LED lamp based on blue light and red light chips and manufacturing method thereof

A technology of LED lights and red light chips, applied in chemical instruments and methods, optical elements for changing the spectral characteristics of emitted light, semiconductor devices of light-emitting elements, etc., to achieve the effects of cost reduction, life extension, and price reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

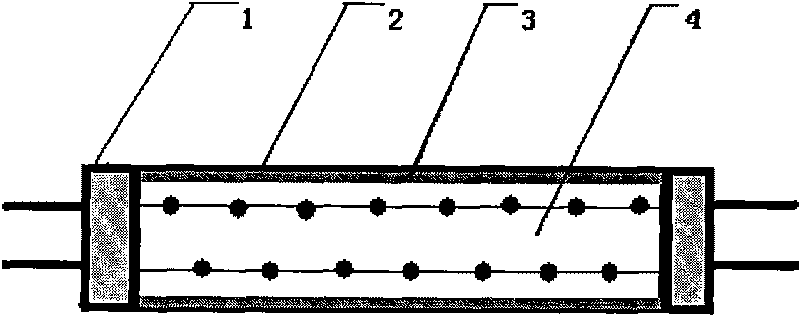

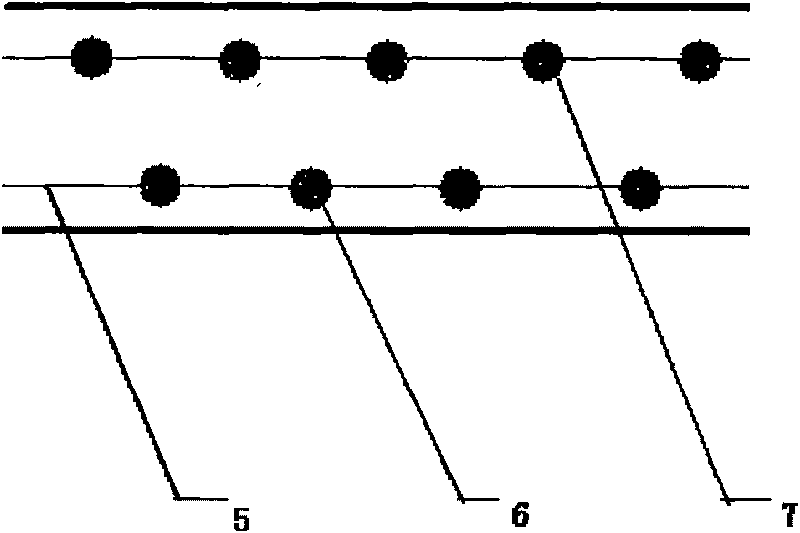

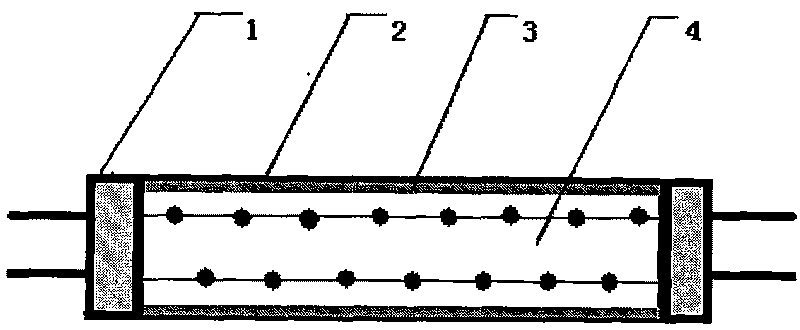

Image

Examples

Embodiment 1

[0024] Example 1. Weigh 10g of silica gel and 5g of YAG phosphor, mix them evenly, and then coat them on the inner wall of a glass tube to control the thickness of the coating to 0.2mm, and coat this glass tube with a mixture of silica gel and phosphor Put it in an oven and cure at 200°C for 6 minutes, take it out, and after it cools, put an LED chip module equal to the length of the glass tube into the tube. The number of blue chips and red chips on the module is 30 and 30 respectively. 15 pieces, connect the chip module and the lamp cap well, and fix the lamp cap on the two sections of the glass tube to make the LED lamp. After testing, the results showed that the light decay was only 2.3%, and the color rendering index was 91.

Embodiment 2

[0025] Example 2. Weigh 10g of silica gel and 10g of YAG phosphor, mix them evenly, and coat them on the inner wall of the glass tube to control the thickness of the coating to 0.3mm, and coat this glass tube with a mixture of silica gel and phosphor Put it in an oven and cure at 160°C for 10 minutes, take it out, and after it cools, put an LED chip module equal to the length of the glass tube into the tube. The number of blue and red chips on the module is 40 and 40 respectively. 10 pieces, connect the chip module and the lamp holder, and fix the lamp holder on the two sections of the glass tube to make the LED lamp. After testing, the results showed that the light decay was only 1.9%, and the color rendering index was 90.

Embodiment 3

[0026] Example 3. Weigh 10g of silica gel and 10g of YAG phosphor, mix them evenly, and then coat them on the inner wall of the quartz tube to control the coating thickness to 0.5mm, and coat this quartz tube with a mixture of silica gel and phosphor Put it in an oven and cure at 300°C for 1 minute, take it out, and after it cools, put an LED chip module equal to the length of the quartz tube into the tube. The number of blue and red chips on the module is 40 and 40 respectively. 20 pieces, connect the chip module and the lamp cap well, and fix the lamp cap on the two sections of the quartz tube to make the LED lamp. After testing, the results showed that the light decay was only 2.2%, and the color rendering index was 91.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com