Self-adaption harmonic wave confocal microscopic measurement method for illumination of ellipsoidal reflector

A technology of mirror illumination and confocal microscopy, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of reduced excitation efficiency of harmonic signals, interference of harmonic signal analysis, and reduction of optical microscopic systems, etc. Achieve the effect of improving measurement resolution and deep image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The implementation examples of the present invention will be described in detail below in conjunction with the accompanying drawings.

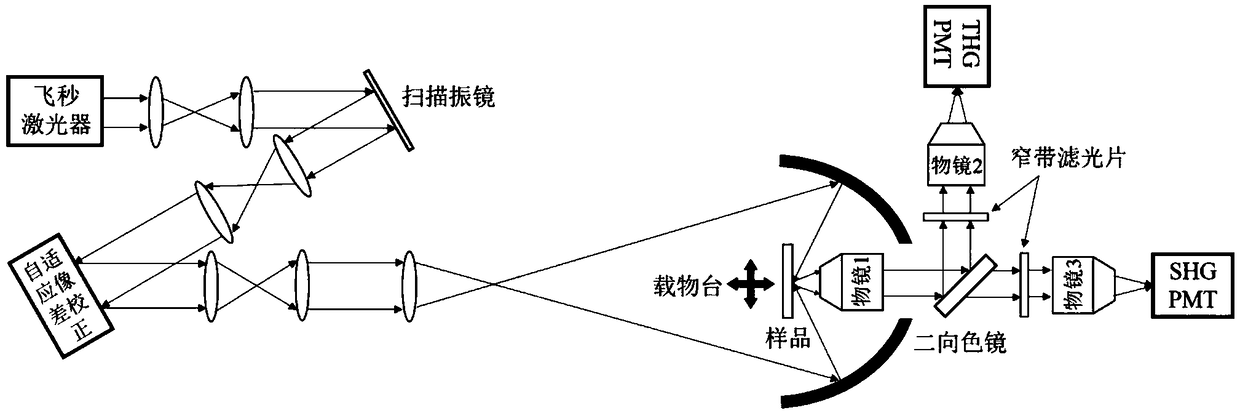

[0013] The schematic diagram of the ellipsoid mirror illumination adaptive harmonic confocal microscopic measurement method in this embodiment is as follows figure 1 shown. The femtosecond laser pulse enters the adaptive optical aberration compensation unit after being beam shaped and reflected by the scanning galvanometer. After phase modulation and aberration correction, it forms an illumination beam that enters the ellipsoid mirror system and converges inside the sample to form a harmonic signal. Desired focus spot for excitation. After the sample is excited by the excitation light, the second and third harmonic signals will be generated simultaneously, which will be collected and analyzed by the two-way composite confocal microscopic measurement system on the right. After the harmonic signal is collected by a large numerical apert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com