Land leveler

A motor grader and engine technology, applied to mechanically driven excavators/dredgers, etc., can solve problems such as inconvenient components, abnormal bumps, etc., achieve the effects of small heat dissipation, avoid abnormal bumps, and facilitate daily inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

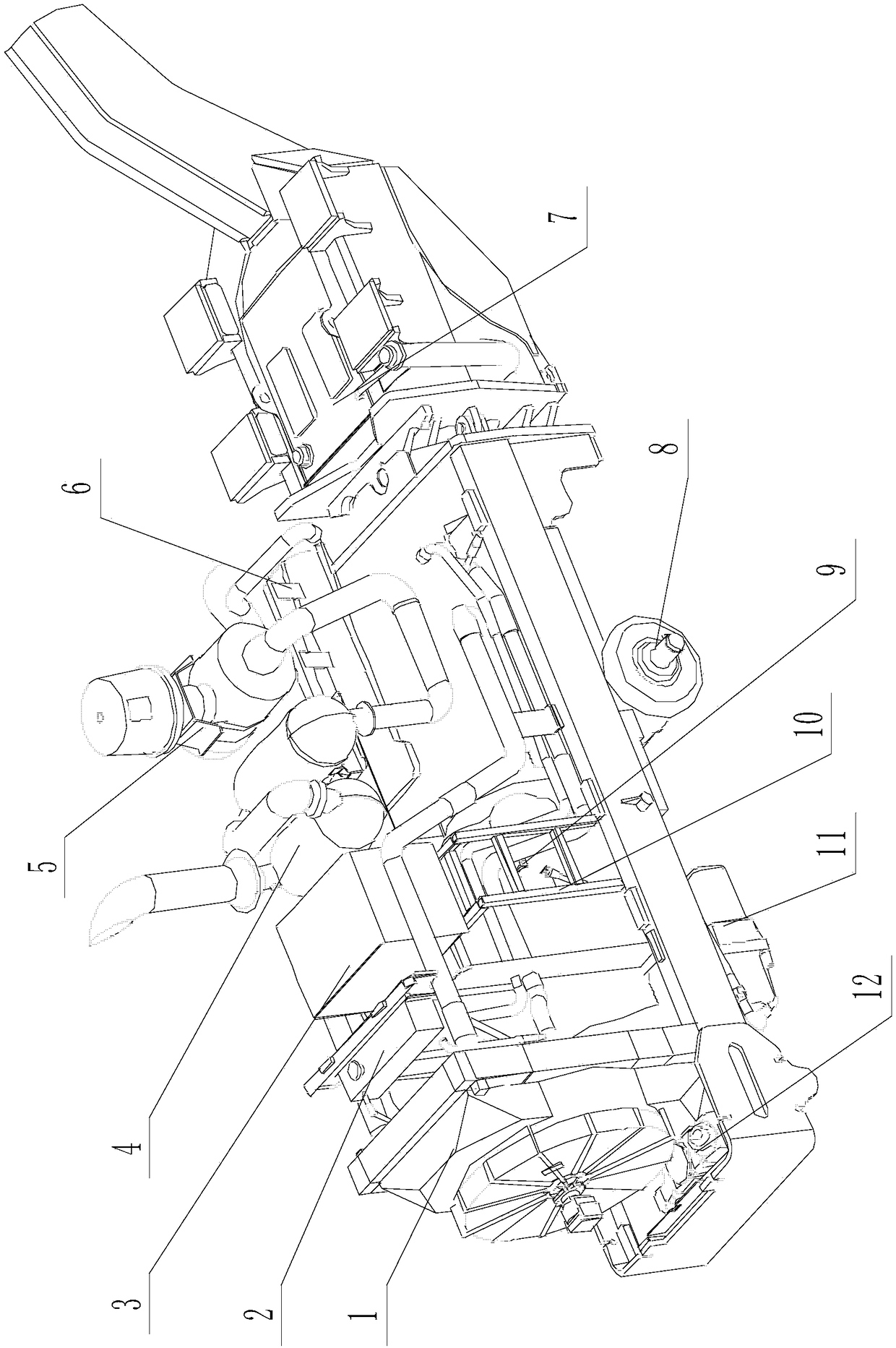

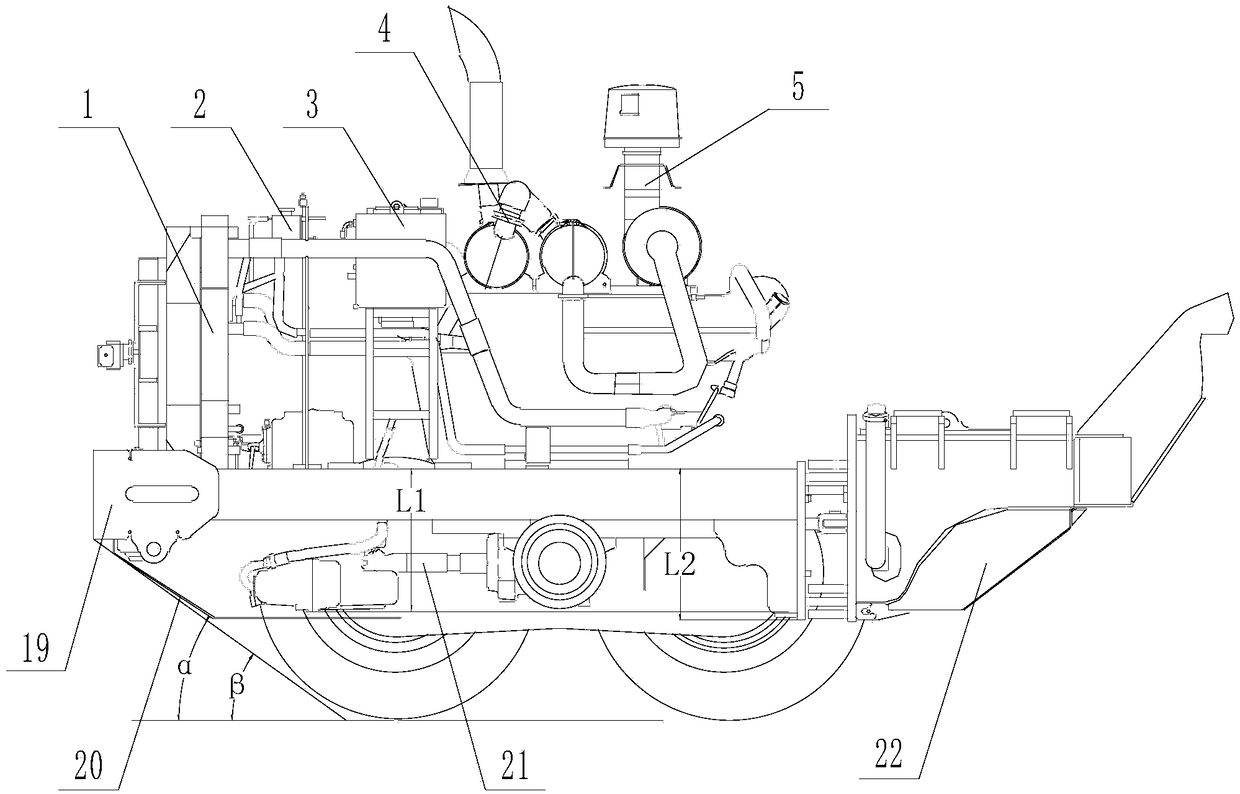

[0028] Such as figure 1 , figure 2 , image 3 As shown, a motor grader includes a front frame 18 and a rear frame 19, the front frame 18 is connected to the rear frame 19, the rear frame 19 is provided with a gearbox 11, and the front frame 18 forms a frame structure , good torsion and bending resistance; a urea tank 12 is provided between the rear end of the rear frame 19 and the gearbox 11, a fuel tank 7 is arranged in the frame of the front frame 18, and the gearbox 11 and The bottom of the urea tank 12 is provided with a first protective plate 20 , and the bottom of the fuel tank 7 is provided with a second protective plate 22 .

Embodiment 2

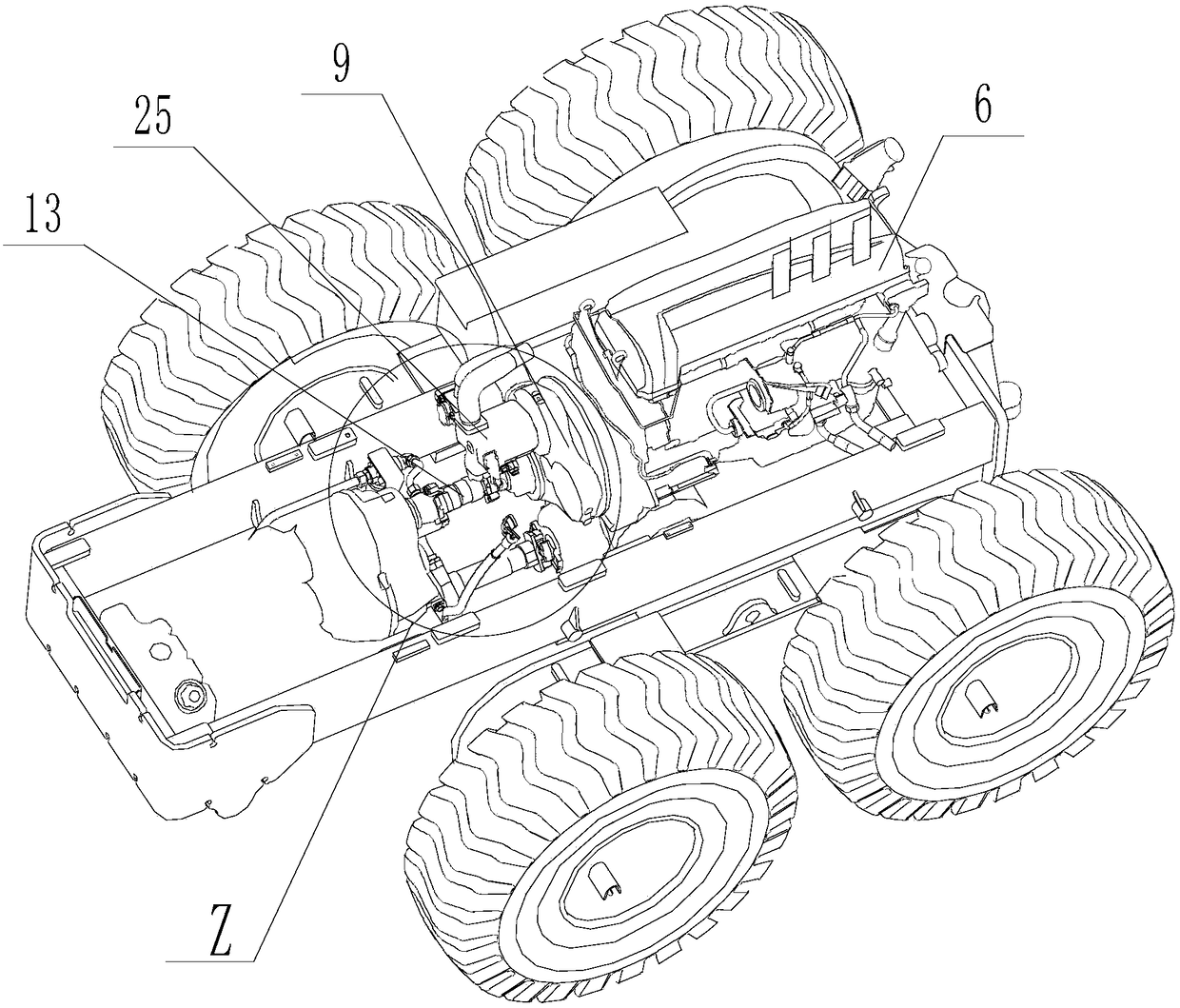

[0030] A motor grader, the rear frame 19 is also provided with an engine 6, a transfer case 9, a drive axle and a tire assembly 8, a hydraulic oil tank 3 and a radiator 1, and the engine 6 and the transfer case 9 are connected through an elastic coupling The engine is connected and installed in the front section of the rear vehicle frame 19 frame through the support and the shock absorber; the intake system 5 and the exhaust aftertreatment system 4 are arranged above the engine 6; between the gearbox 11 and the transfer case 9 An upper transmission shaft 13 is provided, that is, the gearbox 11 is connected to the transfer case 9 through the upper transmission shaft 13, and a lower transmission shaft 21 is arranged between the gearbox 11 and the drive axle and the tire assembly 8; the drive axle and the tire The assembly 8 is arranged at the bottom of the engine 6 and is fixedly connected with the rear frame 19 by bolts; the hydraulic oil tank 3 is arranged above the transfer ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com