Process for covering surface of aluminum diamond composite material with copper foil and embedding ceramic material

A composite material and surface covering technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of power semiconductor device failure, deformation, movement, etc., and achieve the effect of compact structure, convenient operation, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

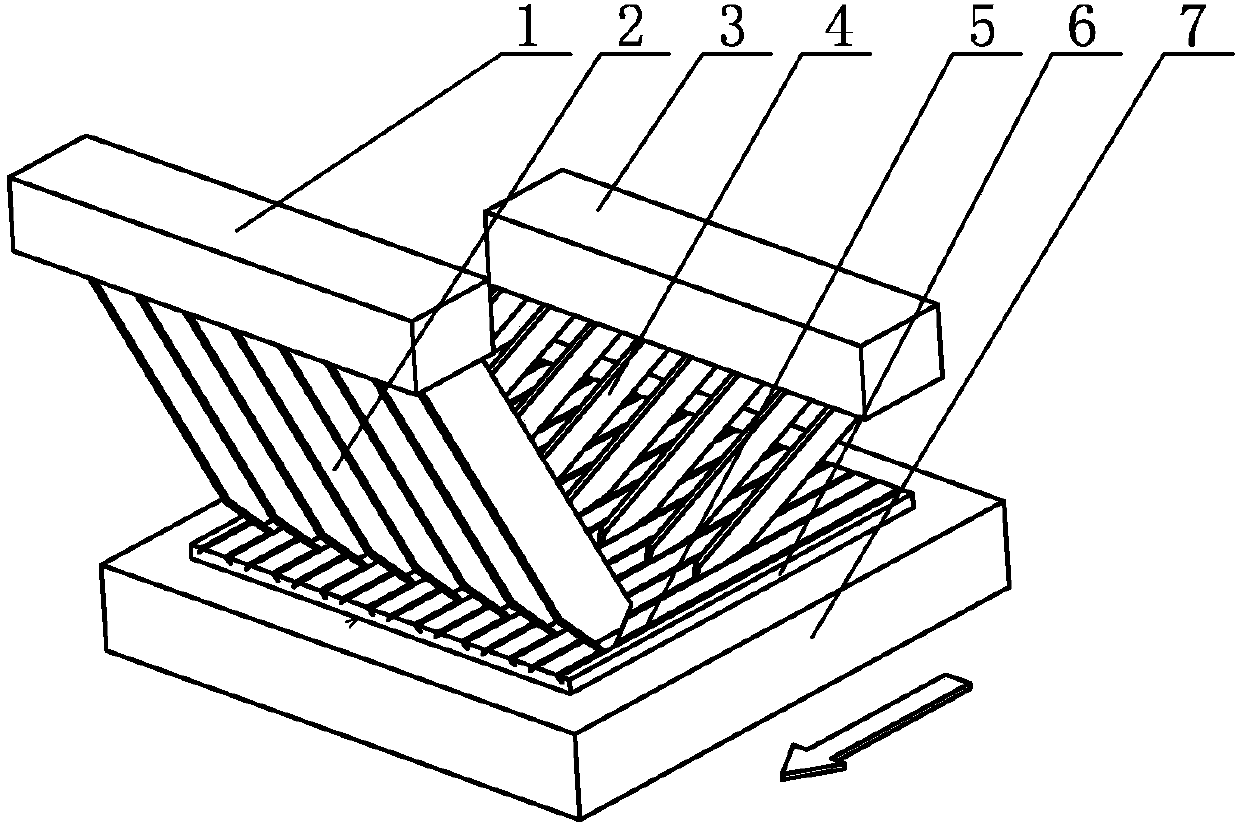

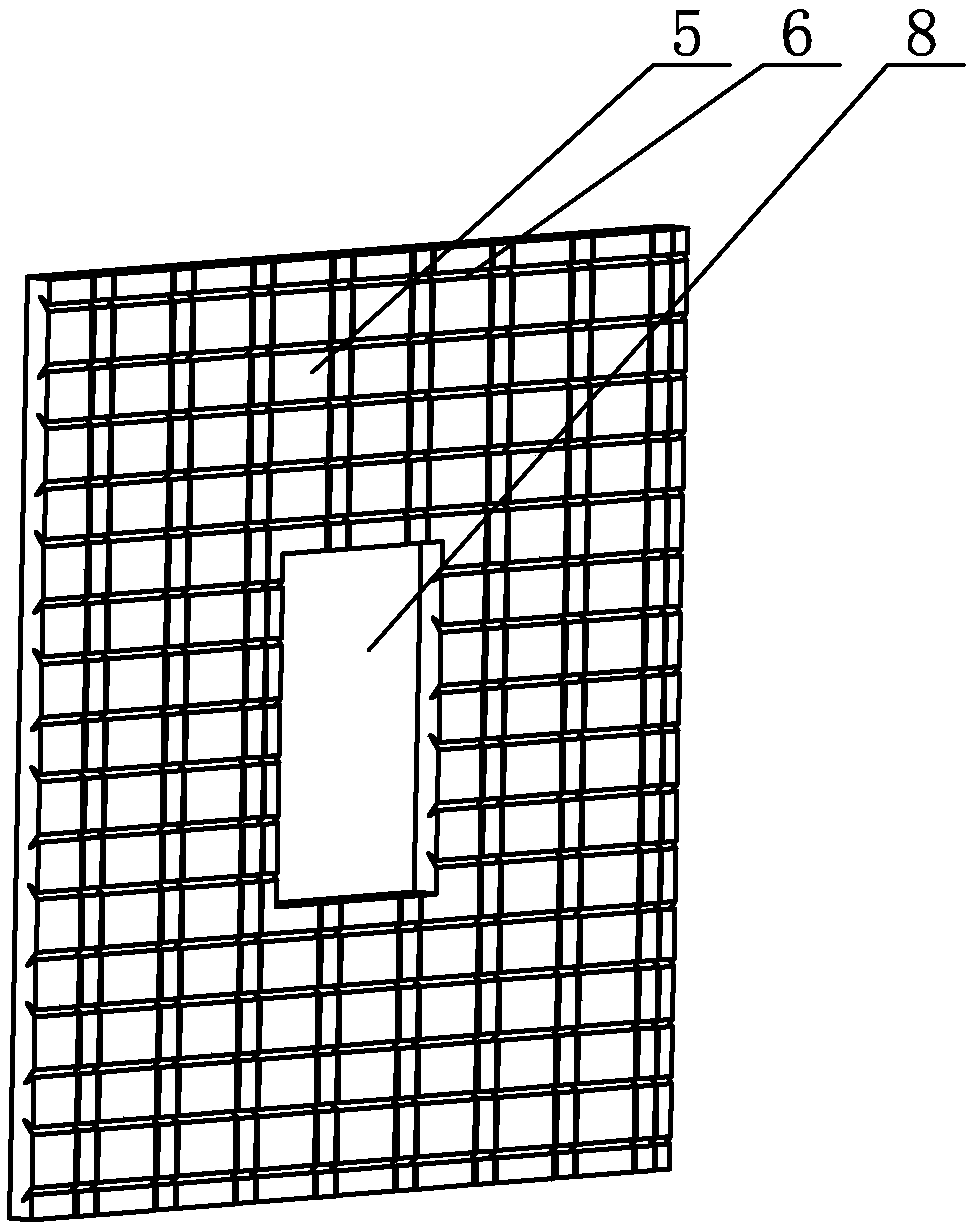

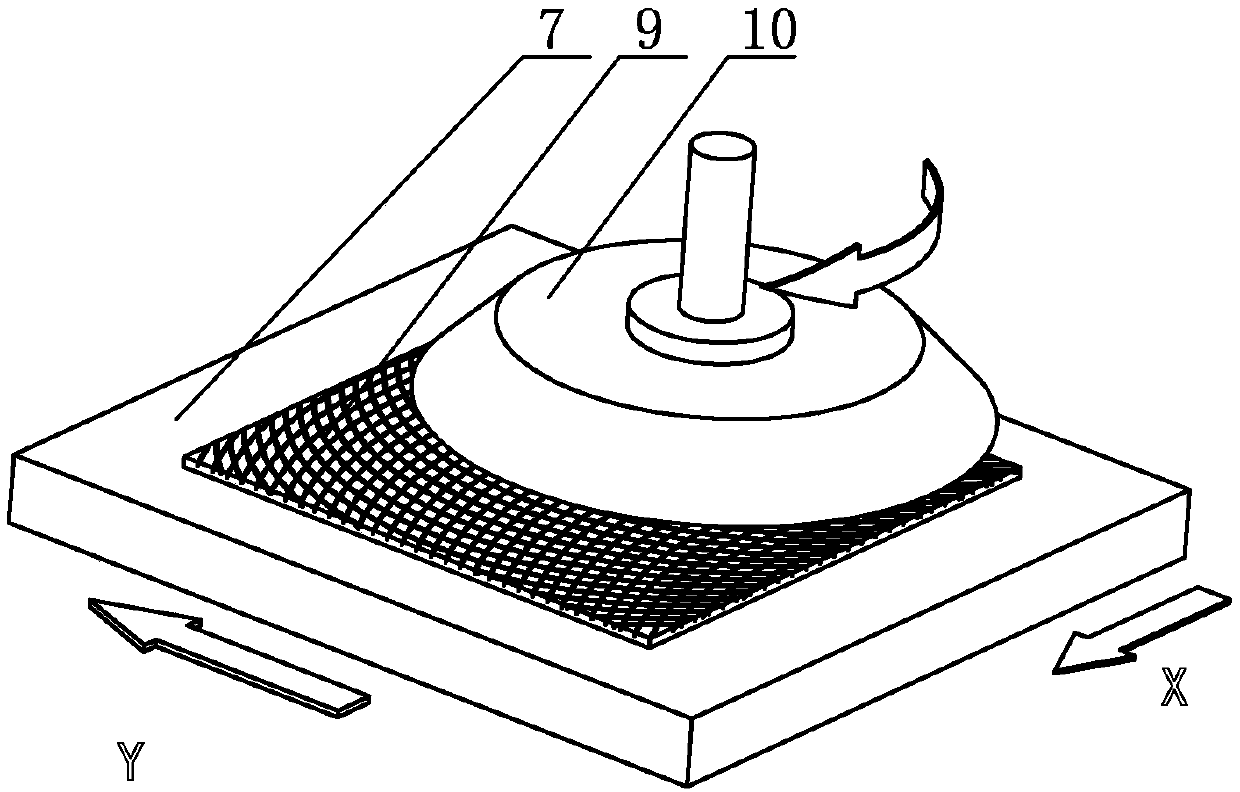

[0037] like Figure 1-Figure 9 As shown, the process of covering the surface of the aluminum-diamond composite material of this embodiment with copper foil while inlaying ceramic materials includes the following steps:

[0038] Step 1: Fix the copper foil 6 to be processed with a thickness of 0.1-0.5mm on the machine tool table 7;

[0039] Step 2: above the copper foil 6, two sets of knife rows are installed, which are respectively the first knife row seat 1, and a plurality of first carving knives 2 are installed in parallel and spaced intervals on the first knife row seat 1, and are also provided with The first knife row seat 1 is parallel to the second knife row seat 3, and a plurality of second carving knives 4 are installed in parallel and spaced intervals on the second knife row seat 3;

[0040] Step 3: The machine table 7 carries ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com