Surface-aluminum-evaporated peep-proof film with anti-reflection performance and preparation method thereof

A privacy film and vapor deposition film technology, applied in the field of optical polarization, can solve the problems of low light transmittance, uneven light, and inability to achieve all-round privacy protection, achieve high light output, reduce the impact of screen heat dissipation, improve The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

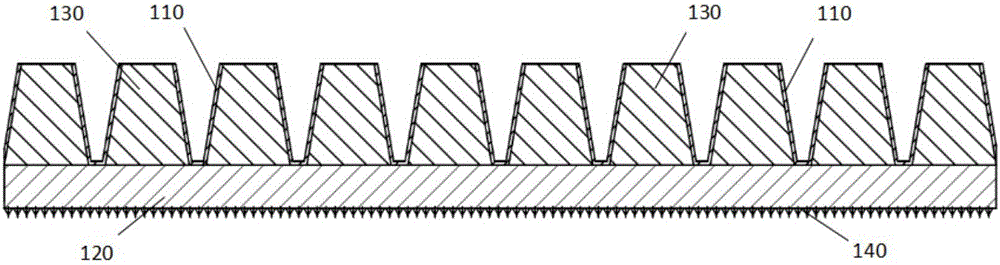

[0040] A surface-evaporated aluminum anti-spy film with anti-reflection performance, its structure is as follows figure 1 As shown, it includes a PET layer 120 , an anti-peeping structural layer and a moth-eye anti-reflective structural layer 140 . The anti-peeping structural layer is composed of a UV photocurable resin layer 130 and an evaporated film layer 110 . The UV light-curable resin layer 130 is composed of a resin bottom layer and a resin structure disposed on the bottom layer in an array, wherein the resin structure can be a trapezoidal structure arranged in an array, or a circular frustum structure, or a prism structure. In this embodiment, The elongated structure with trapezoidal array in cross section is adopted, the trapezoid upper base is 20-200 microns, the lower base is 20-200 microns, and the height is 20-200 microns. In a preferred embodiment, the upper base of the trapezoid is 63 microns, the lower base is 106 microns, and the height is 120 microns.

[00...

Embodiment 2

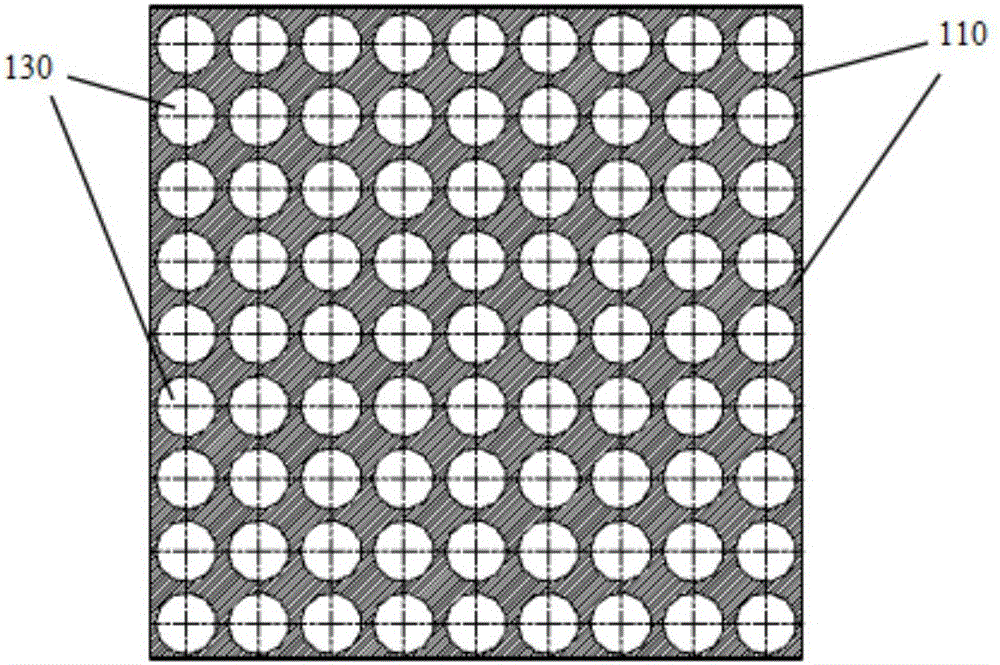

[0045] A surface-evaporated aluminum anti-spy film with anti-reflection performance, its structure is as follows figure 2 As shown, its structure is roughly the same as that of Example 1, except that the truncated-cone-shaped resin structures are arranged in a rectangular array. The moth-eye anti-reflection structure layer is a cone arranged in an array, and the diameter of the bottom of the cone is less than one-half of the incident light wavelength. In this embodiment, the ratio of the depth of the cone to the bottom diameter is 0.5, and the distance between the center and the diameter of the bottom of the cone is 0.5. The ratio is 1.

Embodiment 3

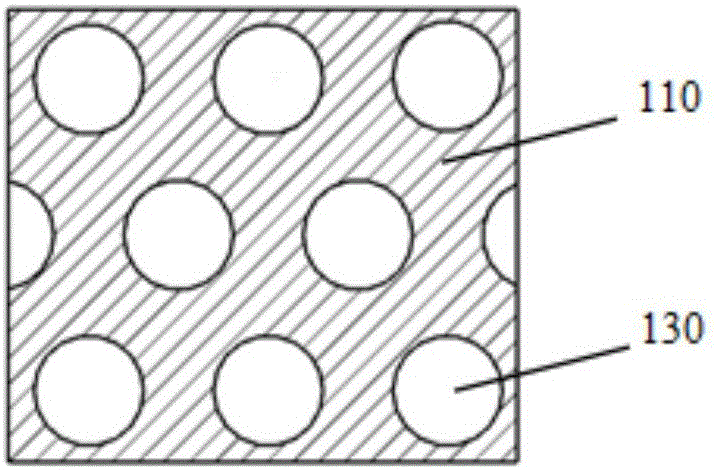

[0047] A surface-evaporated aluminum anti-spy film with anti-reflection performance, its structure is as follows image 3 As shown, its structure is roughly the same as that of Example 1, except that the frustum-shaped resin structures are arranged in a regular hexagonal array. The moth-eye anti-reflective structure layer is a cone arranged in an array, and the diameter of the bottom of the cone is less than one-half of the incident light wavelength. The ratio is 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com