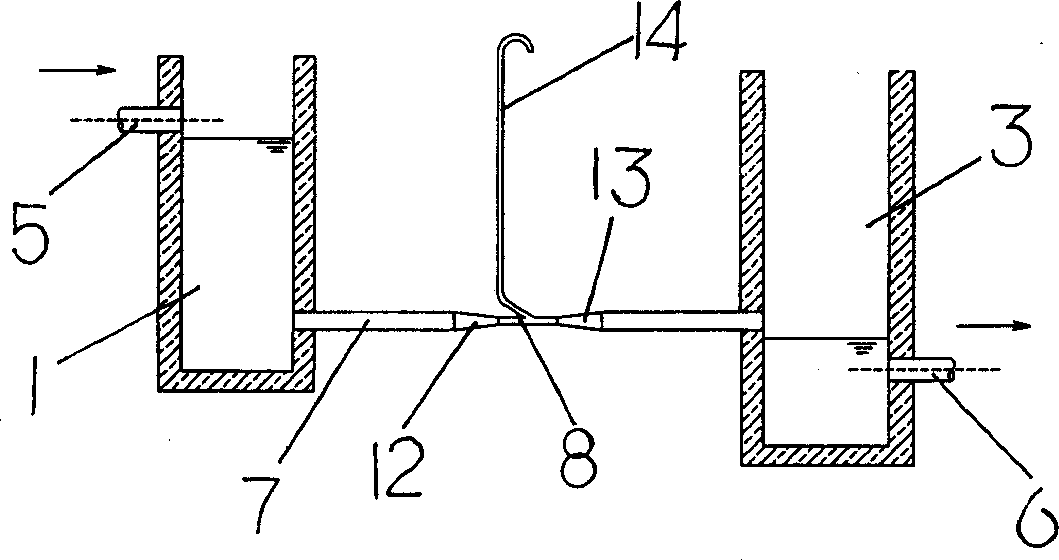

[0025] Referring to Fig. 3 (A), Fig. 3 (B), in the present embodiment, aerator 2 is to be connected on the connecting pipe 7 between No. I aerator water tank 1 and No. II aerator water tank 3, jet flow is set device 8. In a specific implementation, a tapered joint 12 and a tapered joint 13 are arranged in series in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com