Phosphor-nanoparticle combinations

a technology of phosphor and nanoparticles, applied in the field of lighting devices, can solve the problems of inability to generate “white” light, which is required for a very large portion of the lighting industry, and the inability to use a conventional led, etc., and achieve the effects of improving the optical properties, controlling color, and improving the choi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

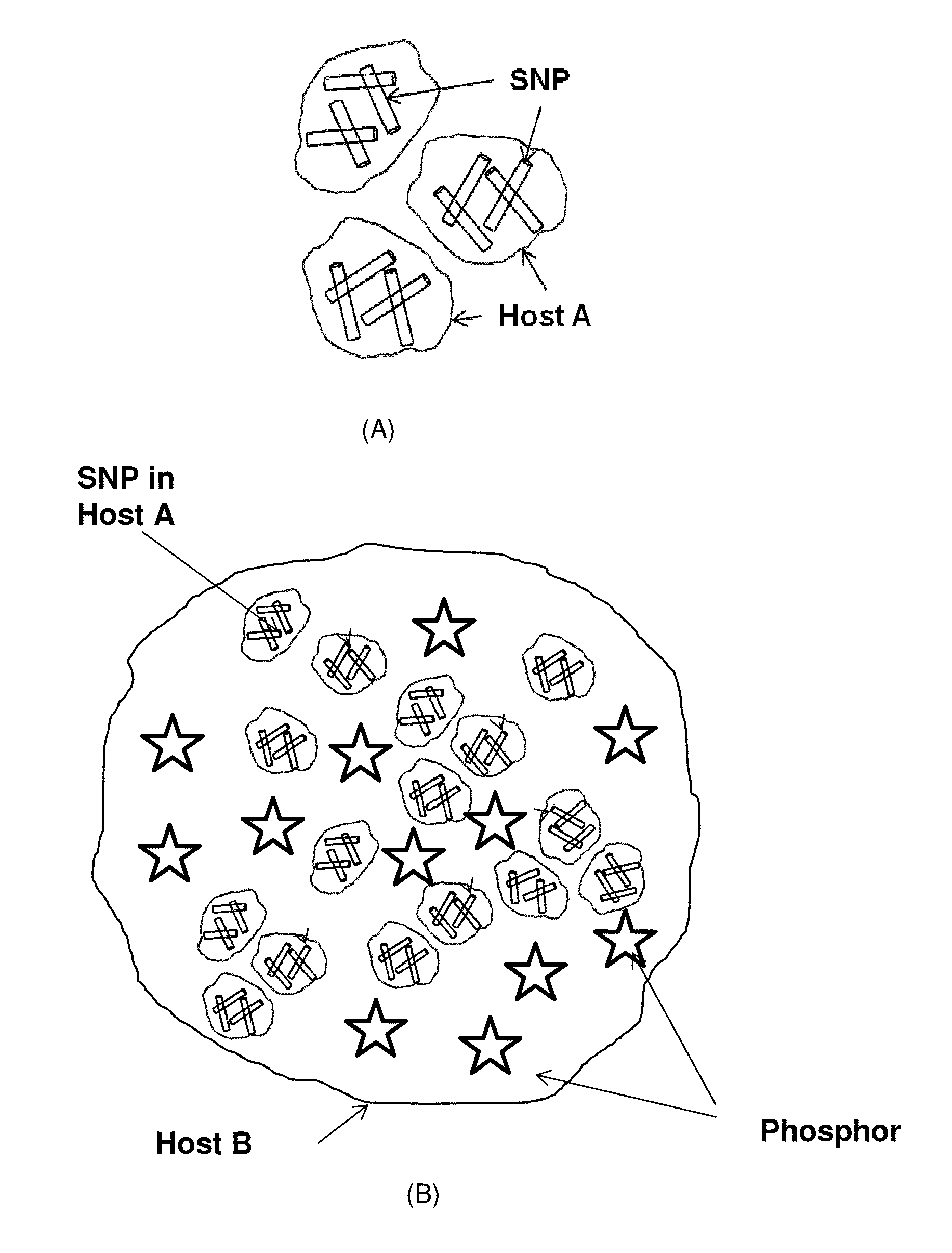

Phosphor—RSNP Combination in Silicone

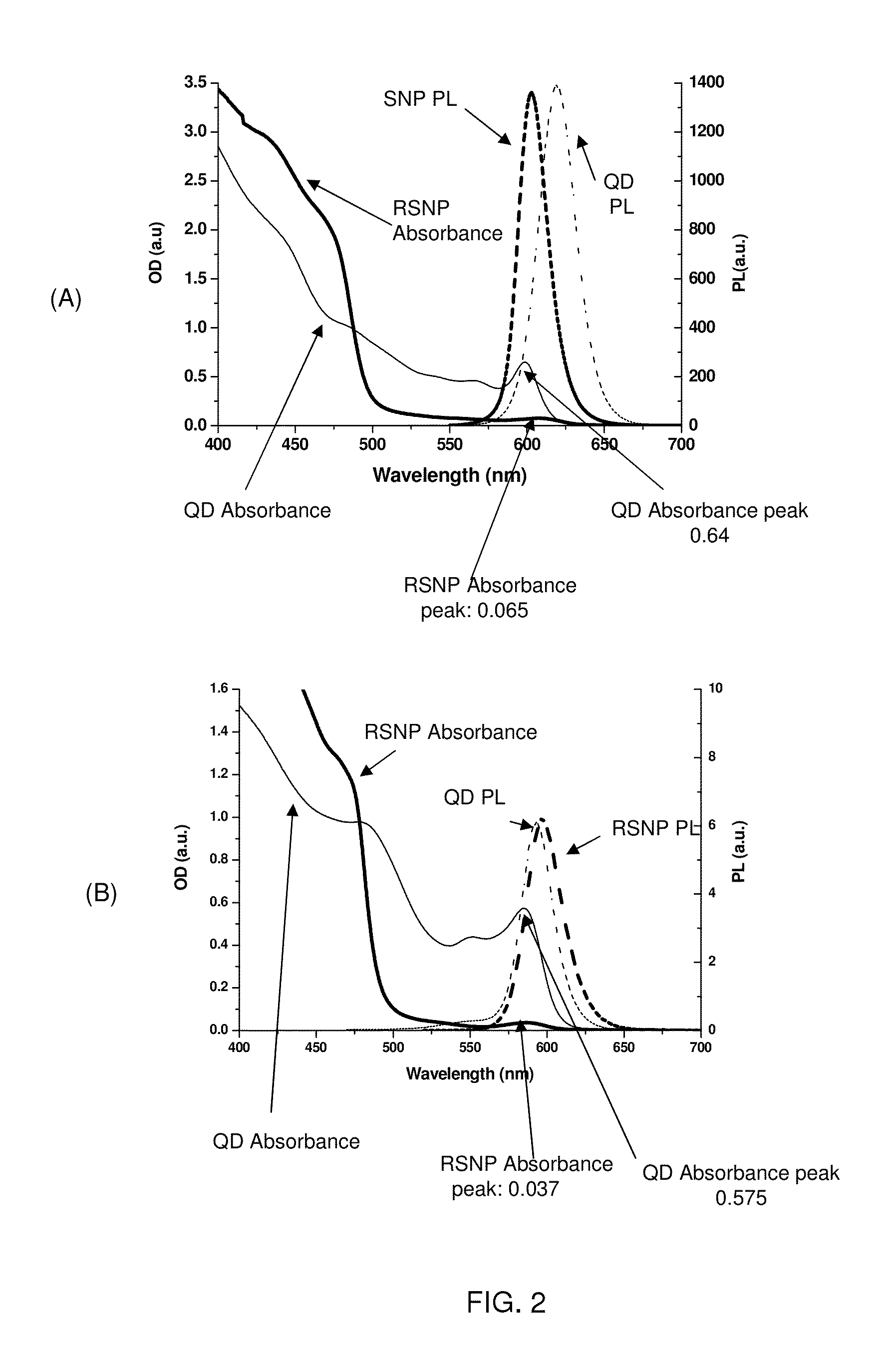

[0045]35×5.6 nm CdSe / CdS RSNPs emitting at 638 nm were first prepared using a procedure similar to that described in L. Carbone et al. “Synthesis and Micrometer-Scale Assembly of Colloidal CdSe / CdS Nanorods Prepared by a Seeded Growth Approach” Nano Letters, 2007, 7 (10), pp 2942-2950. 0.5 g of RTV615A (Momentive, 22 Corporate Woods Boulevard, Albany, N.Y. 12211 USA) was stirred with 0.15 g of RTV615B for 10 minutes. 4.0 mg of the RSNPs were dissolved in 0.4 ml Toluene. 615 mg of yellow phosphor (BYW01A, PhosphorTech, 351 Thornton Rd Ste. 130, Lithia Springs, Ga. 30122, USA) were provided to give a RSNP to Phosphor weight ratio of 4 / 615, i.e. ˜0.65%. The RSNP solution was added to the silicone RTV mixture while stirring. The BYW01A phosphor was then added and the RSNP / phosphor / silicone solution was stirred for 15 minutes. The RSNP / phosphor / silicone solution in then vacuumed until no bubbles were left. The solution was then poured on a glass subst...

example 2

Insertion of RSNP Encapsulated in Polymer into Silicone

[0047]The RSNPs prepared as described in Example 1 were embedded in PVB with 3% loading ratio (weight) and were ground to fine powder. The final powder mean particle size was less than 15 μm. 1.5 g of RTV615A (Momentive, 22 Corporate Woods Boulevard, Albany, N.Y. 12211 USA) was stirred with 0.15 g of RTV615B for 10 min 77 mg of the RSNP / PVB powder was added to the silicone mixture while stirring. 345 mg of Yttrium Aluminum Garnet phosphor (BYW01A, PhosphorTech, 351 Thornton Rd Ste. 130, Lithia Springs, Ga. 30122, USA) were added and the solution was stirred for 15 minutes. The RSNP / phosphor / silicone RTV solution was then vacuumed until no bubbles were left. The solution was then poured on a glass substrate and sandwiched using another glass substrate. 250 μm-thick spacers were positioned between the two glass substrates to obtain the desired film thickness. The sandwiched structure was then placed on a hot plate at 100 C for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| central emission wavelength | aaaaa | aaaaa |

| central emission wavelength | aaaaa | aaaaa |

| wavelength range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com