LED lamp cooling component and production method thereof

A technology of LED lamps and heat dissipation components, applied in lighting and heating equipment, cooling/heating devices of lighting devices, ion implantation plating, etc., can solve problems such as temperature rise, reduce heat shielding, improve heat dissipation effect, and increase contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

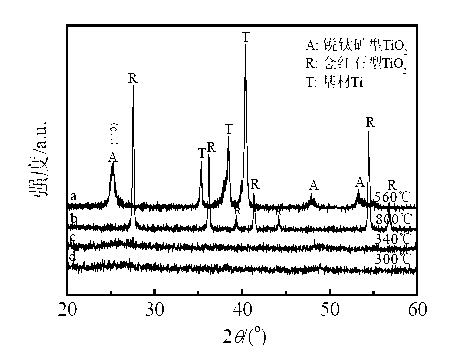

[0031] Titanium dioxide film doped with lanthanum or cerium, wherein the rare earth doping amount is the total molar mass of the entire rare earth doped titanium dioxide film:

[0032] Lanthanum 0

[0033] Ce 0

[0034] The steps are as follows:

[0035] Step 1: The cooling parts of LED lamps are made of aluminum alloy;

[0036] Step 2: The heat dissipation parts of LED lamps are cleaned twice with ultrasonic waves and dried;

[0037] Step 3: Coating a titanium dioxide film with a thickness of 50 nm on the surface of the heat dissipation part of the LED lamp by using the sol-gel method or the vacuum evaporation method.

Embodiment 2

[0039] Titanium dioxide film doped with lanthanum or cerium, wherein the rare earth doping amount is the total molar mass of the entire rare earth doped titanium dioxide film:

[0040] Lanthanum 1.0%

[0041] Cerium 1.0%

[0042] The steps are as follows:

[0043] Step 1: The cooling parts of LED lamps are made of aluminum alloy;

[0044] Step 2: The heat dissipation parts of LED lamps are cleaned three times with ultrasonic waves and dried;

[0045] Step 3: Coating a titanium dioxide film doped with lanthanum or cerium with a thickness of 60 nm on the surface of the heat dissipation part of the LED lamp by the sol-gel method or the vacuum evaporation method.

Embodiment 3

[0047] Titanium dioxide film doped with lanthanum or cerium, wherein the rare earth doping amount is the total molar mass of the entire rare earth doped titanium dioxide film:

[0048] Lanthanum 3.0%

[0049] Cerium 3.0%

[0050] The steps are as follows:

[0051] Step 1: The cooling parts of LED lamps are made of aluminum alloy;

[0052] Step 2: The heat dissipation parts of LED lamps are cleaned three times with ultrasonic waves and dried;

[0053] Step 3: Coating a titanium dioxide film doped with lanthanum or cerium with a thickness of 70 nm on the surface of the heat dissipation part of the LED lamp by the sol-gel method or the vacuum evaporation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com