High-precision roll angle measuring method and device based on transmission grating

A roll angle measurement and transmission grating technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of direct measurement of roll angle errors, difficult to obtain accurate measurement values of roll angle errors, etc., to eliminate measurement errors, detect The effect of compact unit and enhanced anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

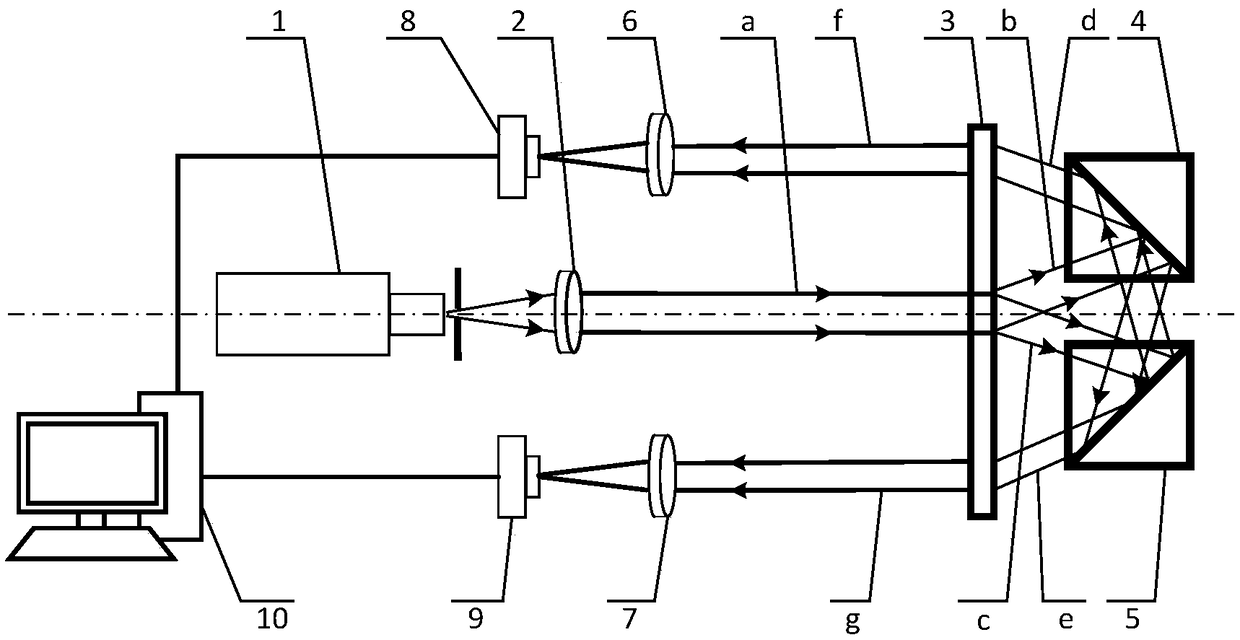

[0026] The high-precision roll angle measurement method based on the transmission grating of the present invention comprises the following steps:

[0027] ①. The beam emitted by the laser light source passes through the collimating objective lens to form a collimated beam;

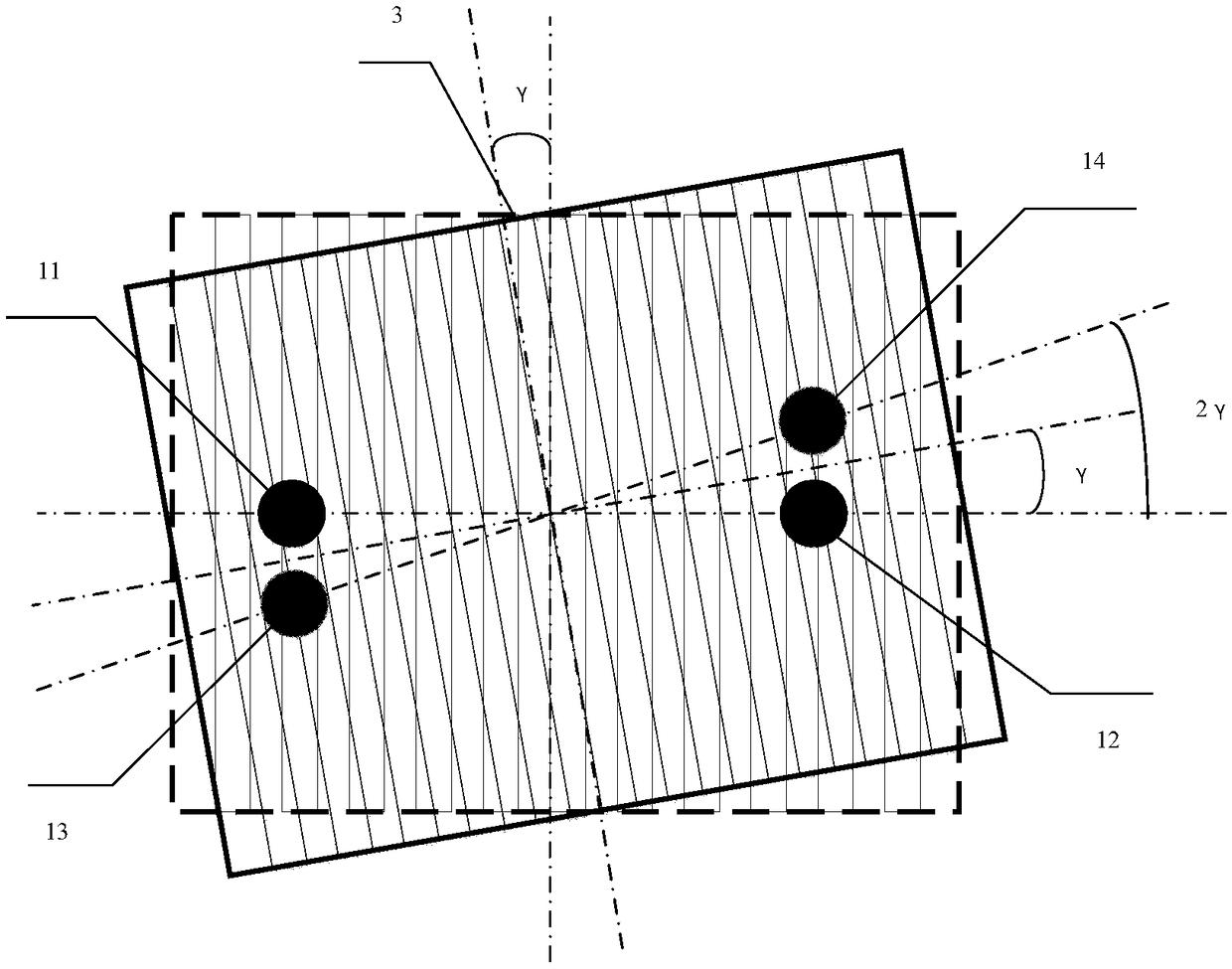

[0028] ②. After the collimated beam passes through the one-dimensional plane transmission grating, a positive first-order diffraction beam and a negative first-order diffraction beam are generated, and the one-dimensional plane transmission grating is rigidly connected to the platform to be measured;

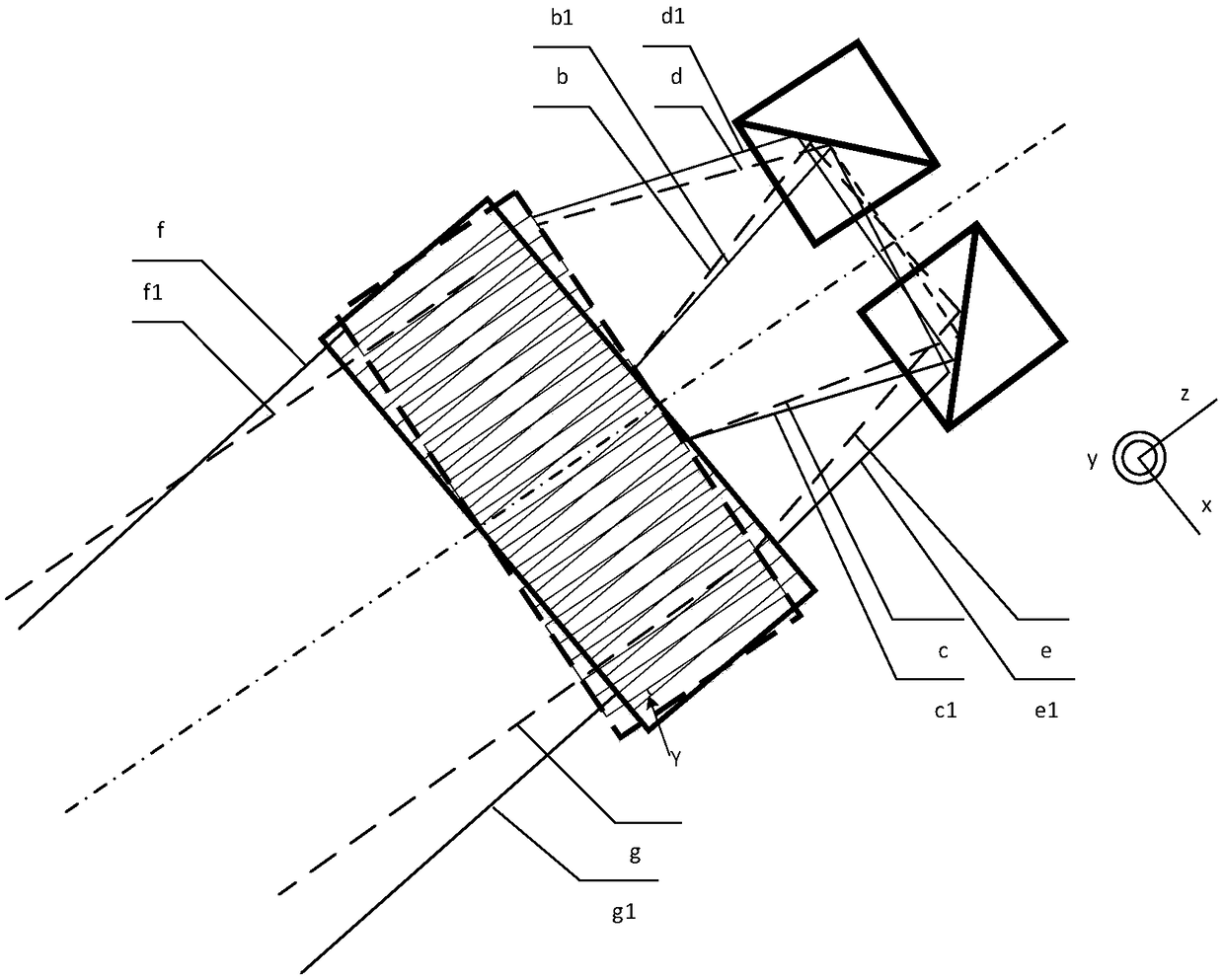

[0029] The positive first-order diffracted beam and the negative first-order diffracted beam described in ③ and ② pass through a set of polarizing beamsplitters whose diagonals are perpendicular to each other to obtain a set of beams parallel to the positive first-order dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com