An absolute time grating linear displacement sensor

A linear displacement, absolute technology, applied in the direction of instruments, measuring devices, electrical devices, etc., can solve difficult problems such as measurement resolution and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

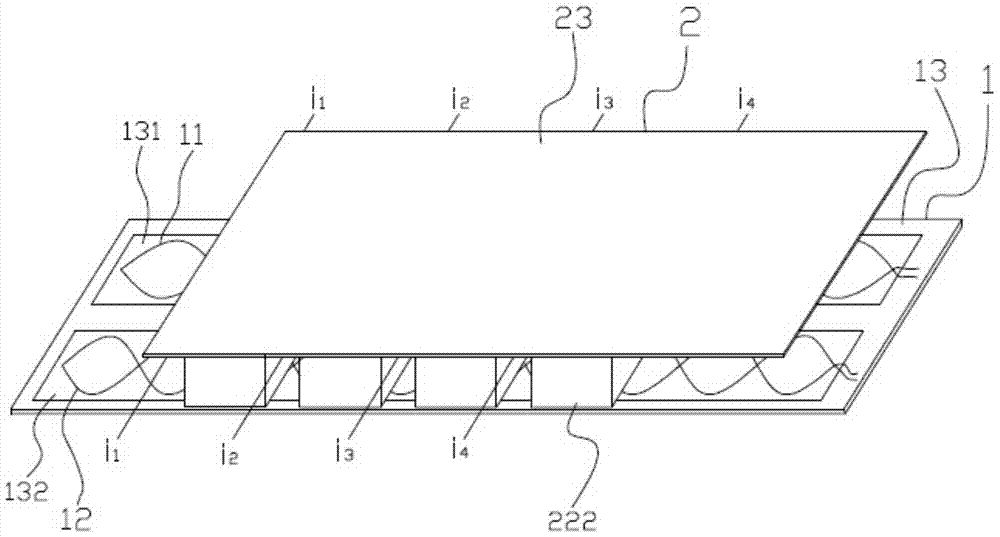

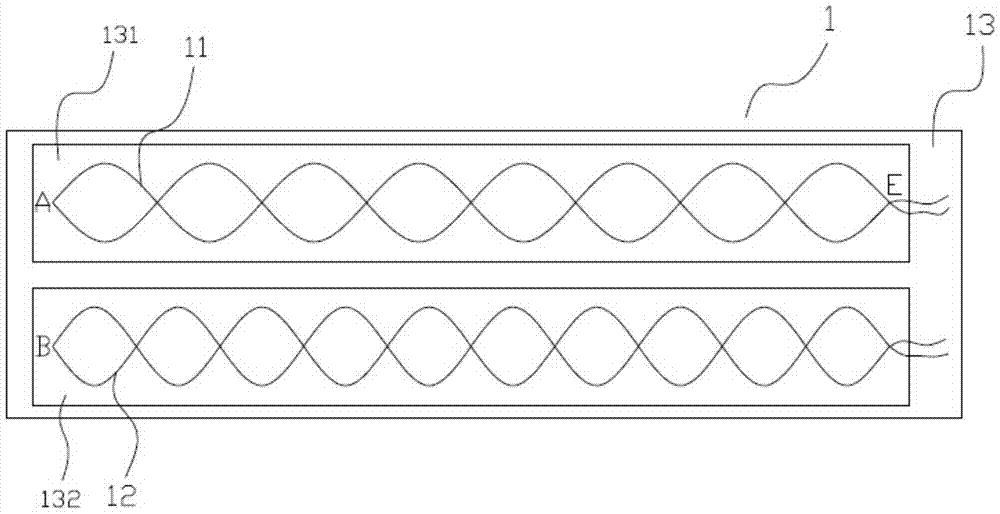

[0030] Embodiment 1: as Figure 1 to Figure 6 The absolute time grating linear displacement sensor shown includes fixed scale 1 and moving scale 2.

[0031] The fixed length 1 is made of a magnetically conductive fixed length substrate 13, a first induction coil 11 and a second induction coil 12. The fixed length substrate 13 adopts a cuboid iron substrate, and the long side direction of the fixed length substrate 13 is the measurement direction. The upper part of the front surface of the ruler base 13 is provided with a first wire insertion groove 131, and the first induction coil 11 is embedded in the first wire insertion groove 131. Embedded in the second wire slot 132, the first induction coil 11 and the second induction coil 12 do not interfere with each other (that is, the first induction signal generated by the first induction coil 11 and the second induction signal generated by the second induction coil 12 do not affect each other).

[0032] The first induction coil ...

Embodiment 2

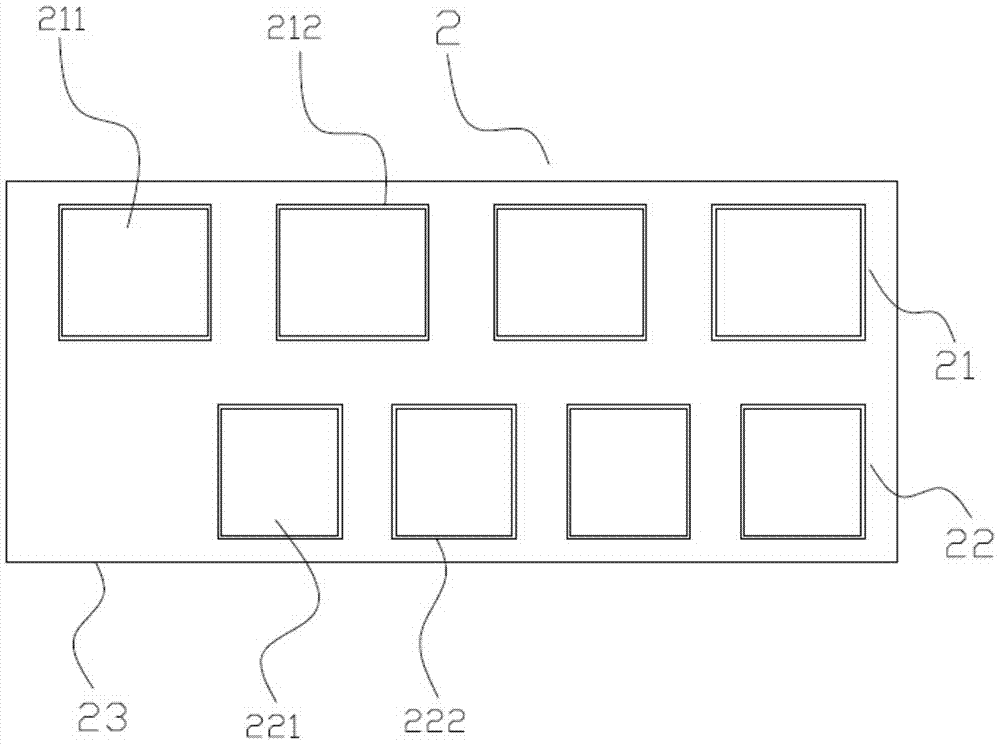

[0038] Embodiment 2: as Figure 7 to Figure 9 The structure and working principle of the absolute time grating linear displacement sensor shown are mostly the same as those in Embodiment 1, the difference is that the first induction coil 11 and the second induction coil 12 are independently arranged on a fixed-length printed circuit board. On the wiring layer of the circuit board 14, the fixed-length printed circuit board 14 is installed on the fixed-length substrate 13, and the initial position of the first induction coil winding track (corresponding to Figure 7 Point C in the measurement direction and the starting position of the second induction coil winding track (corresponding to Figure 7 Point D in the center) is 2mm apart. The first excitation coil 212 is arranged on the first printed circuit board 24, and the center of the first printed circuit board is provided with a rectangular hole matching the shape of the first magnetic conductor 211, and the first printed cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com