Integrated heat radiation method, system and corresponding heat radiation device

A technology of heat dissipation system and heat dissipation method, applied in cooling/ventilation/heating transformation, electrical components, electrical solid devices, etc., can solve the problems of reducing the effective contact area between the heat sink and the chip, deteriorating heat dissipation performance, and poor thermal conductivity, etc. Achieve the effect of improving the overall heat dissipation effect, reducing the generation of thermal stress, and improving the diffusion of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

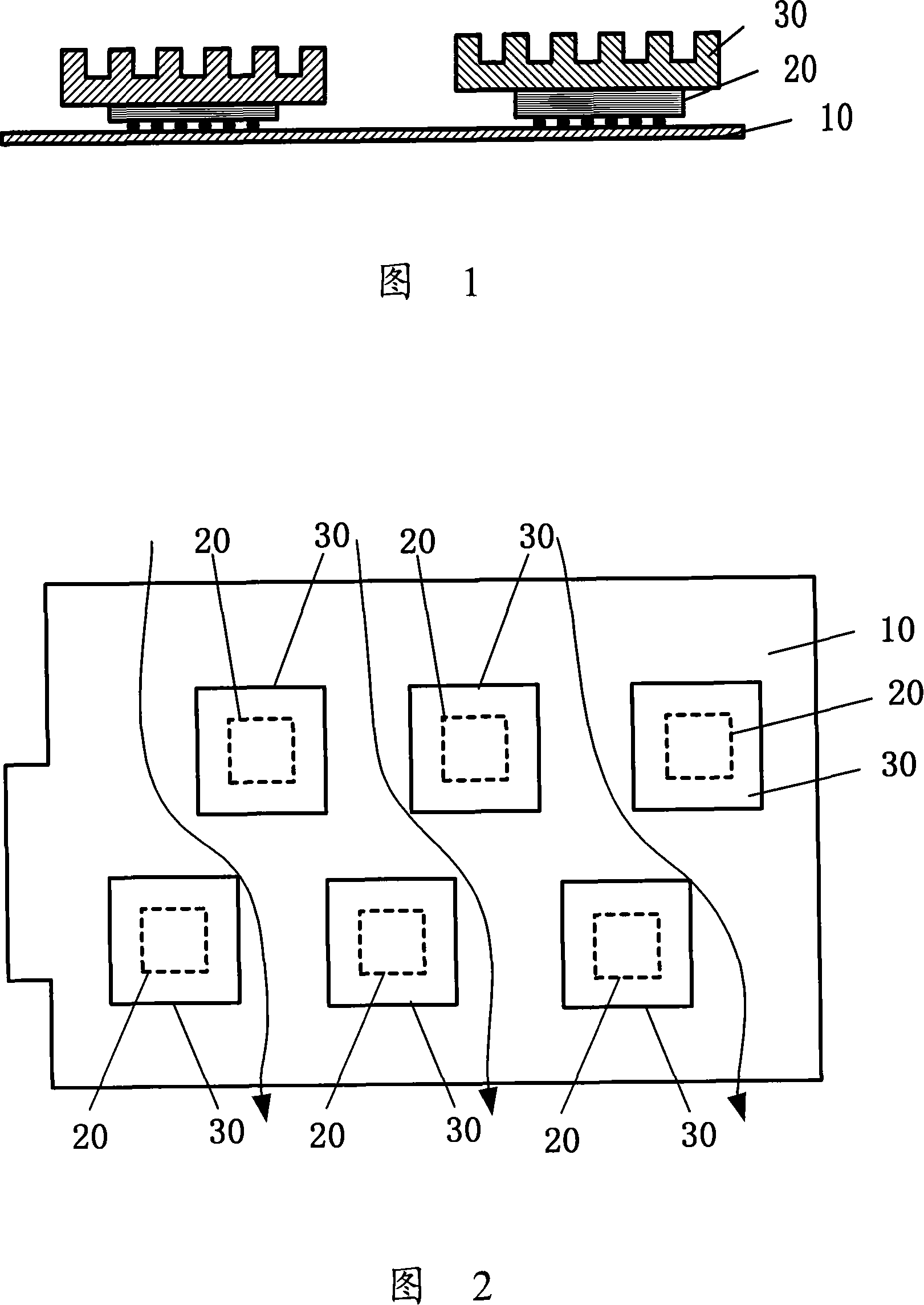

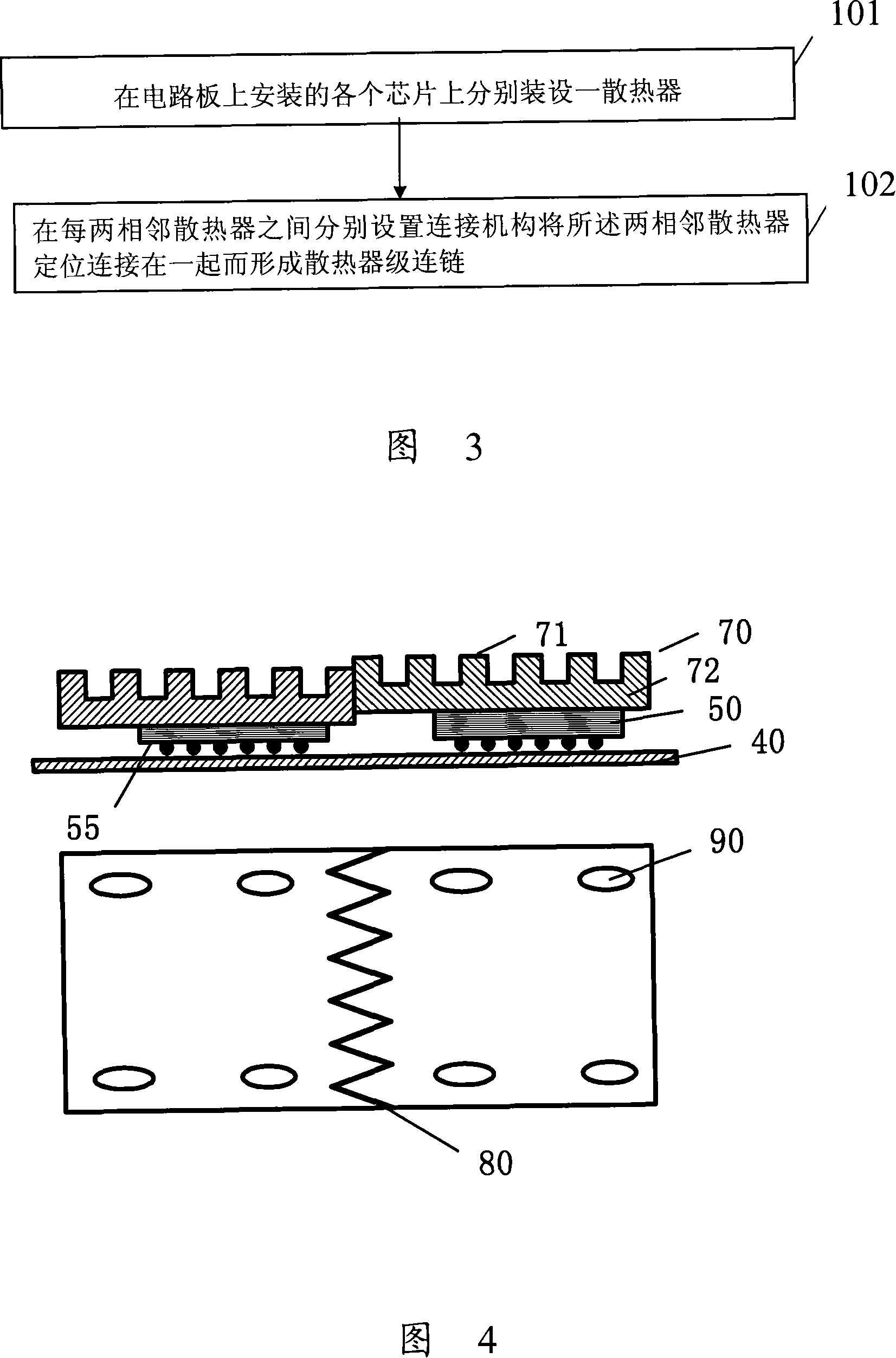

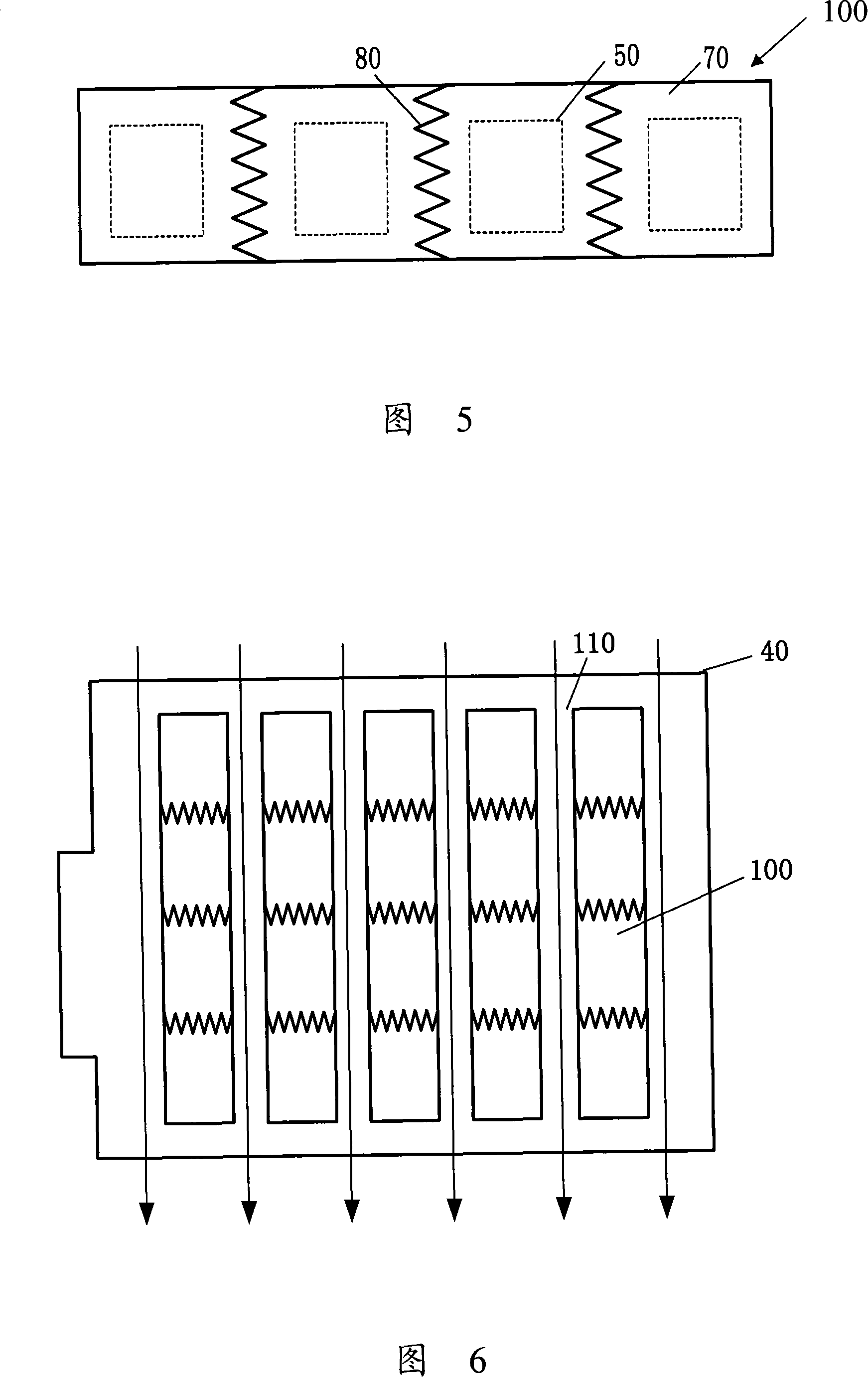

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

[0023] As shown in FIG. 3 , an embodiment of the present invention provides an integrated heat dissipation method, which is applied to various network communication devices to dissipate heat for multiple chips installed on a circuit board inside the device. The integrated heat dissipation method of the embodiment of the present invention can be applied to natural heat dissipation conditions, and can also be applied to forced air cooling heat dissipation conditions driven by air with fans, such as installing a fan or forced air cooling on one side of the circuit board. A cooling and heat dissipation system, etc., to form an air flow channel for heat dissipation on the circuit board. The integrated cooling method mainly includes the following steps:

[0024] Step 101, install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com