Method for extracting sodium carbonate and sodium thiocyanate from sodium-alkali desulfurization waste liquid by causticization-acidification

A technology for desulfurization waste liquid and sodium thiocyanate, which is applied to chemical instruments and methods, thiocyanic acid, carbonate preparations, etc., can solve the problems of high construction and maintenance costs of production equipment, long waste liquid treatment process routes, and overall Low economic benefits and other problems, to achieve the effect of saving the refrigerator system, low operating costs, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

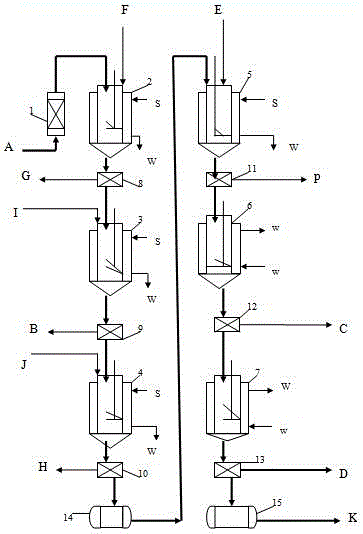

[0039] The method of the present invention firstly puts the sodium-alkali desulfurization waste liquid, that is, the raw material solution A, into the filter 1, and the filter 1 has built-in coke or activated carbon or other adsorption materials, and the raw material solution A is adsorbed after passing through the coke or activated carbon adsorption materials at normal temperature and pressure. To separate the solid impurities entrained in the waste liquid, the filter can be operated continuously for several weeks or even months. When the adsorption reaches saturation or the resistance increases, the adsorber can be kept working normally by backflushing or replacing the adsorbent.

[0040] Send the raw material liquid A after preliminary purification into the thermal decomposer 2, and heat it with steam S, so that components such as sodium thiosulfate and sodium polysulfide are decomposed into sodium sulfite and sodium sulfide, and elemental sulfur is precipitated and part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com