Heat radiating device

一种散热装置、散热片的技术,应用在间接换热器、照明和加热设备、冷却/通风/加热改造等方向,能够解决不利热管散热、影响散热装置散热效果等问题,达到增强热交换、提升散热效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

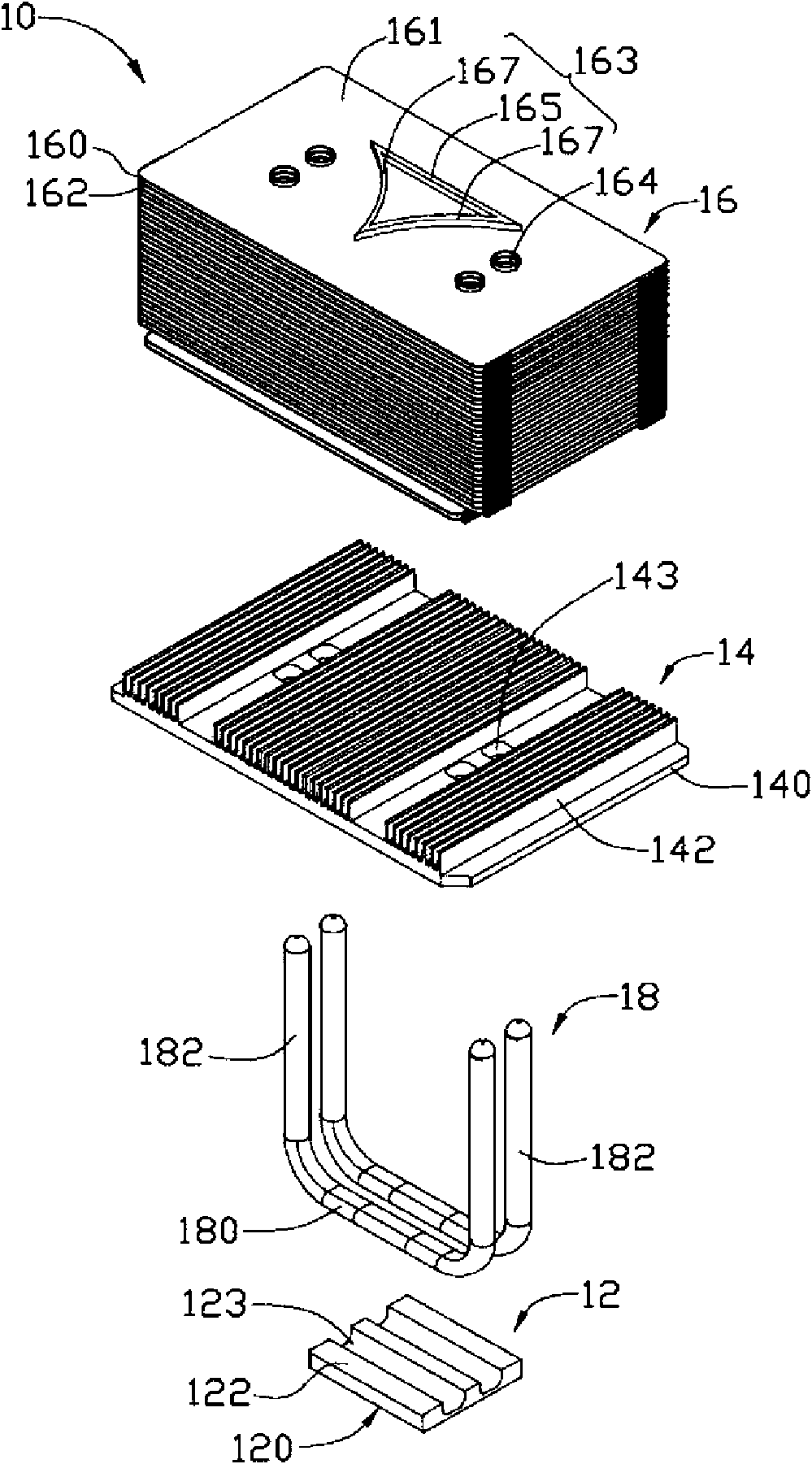

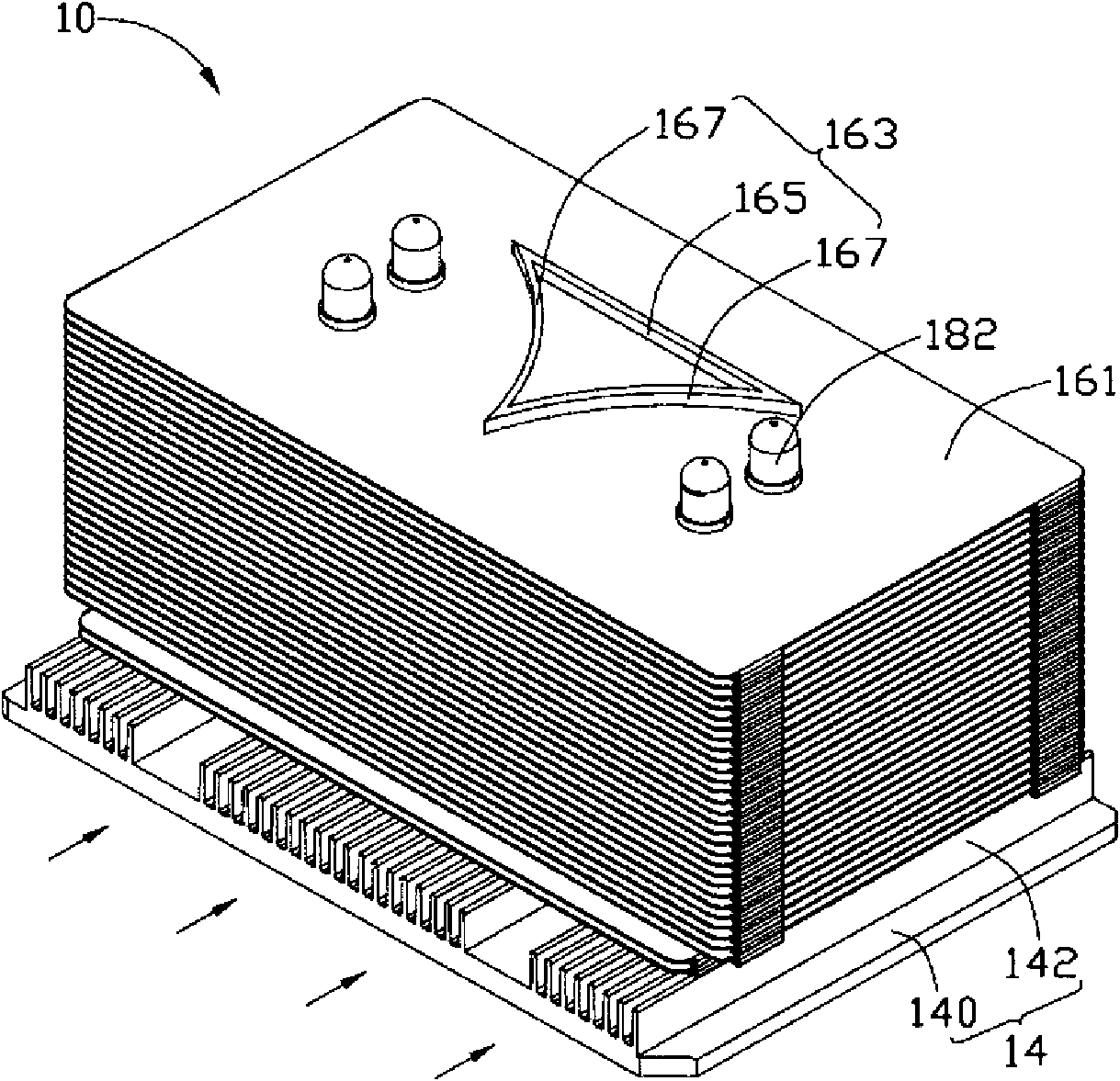

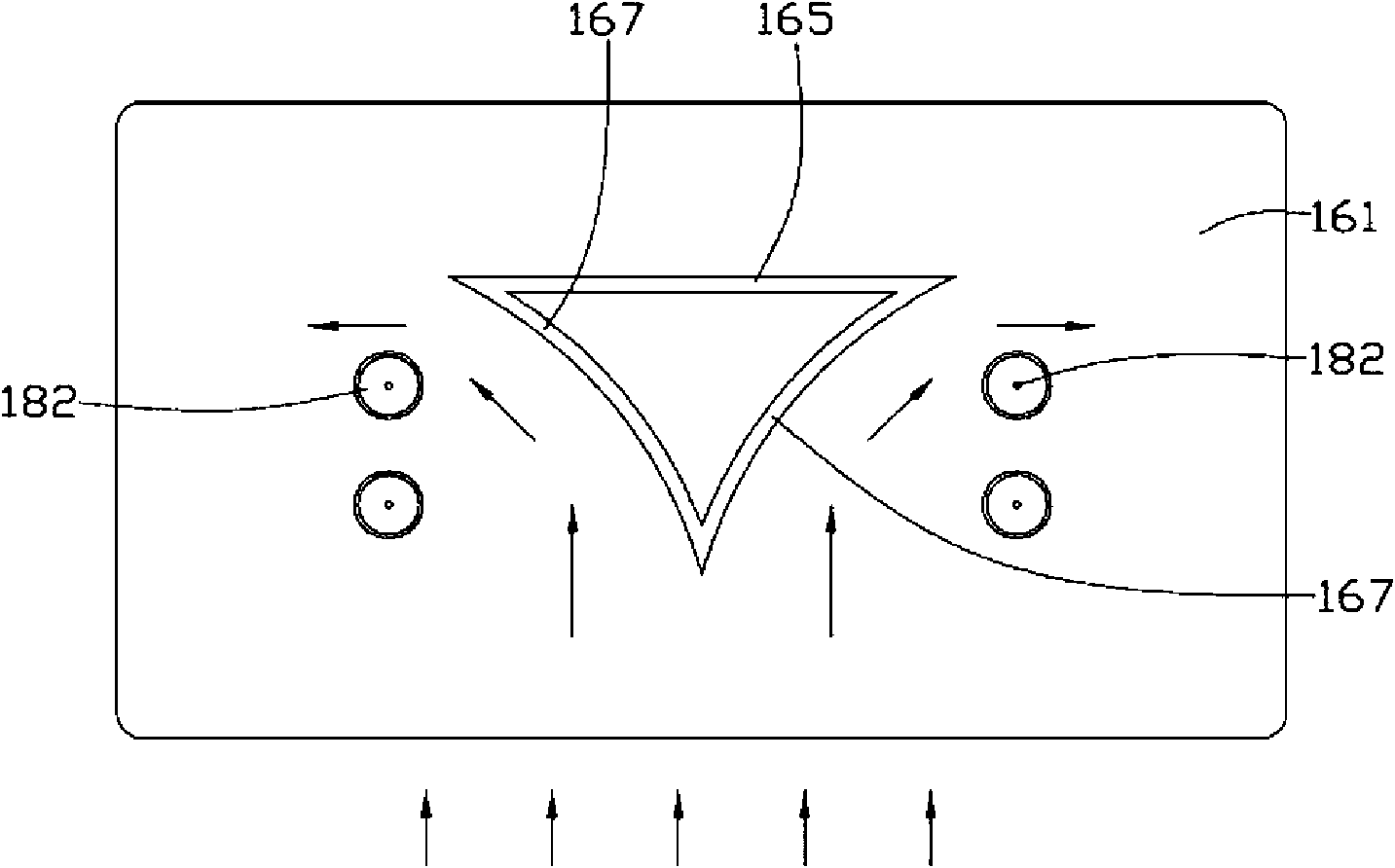

[0013] The heat dissipation device of the present invention will be further described below with reference to the accompanying drawings.

[0014] Such as figure 1 and figure 2 As shown, the heat dissipation device 10 includes a base plate 12, a first heat sink 14 disposed on the base plate 12, a second heat sink 16 disposed on the first heat sink 14, and a second heat sink 16 disposed on the base plate 12 and the base plate 12. Two heat pipes 18 between the first radiator 14 and the second radiator 16 .

[0015] The substrate 12 is in the shape of a rectangular plate and has a flat lower surface 120 and an upper surface 122 opposite to the lower surface 120 . Two parallel horizontal and vertical grooves 123 are arranged side by side on the upper surface 122 .

[0016] The first heat sink 14 is attached on the upper surface 122 of the substrate 12 , and includes a bottom plate 140 and a plurality of first heat sink fins 142 vertically extending upward from the top surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com