Evaporation-type condenser based on dew point indirect evaporation cooling and pre-cooling

An evaporative condenser and evaporative cooling technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problem of the heat transfer efficiency drop of the evaporative condenser, so as to improve the efficiency of direct evaporative cooling and save cooling Water circulation system, the effect of reducing scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

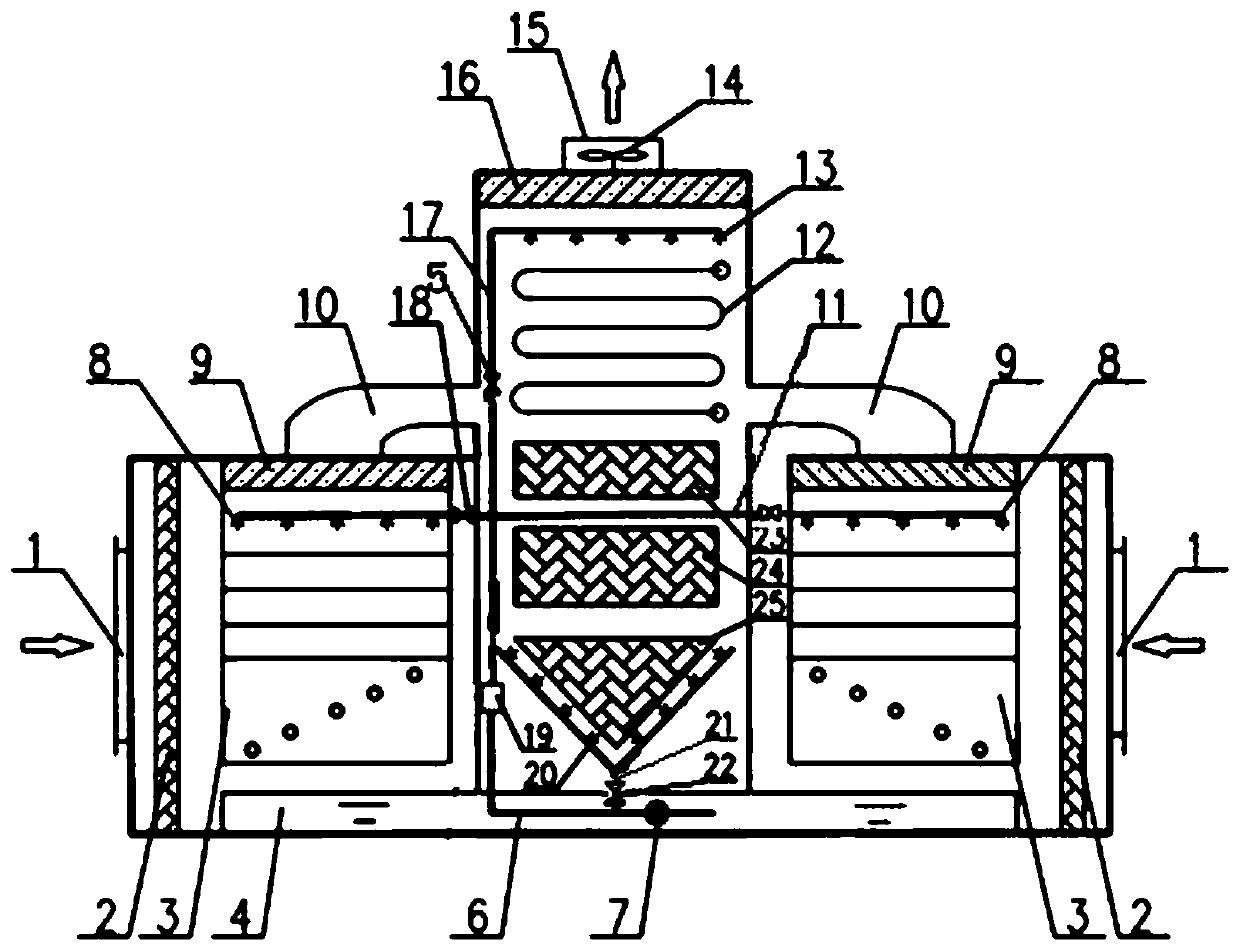

[0028] The present invention is based on the dew point indirect evaporative cooling precooling evaporative condenser, such as figure 1 As shown, it includes an organic unit casing, and an air inlet 1 is arranged on the opposite side walls of the unit casing; a packing-coil composite evaporative cooling unit is arranged in the casing, and the packing-coil composite evaporative cooling unit There is an air outlet 15 on the top wall of the corresponding unit shell above the unit, and a dew point indirect evaporative cooling section is provided on the left and right sides of the packing-coil compound evaporative cooling unit; The section is symmetrical to improve the pre-cooling capacity of outdoor air;

[0029] There is also a water tank 4 inside the casing of the unit. The water tank 4 is located below the two dew point indirect evaporative co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com