A Method for Measuring the Shape of Freeform Surface

A surface and curved surface technology, which is applied to measuring devices, instruments, optical devices, etc., to achieve the effect of improving the measurement resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0028] This embodiment is a device embodiment.

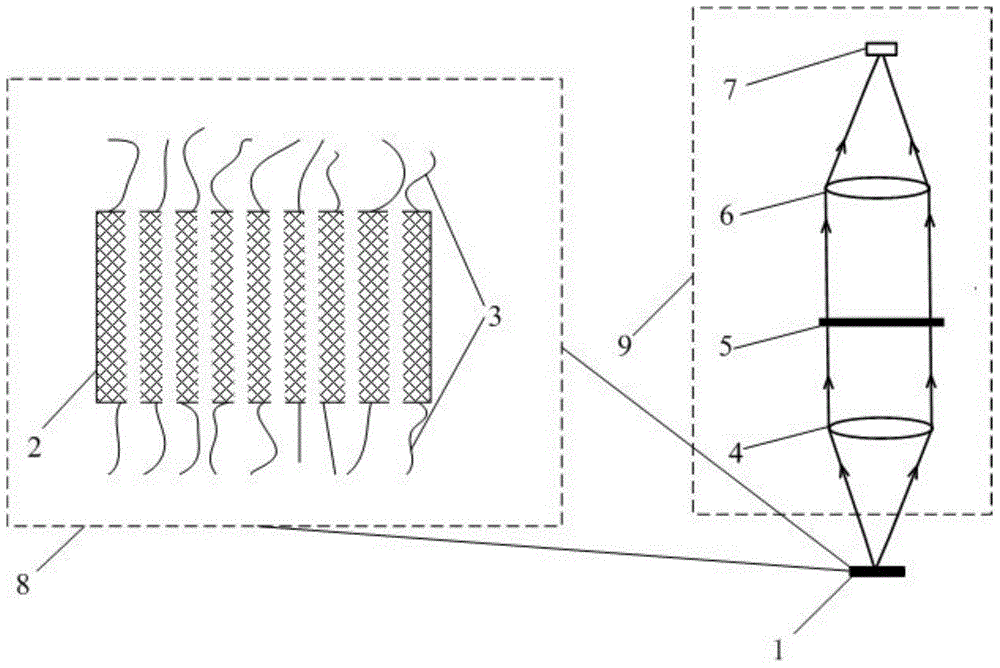

[0029] A device for measuring the shape of a free-form surface in this embodiment, the structural diagram is as follows figure 1 shown. The unit includes:

[0030] Electroluminescent film lighting part 8 and optical imaging measurement part 9;

[0031] The electroluminescent film lighting part is composed of a sample to be tested 1, an electroluminescent film 2 plated on the surface of the sample 1, and positive and negative microelectrodes 3;

[0032] The optical imaging part includes objective lens 4, optical filter 5, tube lens 6 and CCD7 in sequence along the propagation direction of the collected optical signal.

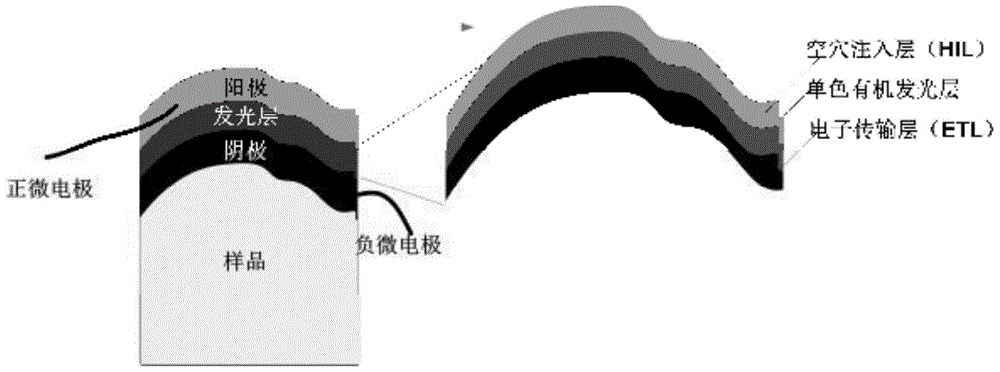

[0033] The above-mentioned device for measuring the shape of a free-form surface, the electroluminescent film as figure 2 As shown, its thickness is not more than 4 μm, and it is composed of a cathode layer, a light-emitting layer and a transparent anode layer, and the thickness of each layer is uniform; the ...

specific Embodiment 2

[0034] This embodiment is an embodiment of the method implemented on the device described in the first specific embodiment.

[0035] A kind of method for measuring free-form surface profile of the present embodiment, comprises the following steps:

[0036] In the first step, a cathode layer, a light-emitting layer, a transparent anode layer and a microelectrode with a total thickness of no more than 4 μm are formed on the surface of the sample 1, and the thickness of each layer is uniform; the film thickness of the light-emitting layer is no more than 1 μm, and the light-emitting layer is an organic layer. It is composed of an electron transport layer, a monochromatic organic light-emitting layer and a hole injection layer. The electroluminescent film is made in different regions and arranged in strips on the surface of sample 1. There are small blank areas without coating between different strips, and the blank areas are The width is less than 5nm, and there are positive and ...

specific Embodiment 3

[0045] This embodiment is a method embodiment.

[0046]In this embodiment, on the basis of the specific embodiment 2, an eleventh step is added to clean all the films on the surface of the sample 1 and the microelectrodes near the surface of the sample 1. In this step, the recovery of the surface topography of the sample can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com