Heat dissipation type power adapter

A power adapter and heat dissipation technology, which is applied in the direction of electrical components, power electronics modification, electrical equipment structural parts, etc., can solve problems such as hindering heat exchange between electronic components and airflow, affecting heat dissipation, etc., to reduce vibration, Reduce the effect of cushioning impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

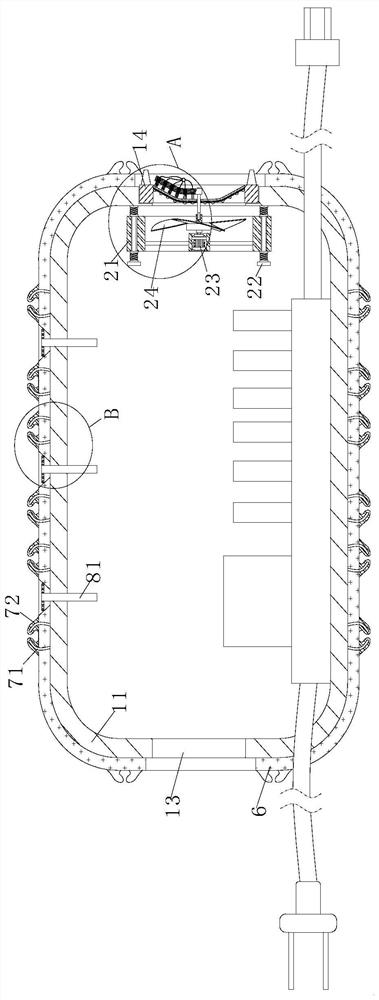

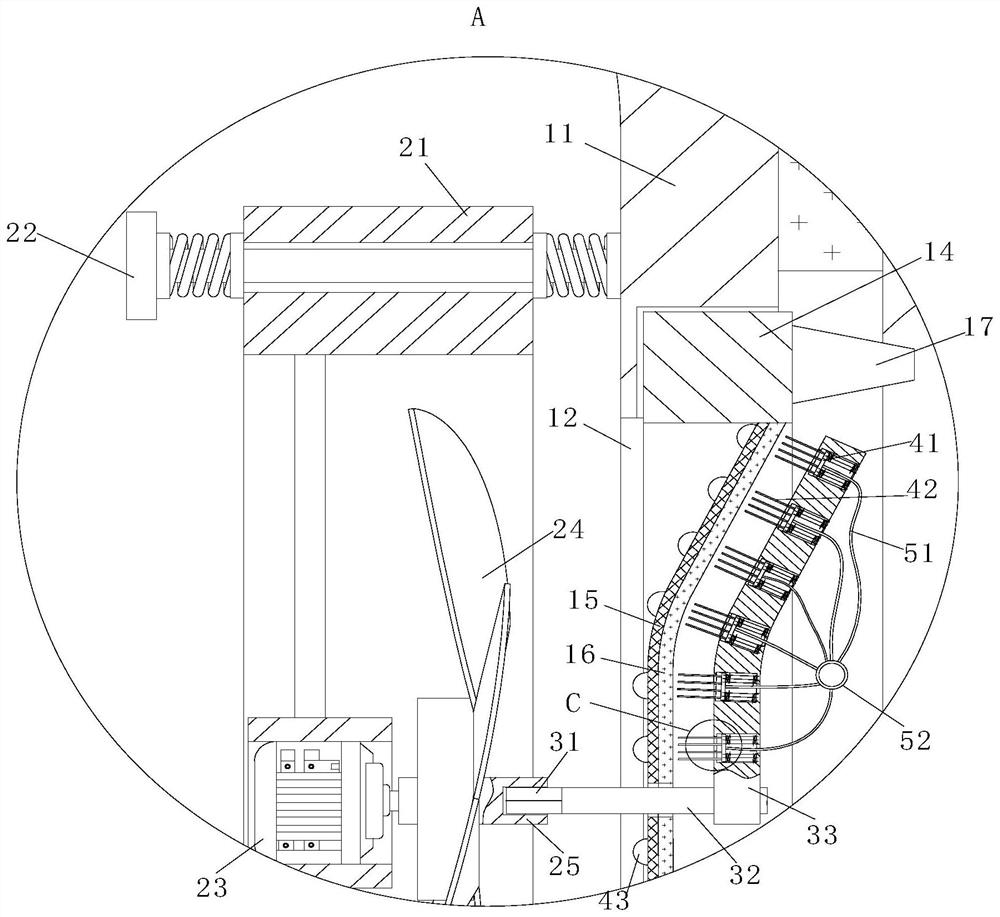

[0026] see Figure 1-5 As shown, a heat dissipation power adapter includes a housing 11, a heat dissipation unit and a fixed frame 14; an air inlet 12 is provided on one side of the housing 11, and an air outlet 13 is provided on the other side of the housing 11; The heat dissipation unit is arranged on the side wall of the housing 11; the air inlet 12 is provided with a threaded groove; the threaded groove is connected with a fixed frame 14 by threads; the fixed frame 14 is fixedly connected with a support net plate 15; The support screen 15 is fixedly connected with a filter screen 16 on the side away from the heat dissipation unit; the section of the support screen 15 is designed as a trapezoidal structure; the fixed frame 14 is provided with a block 17 on the side away from the heat dissipation unit; , by rotating the fixed frame 14, the fixed frame 14 is rotated into the thread groove to complete the installation of the filter screen 16, and by setting the clamping block ...

Embodiment 2

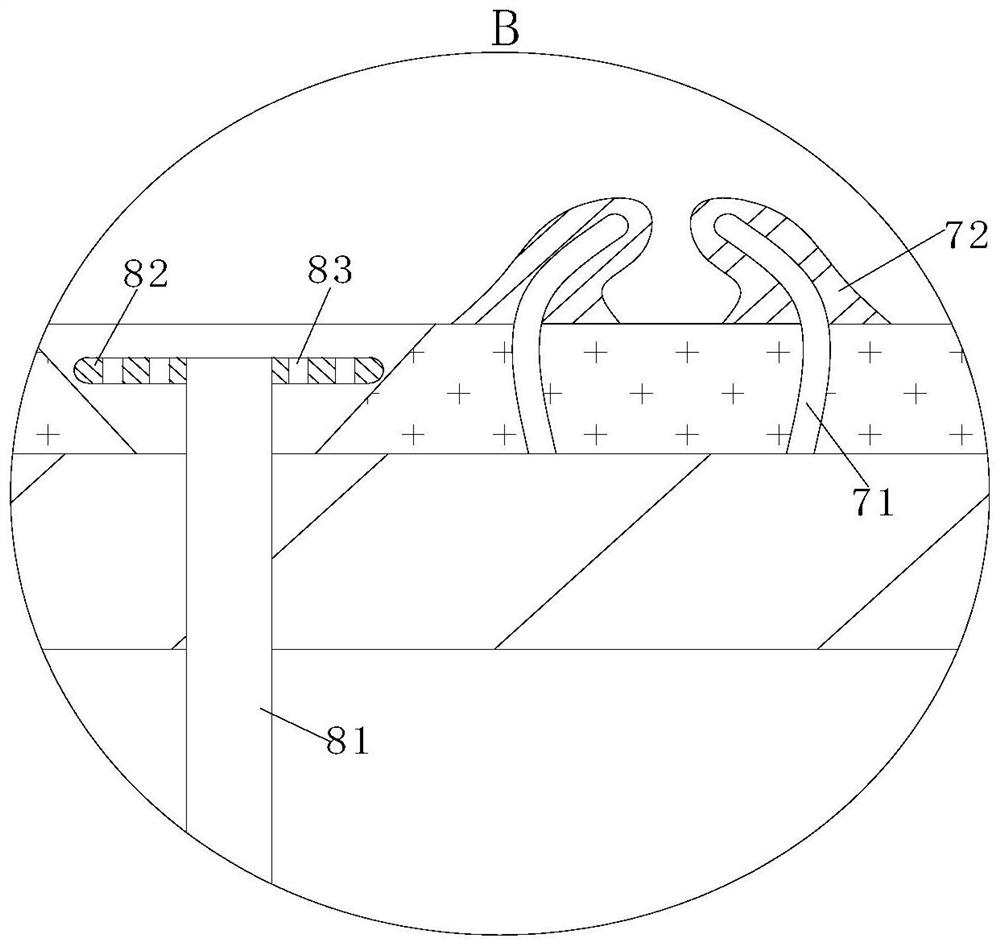

[0035] see Image 6 As shown in Comparative Example 1, as another embodiment of the present invention, a wax block 9 is fixedly attached to the side wall of the sliding hole; the wax block 9 is in contact with the surface of the guide rod 22. When in use, the wax block 9 will rub against the guide rod 22, and then produce some powder, through which the sliding of the guide rod 22 and the support frame 21 can be lubricated, thereby reducing the friction force and reducing the noise generated during sliding.

[0036] Working principle, during installation, by rotating the fixed frame 14, the fixed frame 14 is rotated into the threaded groove to complete the installation of the filter screen 16, and the side of the fixed frame 14 has a protrusion by setting the clamping block 17 , it is convenient to rotate the fixed frame 14, and the filter screen 16 is supported and fixed by setting the support screen 15, and the filter screen 16 is set to filter the air sucked into the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com