New type dual oblique wave spraywater stuffing for cooling tower

A cooling tower, a new type of technology, applied in the direction of water shower cooler, heat exchanger type, direct contact heat exchanger, etc., can solve the problem of insufficient and uniform contact between hot water and cooling airflow, failure to achieve the best cooling effect, Problems such as poor homogenization and distribution of cooling water, to ensure uniformity, optimal cooling and cooling effect, and reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

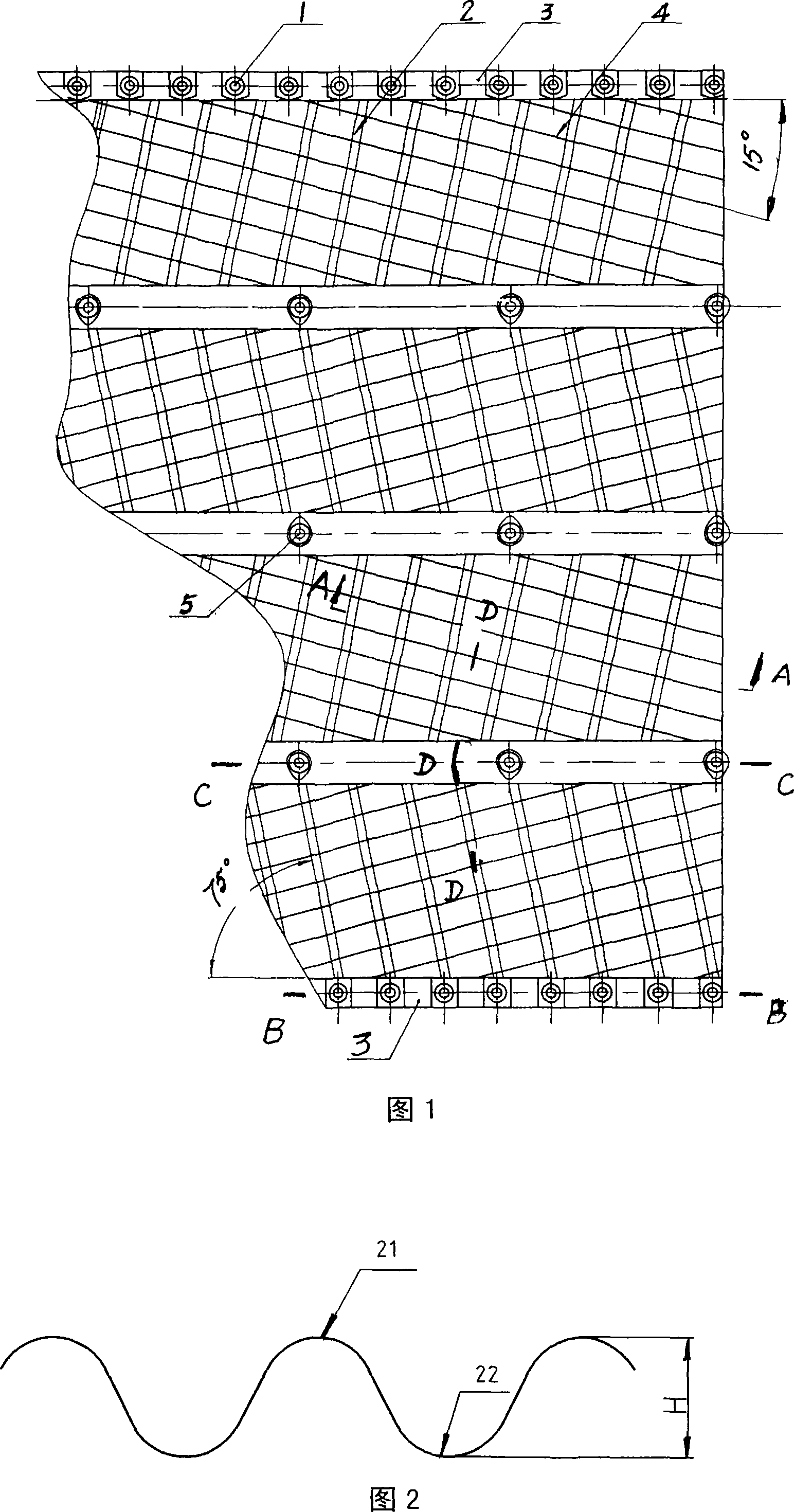

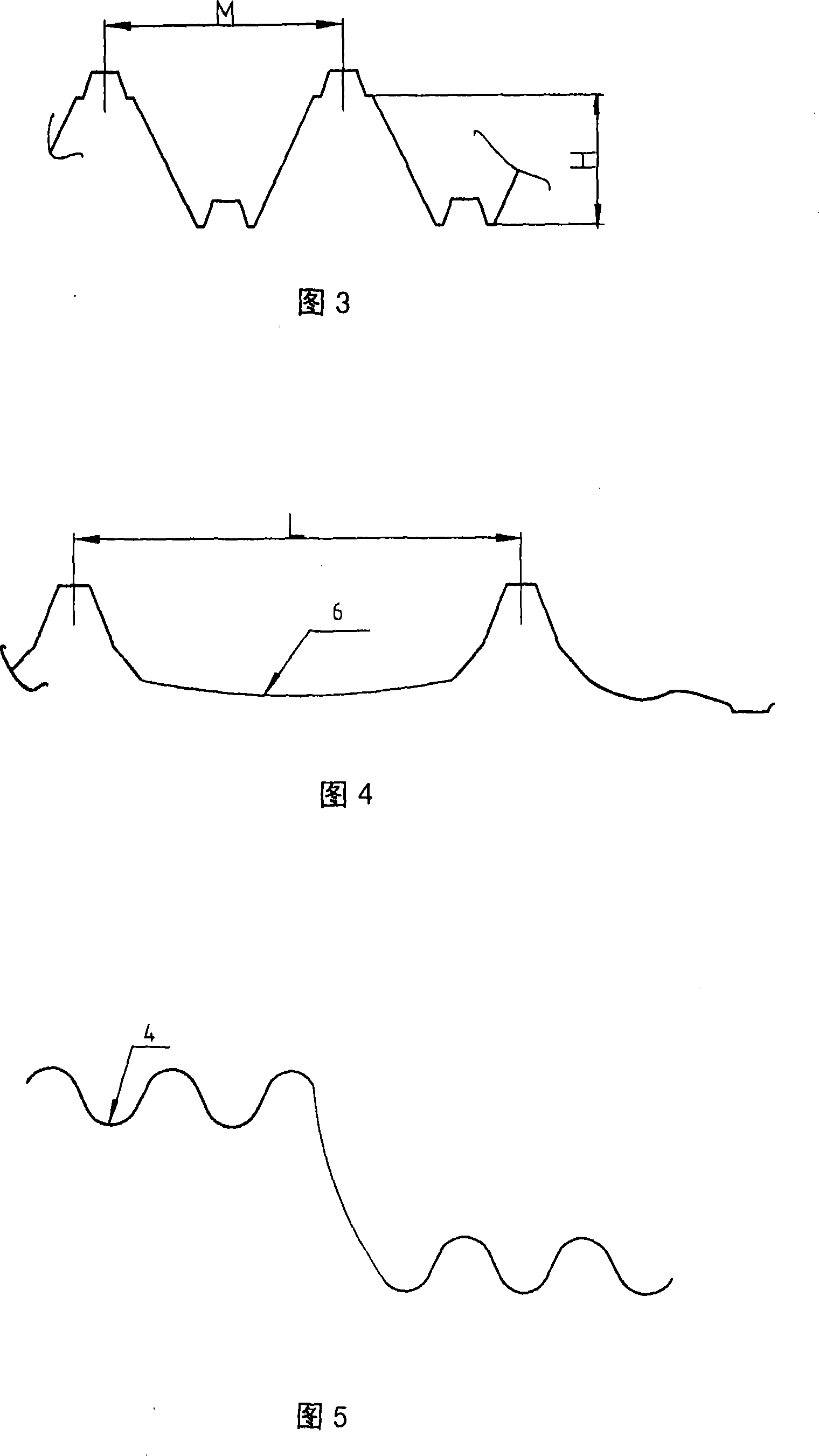

[0016] As shown in accompanying drawings 1-4, the cooling tower’s novel double-slant-wave spraying filler has several outer bonding points 1 on its length side 3, and four sets of main cooling bands 2 are arranged on the entire plate surface. , each main cooling band 2 is obliquely distributed and arranged at equal intervals. A wave distance is dislocated and reversed to form a "herringbone"-shaped water film flow channel. There are several inner bonding points 5 between two adjacent groups of main cooling bands 2, and the distance between the inner bonding points 5 is the outer bonding. 2 to 3 times the distance of point 1, 2 times in this example; several secondary retention corrugated grooves 4 with the same interval are added on the main cooling band 2, the cross-sectional shape of which is sinusoidal, and the length of the secondary retention corrugated grooves 4 is equal to The included angle between the sides 3 is 15°, the peak 21 of the main cooling band 2 and the trou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com