High-temperature-resistant switch

A switch and anti-high temperature technology, which is applied in the field of switches, can solve problems such as unsatisfactory working conditions of switches, burnt parts of switches, and lack of high-temperature anti-performance, so as to avoid self-rotation, prevent damage caused by high temperatures, and facilitate cooling and heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

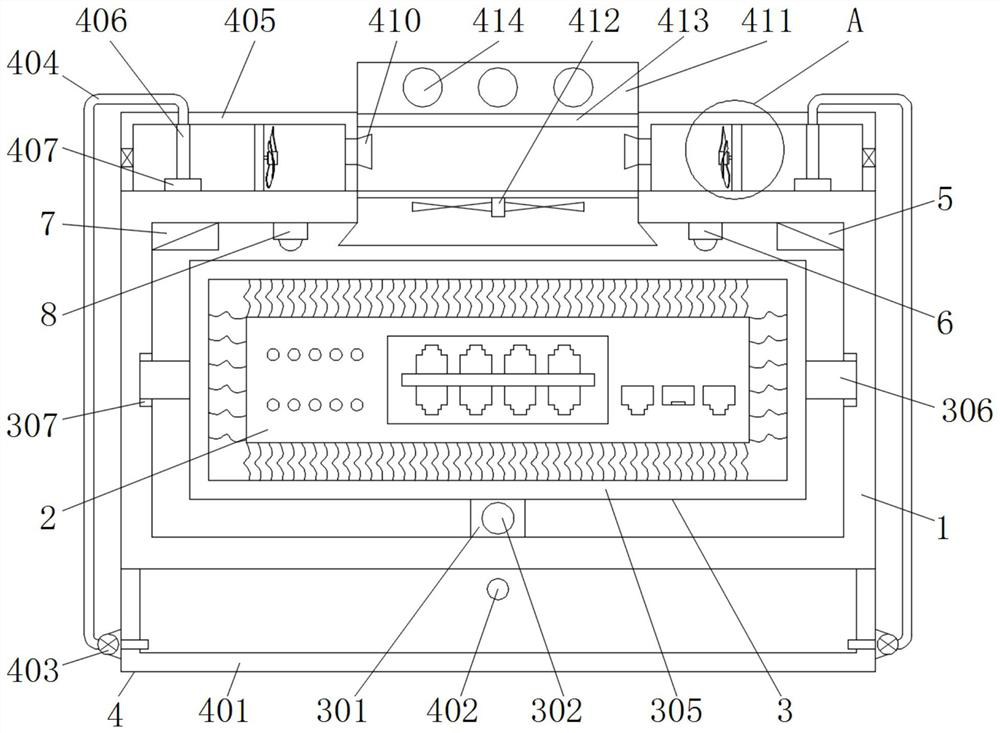

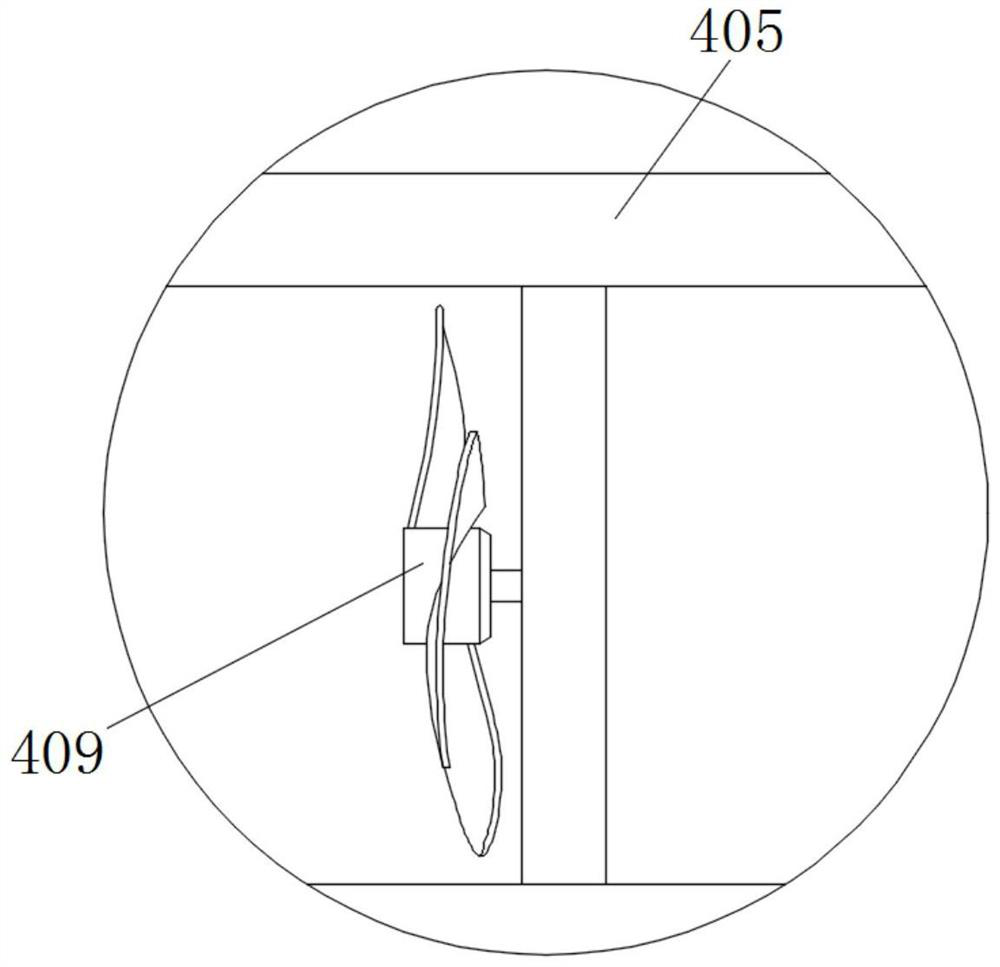

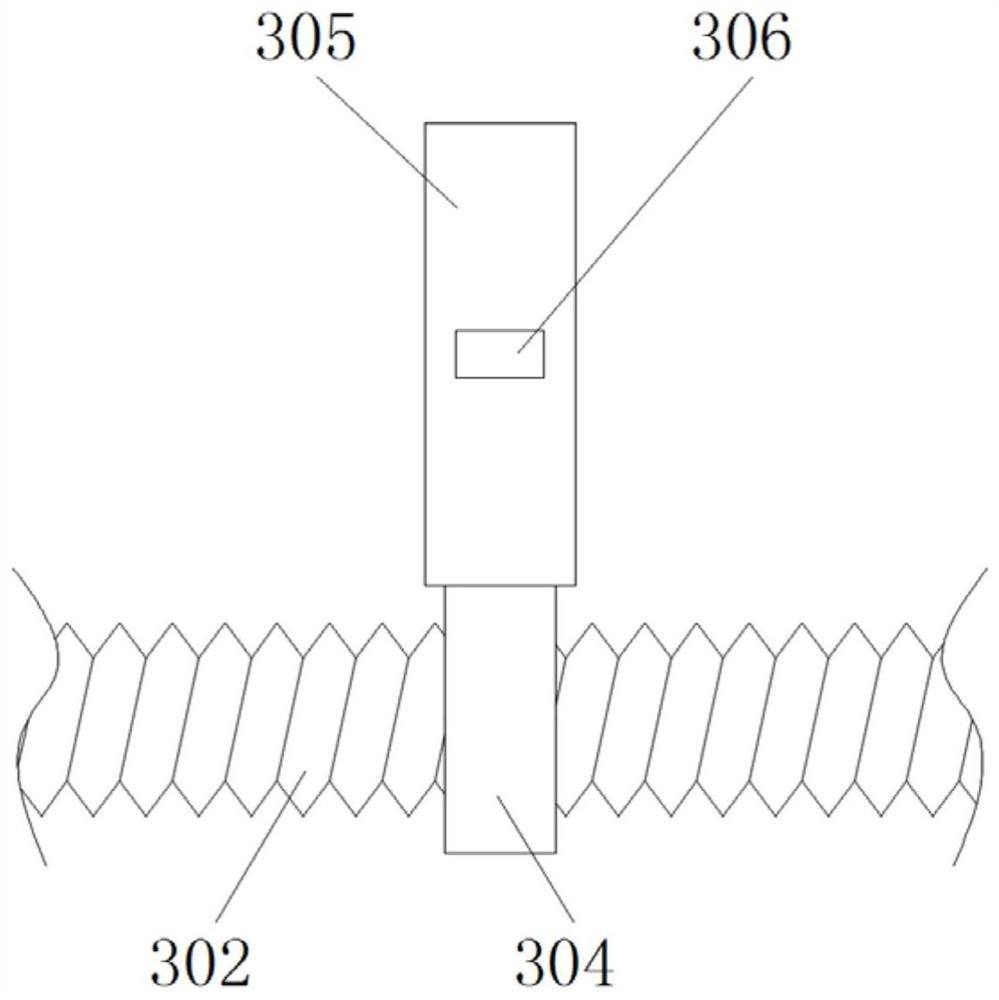

[0023] see Figure 1-5 , the present invention provides a technical solution:

[0024] A high-temperature-proof switch, comprising a mounting frame 1, a switch 2 is fixedly connected to the inner side of the rear end surface of the mounting frame 1, and a dust cleaning device 3 is provided on the inside of the mounting frame 1, which is beneficial to cleaning the switch 2 and avoiding dust on the switch 2 The accumulation on the outer surface affects its heat dissipation. The dust cleaning device 3 includes a fixed seat 301. The inner side of the bottom end surface of the installation frame 1 is fixedly connected with the fixed seat 301. The inner side of the fixed seat 301 is rotatably connected with an adjustment screw 302. The rear end surface of the installation frame 1 is fixed. A three-phase motor 303 is connected, and a screw collar 304 is sleeved on the outside of the adjusting screw 302. Under the action of the adjusting screw 302, the screw collar 304 can be moved, a...

Embodiment 2

[0026] Example 2: see Figure 1-5 , the present invention provides a technical solution:

[0027] A high-temperature-proof switch, comprising a mounting frame 1, a switch 2 is fixedly connected to the inner side of the rear end surface of the mounting frame 1, and a dust cleaning device 3 is provided on the inside of the mounting frame 1, which is beneficial to cleaning the switch 2 and avoiding dust on the switch 2 The accumulation on the outer surface affects its heat dissipation. The dust cleaning device 3 includes a fixed seat 301. The inner side of the bottom end surface of the installation frame 1 is fixedly connected with the fixed seat 301. The inner side of the fixed seat 301 is rotatably connected with an adjustment screw 302. The rear end surface of the installation frame 1 is fixed. A three-phase motor 303 is connected, and a screw collar 304 is sleeved on the outside of the adjusting screw 302. Under the action of the adjusting screw 302, the screw collar 304 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com