Patents

Literature

65results about How to "Reduce the impact of heat dissipation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

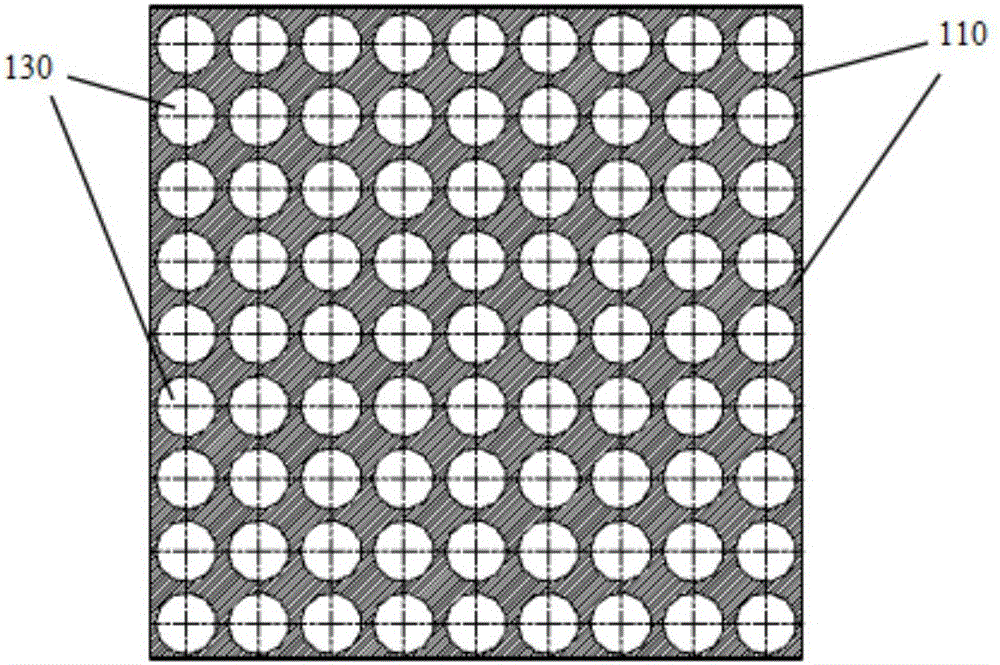

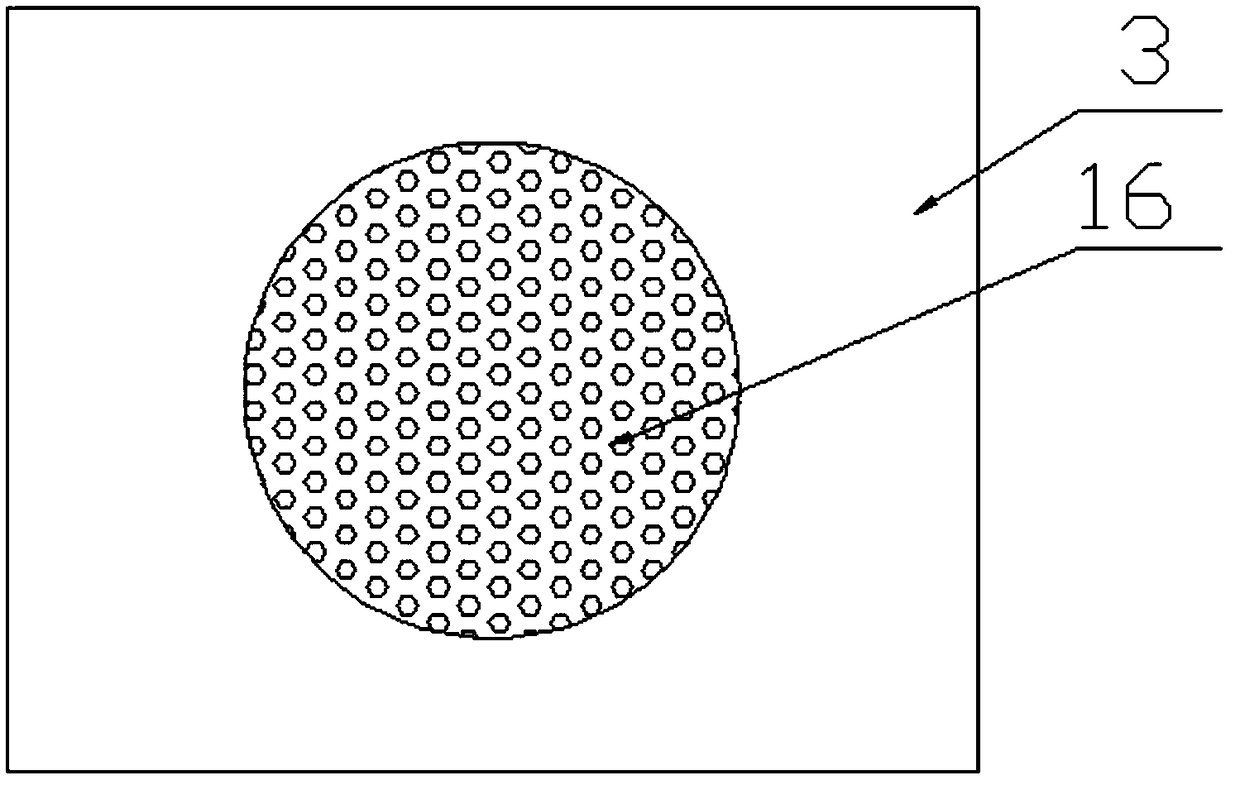

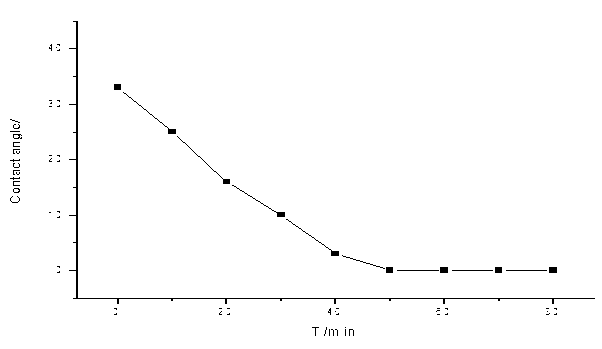

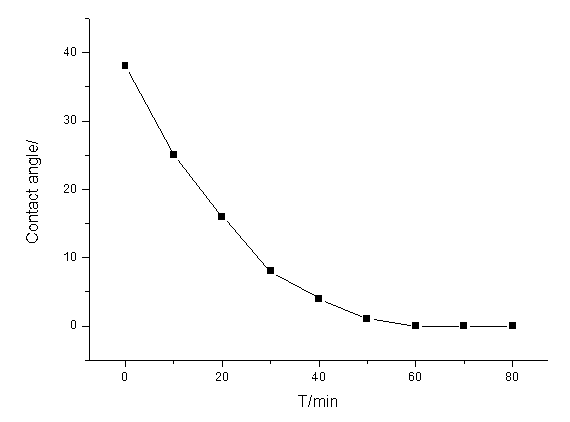

Surface-aluminum-evaporated peep-proof film with anti-reflection performance and preparation method thereof

ActiveCN105667042AInhibition lossReduce the impact of heat dissipationLamination ancillary operationsSynthetic resin layered productsHigh fluxImage resolution

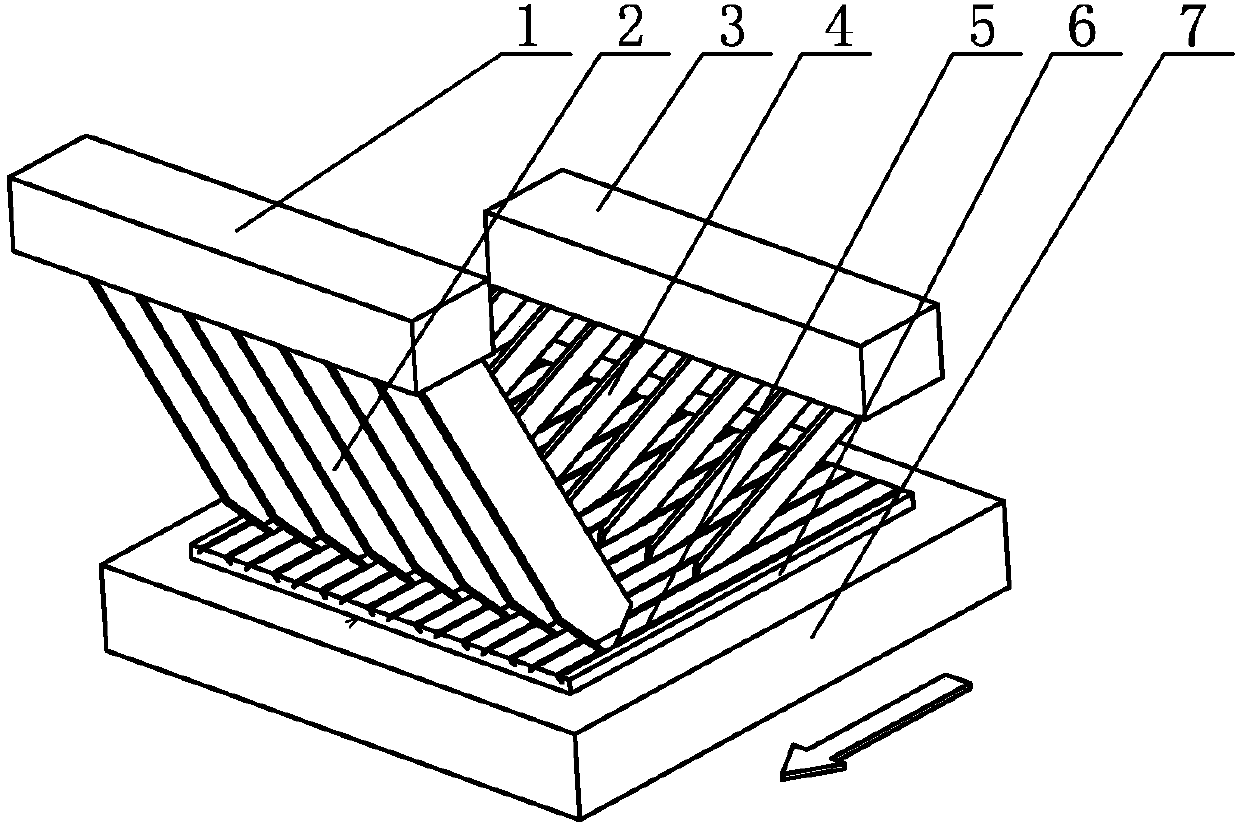

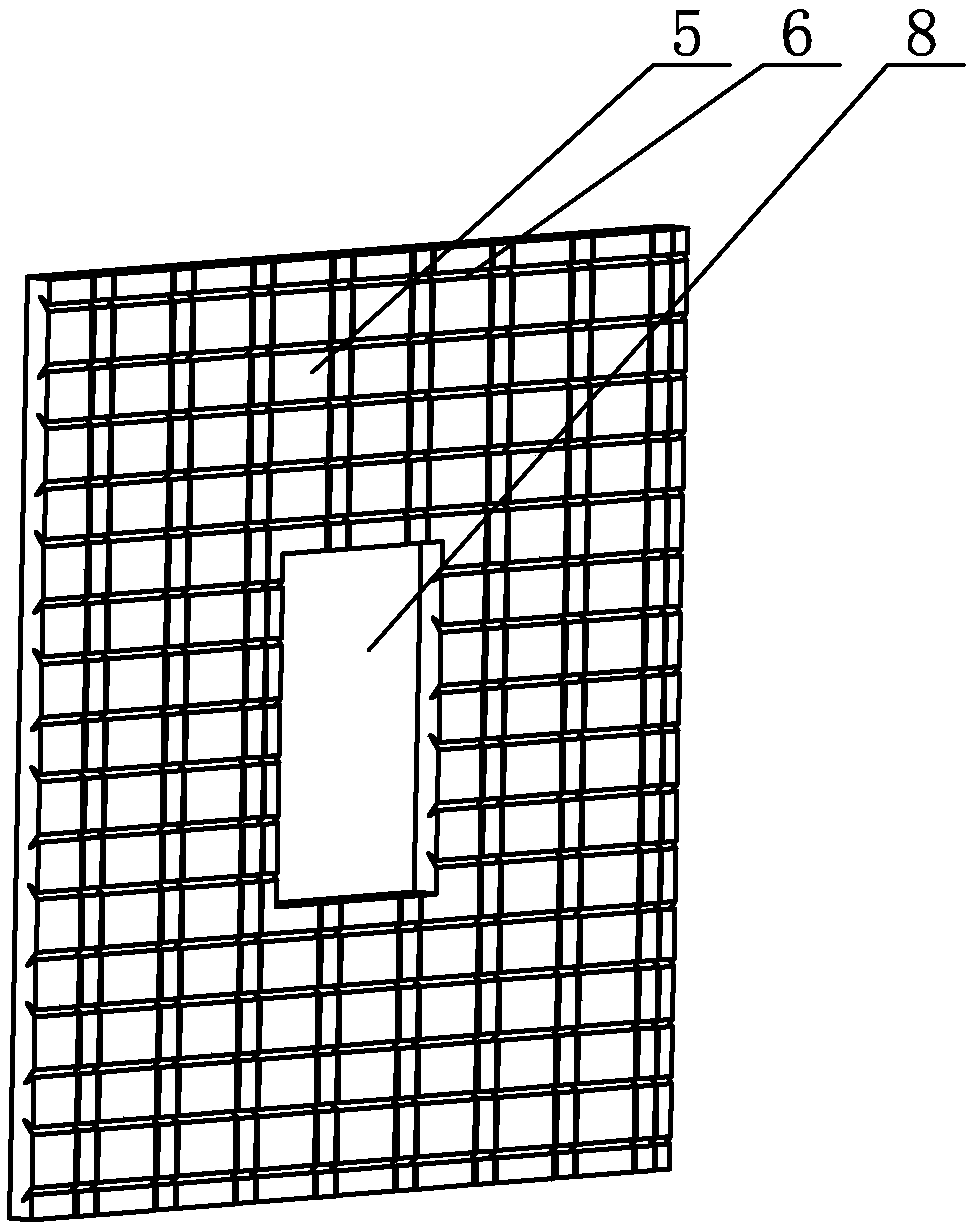

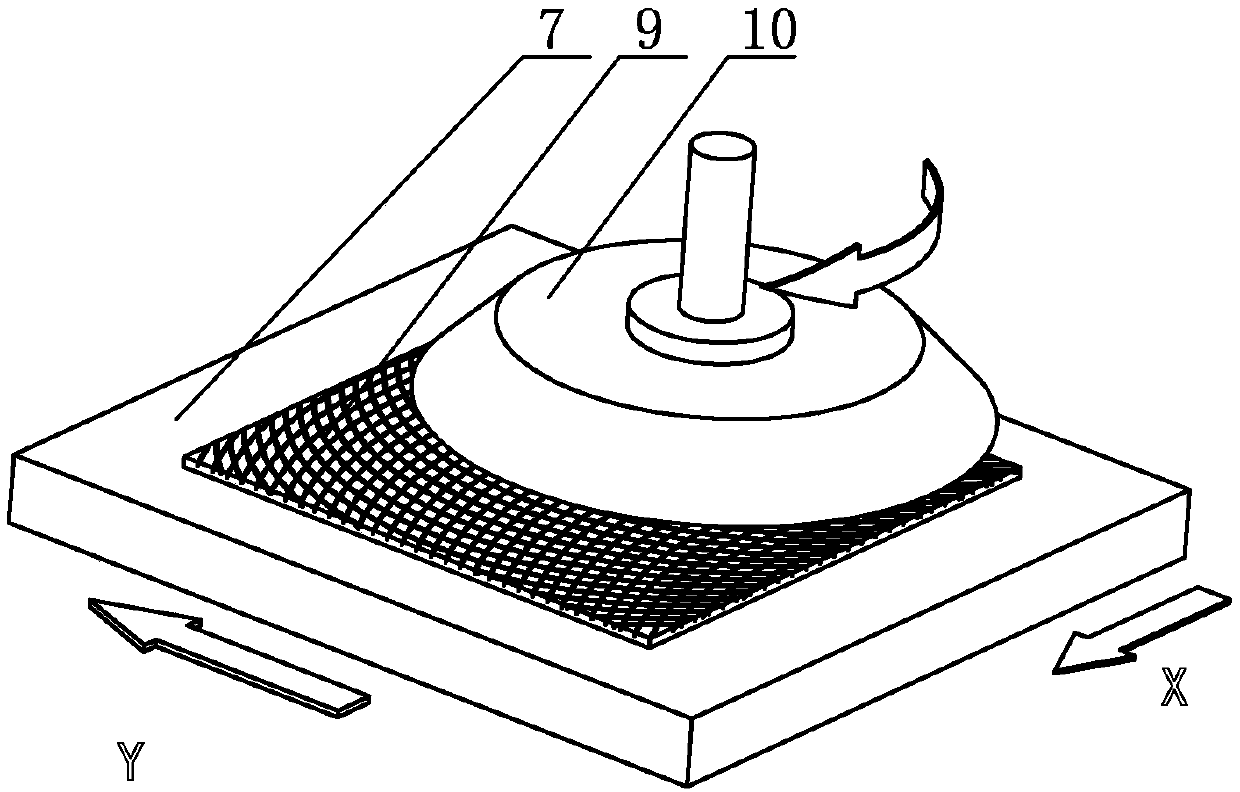

The invention relates to a surface-aluminum-evaporated peep-proof film with anti-reflection performance and a preparation method thereof. The peep-proof film comprises a PET layer and a peep-proof structure layer arranged on the surface of one side of the PET layer, wherein the peep-proof structure layer comprises a UV light-cured resin layer and an evaporated film layer evaporated on the surface of the resin layer; and the surface-aluminum-evaporated peep-proof film further comprises a moth-eye anti-reflection structure layer arranged on the surface of the other side of the PET layer. The preparation method comprises an adhesive dripping process, a filling process, a UV illumination process and a demolding process. Compared with the prior art, the surface-aluminum-evaporated peep-proof film disclosed by the invention has the advantages that different surfaces can be imprinted on both side surfaces of the PET layer; and the preparation method is simple, and commercial requirements on high speed, large area, high resolution and high flux can be met.

Owner:SHANGHAI JIAO TONG UNIV +1

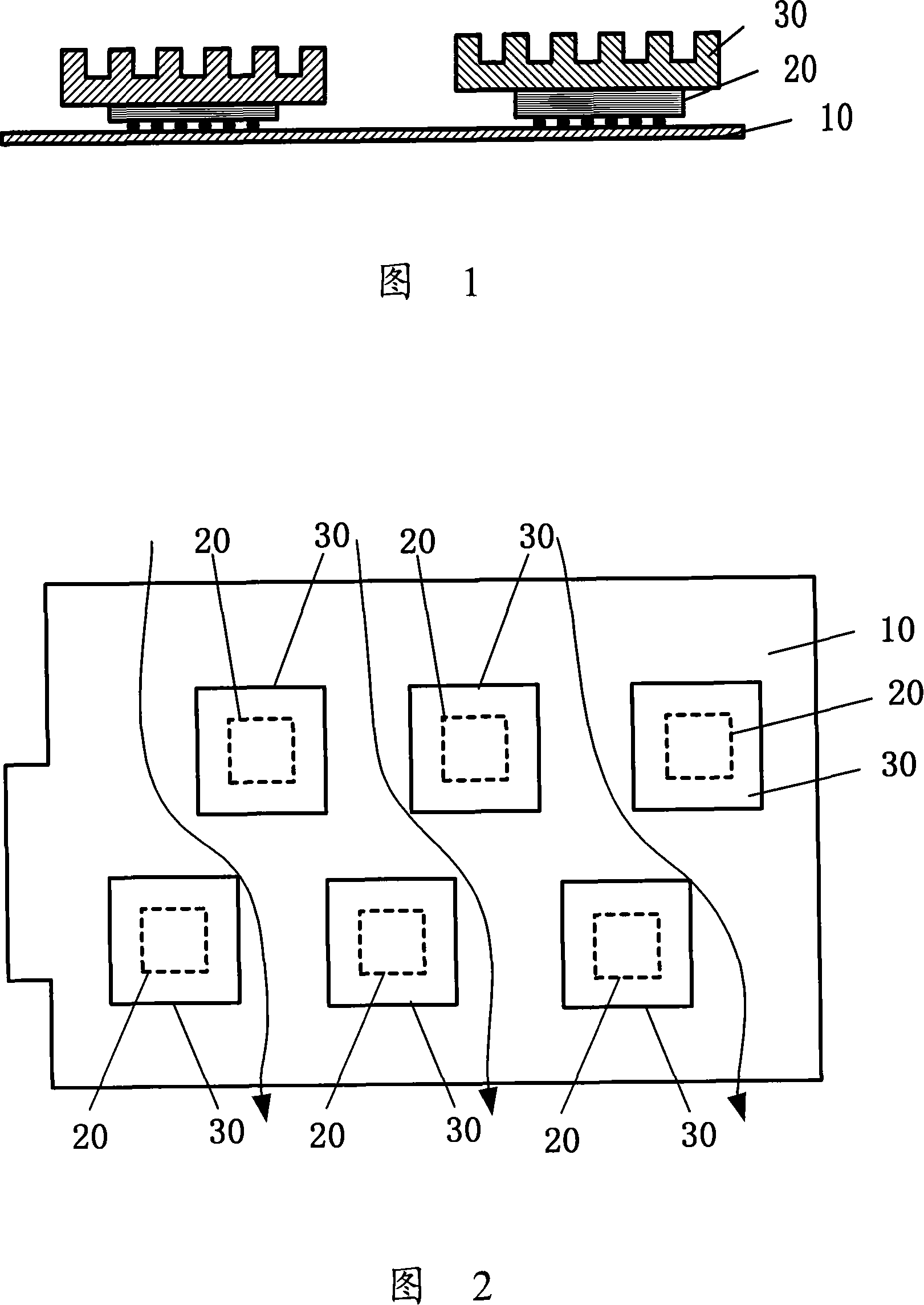

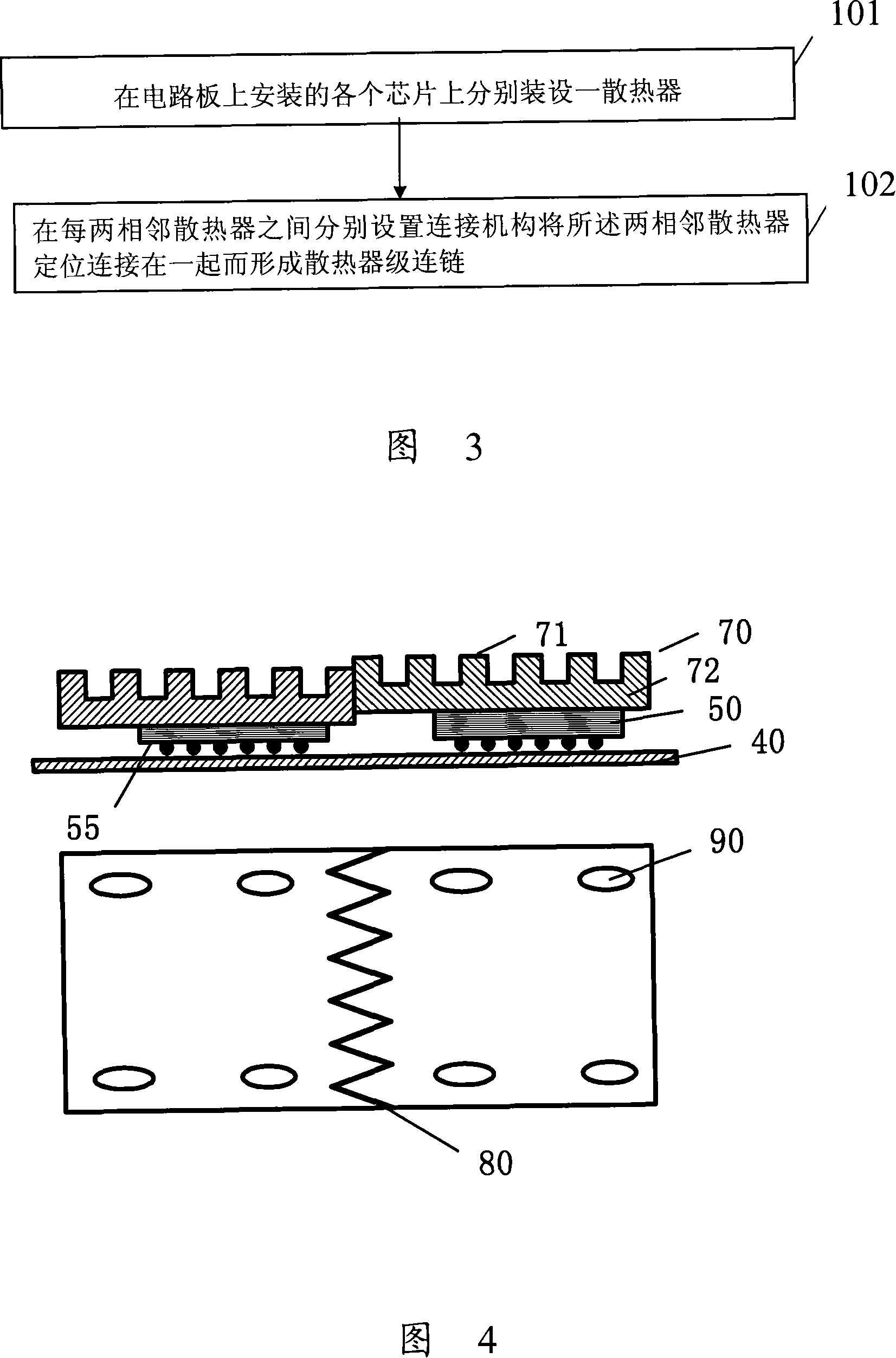

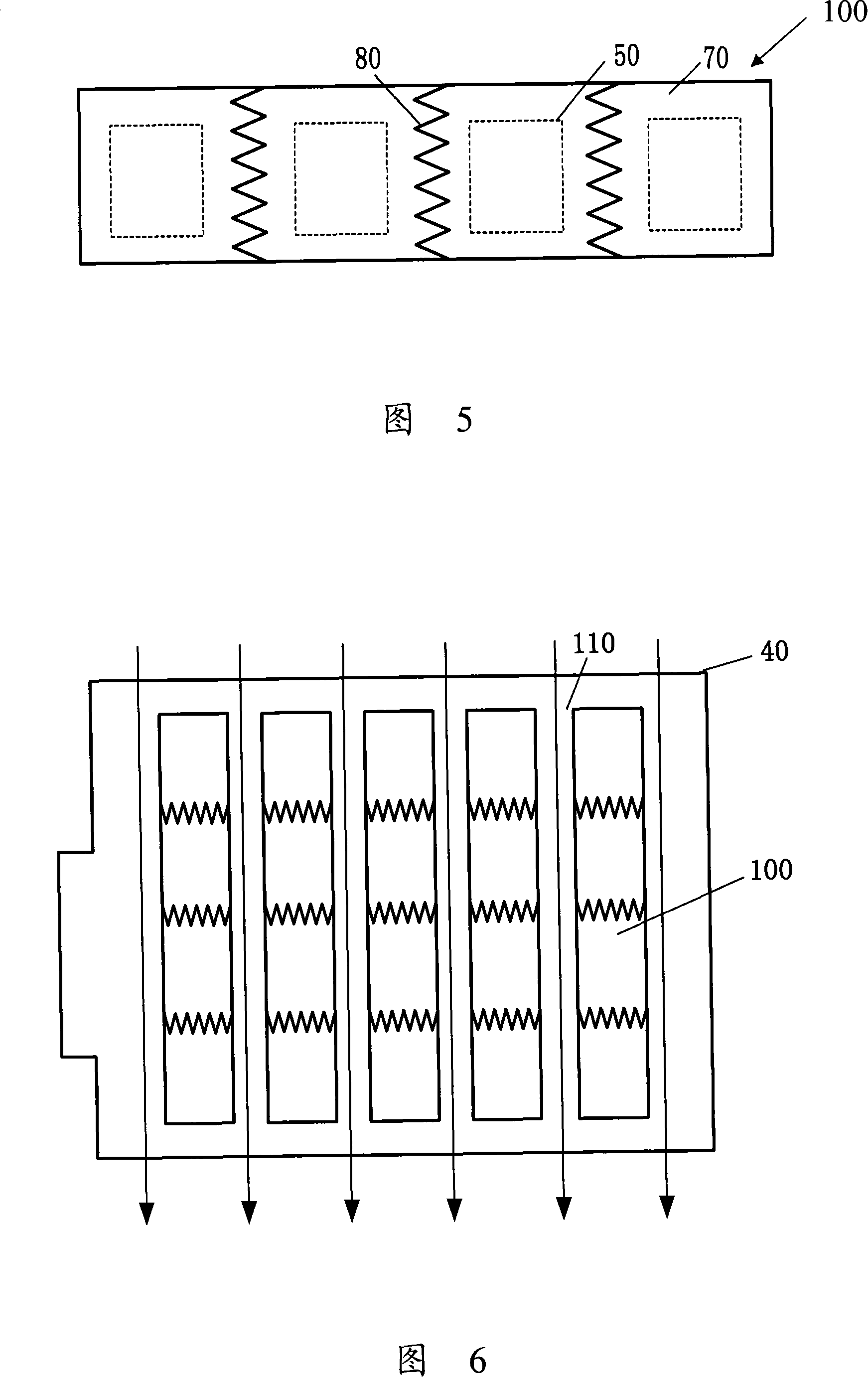

Integrated heat radiation method, system and corresponding heat radiation device

ActiveCN101150101AImprove cooling effectClose contactSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

This invention relates to an integrated radiation method, a system and a corresponding radiation device, which installs a radiator on each chip mounted on a CB and sets a connecting unit between two adjacent radiators to form a cascade chain to radiate for the covered chips, in which, chips at high temperature trabsmit heat to radiators with low temperature via the chain so as to provide a fine radiation performance for chips on a CB.

Owner:HUAWEI TECH CO LTD

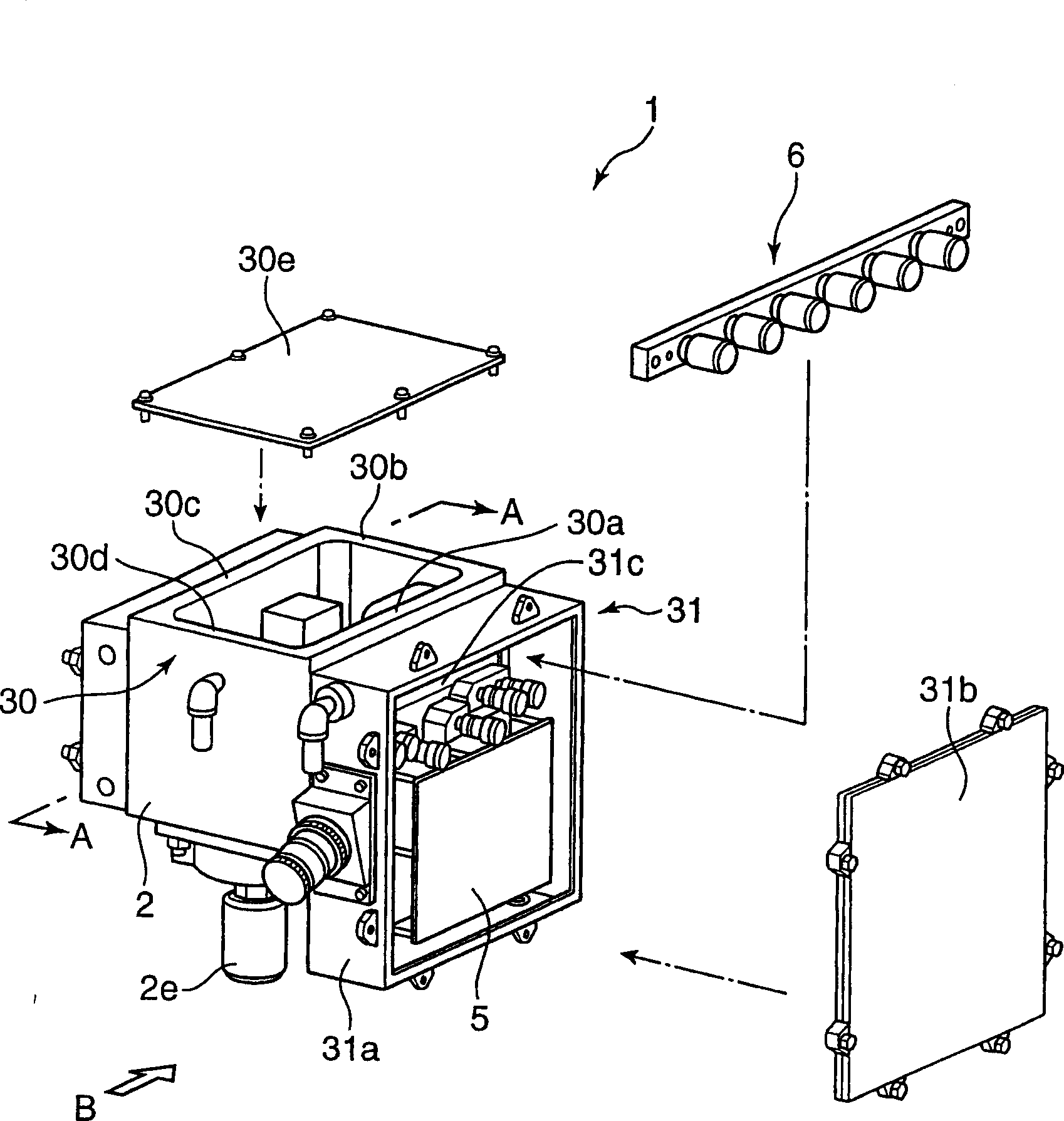

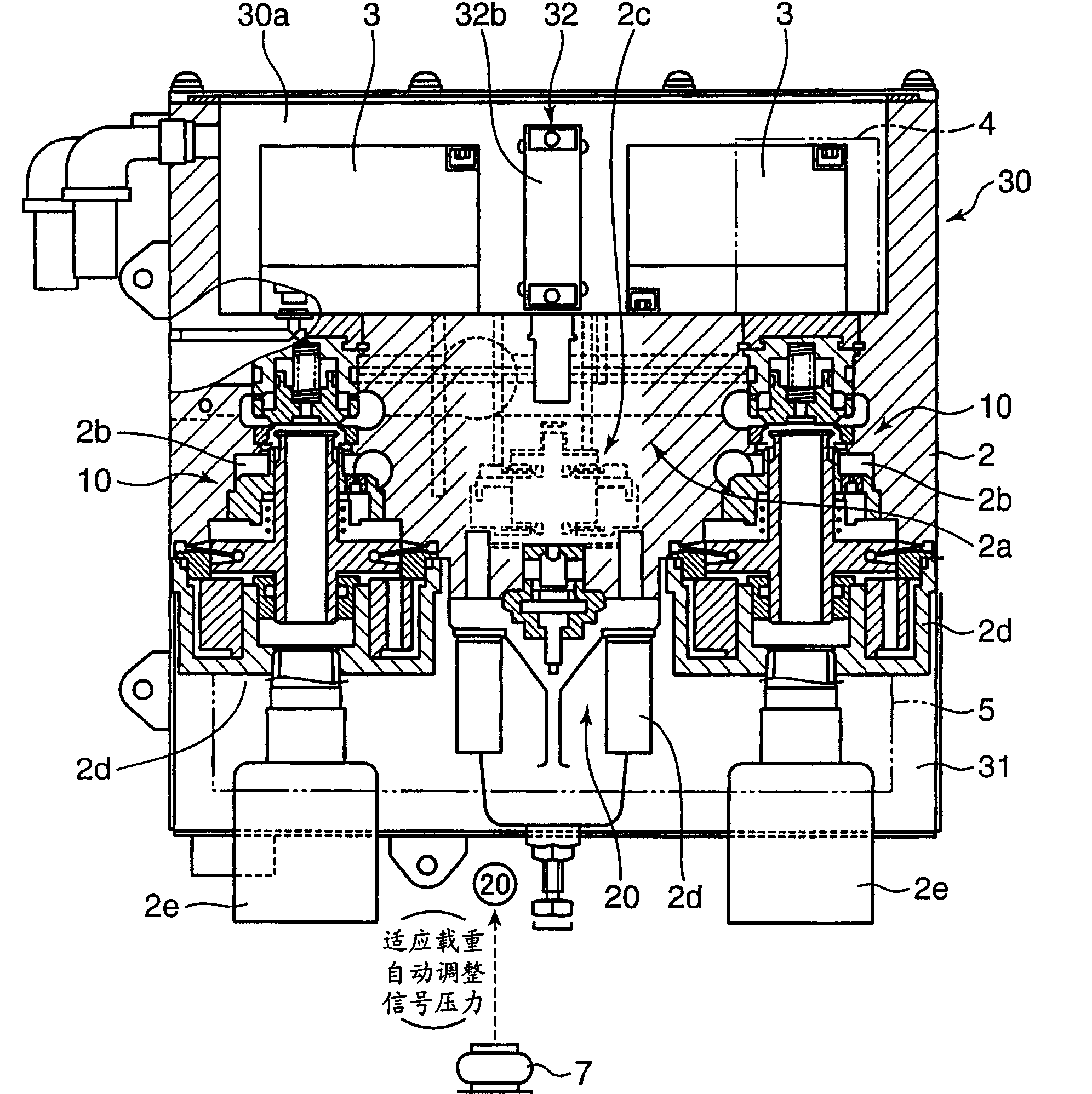

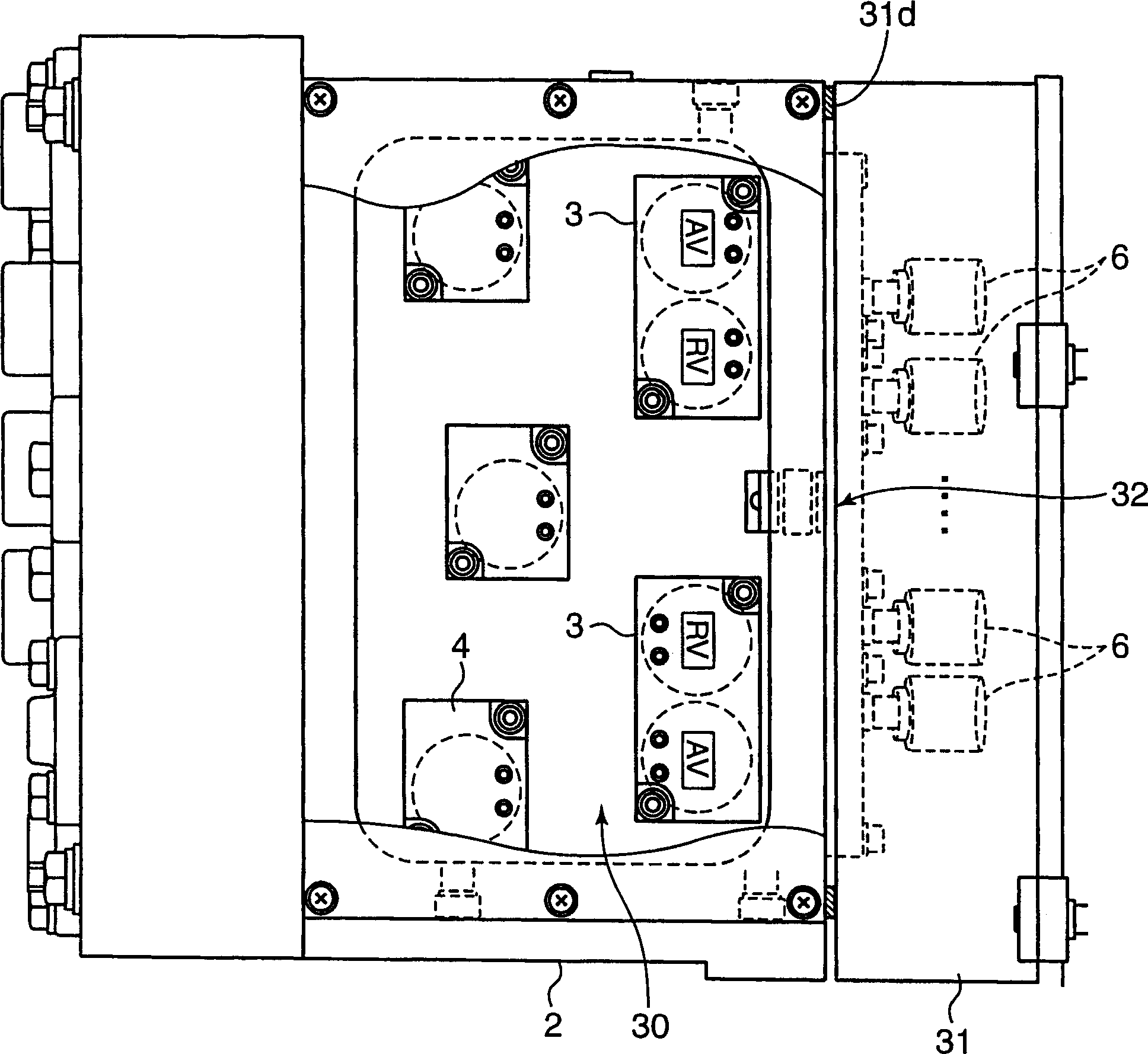

Brake controller

InactiveCN1792691ANo need or reduced cooling countermeasuresGuaranteed distanceApplication and release valvesSolenoid valveEngineering

A brake control device whose purpose is to achieve miniaturization and to make a control panel less affected by heat dissipation from a solenoid valve. The brake control device has a common solenoid valve (3) that supplies control pressure based on an electrical signal, a relay valve (10) that sends brake pressure to the brake cylinder based on the above-mentioned control pressure, and an adaptation valve based on the air spring (7). The load-adaptive automatic adjustment valve (20) that automatically adjusts the signal pressure to supply emergency braking pressure, the emergency solenoid valve (4) that supplies the emergency control pressure to the relay valve (10) based on the electrical signal, and the A control panel (5) for controlling the voltage on the solenoid valve (3) and the emergency solenoid valve (4), which has a relay valve (10), an automatic load-adaptive adjustment valve (20) and their internal components. The valve main unit (2) of the input and output pipeline is provided with a regular solenoid valve (3) and an emergency solenoid valve (4) on the upper side outside the valve main unit (2). A control panel (5) is provided on the side.

Owner:NABLESCO CORP

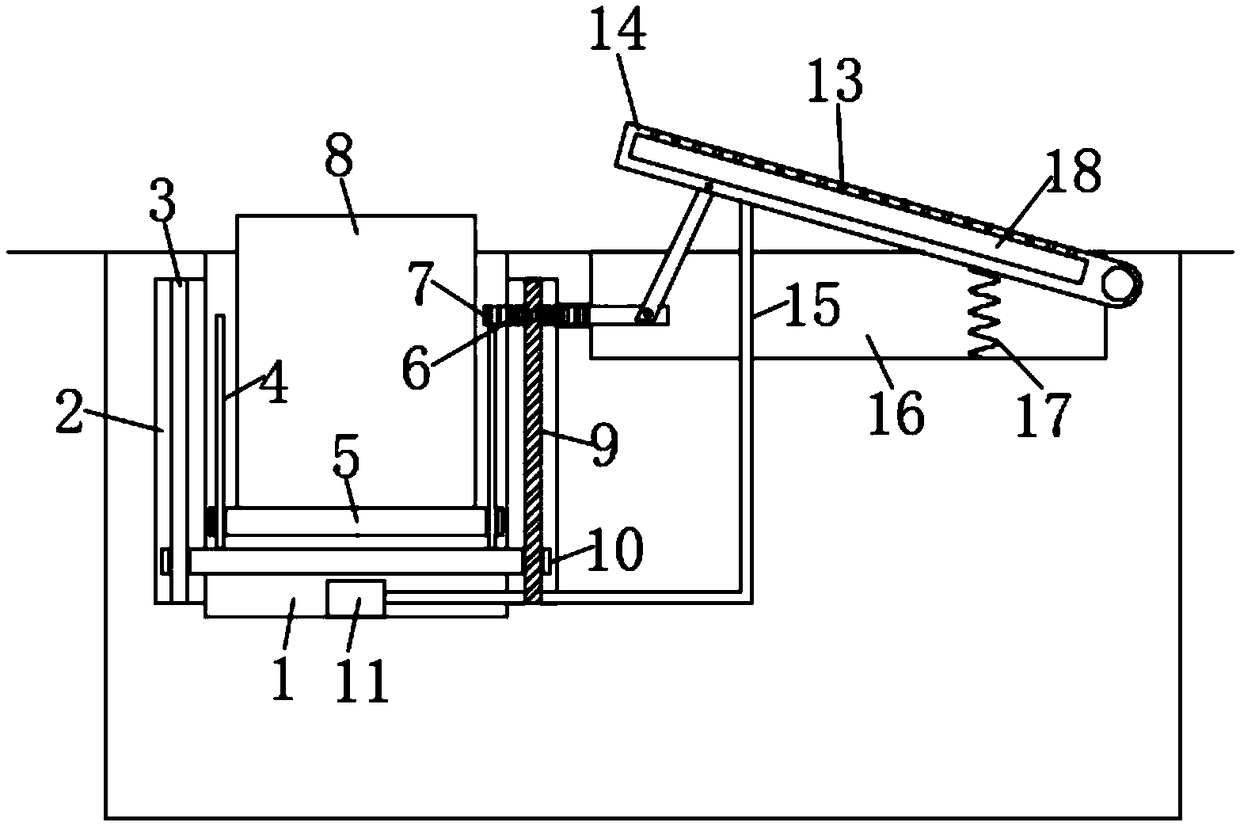

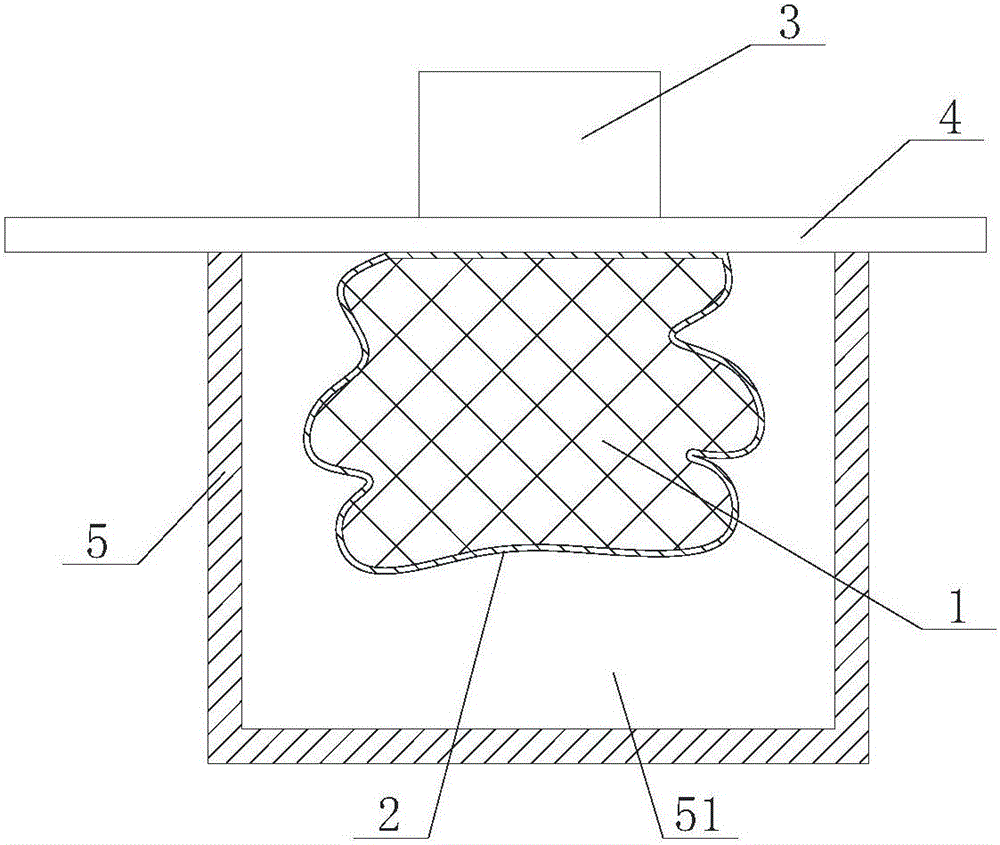

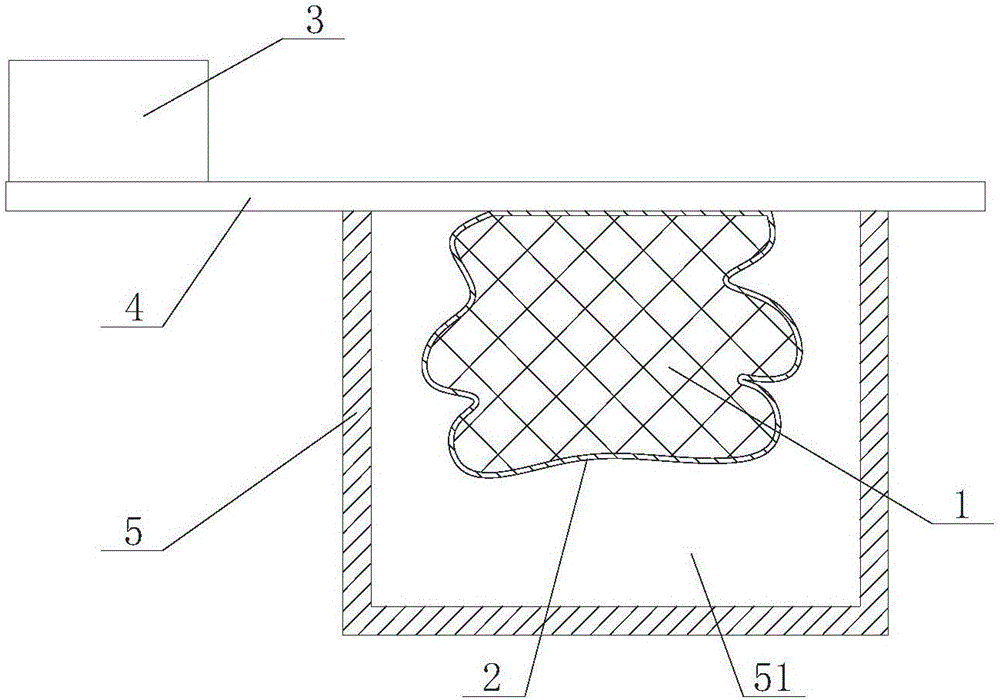

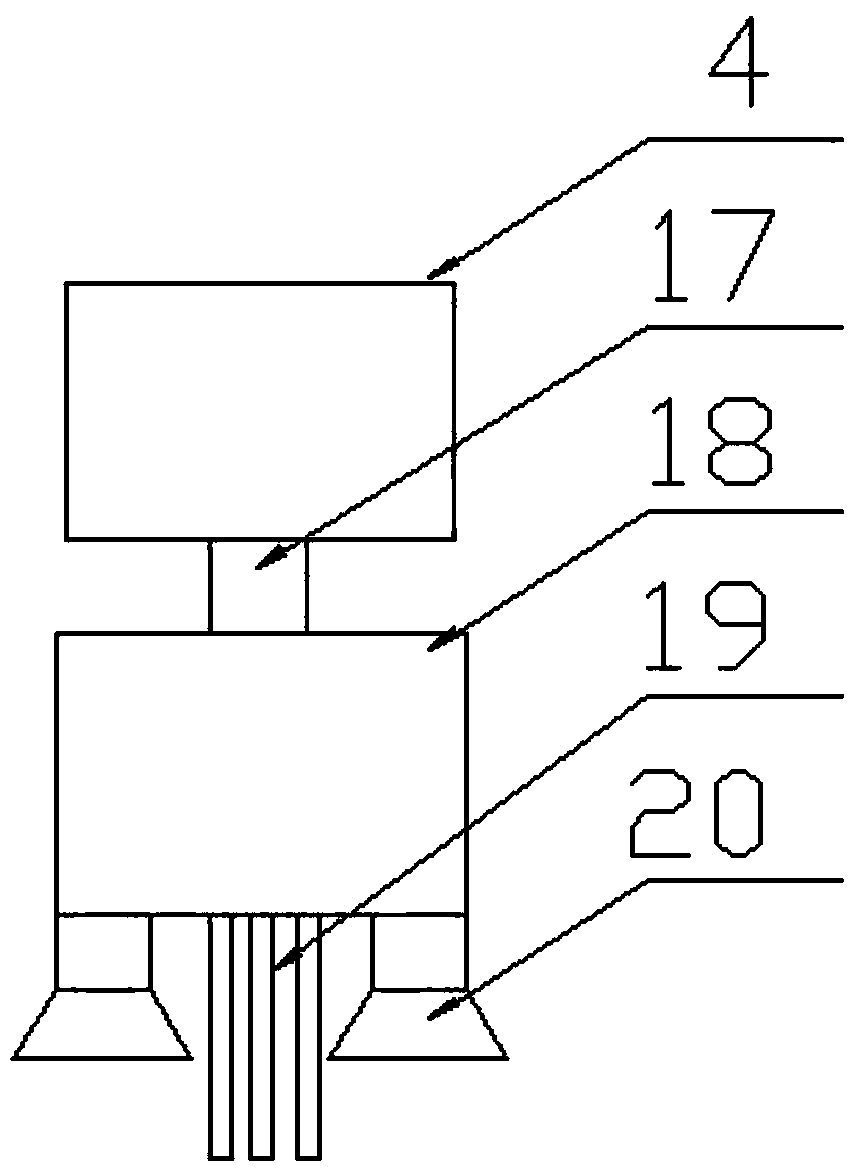

Buried new energy vehicle charging pile with water flooding prevention function

ActiveCN109159707APrevent crashAvoid occupyingCharging stationsElectric vehicle charging technologyNew energyWater flooding

The invention discloses a buried new energy vehicle charging pile with water flooding prevention function. The buried new energy vehicle charging pile includes a first groove and a second groove disposed on the ground, the opposite inner walls of the first groove are provided with sliding grooves. A guide rod and a threaded rod are fixedly connected between the inner top and the inner bottom of the two sliding grooves. The guide rod and the threaded rod are sleeved together with a sliding plate, the sliding plate is slidably connected with the guide rod, the sliding plate is threadably connected with the threaded rod, the upper end part of the sliding plate in the first groove is fixedly connected with the vertical rod, two vertical rods are sleeved together with a buoyancy plate, and theupper end of the buoyancy plate is fixedly connected with the charging pile body. The invention effectively prevents the charging pile body from being submerged by water, solves the problem that in rainwater weather, the charging pile body enters water due to the water drainage blockage, and continuously sprays water on the vehicle chassis to lower the temperature of the battery when charging, thereby effectively reducing the temperature of the battery when charging, and prolonging the service life of the battery of the new energy vehicle.

Owner:ANHUI YI WEISS NEW ENERGY TECH

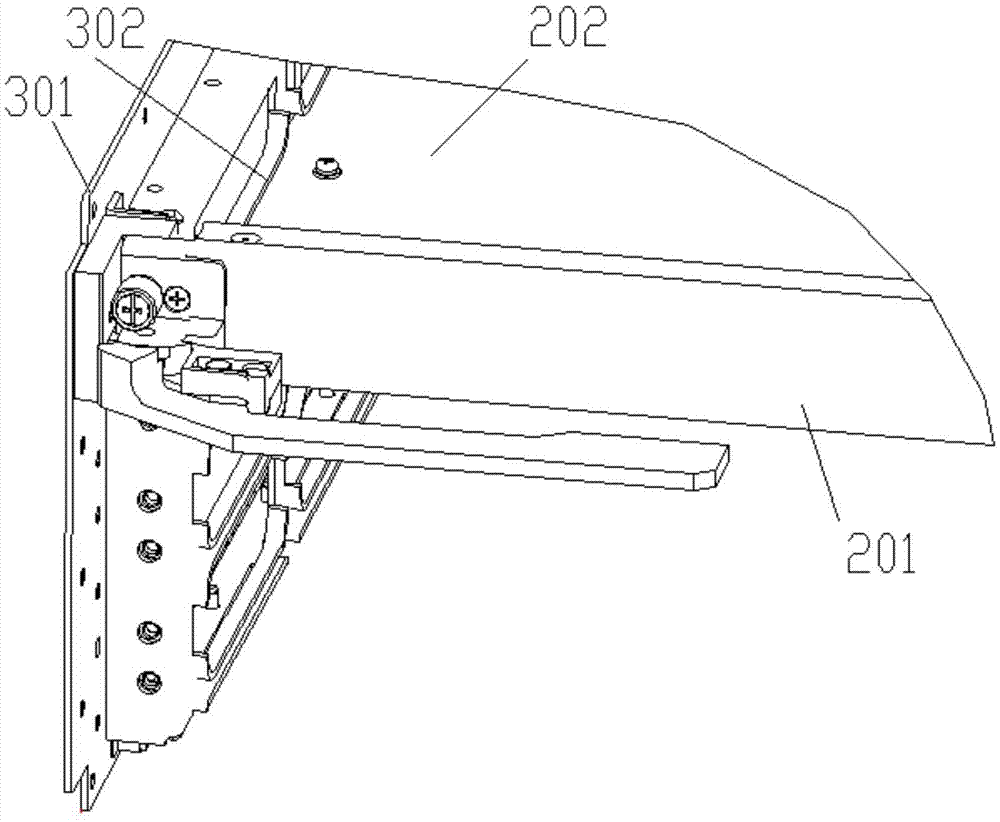

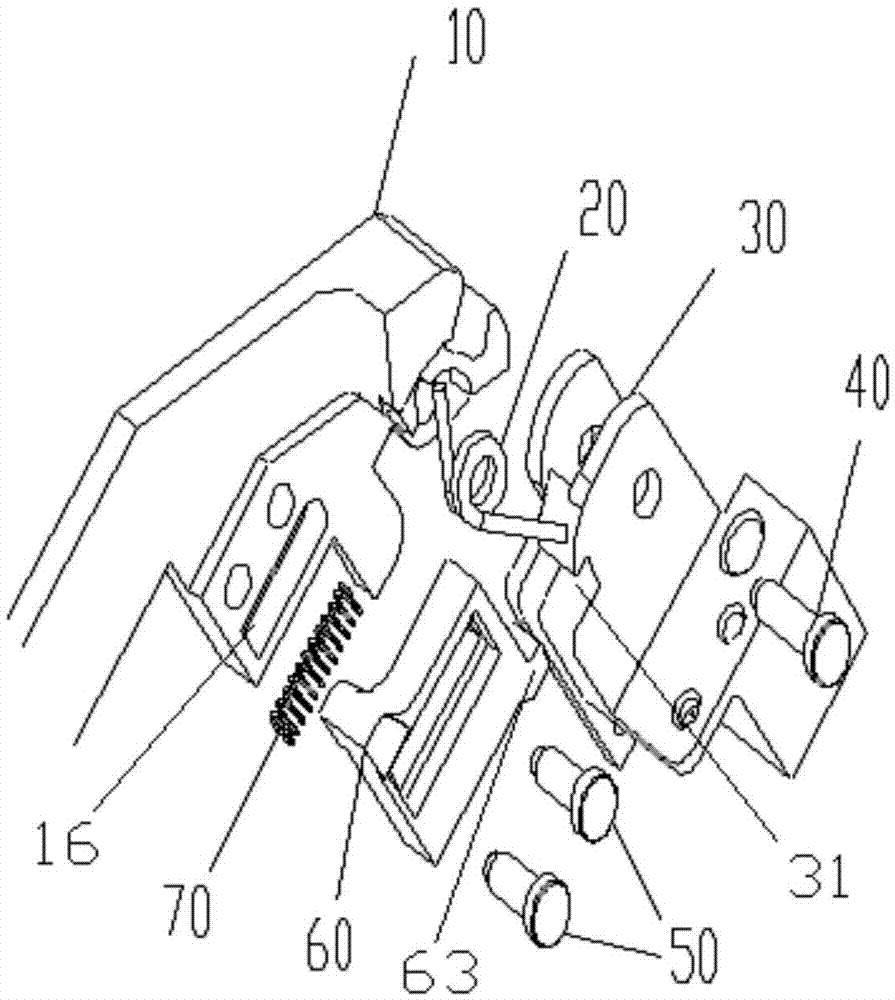

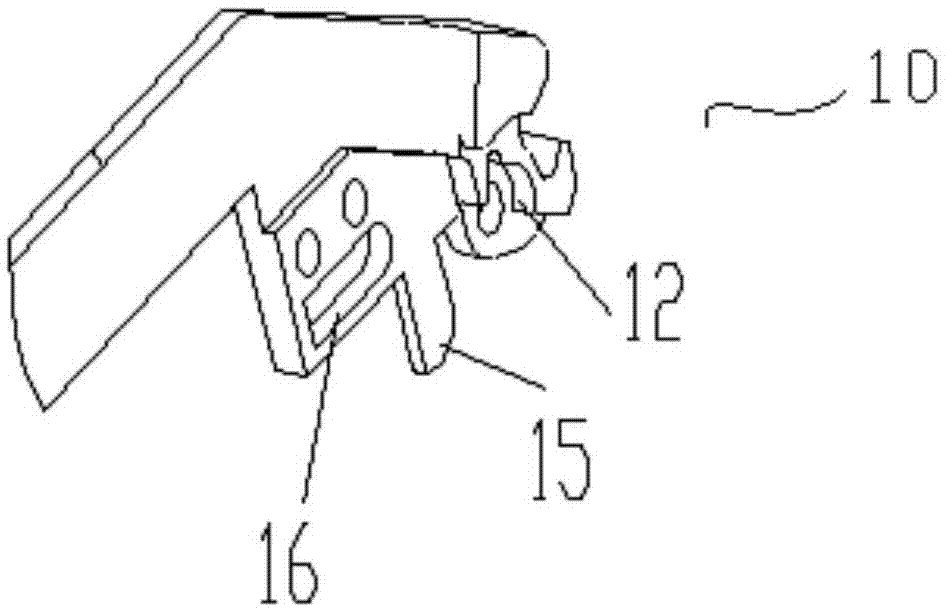

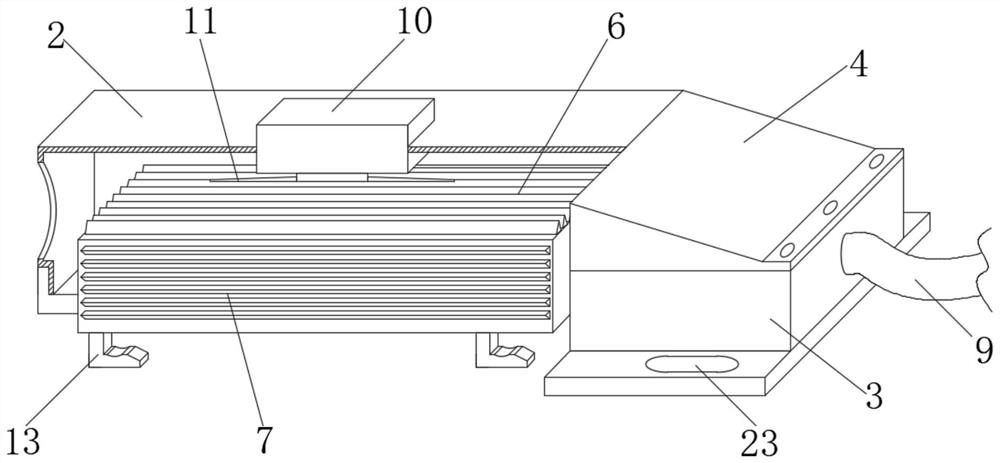

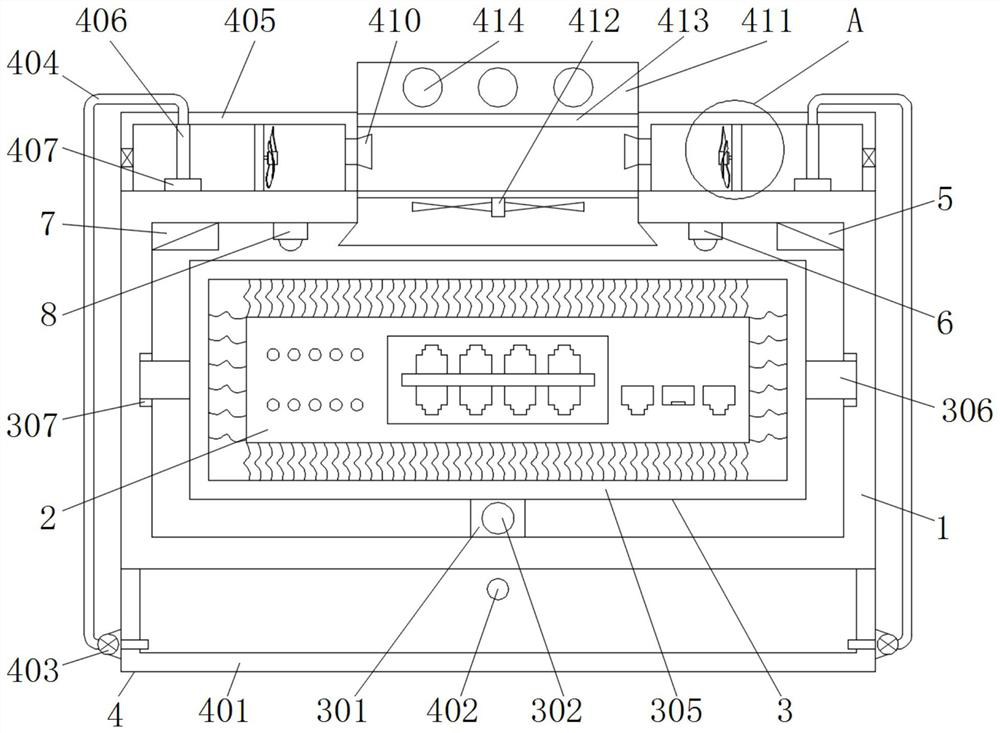

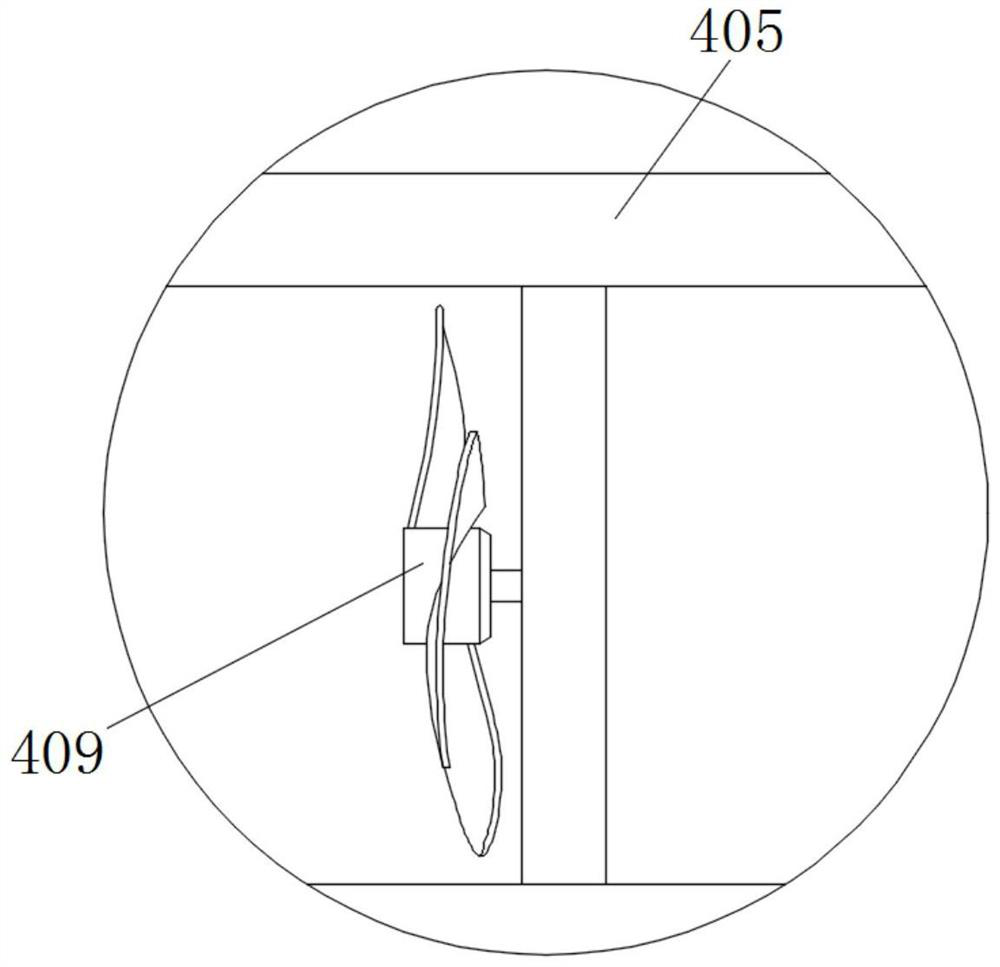

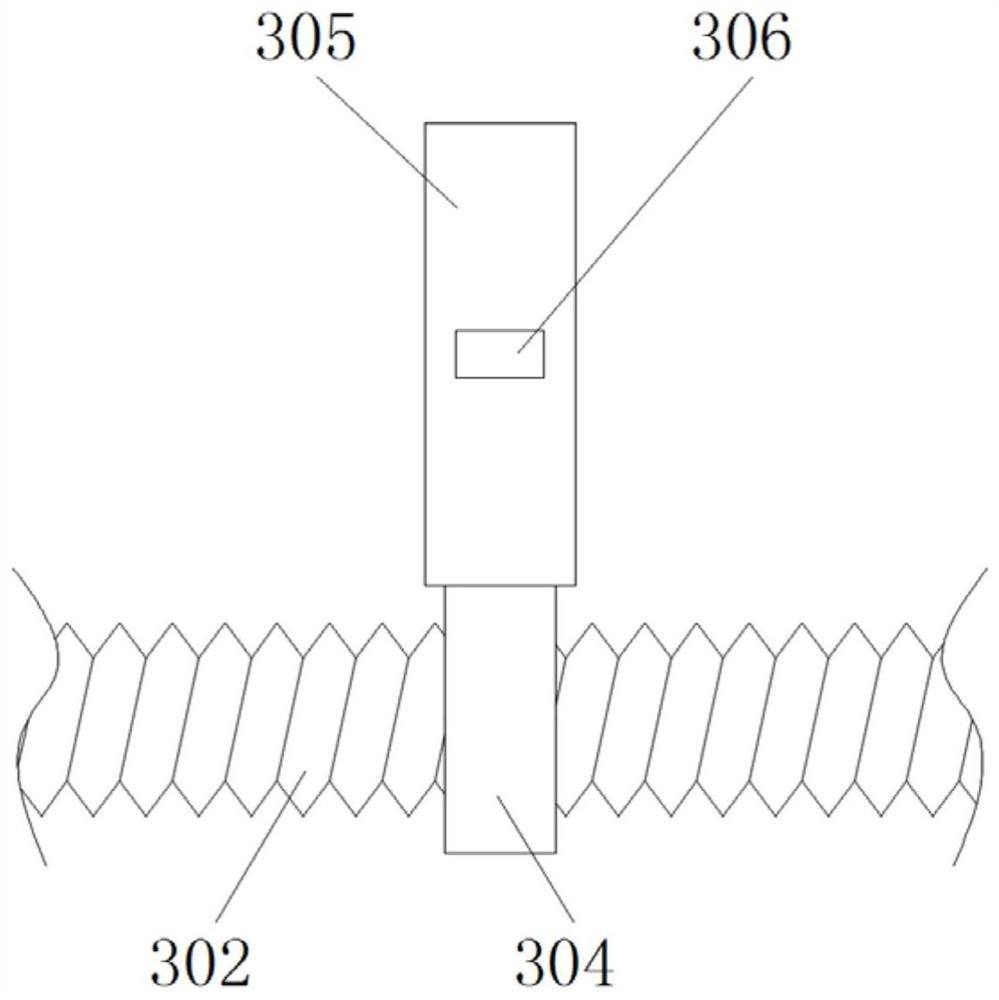

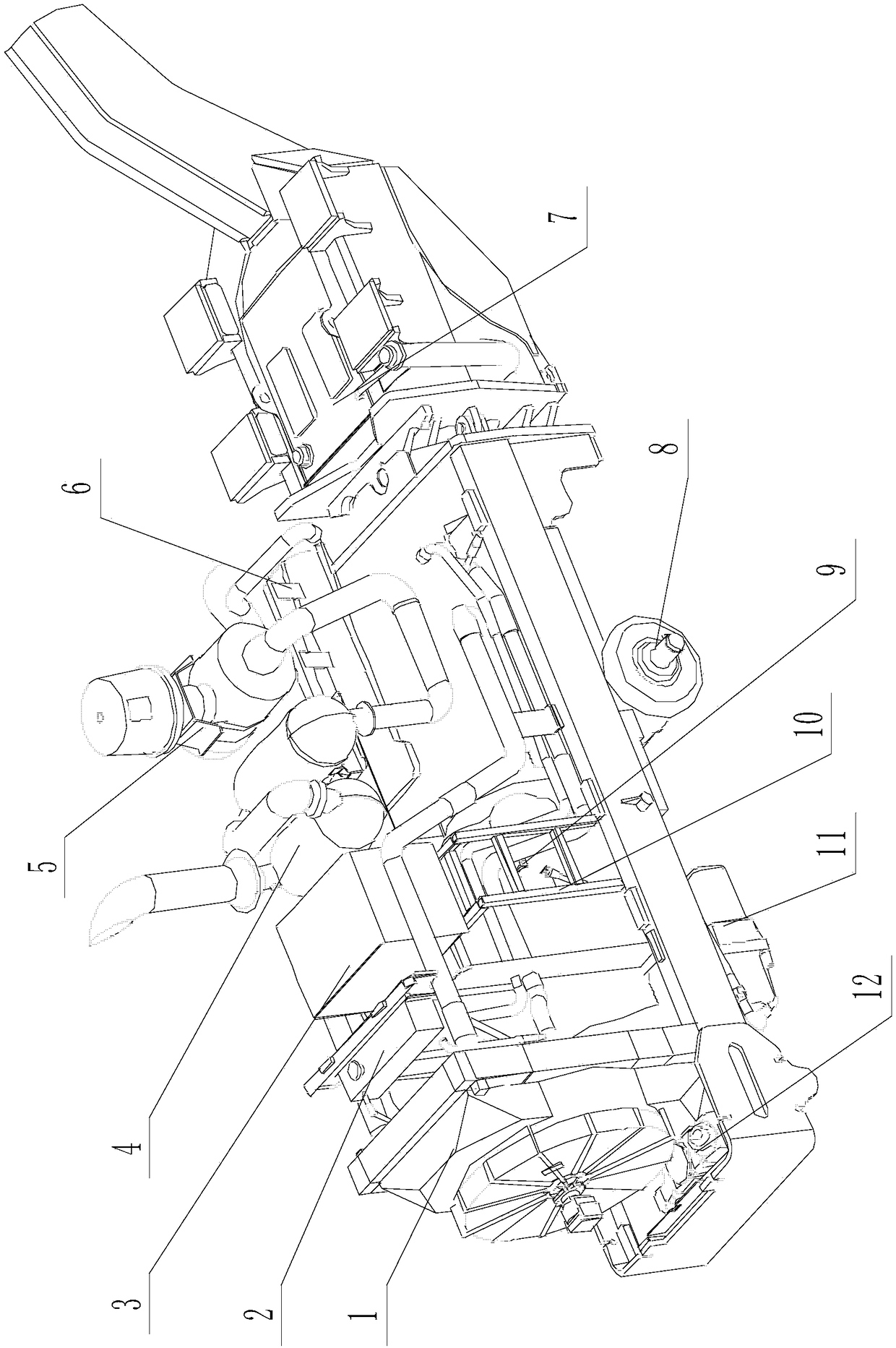

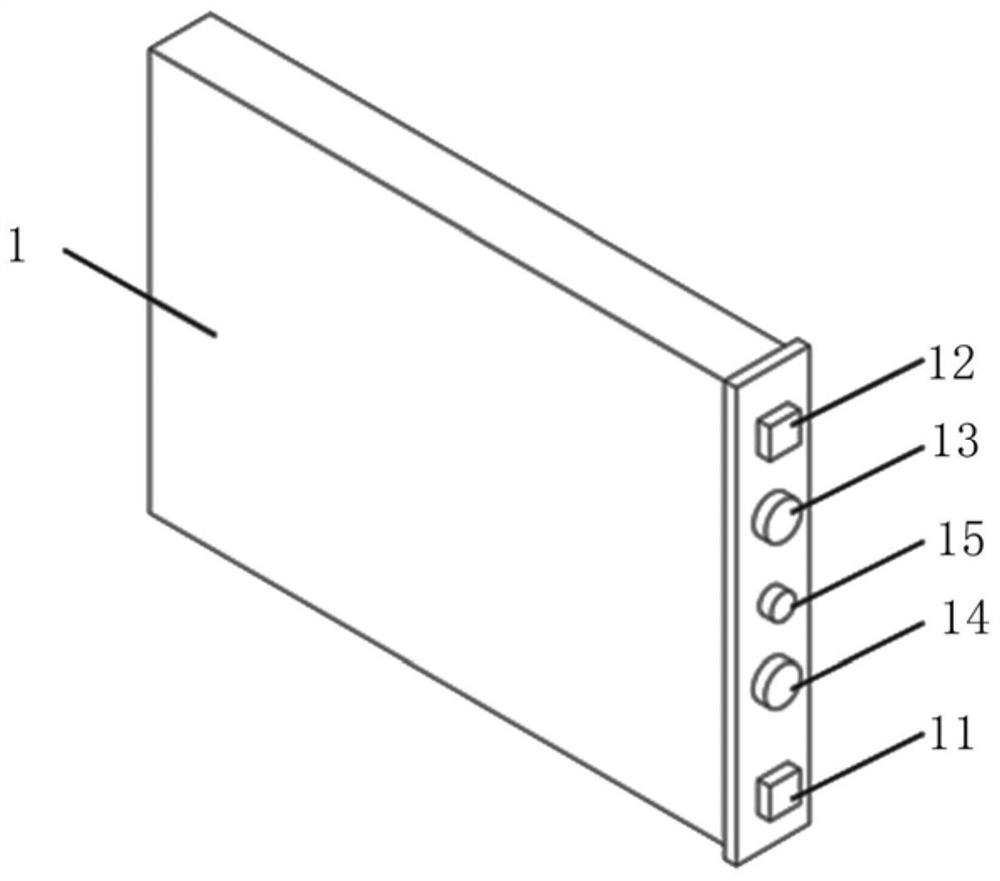

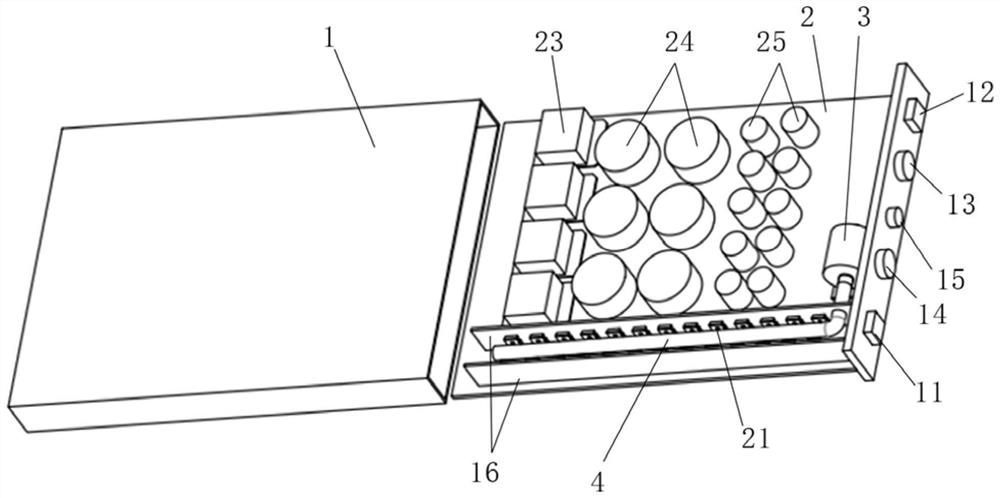

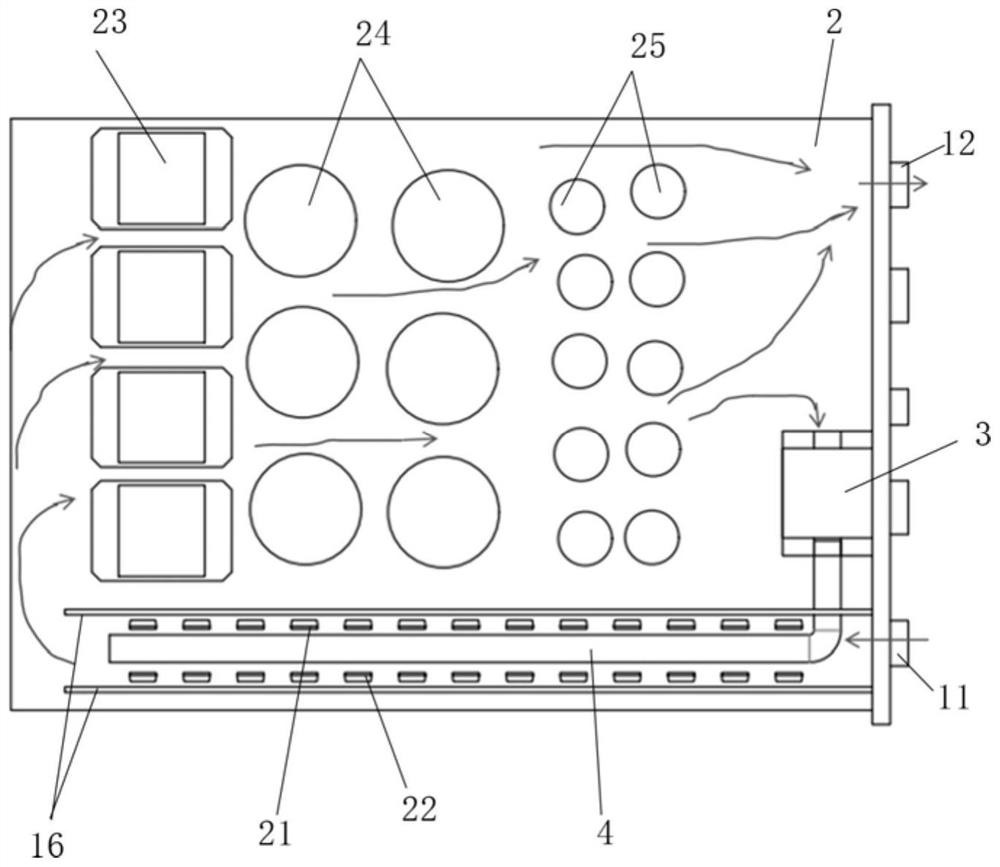

Plugging mechanism and communication equipment employing plugging mechanism

InactiveCN106941767AReduce the impact of heat dissipationSave spaceClamping/extracting meansElastic componentEngineering

The invention discloses a plug-in mechanism and communication equipment using the plug-in mechanism. A plug-in mechanism, installed on a panel assembly and used for inserting the panel assembly into or pulling it out from the chassis of a communication device, comprising: a wrench seat installed on the panel assembly, having a locking slot; and the wrench A wrench connected to the seat in rotation has a first groove for accommodating the first elastic member; a locking member slidably installed on the wrench has a structure placed in the first groove and connected with the first elastic member A projection that can slide along the first groove when interacting with each other; wherein, the locking member has a locking hook that can engage with the locking slot. The invention not only occupies a small space of the panel, reduces the influence on the heat dissipation of the panel assembly, but also triggers the micro switch while locking and unlocking, thereby increasing the safety of use.

Owner:ZTE CORP

Cooling device, battery and electronic equipment

ActiveCN106102415ASmall temperature changeReduce the temperatureSecondary cellsModifications by conduction heat transferHeat conductingEngineering

The invention provides a cooling device, a battery and electronic equipment, and relates to the technical field of electronic products. The operating temperature of a system in the equipment can be reduced and the cooling effect is improved. The cooling device comprises a heat-absorbing material and a packaging cavity, wherein the specific heat capacity of the heat-absorbing material is greater than that of a heat-conducting material; the packaging cavity is enclosed by side walls; the heat-absorbing material is arranged in the packaging cavity; the material of each side wall of the packaging cavity is the heat-conducting material; the side walls of the packaging cavity are used for being connected with a heating device; and heat emitted from the heating device is transmitted to the heat-absorbing material. The cooling device is mainly used for cooling in the equipment.

Owner:LENOVO (BEIJING) LTD

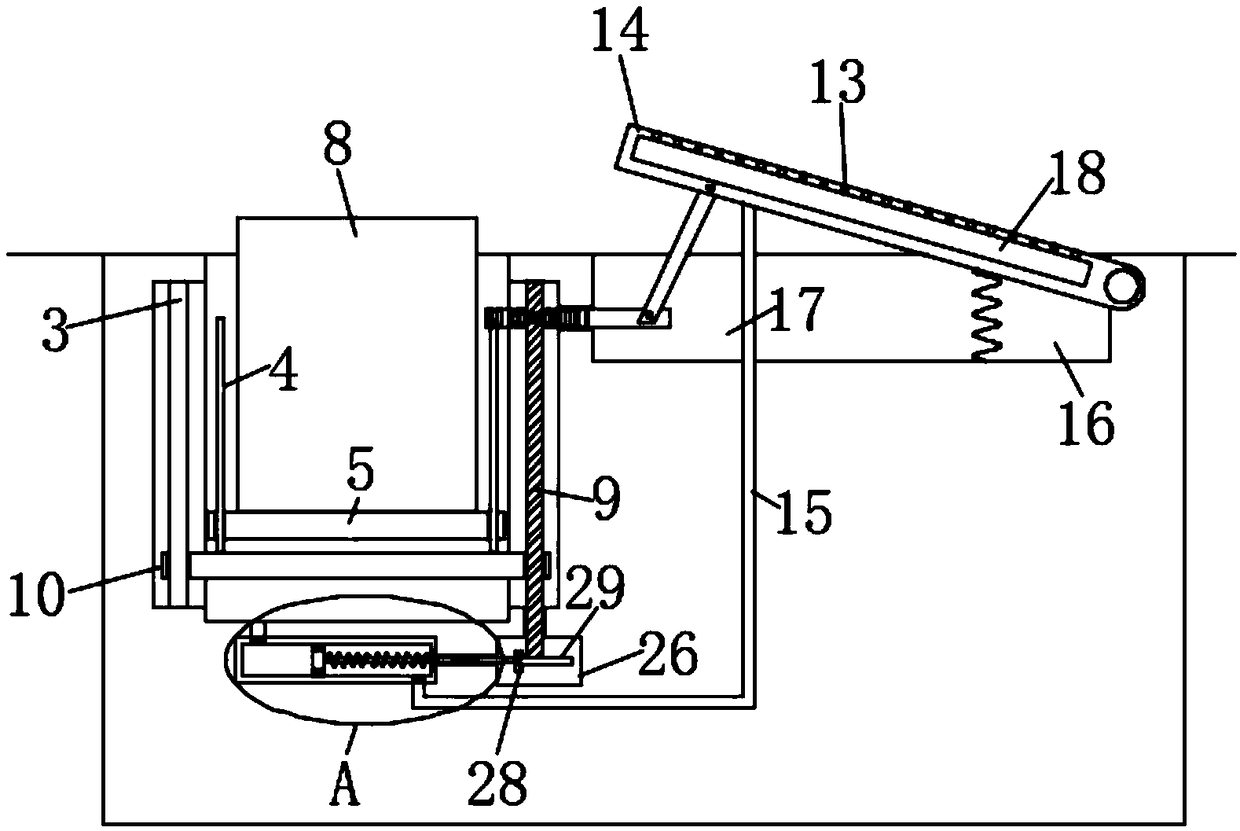

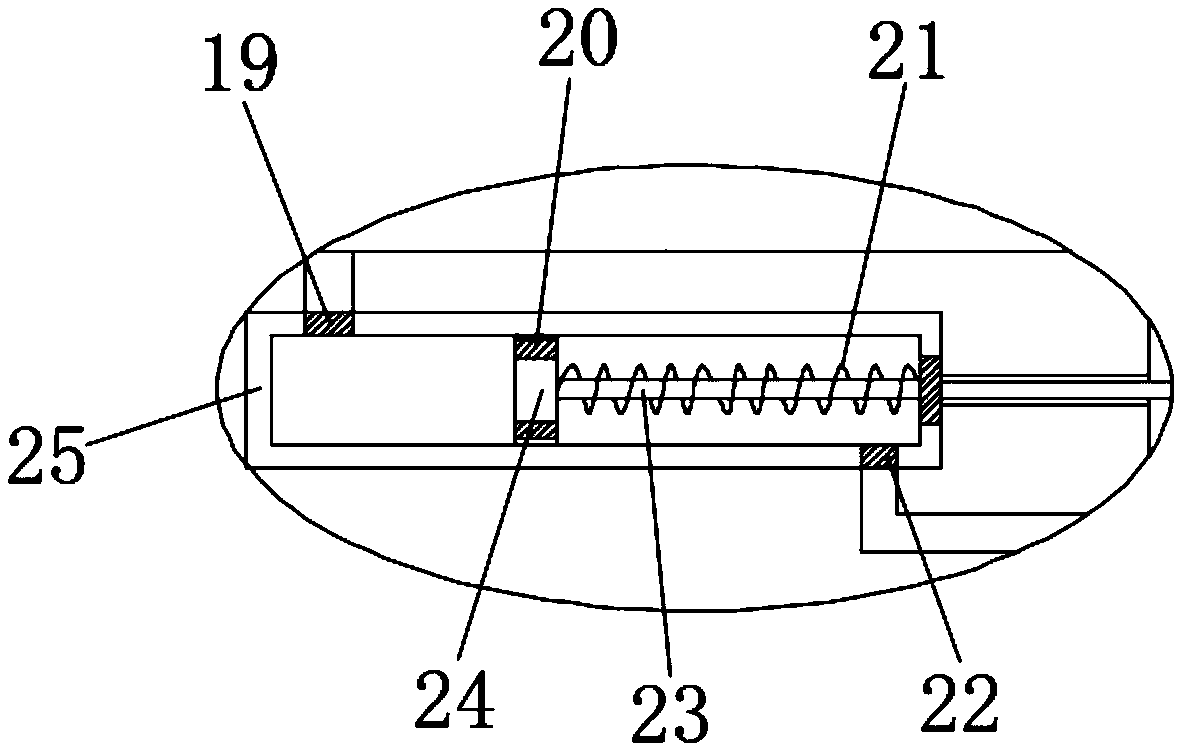

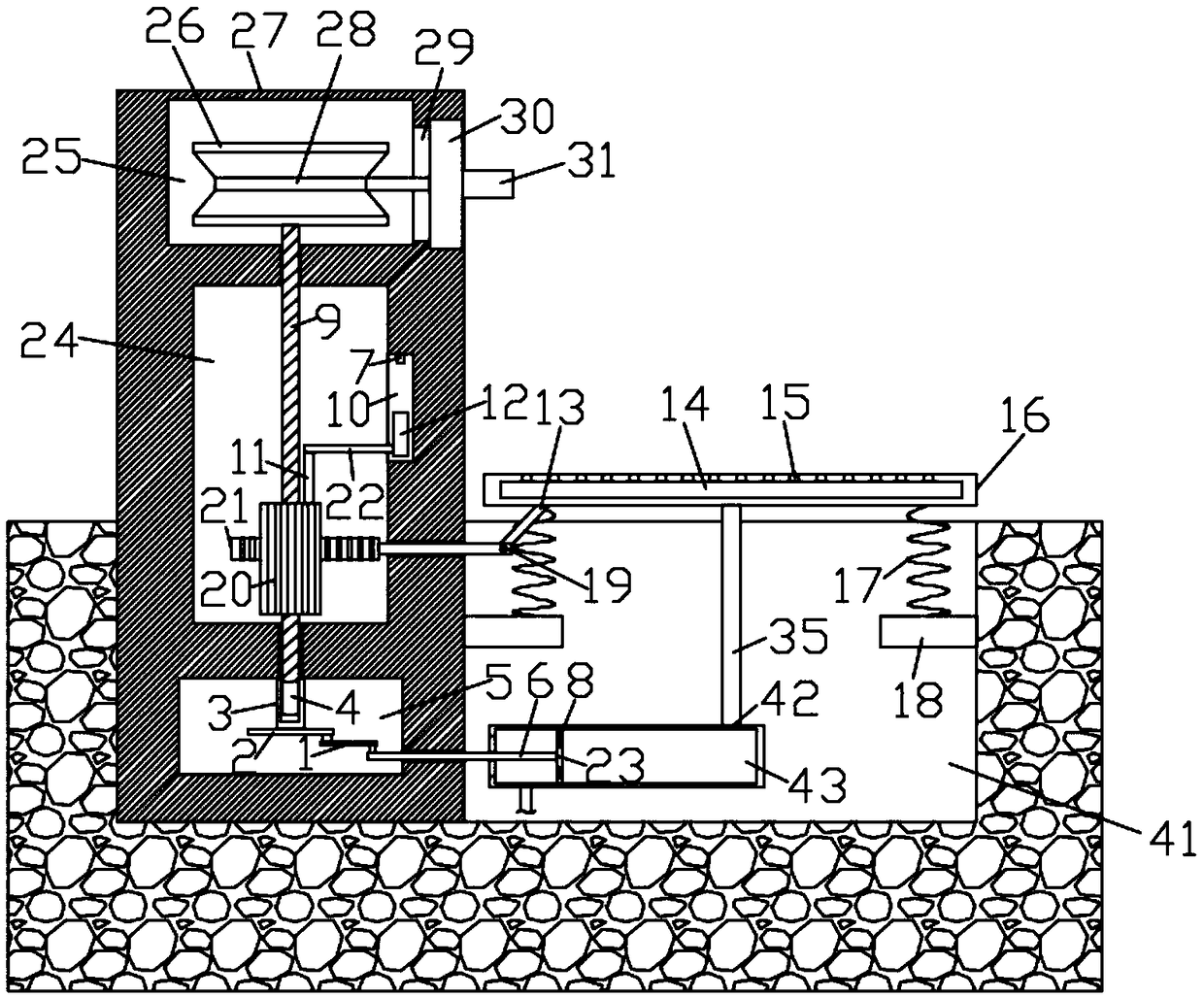

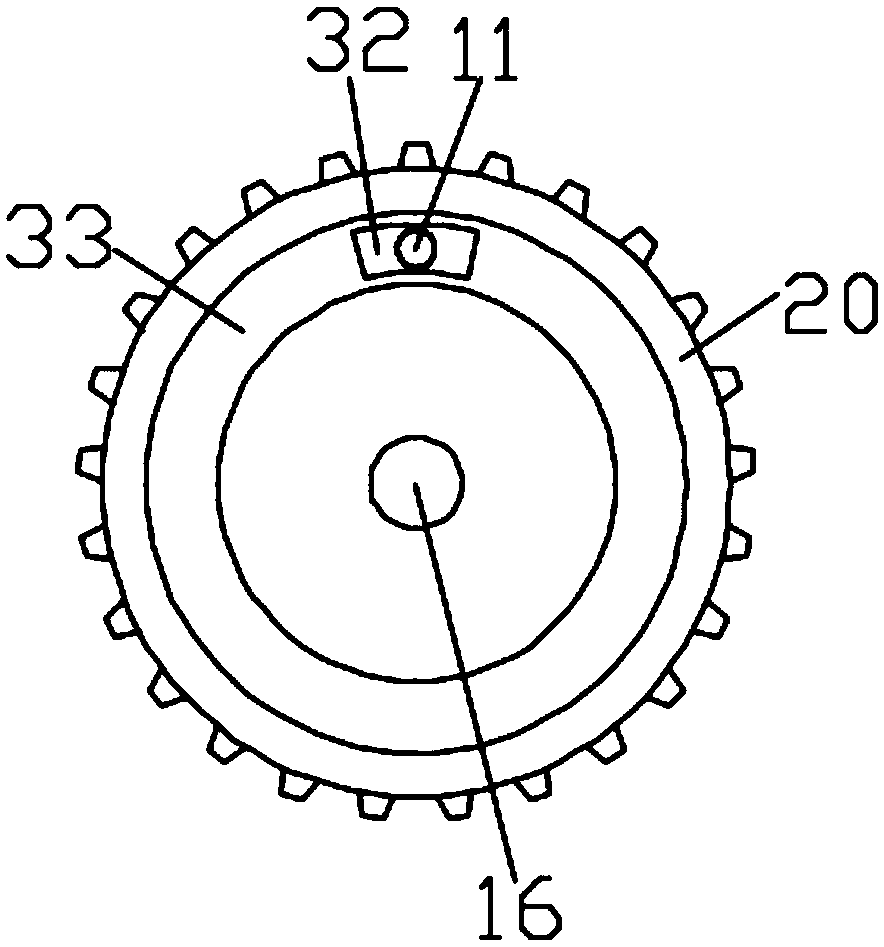

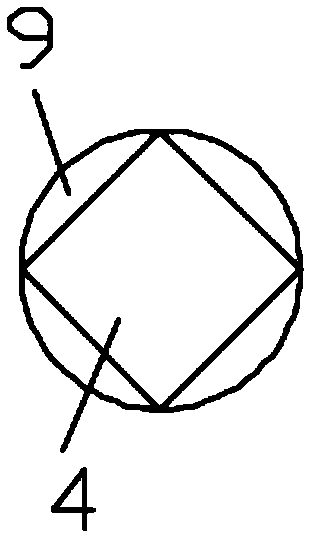

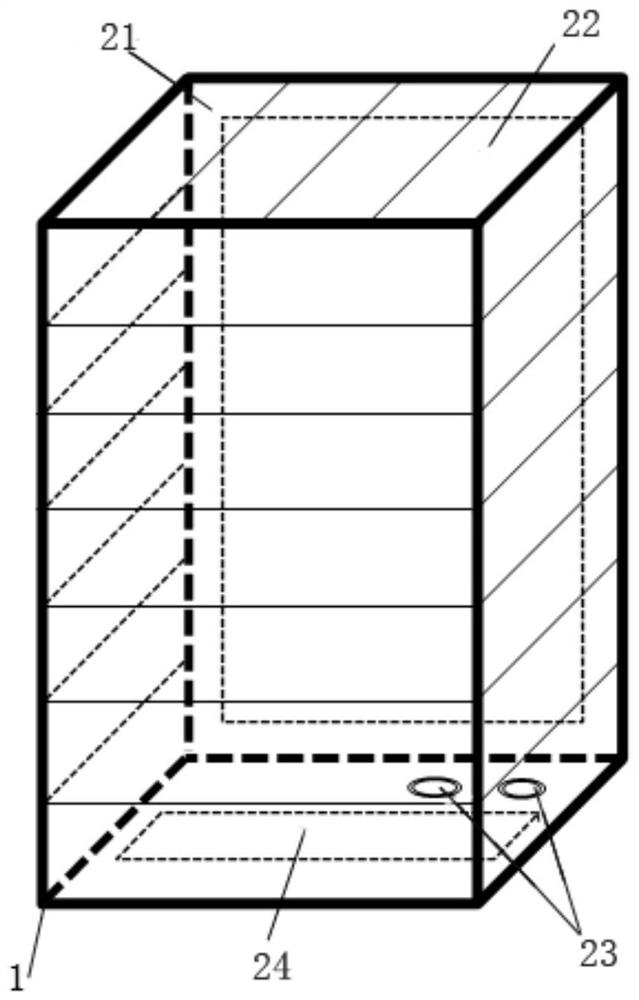

Charging pile for new energy automobile

ActiveCN109367420AAvoid Electric Shock AccidentsReduce the impact of heat dissipationCharging stationsCleaning apparatus for vehicle exteriorsNew energyElectric shock

The invention discloses a charging pile for a new energy automobile. The charging pile comprises a groove and a charging pile shell, wherein the groove is formed in the upper end face of the ground, and the charging pile shell is arranged at the bottom inside the groove. Fixing blocks are fixedly connected to the opposite left inner wall and the right inner wall of the groove correspondingly. A tread plate is arranged above the groove and elastically connected to the upper ends of the fixing blocks through springs. A first device cavity, a second device cavity and a third device cavity are sequentially formed in the charging pile shell in the vertical direction. The second device cavity is internally provided with a threaded rod. The upper end of the threaded rod penetrates the top insidethe second device cavity and extends into the first device cavity. The threaded rod is in threaded connection with the top inside the second device cavity. A rotating shaft is rotatably connected to the top inside the third device cavity. By means of the charging pile, the problem that a child touches a charging head to cause an electric shock accident is effectively prevented; water is continuously sprayed to a chassis of the automobile for cooling; the temperature of a battery is effectively lowered in the charging process; and the service life of the battery of the new energy automobile isprolonged.

Owner:泰州市扬帆车件有限公司

Thermoelectrically separated type PCB member and processing method thereof

PendingCN108322993AImprove cooling effectImprove light outputCircuit thermal detailsCircuit susbtrate materialsMetal foilMetal substrate

The invention discloses a thermoelectrically separated type PCB member and a processing method thereof. The PCB member comprises a metal substrate; depth-controlling etching is carried out on the middle part of the metal substrate to form a boss bonding pad and a PP layer is arranged around the metal substrate; and a circuit layer is arranged on the PP layer and is formed by etching of a metal foil layer laminated on the PP layer and the boss bonding pad. In addition, the preparation method includes: S1, a metal substrate is made to form an inner pattern and etching is carried out on the substrate to form a salient point bonding pad; S2, a PP layer and a metal foil are excavated; S3, the metal substrate with the salient point bonding pad etched, the PP layer, and the metal foil are laminated to form a half-finished laminated multi-layer board product; S4, mechanical grinding is carried out to grind the salient point bonding pad to expose the salient point bonding pad; and S5, the circuit is etched. The method aims at realizing processing of a thermoelectrically separated type PCB member. According to the thermoelectrically separated type PCB member, components are connected with the copper substrate directly to realize a direct cooling effect, so that the heat dissipation effect is improved substantially, the light output rate of the LED is enhanced, and the high stability of the lighting effect is guaranteed.

Owner:长沙牧泰莱电路技术有限公司

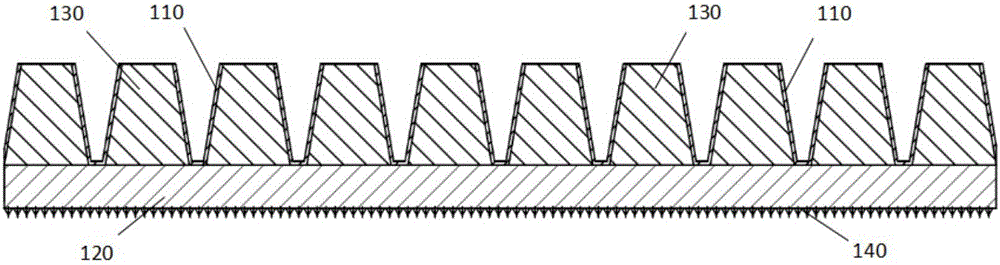

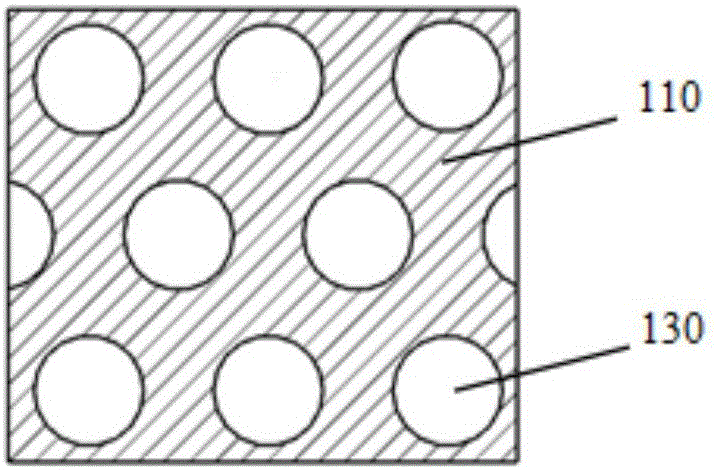

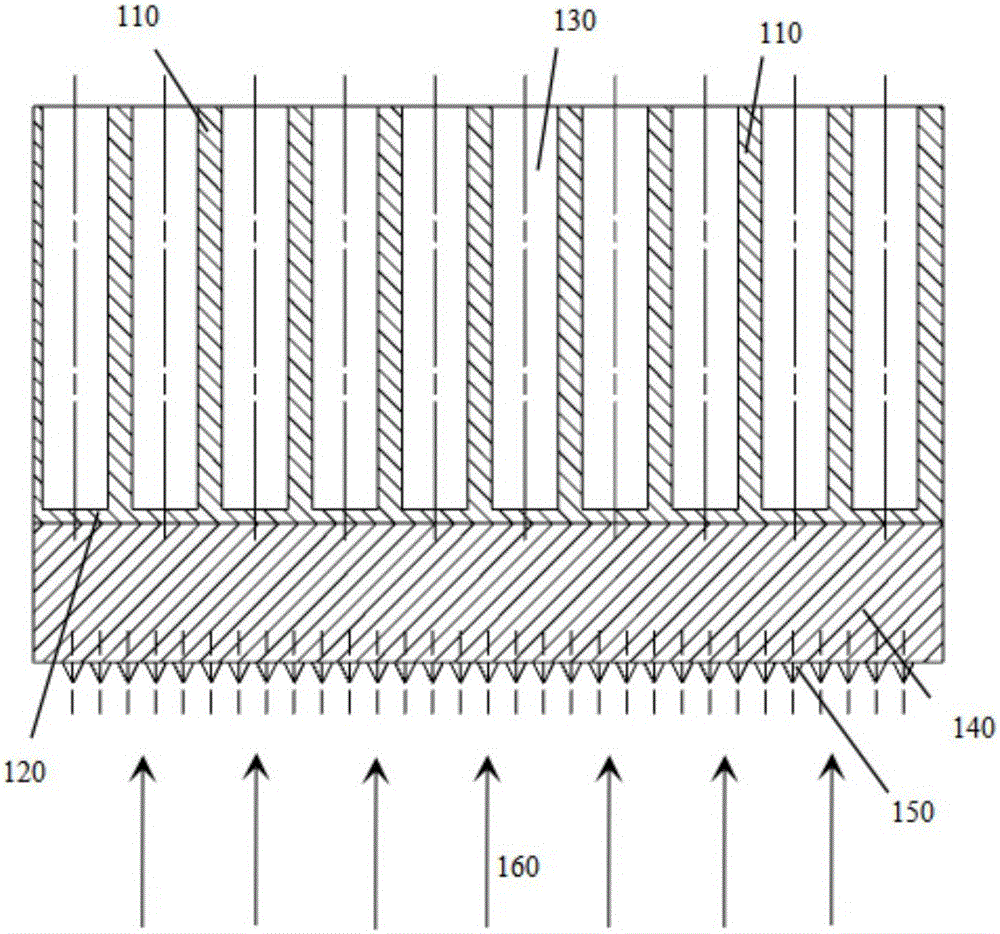

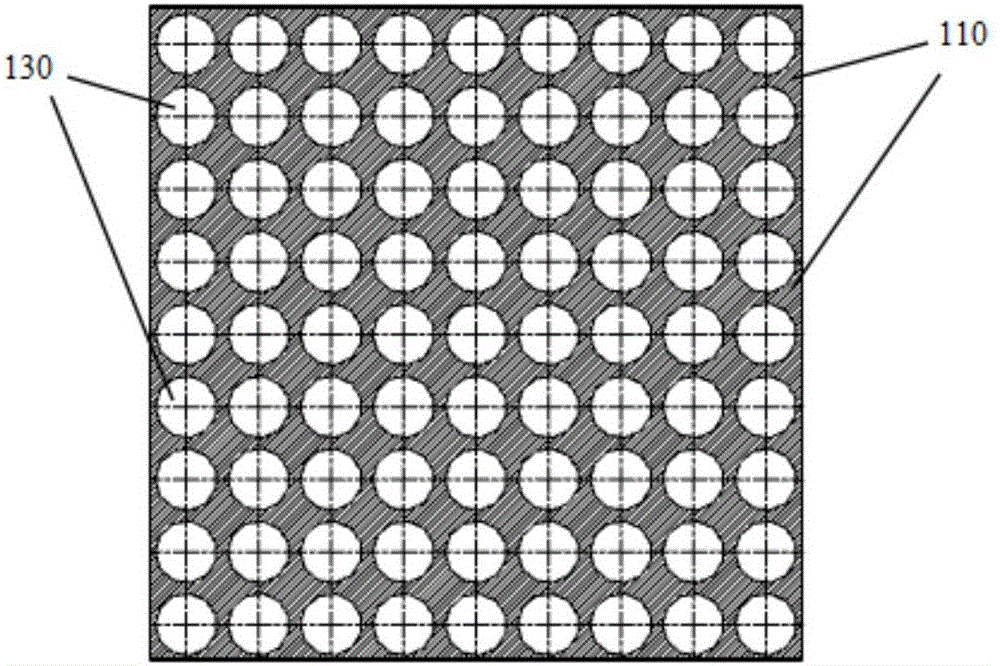

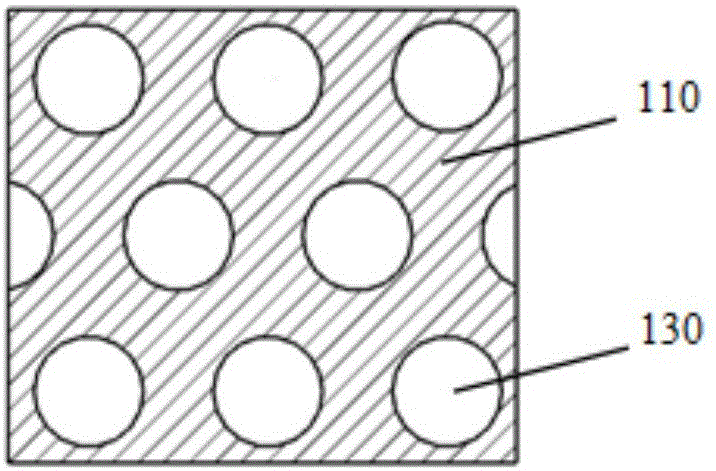

Omnibearing peep-proof film with antireflection function and manufacturing process thereof

ActiveCN105667043ASimple structureReasonable designSynthetic resin layered productsLaminationMicro nanoImage resolution

The invention relates to an omnibearing peep-proof film with an antireflection function and a manufacturing process thereof. The omnibearing peep-proof film comprises a PET layer, a peep-proof structural layer arranged on one side surface of the PET layer and a moth-eye antireflection structural layer arranged on the other side surface of the PET layer, wherein the peep-proof structural layer comprises a resin bottom layer and a UV light-cured resin layer; parameters can be changed according to the actual requirement, so that a visual angle can be freely selected, the security of a display screen in any direction is guaranteed, and the light transmittance in a visual range is high; by virtue of the bionics principle, the moth-eye antireflection structural layer adopts a moth-eye-like micro-nano structure as the antireflection layer, so that the loss of reflected light can be effectively inhibited in a relatively wide wave spectrum range; a reel-to-reel UV double-side rolling process comprises an adhesive dripping step, a filling step, a UV illuminating step and a demolding step, and different structures can be separately press-printed on two side surfaces of the PET layer, so that the manufacturing process is simple, and the commercialization requirement on rapidness, large area, high resolution and high flux can be met.

Owner:SHANGHAI JIAO TONG UNIV +1

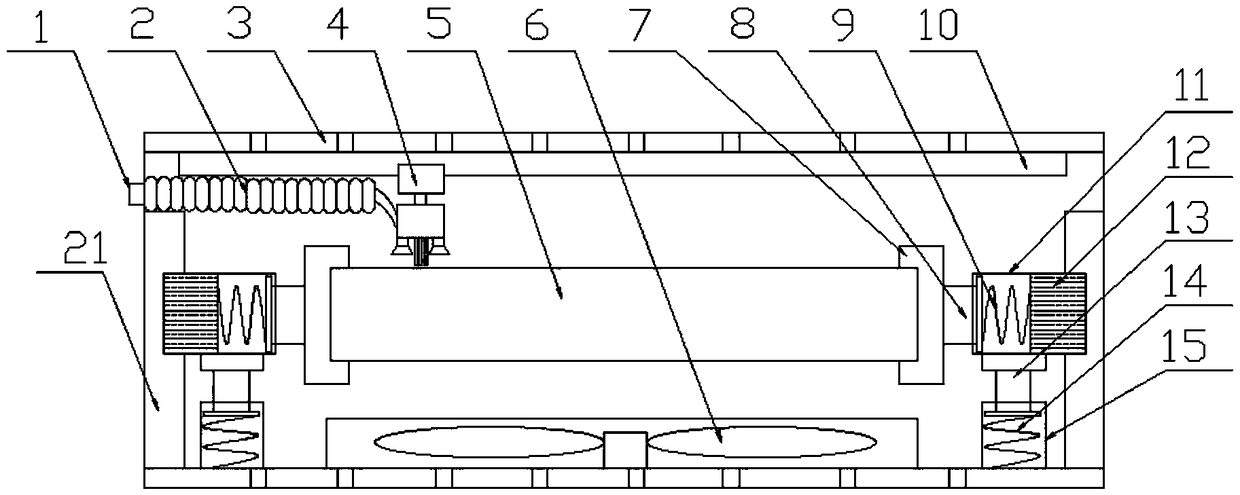

A computer hardware fixed cooling and dust removing device

InactiveCN109144201AReduce vibrationReduce the possibility of damageDigital data processing detailsDirt cleaningEngineeringComputer fan

The invention discloses a computer hardware fixed cooling and dust removing device, including a hardware fixture body, wherein a heat dissipation window is arranged on the upper and lower end surfacesof the main body of the hardware fixing device, an upper end surface of the main body of the hardware fix device is provided with a first slide rail, a sliding motor is arranged on the surface of thefirst slide rail, a lower end of the sliding motor is provided with a third connecting rod, a low end of that third connecting rod is provided with a small air extractor, a brush is arranged at the lower end of the small-sized suction fan, a suction port is arranged on both sides of that brush, a telescopic throat tube is arranged on one side of that dust suction opening, a dust outlet is arranged on one side of the telescopic throat tube, and a heat dissipation fan is arranged on the lower end surface of the hardware fixing device main body. By providing a first shock absorbing device and asecond shock absorbing device, the lateral and longitudinal vibration of the hardware can be reduced, the possibility of damage to the hardware is greatly reduced, and the safety is improved.

Owner:ANHUI DOUZHUANXINGYI INFORMATION TECH CO LTD

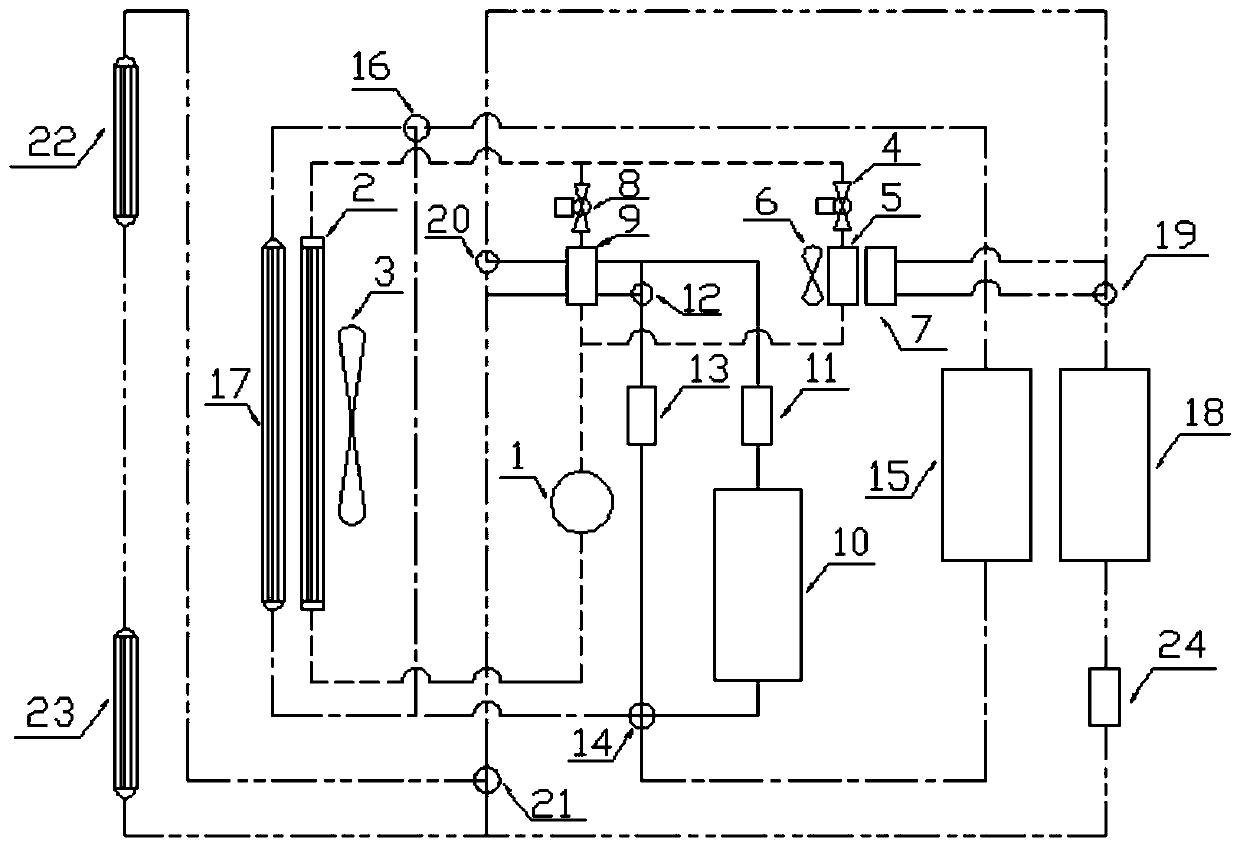

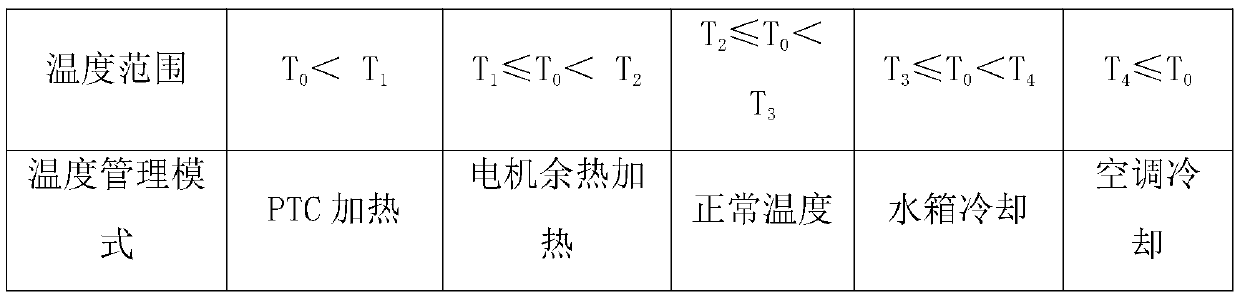

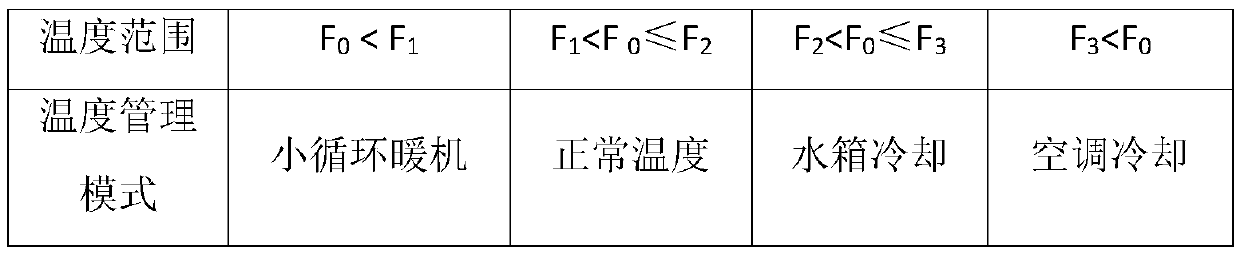

Multi-mode temperature management system of hybrid electric vehicle

InactiveCN111098664AEfficient and reliable heat dissipationImprove cooling efficiencyAir-treating devicesVehicle heating/cooling devicesPower batteryTemperature control

The invention provides a multi-mode temperature management system of a hybrid electric vehicle. The multi-mode temperature management system comprises an air conditioning system, a power battery temperature management system, a driving motor temperature management system and an engine temperature management system, wherein communication and disconnection among the air conditioning system, the power battery temperature management system, the driving motor temperature management system and the engine temperature management system are controlled through pipelines and valves. The multi-mode temperature management system is advantaged in that power battery temperature management modes are dynamically switched according to the real-time temperature of a power battery, driving motor temperature management modes are dynamically switched according to the real-time temperature of a driving motor, and engine temperature management modes are dynamically switched according to the real-time temperature of an engine, temperature management of multiple modes is achieved, the temperature management modes are more flexible, energy utilization efficiency is higher, and temperature control is more stable.

Owner:深圳市智尊保汽车科技有限公司

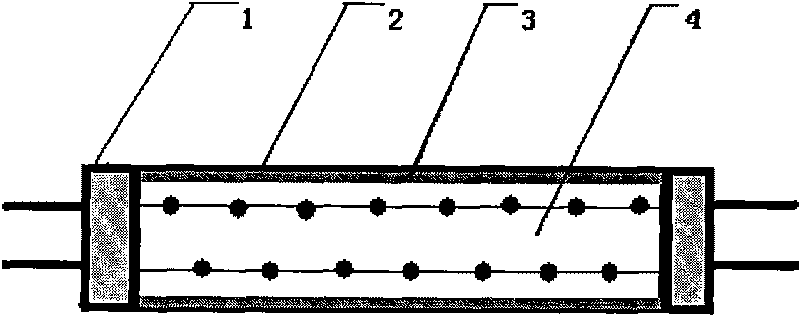

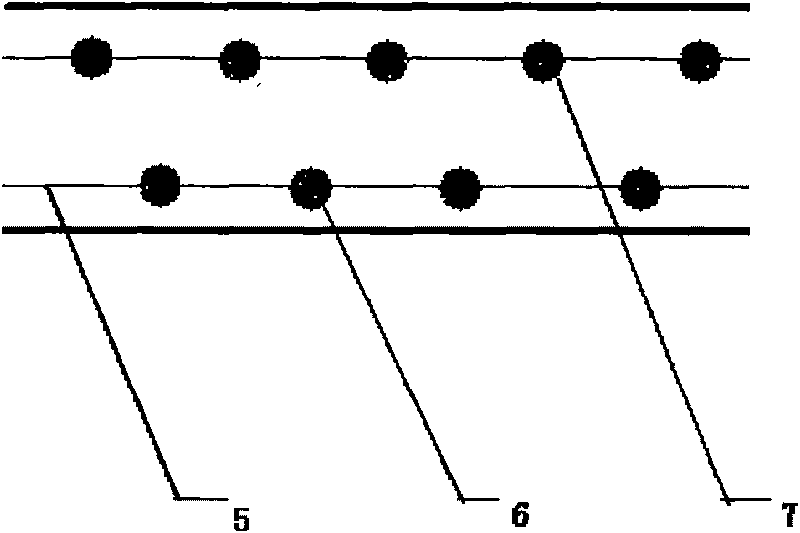

LED lamp based on blue light and red light chips and manufacturing method thereof

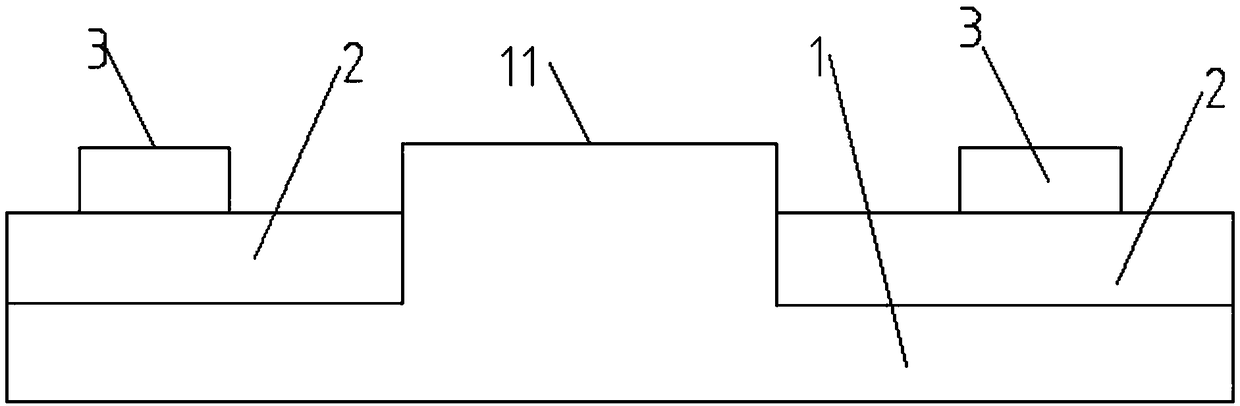

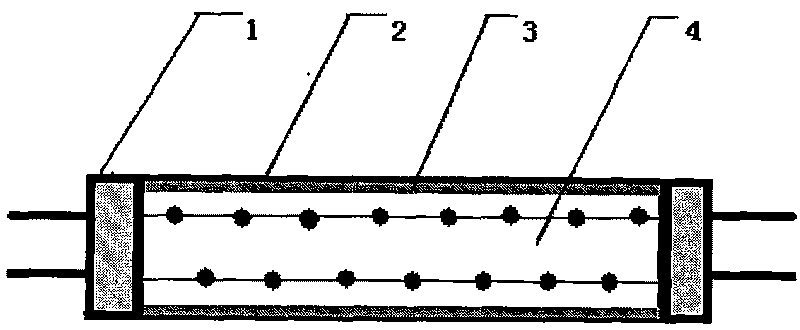

InactiveCN101701684AHigh color rendering indexThere will be no "zebra crossing" phenomenonPoint-like light sourceElectric lightingEngineeringLight head

The invention relates to an LED lamp based on a blue light and a red light chips, which consists of lamp heads 1, a tube 2, a fluorescent powder coating 3 and an LED chip module 4, wherein the fluorescent powder coating is evenly coated on the inner wall of the tube, the LED chip module is arranged inside the tube and connected and fixed on the lamp heads by a circuit, and the lamp heads are fixed at the two ends of the tube; the LED chip module 4 comprises the blue light and the red light chips; and the fluorescent powder coating is the mixture of fluorescent powder and bonding agent. The LED has the advantages of low cost, long service life, simple manufacturing technique and the like, and more particularly, the color rendering property is greatly improved.

Owner:NANJING UNIV OF TECH

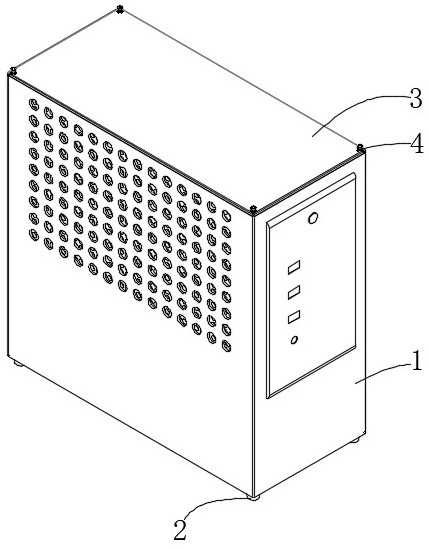

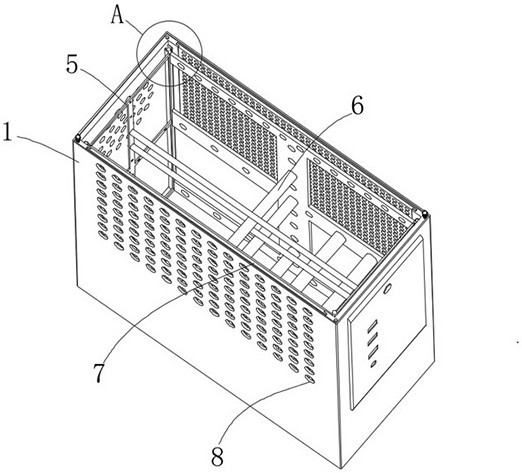

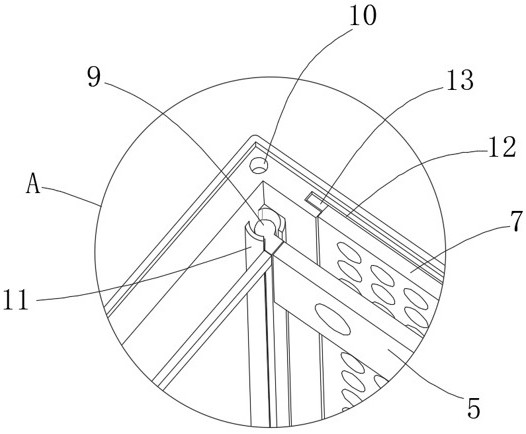

Computer mainframe box used for computer hardware development and convenient for mainboard installation

PendingCN113485533AReduce limitationsIncrease the speed of disassemblyDigital processing power distributionComputer hardwareComputer architecture

The invention provides a computer mainframe box used for computer hardware development and facilitating mainboard installation, and belongs to the technical field of computers. The computer mainframe box used for computer hardware development and facilitating mainboard installation comprises a box body and a cover plate, a sleeve shell is fixedly connected to the inner side of the box body, and a mounting frame is arranged in the box body; and the outer side of the mounting frame is fixedly connected with a fixing column, the mounting frame is movably connected with the box body through the fixing column, and the inner side of the mounting frame is fixedly connected with a connecting rod. According to the computer mainframe box facilitating mainboard installation for computer hardware development, by arranging the box body and the installation frame structure which can be separated, when the mainboard needs to be disassembled and assembled, the installation frame can be separated from the box body, the installation frame is moved out of the box body, and therefore the operation space is increased, the limitation of mainboard disassembly and assembly is reduced, the maintenance cost of the mainboard is reduced, and popularization and application are facilitated.

Owner:HENAN POLYTECHNIC

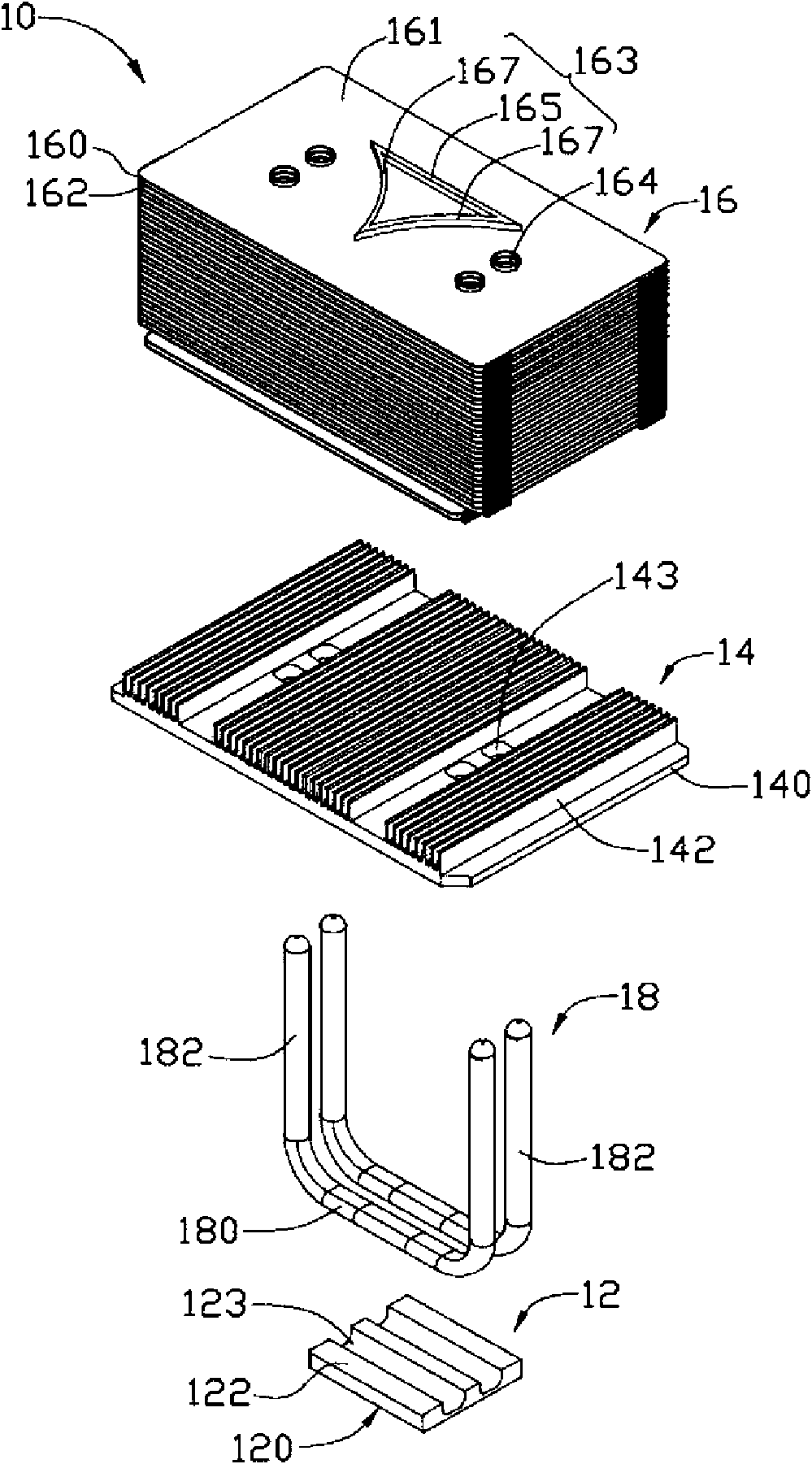

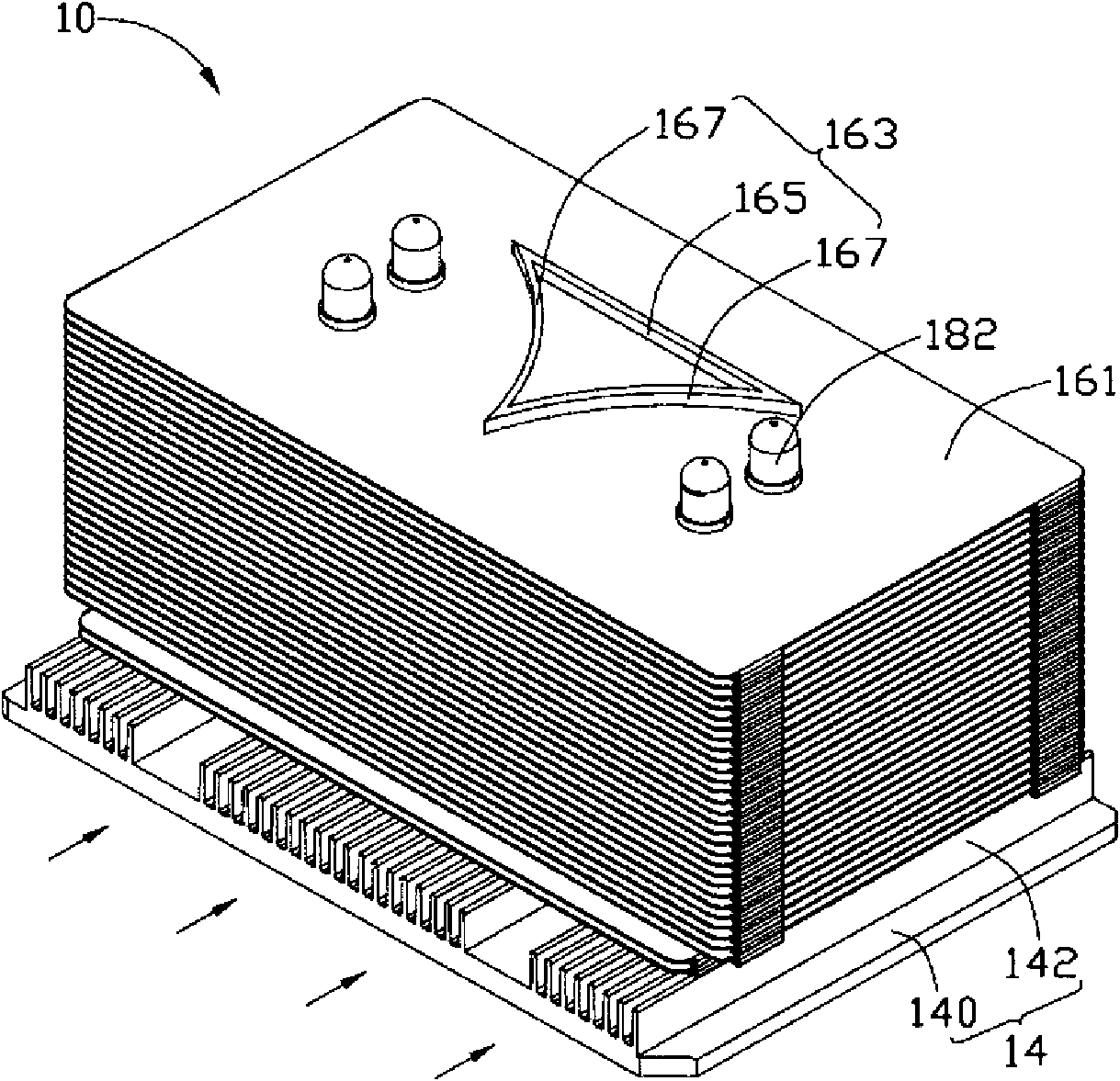

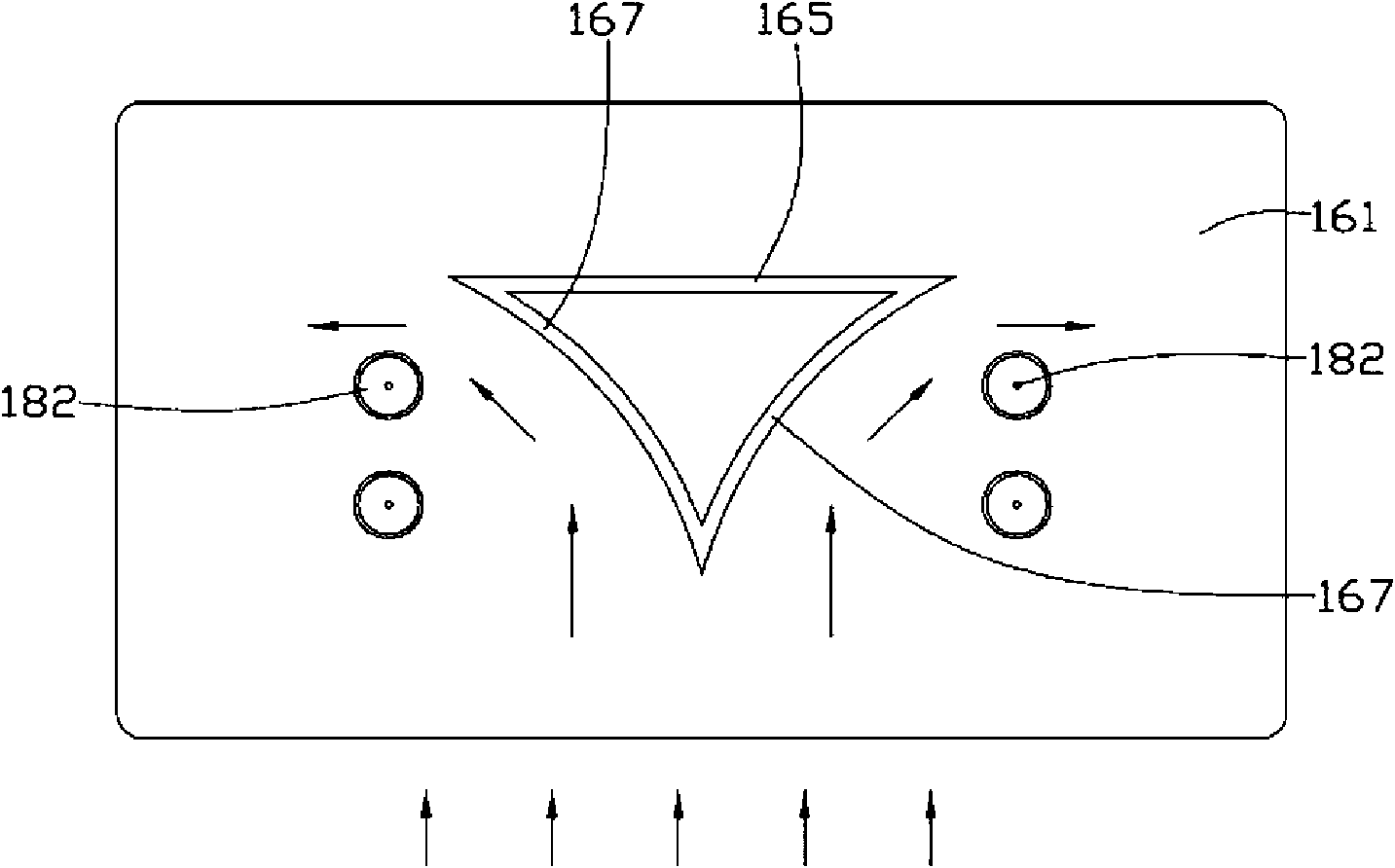

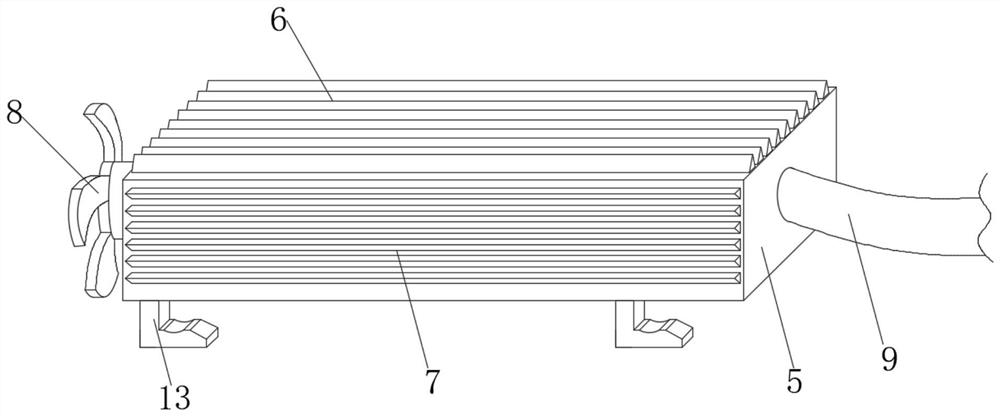

Heat radiating device

InactiveCN102083296AImprove cooling effectSpeed up heat exchangeSemiconductor/solid-state device detailsSolid-state devicesEngineeringMaterial Perforation

The invention discloses a heat radiating device comprising a heat radiator and at least one heat pipe penetrated in the heat radiator; the heat radiator comprises a plurality of heat radiating fins arranged at intervals; air flow channels for air flow to pass through are arranged between every two adjacent heat radiating fans; each heat radiating fin is provided with a perforation for the heat pipe to penetrate in; a flow guiding structure is arranged on a position of each heat radiating fin, near the perforation; the flow guiding structure comprises an arc-shaped wall arranged around one side of the perforation; the arc-shaped wall is obliquely arranged opposite to the direction of the air flow in the air flow channel to guide the air flow in the air flow channel to the heat pipe, thereby enhancing the heat exchange of the heat pipe, weakening the influence of a heat spin in the rear of the heat pipe on heat radiation and further improving the heat radiating effect o the heat radiating device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Household electric vehicle frequency converter

InactiveCN112654188AReduce entryReduce the impact of heat dissipationCasings/cabinets/drawers detailsModifications for power electronicsFrequency changerEngineering

The invention discloses a household electric vehicle frequency converter, which comprises a bottom plate. The top end of the bottom plate is fixedly connected with a protective cover and a wiring harness box; by arranging the protective cover, the protective cover protects the heat dissipation shell at the top end of the bottom plate, external dust can be prevented from entering the protective cover to be accumulated on the surface of the heat dissipation shell, the motor and the fan blades are arranged, the motor drives the fan blades to rotate, then the fan blades blow out air in the protective cover, dust entering is further reduced, and heat radiated in the protective cover can be blown out, and normal heat radiation of thefrequency converter is further ensured. By arranging the wire harness box and the sealing cover, after the frequency converter is connected through the connecting wire harnesses, the redundant connecting wire harnesses are stored in the wire harness box through the through holes, and when the frequency converter jolts and vibrates, the end springs and the top pressure springs buffer vibration generated by the supporting plate in the horizontal direction and the vertical direction correspondingly, and then vibration borne by the heat dissipation shell is reduced.

Owner:李梦

Heat dissipation type power adapter

PendingCN113972812AReduce adhesionReduce the impact of heat dissipationConversion constructional detailsCasings/cabinets/drawers detailsElectronic componentBattery cell

The invention belongs to the field of battery charging devices, and particularly relates to a heat dissipation type power adapter. The heat dissipation type power adapter comprises a shell, a heat dissipation unit and a fixing frame. An air inlet is formed in one side of the shell, and an air outlet is formed in the other side of the shell; the heat dissipation unit is arranged on the side wall of the shell; a threaded groove is formed in the air inlet; a fixing frame is connected into the threaded groove through threads; a supporting net plate is fixedly connected in the fixing frame; a filter screen is fixedly connected to the side, away from the heat dissipation unit, of the supporting screen plate; and the section of the supporting net plate is designed to be of a trapezoidal structure. A clamping block is arranged on the side, away from the heat dissipation unit, of the fixing frame, the fixing shell, the supporting net plate and the filter net are arranged, airflow is conducted through the filter net, dust adhering to the surfaces of internal electronic components is reduced, and then the influence of the dust and catkin on heat dissipation is reduced.

Owner:SHENZHEN TEKA TECH

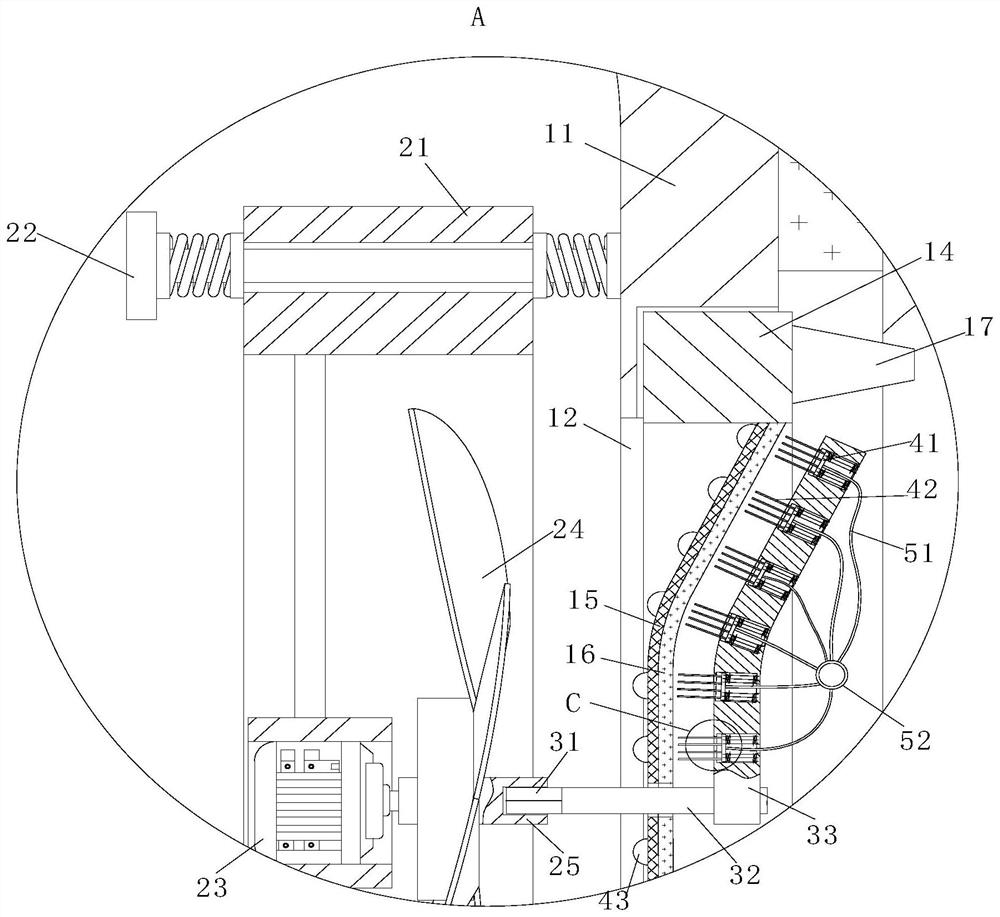

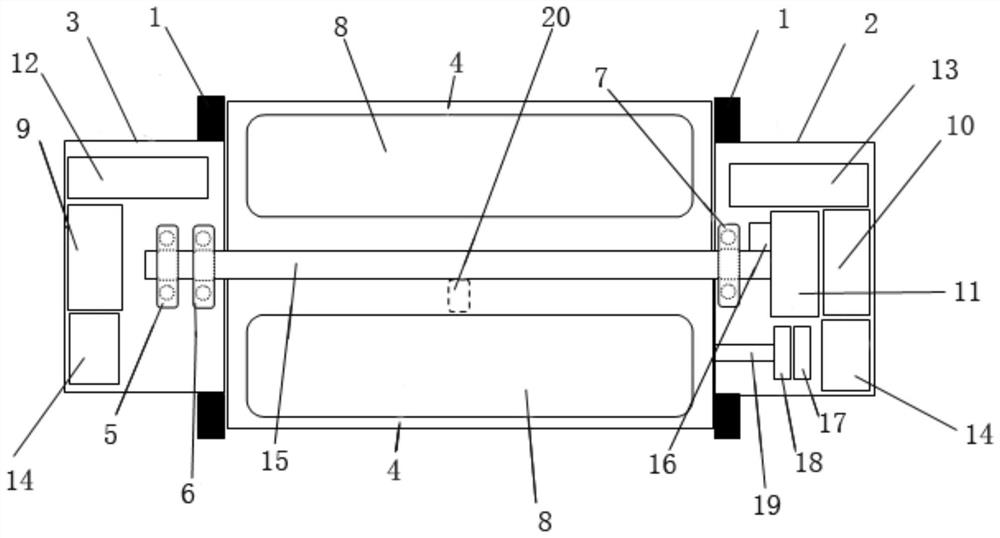

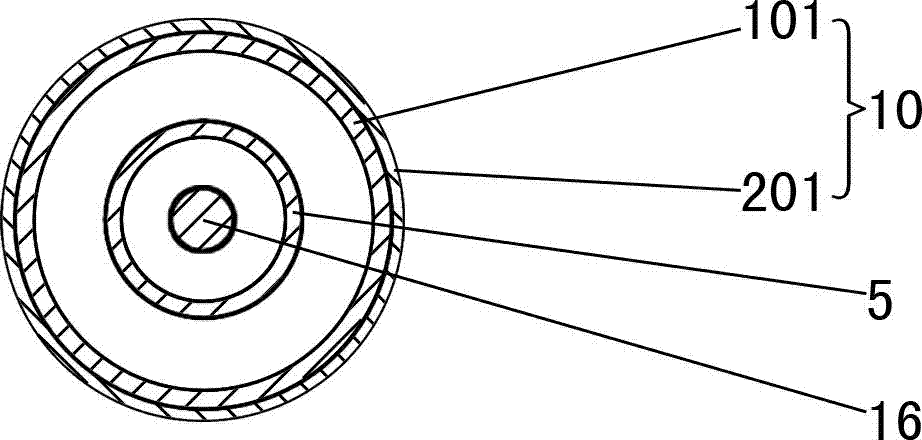

Hub motor driving wheel provided with brake device

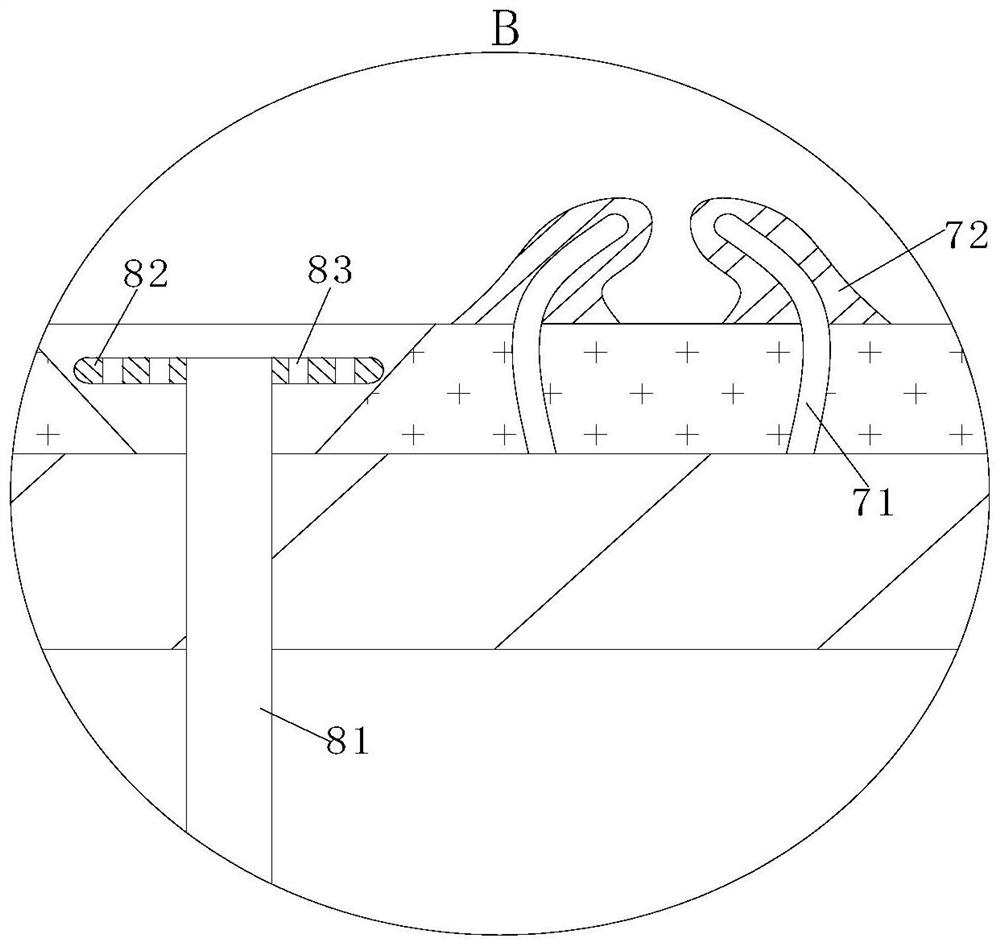

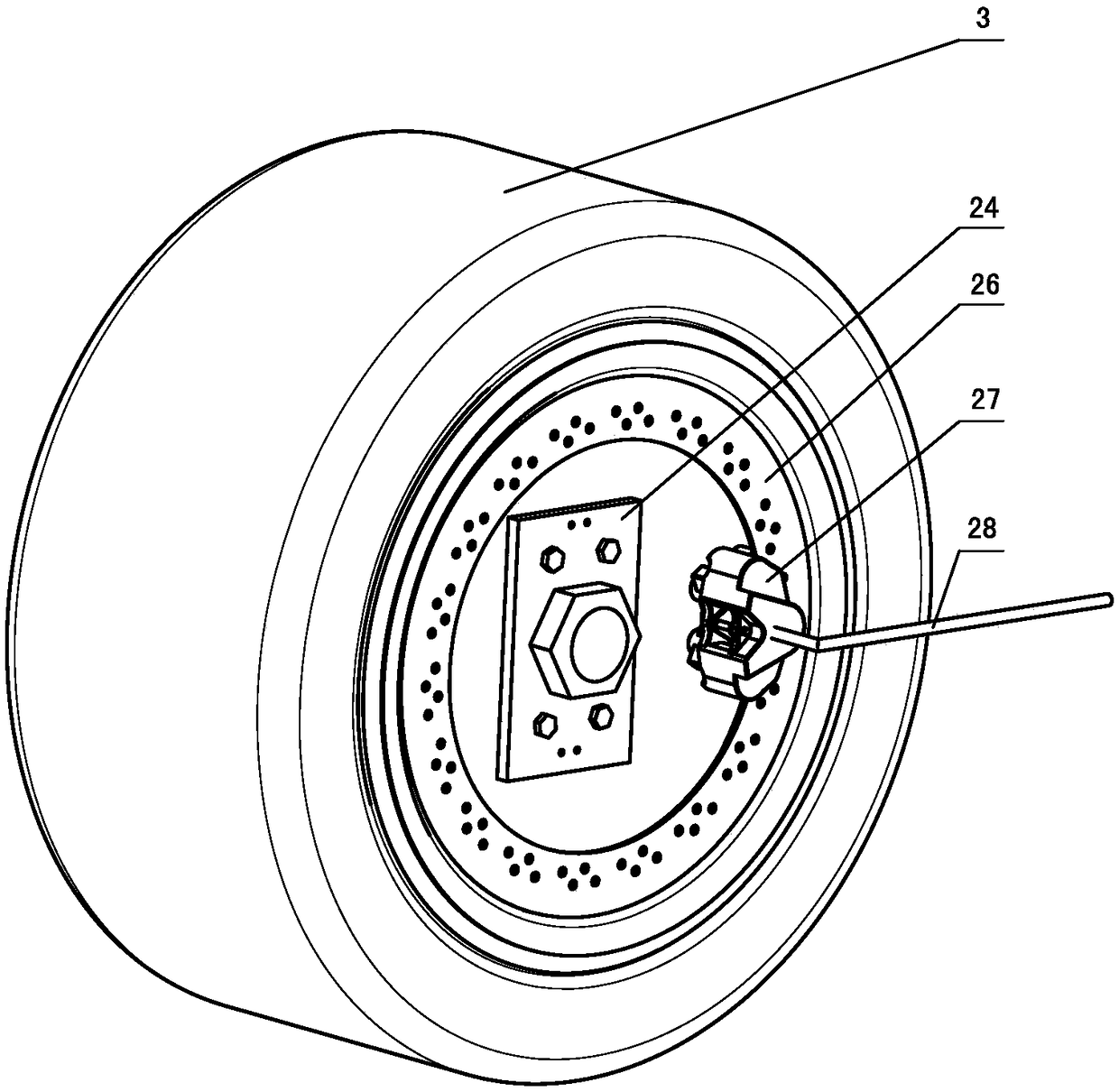

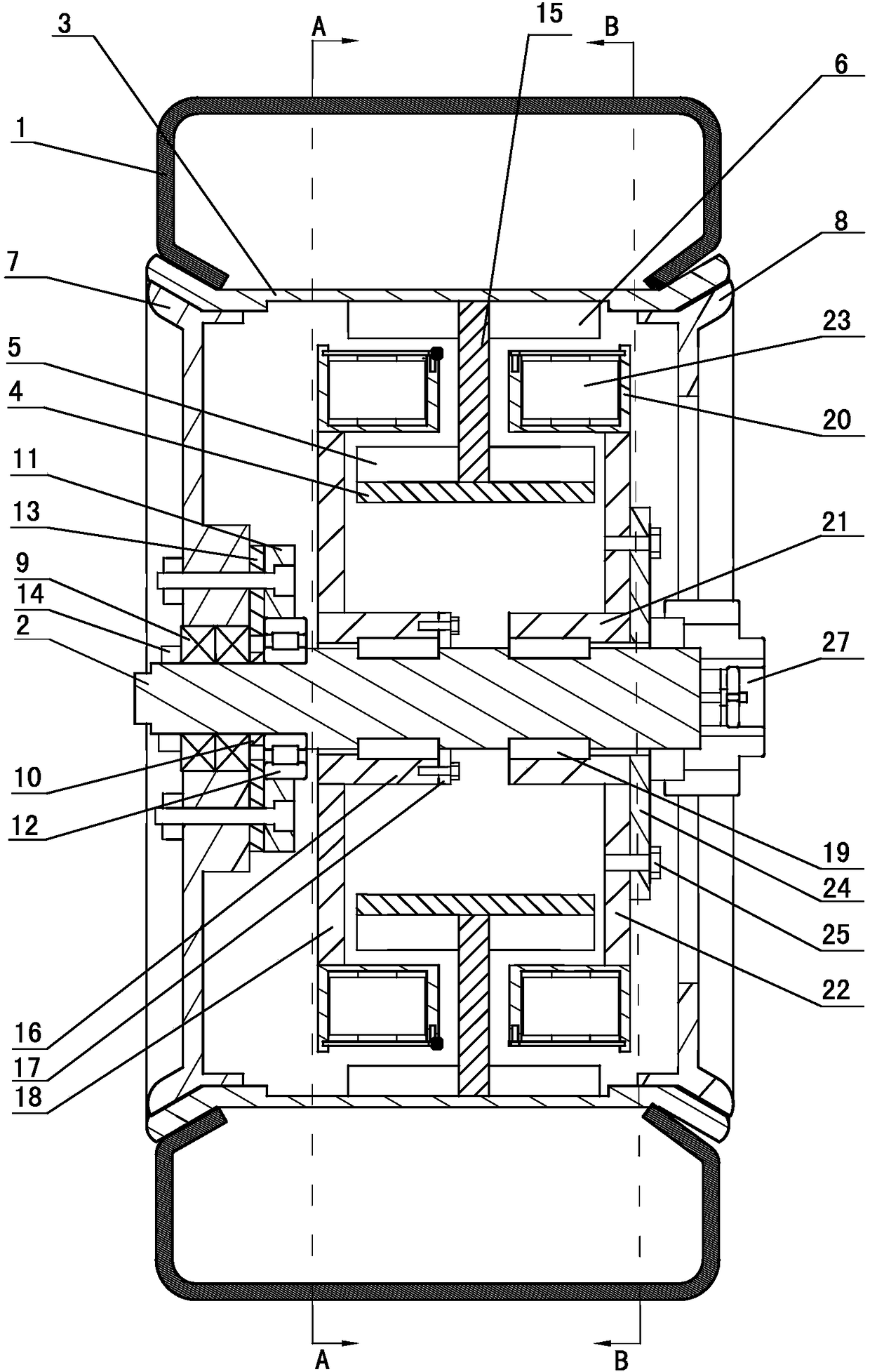

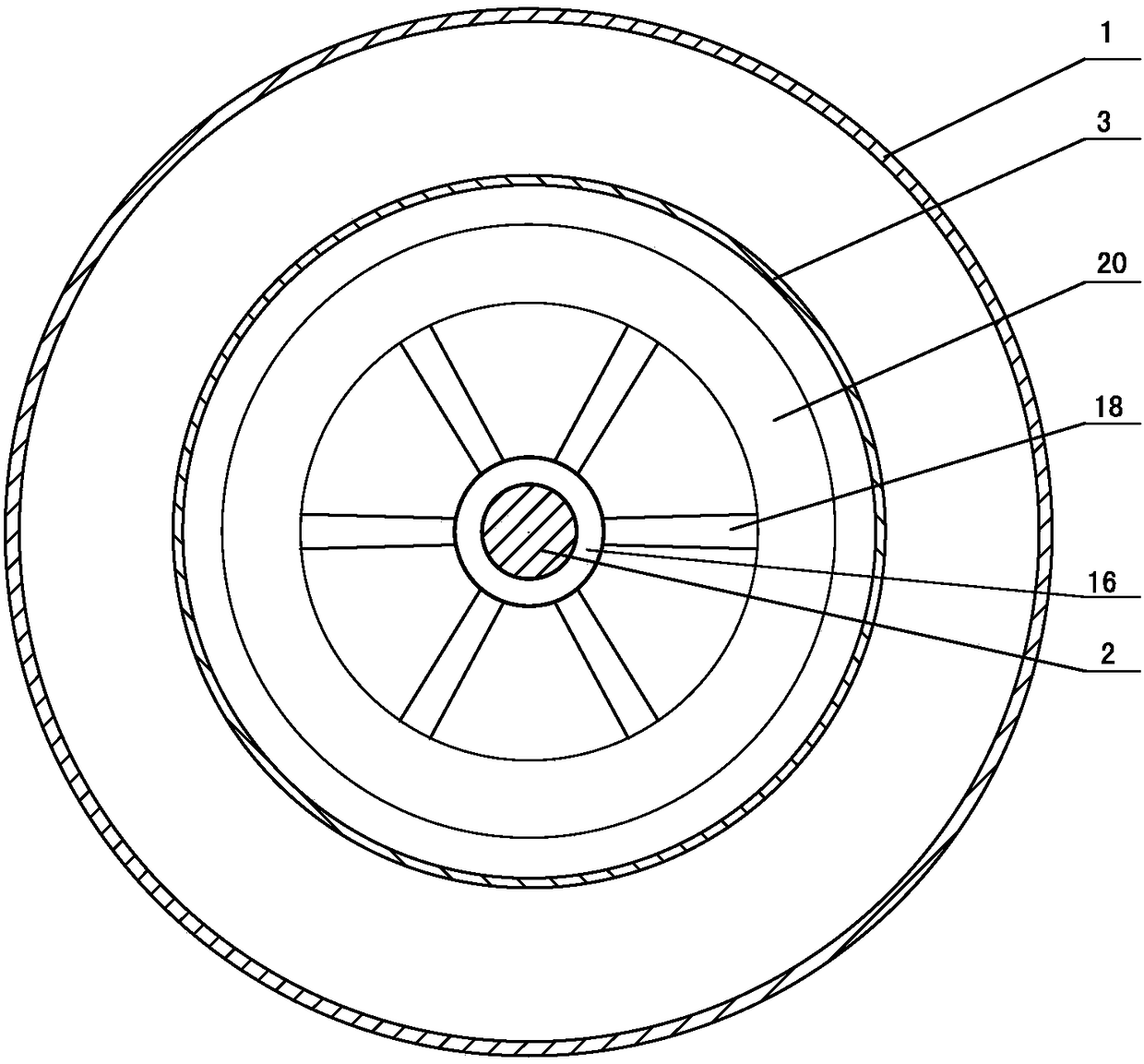

ActiveCN108128144AIncrease the force of the magnetic fieldImprove power densityBraking element arrangementsMotor depositionDrive wheelMotor drive

The invention provides a hub motor driving wheel provided with a brake device. The hub motor driving wheel provided with brake device is characterized in that a rotor assembly comprises a middle shell, a base body, two inner-ring permanent magnets, two outer-ring permanent magnets, a left shell and a right shell; the left shell and the right shell are fixedly connected with the middle shell, and atire is installed on the outer wall of the middle shell; the two outer-ring permanent magnets and the two inner-ring permanent magnets are correspondingly fixed on the side walls that the middle shell is opposite to the base body; a left stator assembly comprises a first base, a base limiting ring and a spoke-shaped connecting piece, a right stator assembly comprises a second base and an annularconnecting disc, annular stator grooves which are concentric with a stator shaft are formed in the outer end of the connecting piece and the outer end of the connecting disc, the two stator grooves are located between the inner-ring permanent magnets and the outer-ring permanent magnets, the quantity of stator windings evenly distributed in the stator grooves is equal, and the stator windings areopposite in pairs; the brake device is of a caliper-disc structure, a brake disc is of an annular structure and is coaxially and fixedly connected with the right shell, and a brake caliper is fixedlyinstalled on the outer wall of the connecting disc and located in an annular ring of the brake disc.

Owner:SHANDONG UNIV OF TECH

Process for covering surface of aluminum diamond composite material with copper foil and embedding ceramic material

ActiveCN107611040AFirmly connectedCompact structureSemiconductor/solid-state device manufacturingCopper foilHigh pressure

The invention relates to a process for covering a surface of an aluminum diamond composite material with a copper foil and embedding a ceramic material. The copper foil covering the surface of aluminum diamond and the ceramic material are etched in advance during the die casting process, the copper foil and the ceramic material wrap an outer side of diamond powder so that firm connection with thediamond composite material is formed very well during the high-pressure die casting and aluminum permeating process, the working reliability of a multi-chip assembly and a large-current power module is improved, and demands such as welding, mechanical processing and coating of a surface of a cooling substrate material are satisfied. The copper foil and the ceramic material which are etched wrap the outer side of the diamond powder, and firm connection among the copper foil, the ceramic material and the aluminum diamond composite material substrate during the die casting process is achieved.

Owner:上海开朋科技有限公司

LED lamp cooling component and production method thereof

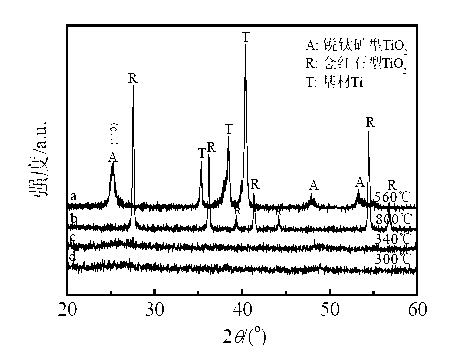

InactiveCN102829456AIncrease contact areaHigh activityPoint-like light sourceLighting heating/cooling arrangementsRare-earth elementCooling effect

The invention relates to an LED lamp cooling component and a production method thereof. The production method comprises the following steps: step (1) of manufacturing the LED lamp cooling component by metals; step (2) of cleaning the LED lamp cooling component at a plurality of times with ultrasonic waves, and drying; and step (3) of plating a la-doped or cerium-doped titanium dioxide film with the thickness of 50-100 mm on the surface of the LED lamp cooling component by using a sol-gel method or a vacuum vapor deposition method. The surface of the LED lamp cooling component processed by the invention is like a form that is macroscopically bright and clean, and microcosmically coarse, thus greatly increasing the contact area between a road lamp cooling component and the outside world, reducing heat shield, significantly improving cooling effects, and also keeping excellent performances such as corresponding corrosion resistance, abrasive resistance and so on. In addition, rare earth element oxides are doped so as to improve actively of the system, and have functions of degrading pollutants, resisting bacteria, sterilizing, resisting fouling and cleaning by self. The film-coated system has no matters and radiation harmful to the human body, so that the LED lamp cooling component is a novel environmental protection energy-saving system, and can be widely applied to surface treatment of the metal LED cooling component.

Owner:SHANGHAI BASFORM POWER ELECTRIC

High-temperature-resistant switch

PendingCN112291636AReduce accumulationGuaranteed stability and securityModifications using liquid coolingModifications using gaseous coolantsStructural engineeringMechanical engineering

The invention relates to the technical field of switches, in particular to a high-temperature-resistant switch which comprises a mounting frame, a switch body is fixedly connected to the inner side ofthe rear end face of the mounting frame, an ash removal device is arranged on the inner side of the mounting frame, a heat dissipation device is arranged on the outer side of the mounting frame, anda controller is fixedly connected to the right of the inner side of the top end face of the mounting frame. An internal temperature sensor is fixedly connected to the side, away from the controller, of the right side of the inner side of the top end face of the mounting frame, and a dust detector is fixedly connected to the left side of the inner side of the top end face of the mounting frame. Bymeans of work of the adjusting lead screw, the ash removing frame can be driven in a circulating and reciprocating mode to remove ash on the surface of the outer side of the exchanger, accumulation ofthe ash on the exchanger is reduced, the influence of dust accumulation on heat dissipation of the exchanger is reduced, and further, under the action of the limiting sliding block and the limiting sliding groove, stability and safety during moving of the ash removing frame are guaranteed; the phenomenon of autorotation during movement of the ash removal frame is avoided, and normal operation ofash removal work is prevented from being affected.

Owner:苏州微推信息科技有限公司

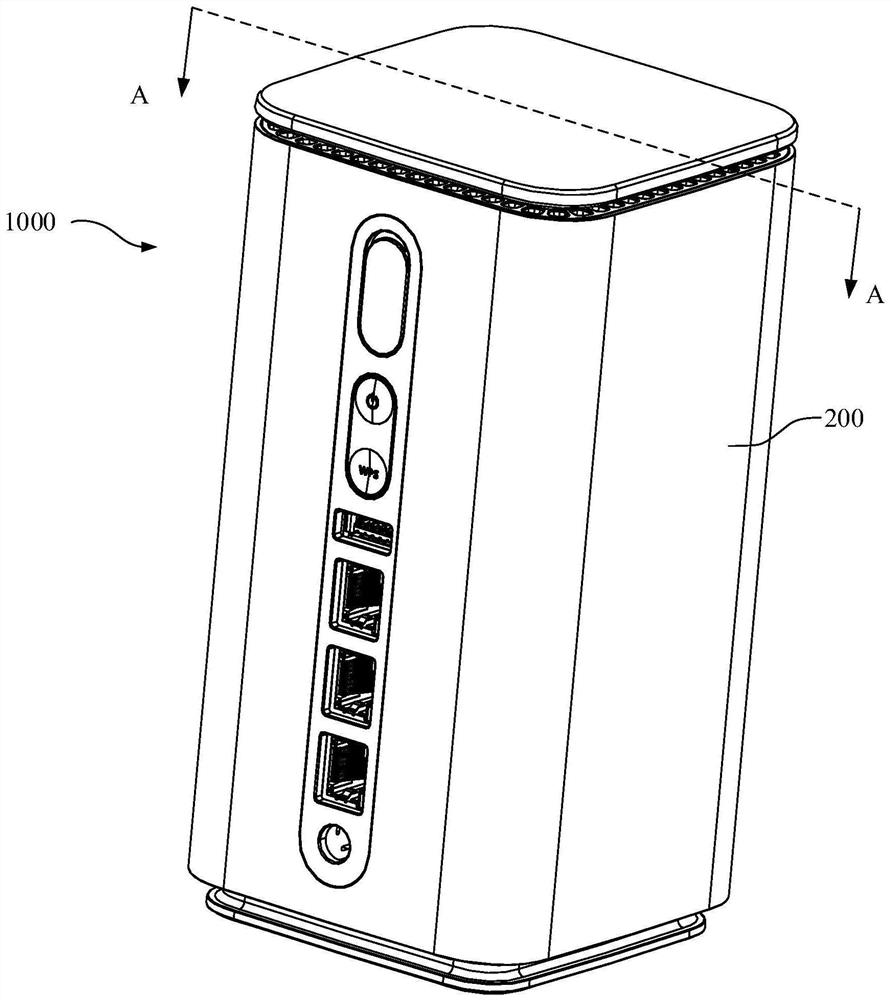

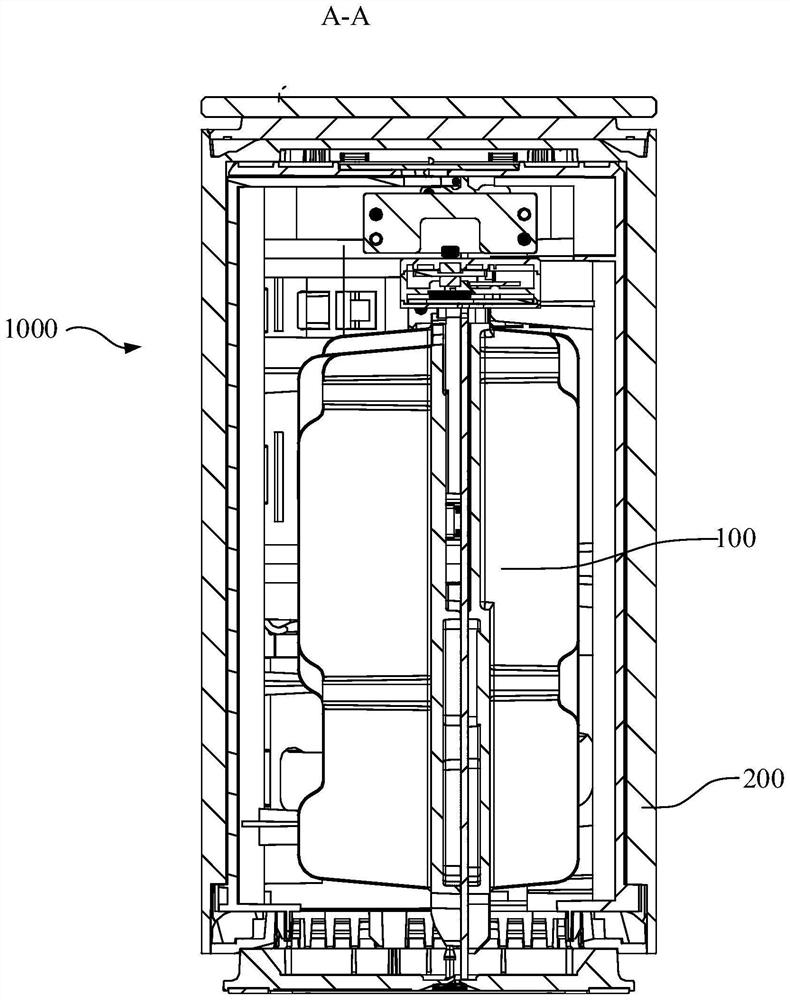

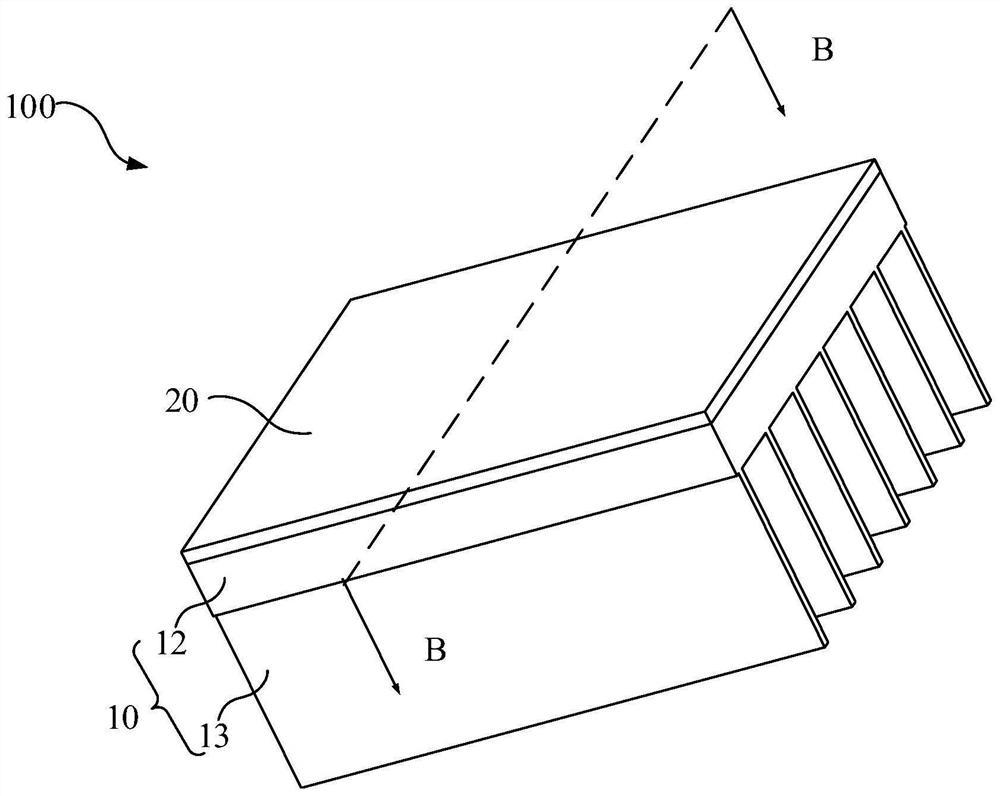

Chip heat dissipation structure and electronic equipment

PendingCN114158183AImprove cooling effectReduce thermal resistancePrinted circuit non-printed electric components associationCooling/ventilation/heating modificationsHeat spreaderElectronic equipment

The invention relates to a chip heat dissipation structure and electronic equipment. The chip heat dissipation structure comprises a radiator, a circuit board, a chip and a heat conduction assembly. The radiator comprises a heat dissipation plate, the circuit board and the heat dissipation plate are arranged in parallel at an interval, the chip is attached to the surface, facing the heat dissipation plate, of the circuit board, and the heat conduction assembly is located between the chip and the heat dissipation plate; wherein the heat conduction assembly comprises a first boundary layer, a heat sink plate and a second boundary layer which are sequentially stacked, the first boundary layer is located between the heat sink plate and the chip, and the second boundary layer is located between the heat sink plate and the heat dissipation plate. The electronic equipment comprises the chip heat dissipation structure. Through the mode, the heat resistance of the heat conduction assembly can be reduced, the heat dissipation effect of the chip is further improved, the tolerance between the chip and the heat dissipation plate can be absorbed, and the influence of the tolerance on heat dissipation is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

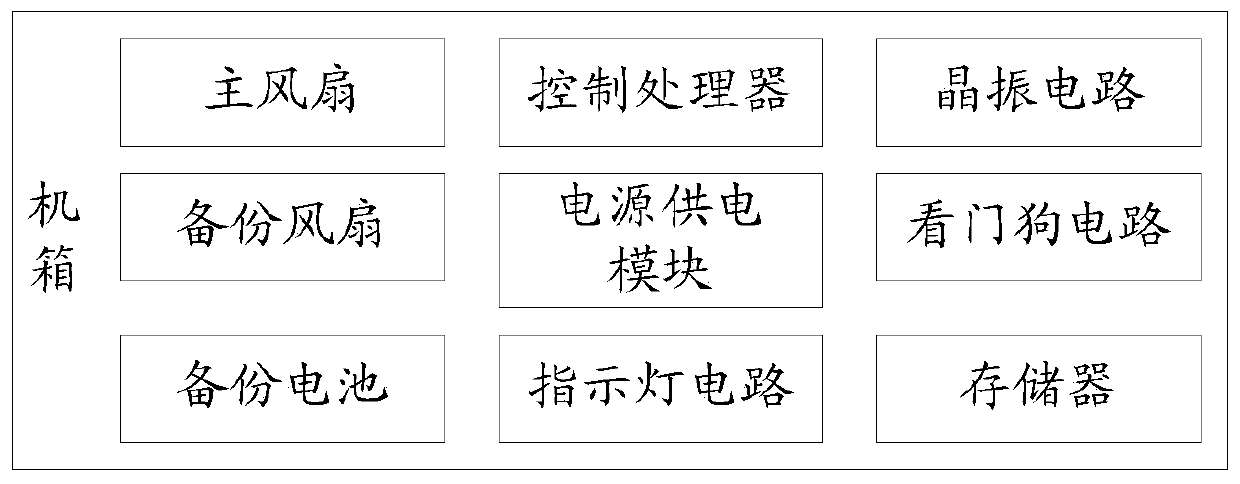

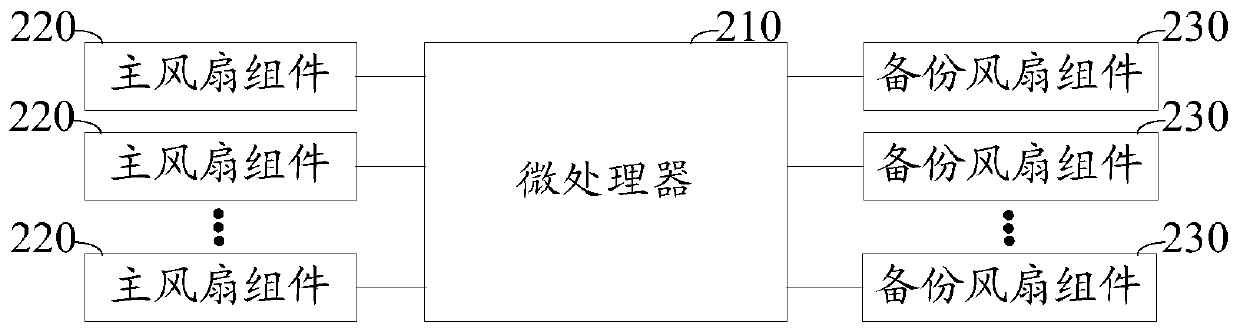

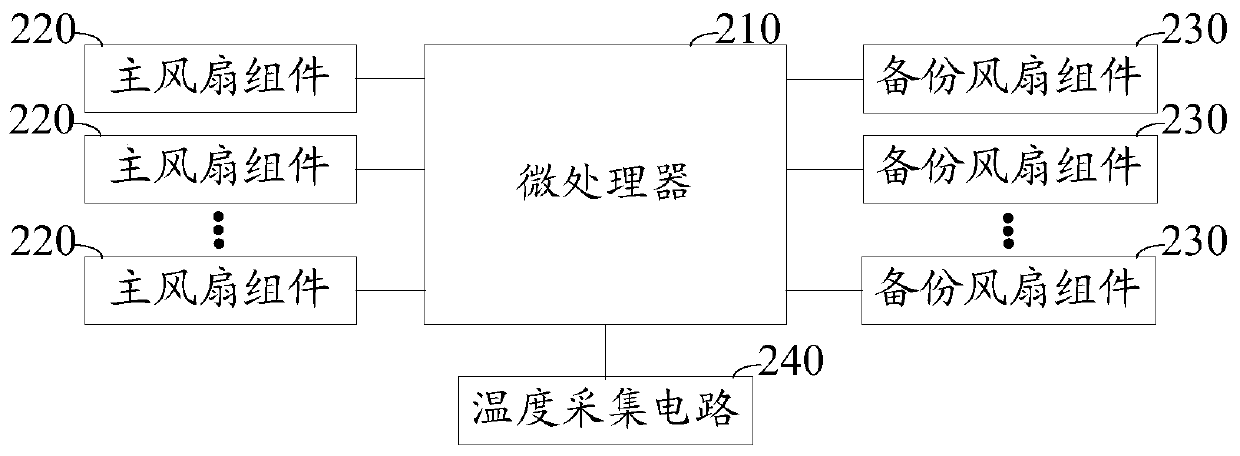

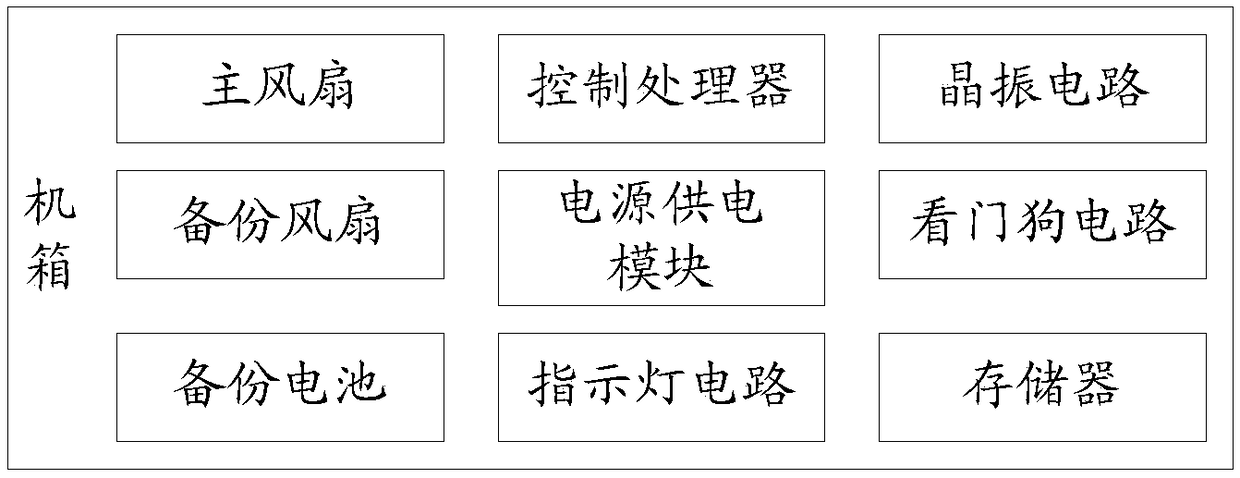

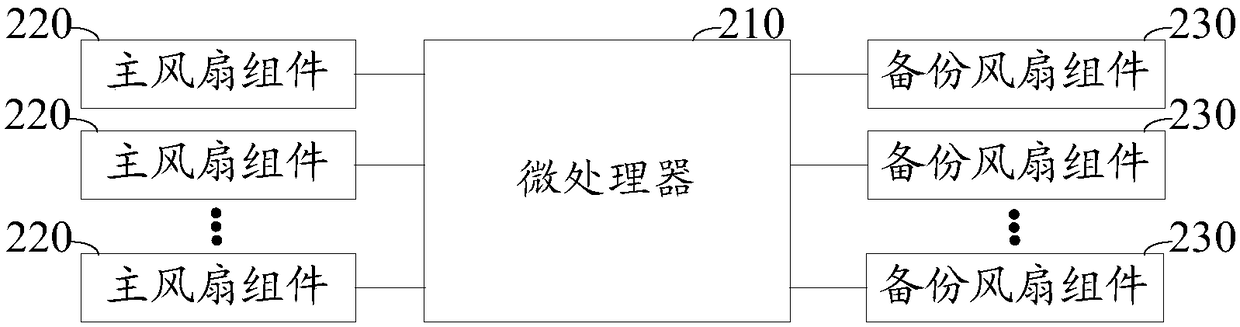

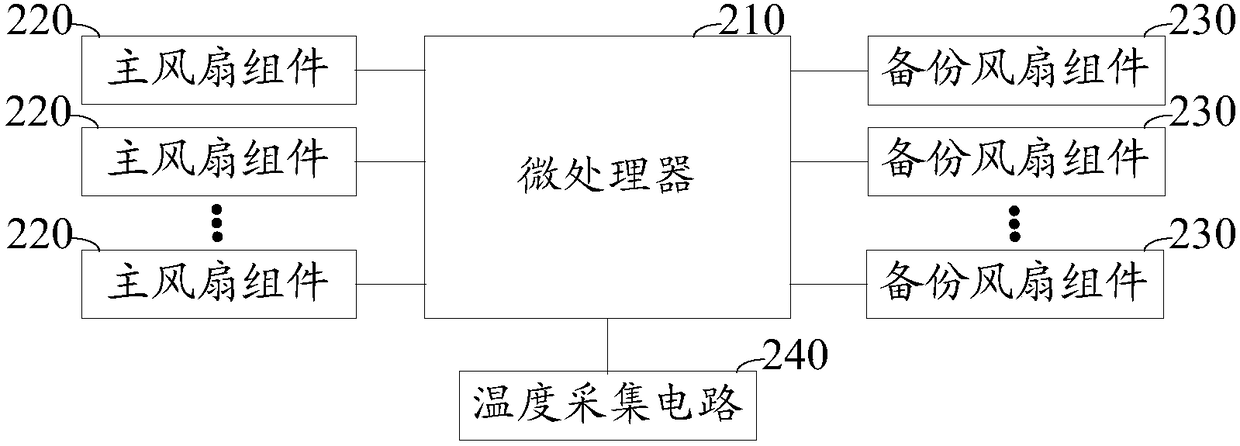

Fan control system and backup battery charging method

ActiveCN108425874BImprove reliabilityImprove stabilityBatteries circuit arrangementsElectric powerControl systemBackup battery

The invention relates to a fan control system and a backup battery charging method. The fan control system comprises a microprocessor, multiple main fan assemblies and multiple backup fan assemblies.The main fan assemblies and the backup fan assemblies are connected with corresponding external expansion interfaces of the microprocessor correspondingly, the main fan assemblies are connected with multiple main fans in a one-to-one correspondence mode, the backup fan assemblies are connected with backup fans in a one-to-one correspondence mode, and each main fan is at least close to one backup fan. The microprocessor is use for obtaining operation states of the main fans through the main fan assemblies. When the microprocessor judges that any main fan is in a fault state according to the operation state of the main fan, the backup fan adjacent to the main fan is controlled by the corresponding backup fan assembly to be started. According to the fan control system, the backup fan adjacentto the corresponding main fan in the fault state is started, the influences of the main fan in the fault state on cooling can be reduced, and reliability and stability of cooling performance of the fan control system are improved.

Owner:COMBA TELECOM SYST CHINA LTD

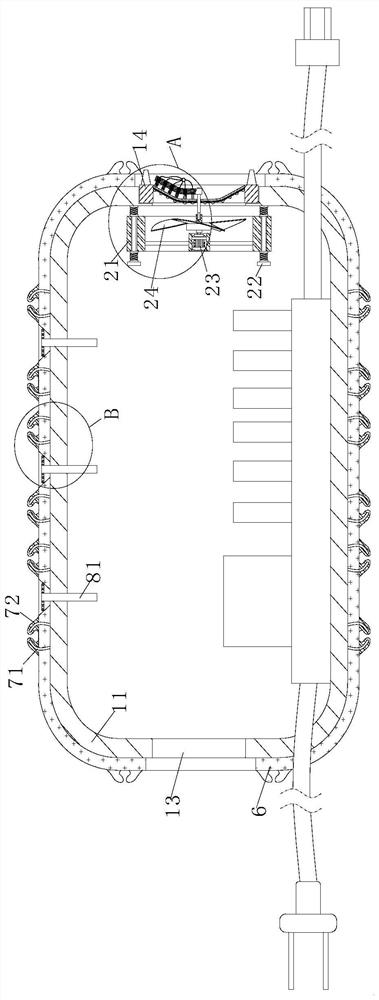

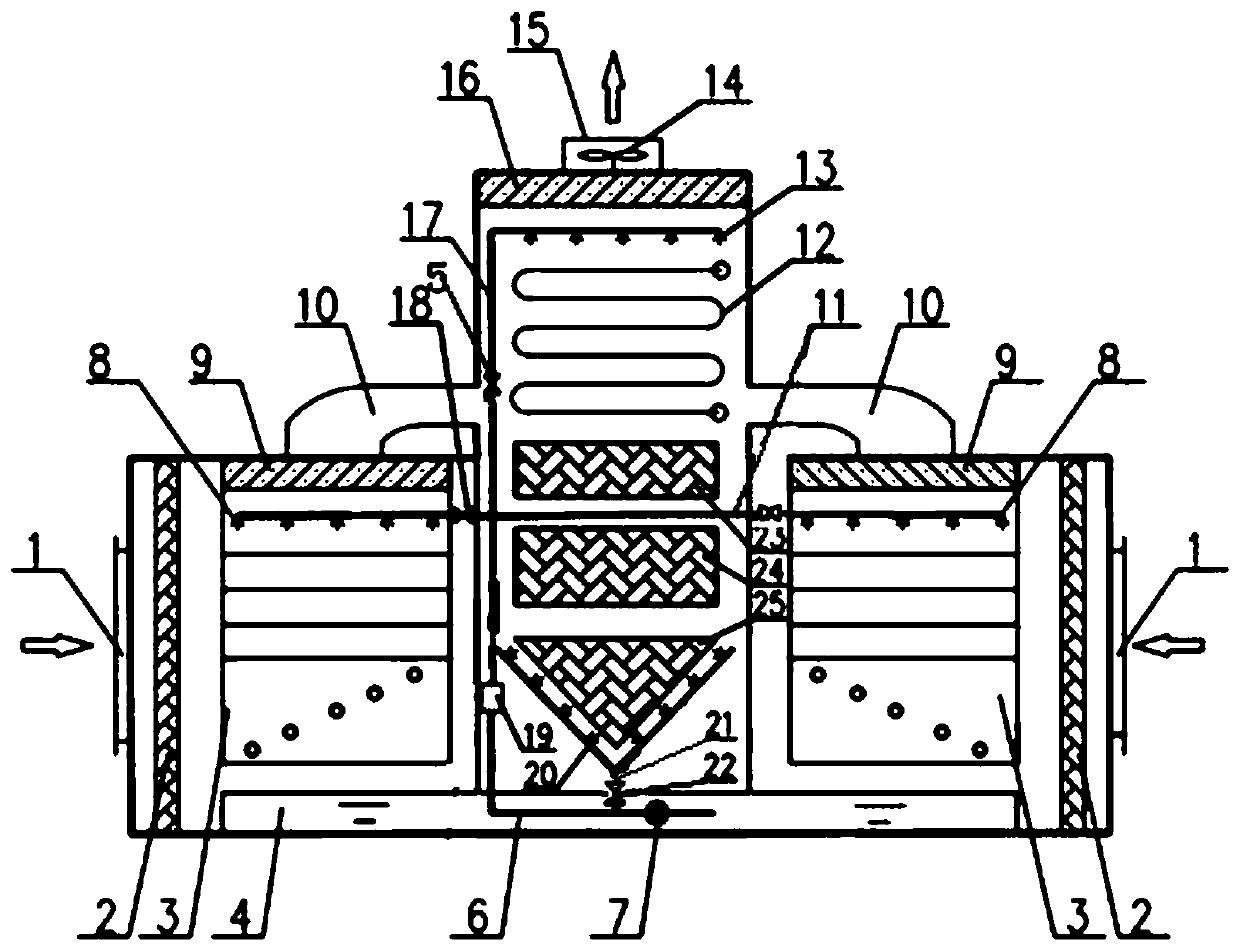

Evaporation-type condenser based on dew point indirect evaporation cooling and pre-cooling

ActiveCN110762909AReduce the impact of heat dissipationImprove cooling efficiencyEvaporators/condensersEngineeringDew

The invention discloses an evaporation-type condenser based on dew point indirect evaporation cooling and pre-cooling. The evaporation-type condenser comprises a unit shell, and the two opposite sidewalls of the unit shell are provided with two air inlets respectively. A filler-coil pipe composite evaporation-type cooling unit is arranged in the unit shell, the top wall, corresponding to the unitshell, of the upper portion of the filler-coil pipe composite evaporation-type cooling unit is provided with an air discharging port, and the left and right sides of the filler-coil pipe composite evaporation-type cooling unit are provided with two dew point indirect evaporation cooling segments respectively. A water tank is further arranged in the unit shell, located below the two dew point indirect evaporation cooling segments and the filler-coil pipe composite evaporation-type cooling unit and connected with the filler-coil pipe composite evaporation-type cooling unit and the two dew pointindirect evaporation cooling segments through a water pipe network. The evaporation-type condenser solves the problem that since the temperature of circulation water is increased, the heat exchange efficiency of the evaporation-type condenser is lowered.

Owner:ZHEJIANG JINLING REFRIGERATION ENG

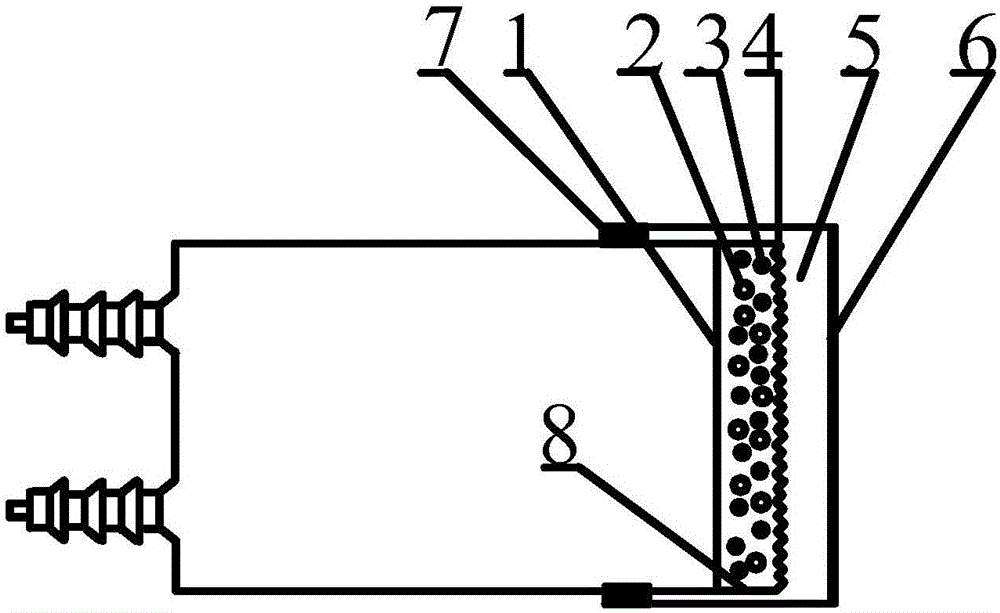

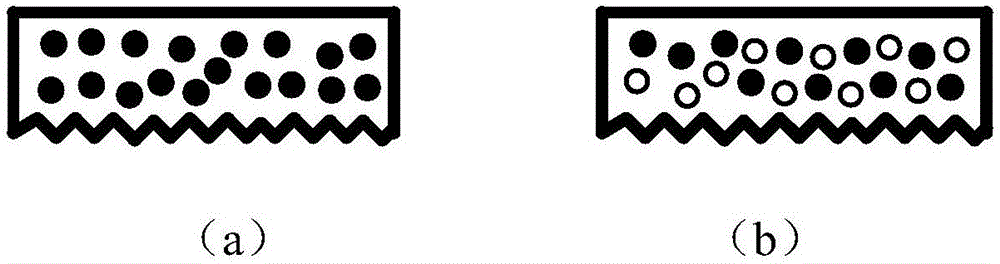

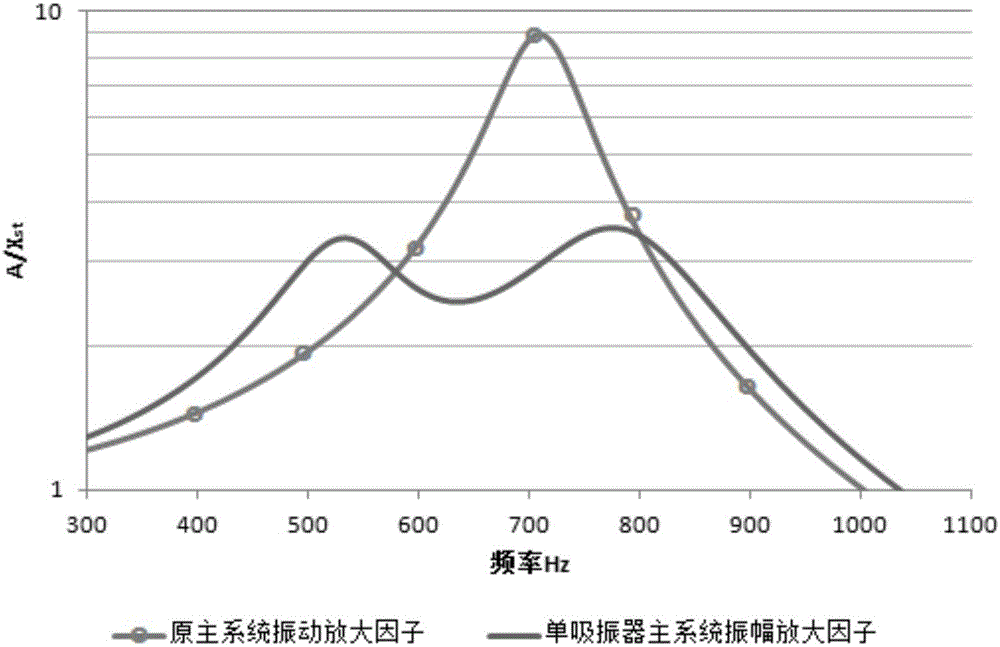

Power capacitor with noise-reducing device

ActiveCN106783167AReduce the impact of heat dissipationSmall and does not affect heat dissipationAnti-noise capacitorsFeed-through capacitorsHigh densityCapacitor

The invention provides a power capacitor with a noise-reducing device. A metal case cover is sealed and connected with a capacitor case. The metal case cover is filled with a damping material, and the damping material is filled with high-density particles and / or bubbles. The quality m and the density of the high-density particles and the change of the equivalent elastic coefficient k and equivalent damping coefficient C of the damping material are regulated to control the frequency of the noise-reducing device, so that the most noise of the capacitor is absorbed. Compared with the common capacitor, the noise radiation quantity of the power capacitor is greatly reduced, the device cost is low, the process is simple, and the production and manufacture are easy. The influence to the heat dissipation of the power capacitor is small, and the stability of the power capacitor is not affected. The noise is reduced under the precondition of ensuring the safety operation of the power capacitor, and the installation and maintenance are convenient.

Owner:XIAN XD POWER CAPACITOR CO LTD +1

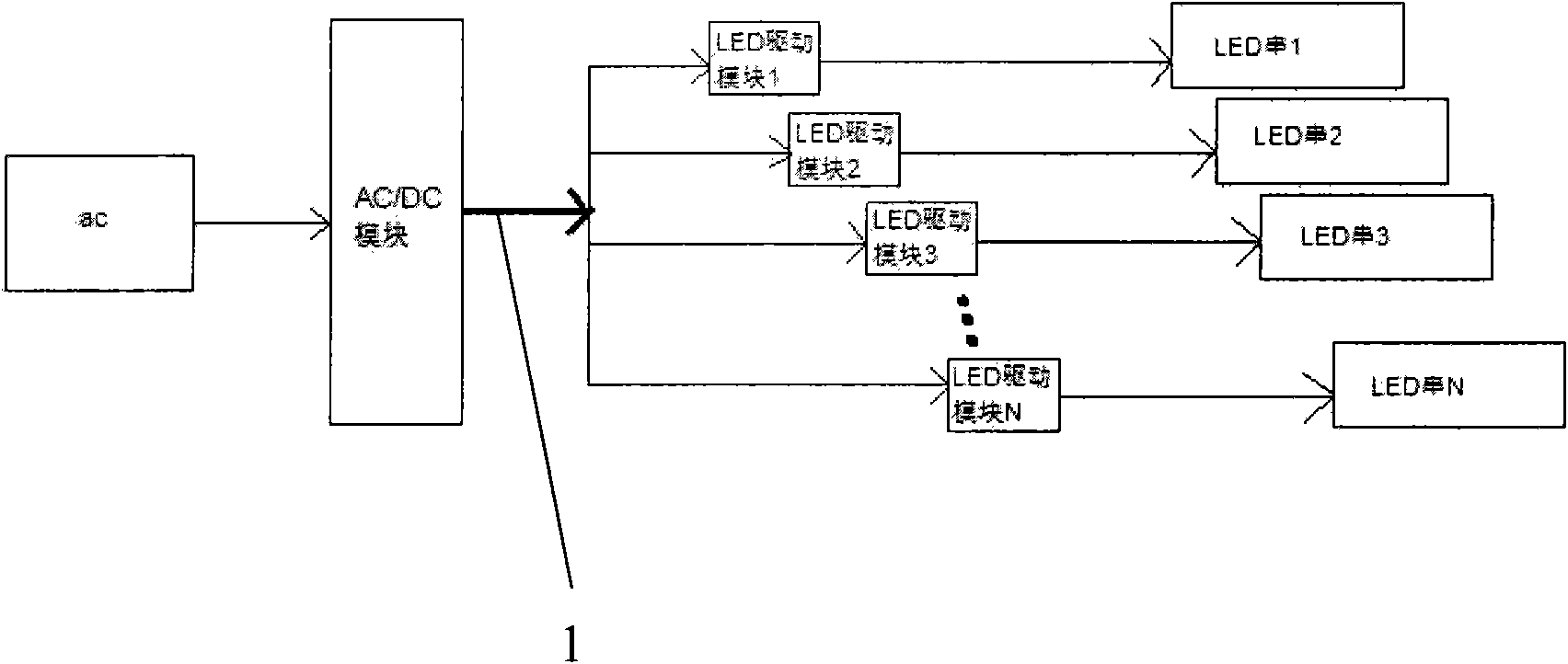

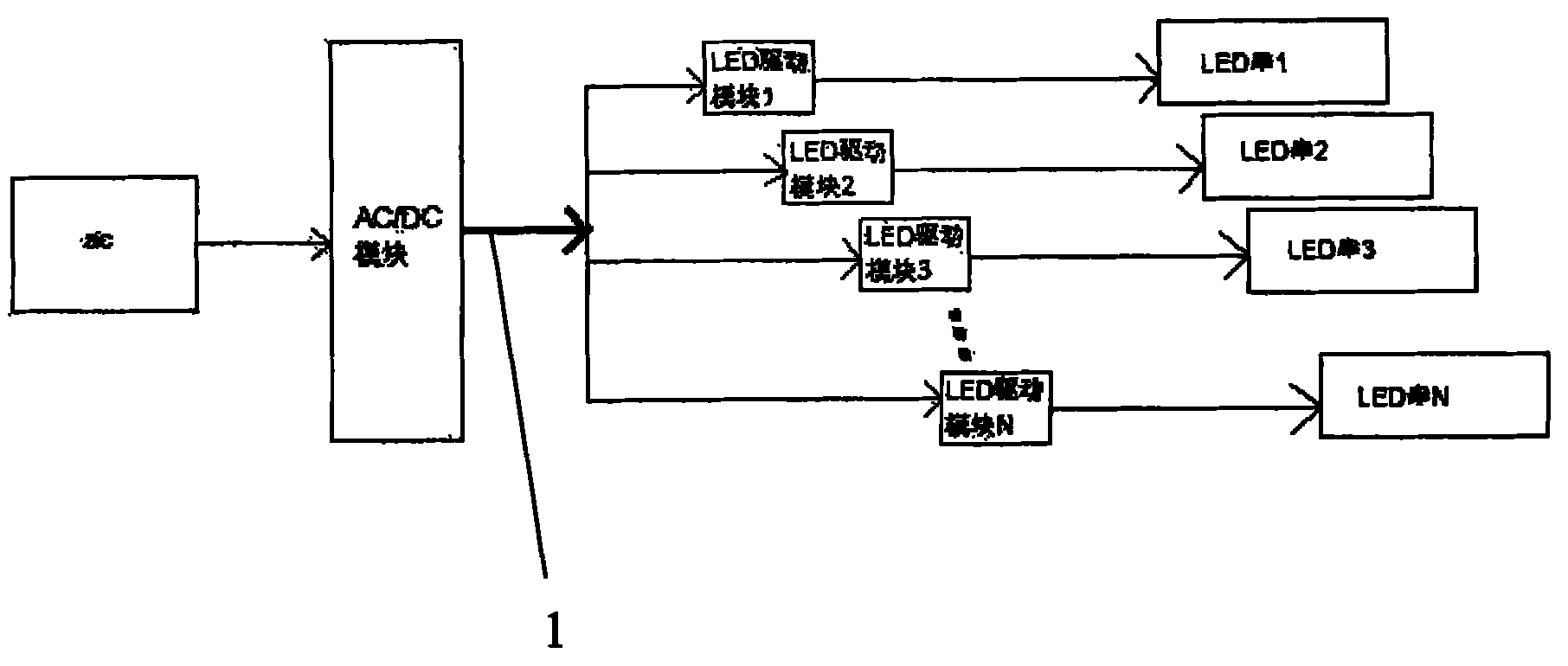

Driving method of LED (Light-Emitting Diode) circuit

InactiveCN101998723AReduce the impact of heat dissipationImprove reliabilityPoint-like light sourceElectric circuit arrangementsEngineeringAlternating current

The invention relates to a driving method of an LED circuit, belonging to the field of LED illumination, wherein an AC / DC (Alternating Current / Direct Current) module, LED driving modules and LED strings are comprised. In the method, a constant-voltage power source is supplied to each LED driving module through a power supply bus, and then is converted into a constant current power source by the LED driving module to drive the LED strings; the number of the LEDs in each string is equal; and the impedance characteristics of all the LEDs are basically consistent, and the impedance characteristics of each string of LEDs are basically consistent so as to ensure that each string of LEDs can run in a current-sharing mode and the brightness of each string of LEDs is consistent so that the LEDs cannot generate the obvious brightness difference, therefore, the final goal of control is guaranteed, i.e. the safe and stable running of the LEDs is ensured.

Owner:高志刚

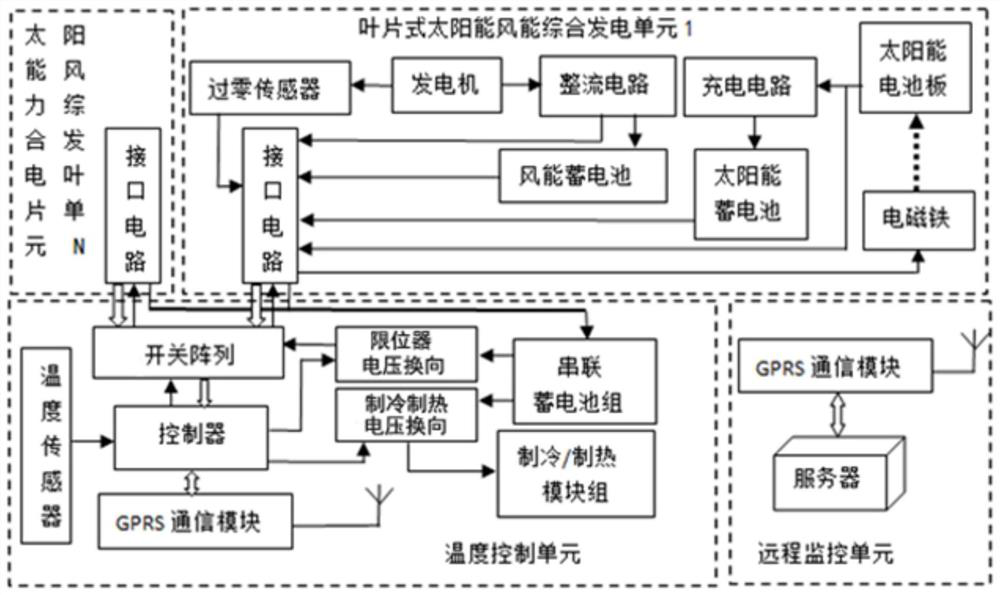

AAU intelligent constant temperature system, device and method of 5G base station

PendingCN112394757AReduce power consumptionGuaranteed to workPV power plantsTemperatue controlRemote monitoring and controlHeat sink

The invention discloses an AAU intelligent constant temperature system, device and method of a 5G base station. The device comprises a box body support, a plurality of blade type solar energy and windenergy comprehensive power generation units, a temperature control unit and a remote monitoring unit. The blade type solar energy and wind energy comprehensive power generation units are used for generating power, storing power, shading sun, cooling and forming a box body; the temperature control unit is used for detecting the temperature of the AAU cooling fin, converting the running state of the refrigerating and heating module group, detecting the running environment, collecting running information and data, and uploading the running information and data to the remote monitoring unit through the communication module; and the remote monitoring unit is used for dynamically storing and monitoring the operation information of the plurality of AAU intelligent constant temperature devices. Solar energy and wind energy power generation is achieved, and power supply is not needed; the judging device realizes intelligent sun shading, and automatically closes or opens the blade plates according to the direction and intensity of the sun; the existing structure of the AAU is not changed, modular design is adopted, module installation is achieved, and installation and maintenance are facilitated.

Owner:GUANGDONG IND TECHN COLLEGE

Fan control system and backup battery charging method

ActiveCN108425874AImprove reliabilityImprove stabilityBatteries circuit arrangementsElectric powerControl systemBackup battery

The invention relates to a fan control system and a backup battery charging method. The fan control system comprises a microprocessor, multiple main fan assemblies and multiple backup fan assemblies.The main fan assemblies and the backup fan assemblies are connected with corresponding external expansion interfaces of the microprocessor correspondingly, the main fan assemblies are connected with multiple main fans in a one-to-one correspondence mode, the backup fan assemblies are connected with backup fans in a one-to-one correspondence mode, and each main fan is at least close to one backup fan. The microprocessor is use for obtaining operation states of the main fans through the main fan assemblies. When the microprocessor judges that any main fan is in a fault state according to the operation state of the main fan, the backup fan adjacent to the main fan is controlled by the corresponding backup fan assembly to be started. According to the fan control system, the backup fan adjacentto the corresponding main fan in the fault state is started, the influences of the main fan in the fault state on cooling can be reduced, and reliability and stability of cooling performance of the fan control system are improved.

Owner:COMBA TELECOM SYST CHINA LTD

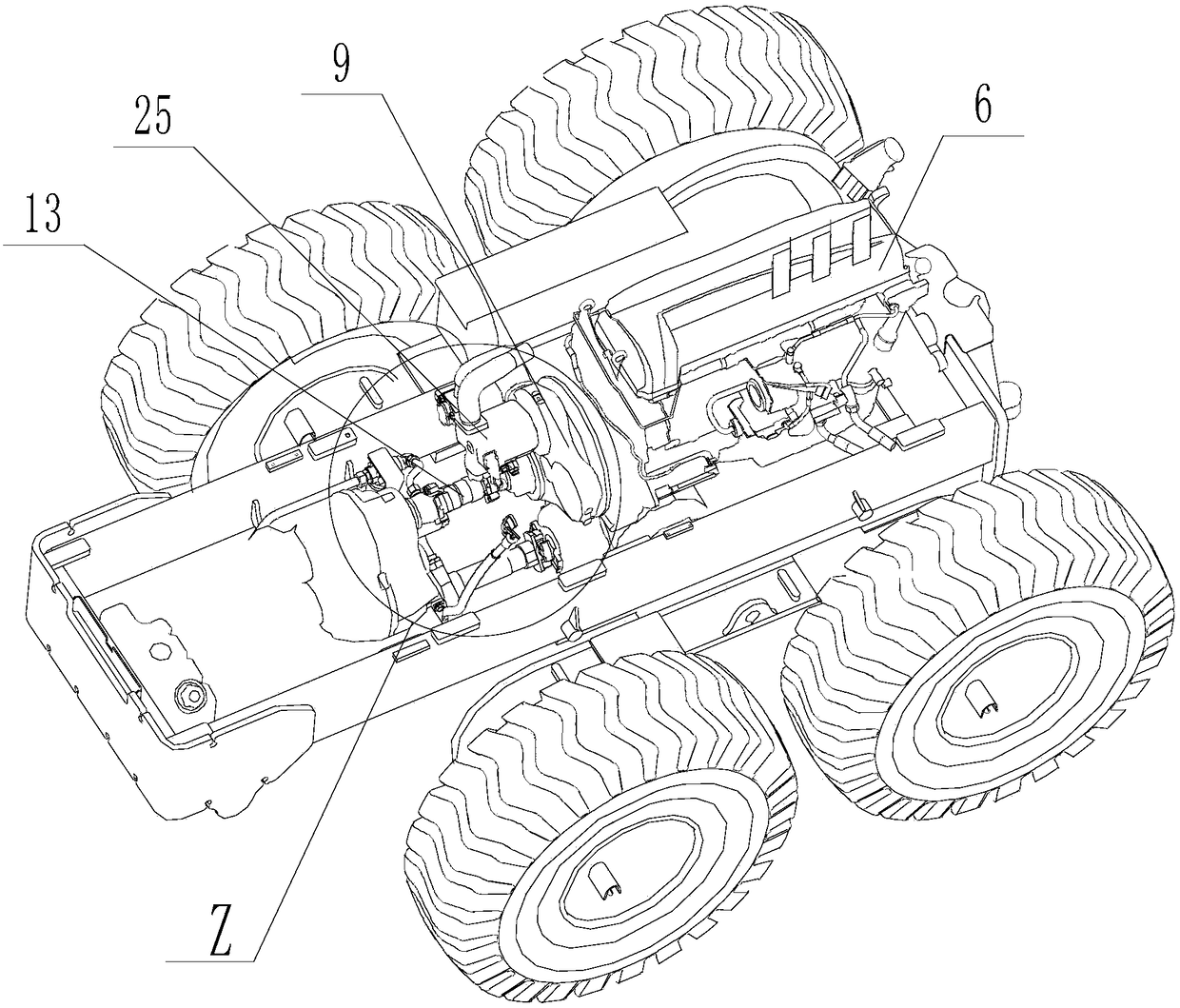

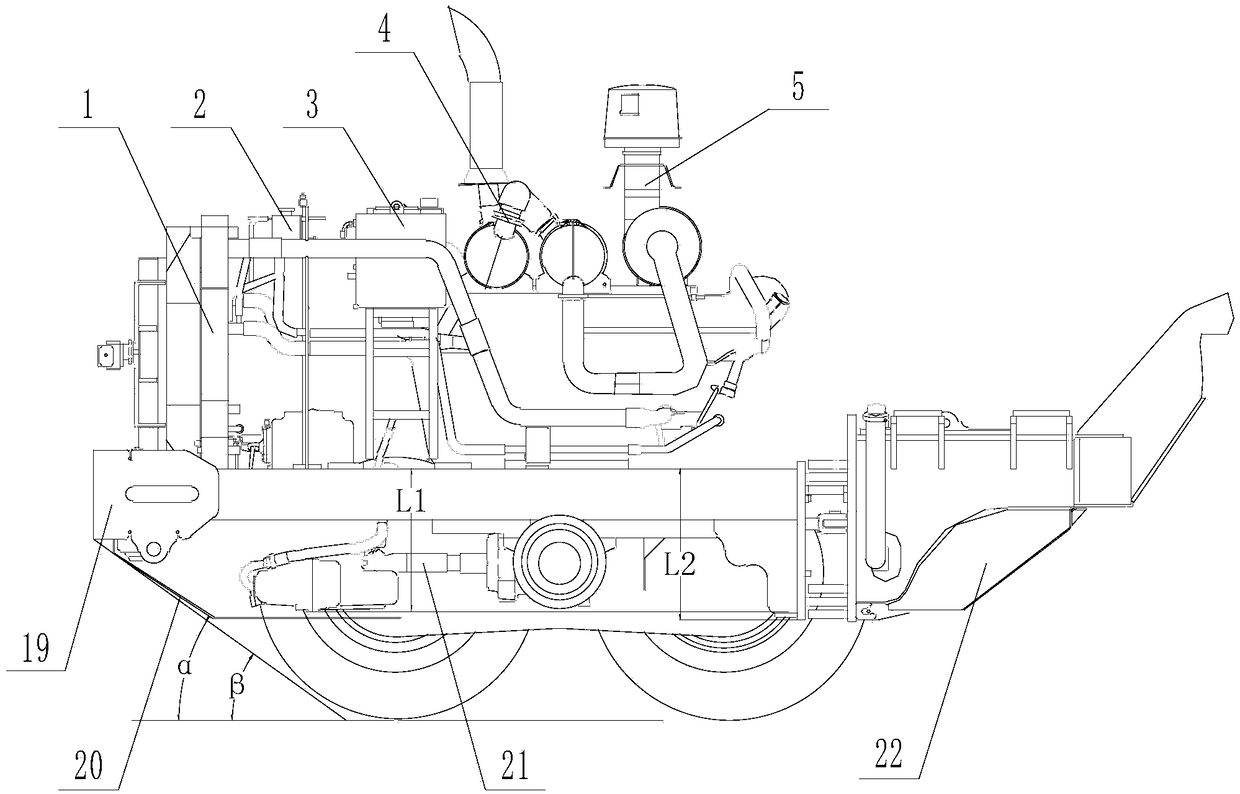

Land leveler

PendingCN108442435ALarge sectionGood torsion and bending resistanceMechanical machines/dredgersState of artVehicle frame

The invention discloses a land leveler, belongs to the technical field of engineering machinery, and solves the problems that in the prior art, due to the arrangement of a traditional land leveler, various elements are inconvenient to daily repair, check and maintain, and the elements are easy to collide by accidents. The land leveler is provided with a main body structure comprising a front frameand a rear frame, wherein the front frame and the rear frame are connected; a gearbox is arranged on the rear frame; a urea tank is arranged between the rear end of the rear frame and the gearbox; afuel tank is arranged in a framework of the front frame; a first protection plate is arranged on the bottom parts of the gearbox and the urea tank; and a second protection plate is arranged on the bottom part of the fuel tank. The invention is mainly applied to the land leveler.

Owner:SHANDONG LINGONG CONSTR MACHINERY

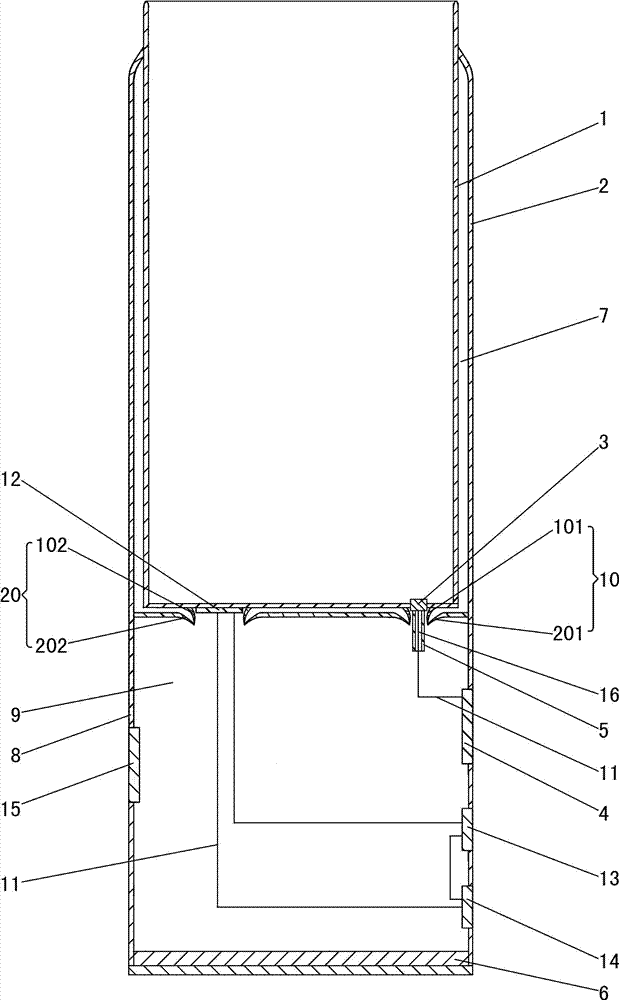

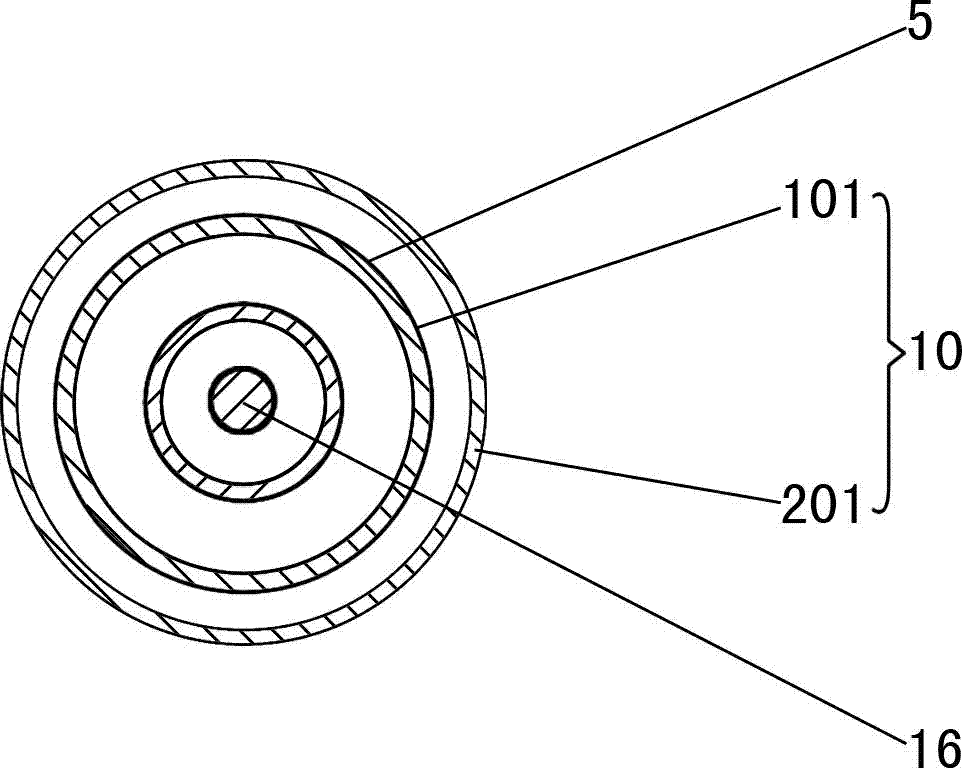

Insulation cup with temperature display function

InactiveCN103536142AWill not damage the vacuum structureImprove insulation effectDrinking vesselsEngineeringElectrode

The invention relates to an insulation cup with a temperature display function. The insulation cup comprises an inner cup body, an outer cup body, a temperature probing electrode and a display screen. An insulation interlayer is arranged between the inner cup body and the outer cup body, an extension portion extending downwards is arranged at the lower end of the side wall of the outer cup body, and the extension portion and the bottom of the outer cup body form an isolation cavity. The temperature probing electrode is arranged at the bottom of the inner cup body. An inner annular protrusion is formed on the inner cup body on the periphery of the temperature probing electrode, an outer annular protrusion is formed on the outer cup body on the periphery of the temperature probing electrode, and the inner annular protrusion and the outer annular protrusion form a vacuum suction nozzle of the insulation interlayer, and are sealed together after vacuumizing. The display screen is mounted on the outer wall of the extension portion, and a pin of the temperature probing electrode is connected with the display screen through a connecting wire. The annular vacuum suction nozzle is formed by the inner annular protrusion and the outer annular protrusion, so that a vacuum structure of the insulation interlayer cannot be destroyed, and the insulation interlayer is still a vacuum interlayer and has excellent insulation effect; besides, temperature display of water in the inner cup body is realized.

Owner:汕头市华仑科技有限公司

Self-circulation immersion jet power supply module

PendingCN113382615AImprove liquidityIncrease loopSemiconductor/solid-state device detailsSolid-state devicesHigh power densityJet flow

The invention relates to a self-circulation immersion jet power supply module which comprises a shell and a circuit board located in the shell. A refrigerant liquid inlet and a refrigerant liquid outlet are formed in the shell, an immersed pump and a jet pipe are arranged in the shell, one end of the jet pipe is connected with the immersed pump, jet holes are distributed in the jet pipe, and the shell is filled with an insulating cooling liquid. The interior of the shell is filled with the insulating cooling liquid. Compared with the prior art, by using the module of the invention,the circuit board is completely soaked in the insulating cooling liquid, a thermal resistance between a power device on the circuit board and a refrigerant can be reduced, and therefore the heat dissipation efficiency is improved, the power supply module can have the smaller size and the higher power density, and a wind noise is avoided. Meanwhile, the immersed pump and the jet pipe can accelerate flowing and circulation of the insulating cooling liquid, and the heat dissipation effect is improved.

Owner:立酷新能源技术(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com