Heat exchanger and air conditioner having the heat exchanger

A heat exchanger and air flow technology, applied in heat exchange equipment, fixed heat exchangers, indirect heat exchangers, etc., can solve the problems of increased heat transfer rate, increased pressure loss, increased cost, etc., to achieve thermal Increased interchangeability, good assembling properties, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

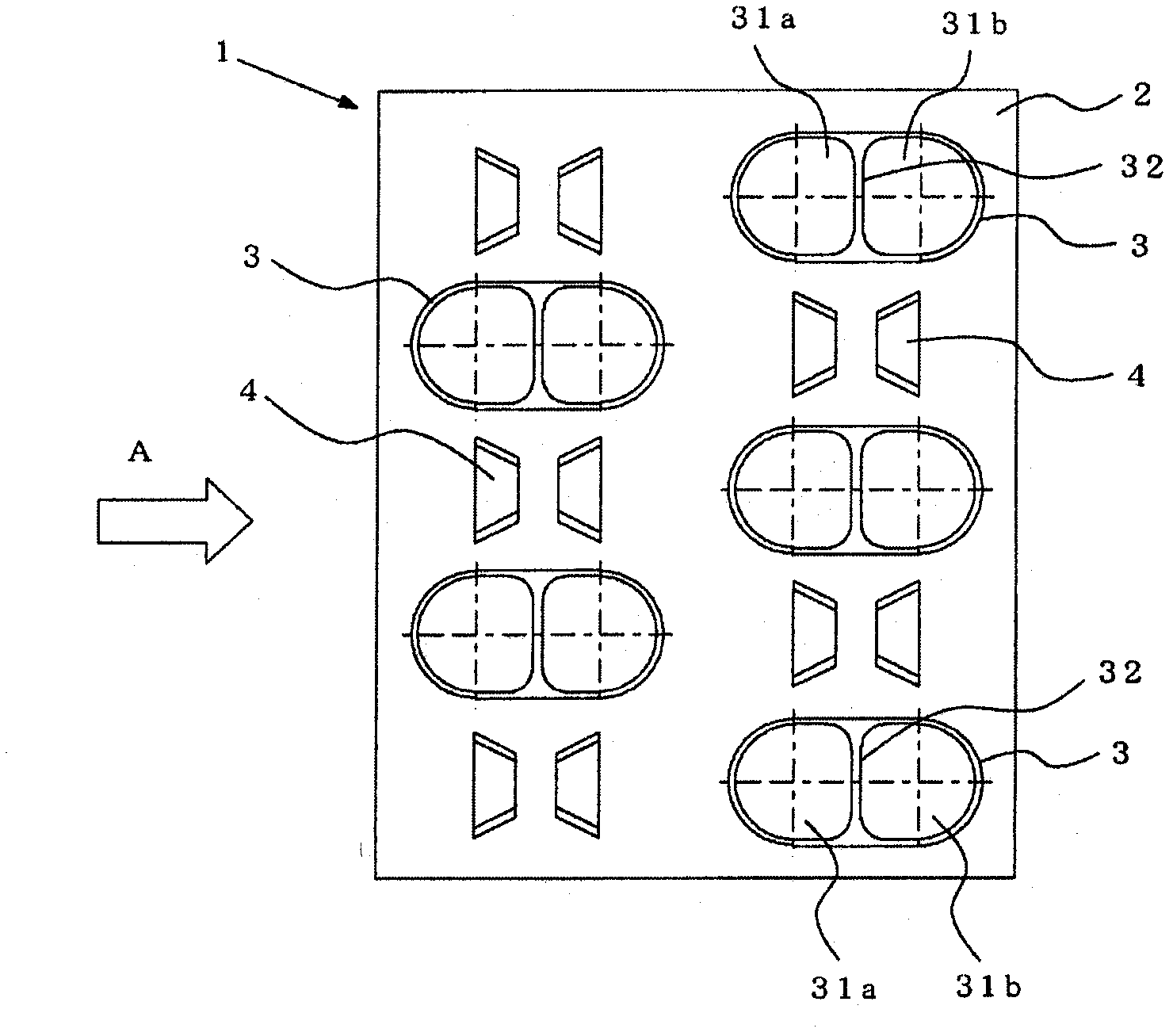

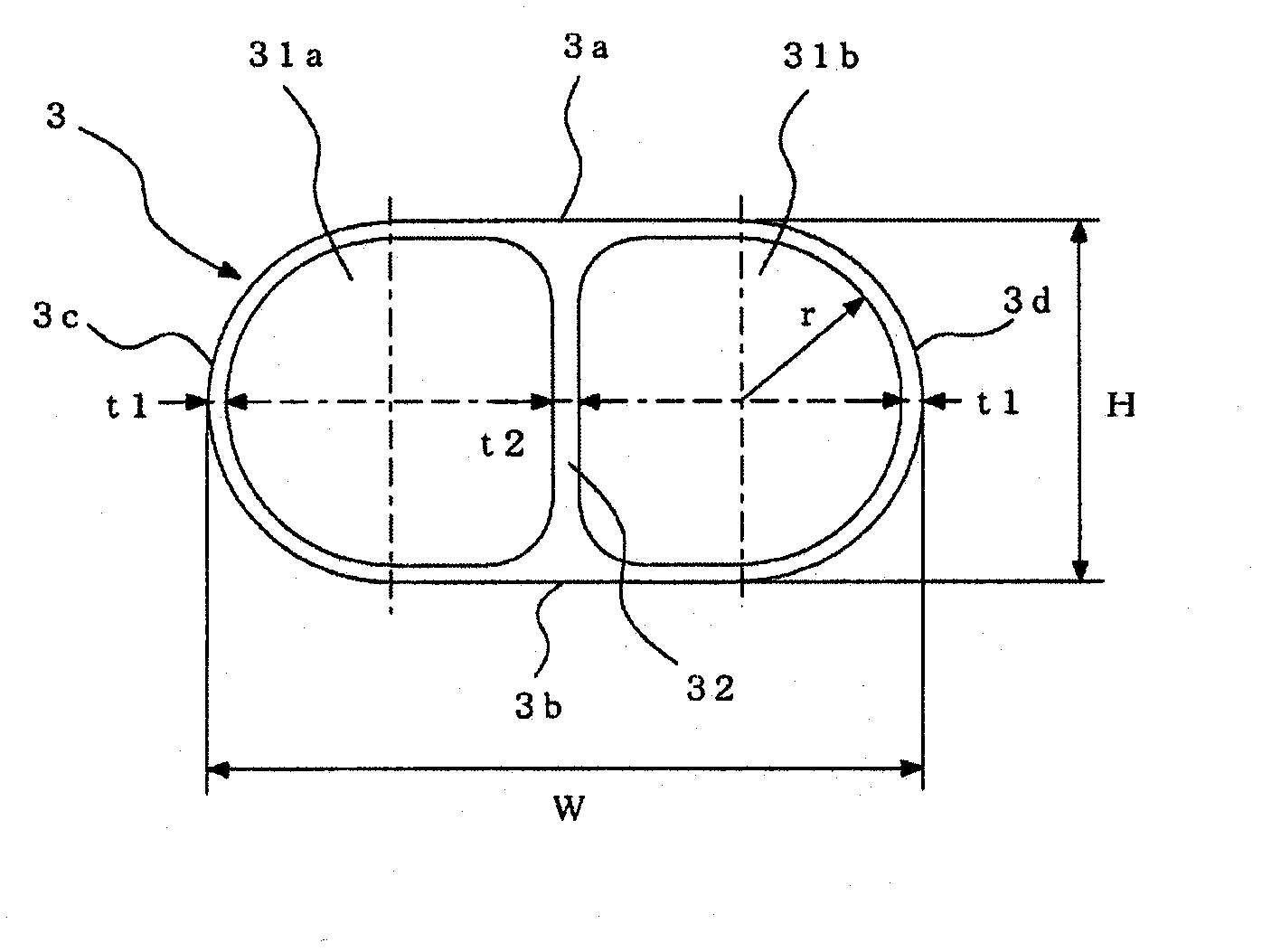

[0025] figure 1 It is a front view showing the outline of the heat exchanger according to Embodiment 1 of the present invention. exist figure 1 Among them, 1 is a heat exchanger, including: a plurality of plate-shaped fins 2 arranged at predetermined intervals; inserted in the direction perpendicular to the plate-shaped fins 2, through which the pipe is expanded (also called diameter expansion) ) and a plurality of flat-shaped heat transfer tubes 3 joined to the plate fins 2 . The plate-shaped fins 2 are made of metal plates such as copper or copper alloys, or aluminum or aluminum alloys (the same applies to other embodiments), and are parallel to the air flow direction A and at predetermined intervals in the vertical direction (depth direction) of the drawing. Arrange settings. Further, on the plate-shaped fins 2 , flat-shaped heat transfer tubes 3 , which will be described later, are provided in a plurality of stages and in one row or more in a direction perpendicular t...

Embodiment approach 2

[0033] Figure 5 It is a front view showing the flat heat transfer tube of Embodiment 2. The heat transfer tube 3 of this embodiment and figure 2 In the same way as in the case of FIG. 1 , first and second refrigerant passages 31a and 31b constituted by through holes having a substantially D-shaped cross section are provided on both sides in the width direction. In addition, on the inner wall surfaces of the first and second refrigerant passages 31a, 31b, there are provided in the axial direction at predetermined heights and intervals, respectively, with substantially quadrangular cross-section (the front end is formed in a shape with some roundness). a plurality of protrusions 33 .

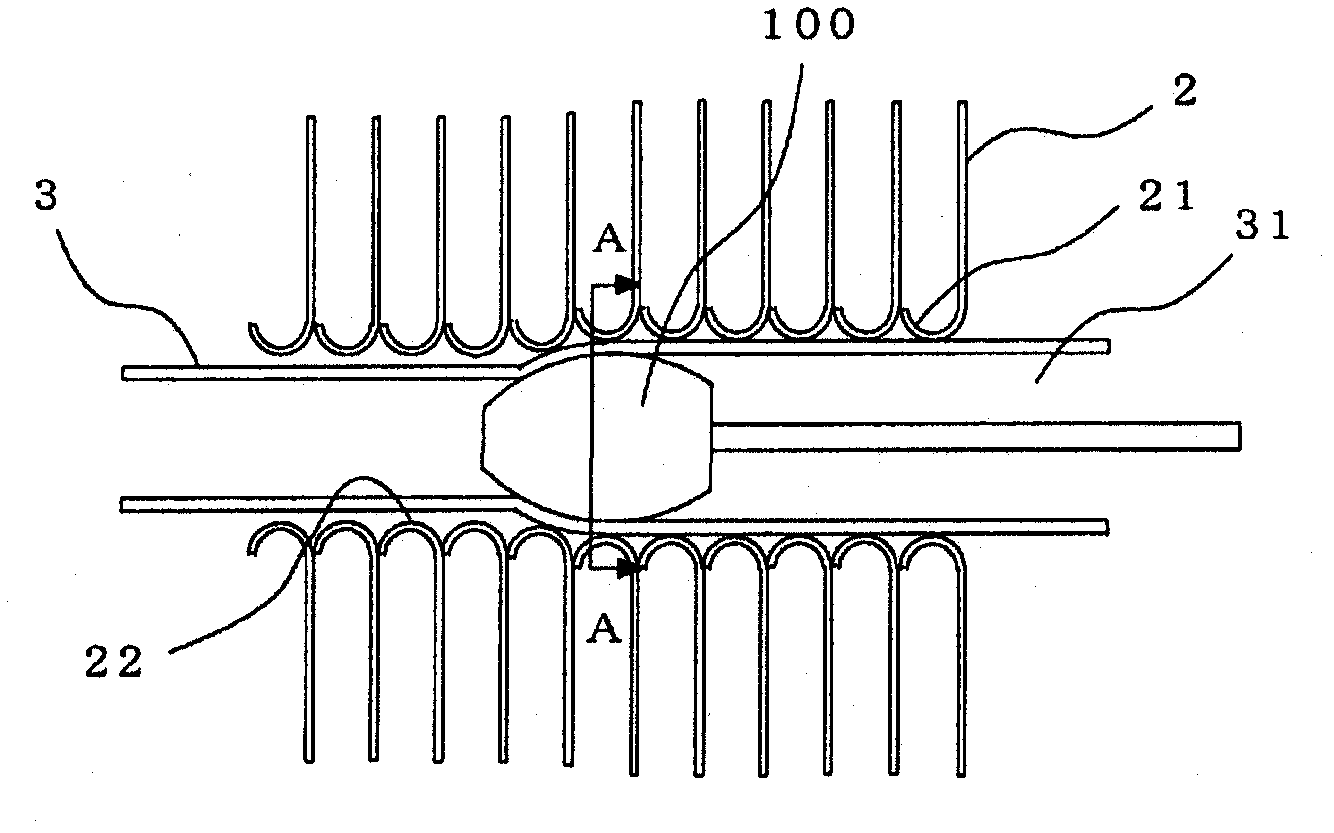

[0034]Such a flat-shaped heat transfer tube 3 is inserted into the mounting hole 22 of the plate-shaped fin 2 according to the above-mentioned point, and the pipe expander scraper ball 100 with the same cross-sectional shape (approximately D-shaped) as the above is used to pass through each pr...

Embodiment approach 3

[0037] Figure 7 It is a front view showing the flat heat transfer tube of Embodiment 3. The heat transfer tube 3 of this embodiment and figure 2 In the same way as in the case of FIG. 1 , first and second refrigerant passages 31a and 31b constituted by through holes having a substantially D-shaped cross section are provided on both sides in the width direction. In addition, on the inner wall surfaces of the first and second refrigerant passages 31a and 31b, a plurality of refrigerant passages having a substantially quadrilateral cross section (with some roundness at the front ends) are provided in the axial direction at predetermined heights and intervals. Protruding strips 33,34. The protruding strips 34 are arranged at the corners of the partition wall 32, and then set to the front ends of the protruding strips 33, 34 and the circle of the radius R according to the required height h, that is, the circular outer peripheral surface of the expander scraper ball 100 (refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com