Air needle type sensor

A sensor and gas needle technology, which is applied in the direction of instruments, measuring devices, and fluid devices, can solve the problems of small measurement point area, high resolution, and measurement accuracy that cannot be continuously improved, and achieve high measurement resolution and easy installation and use. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

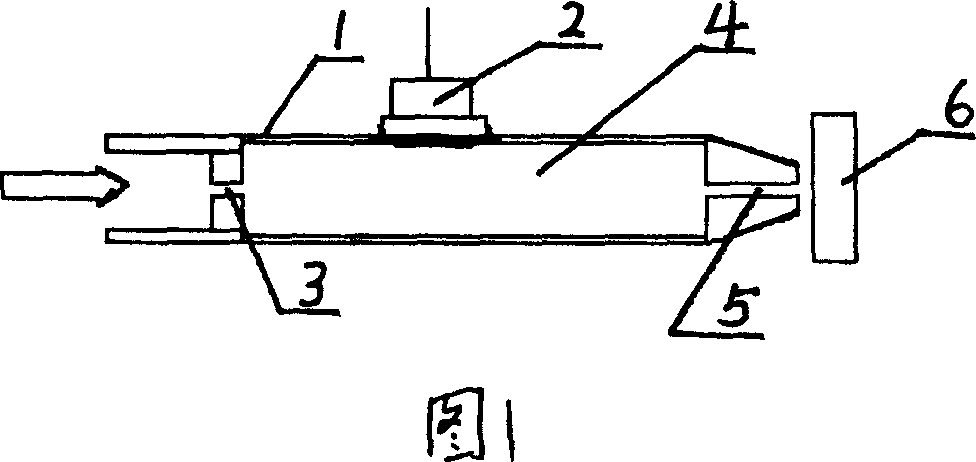

[0010] As shown in Figure 1, the present invention includes a needle body 1 and a pressure sensor 2. It is characterized in that one end of the needle body 1 is an air inlet nozzle 3, and the other end is a measuring nozzle 5. The pressure sensor 2 is connected to the wall of the needle body 1, and the needle body 1 The inner cavity of the body 1 is an air chamber 4, and the entire needle body 1 is cylindrical, with a diameter of less than 10 mm and a length of less than 100 mm. Its air inlet nozzle 3 is parallel to or coincides with the central axis of the measuring nozzle 5 . The diameter of the nozzle is about 100um using a microfabrication method. During the measurement, the workpiece 6 faces the measuring nozzle 5, and the airflow ejected from the measuring nozzle is cylindrical, shaped like a thin needle. The measured displacement resolution can reach 0.1um.

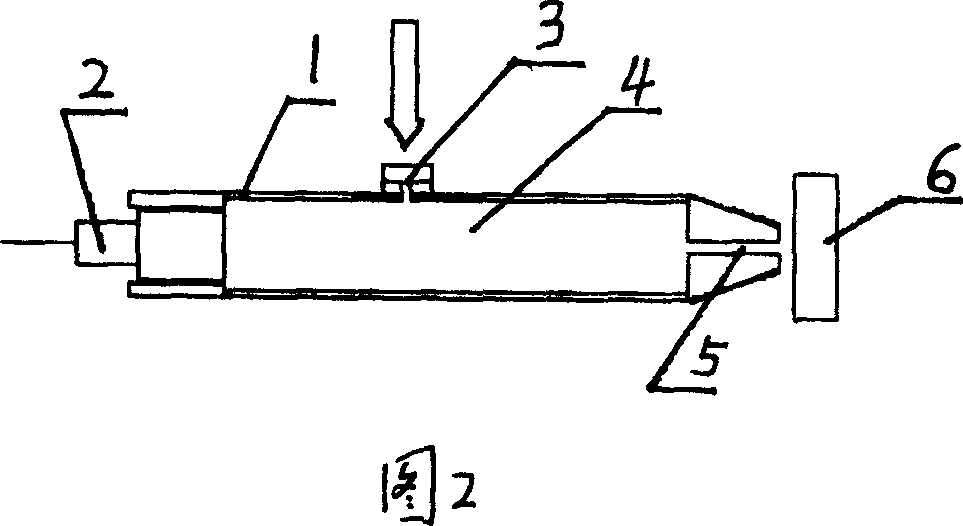

[0011] As shown in Figure 2, the present invention includes a needle body 1 and a pressure sensor 2, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com