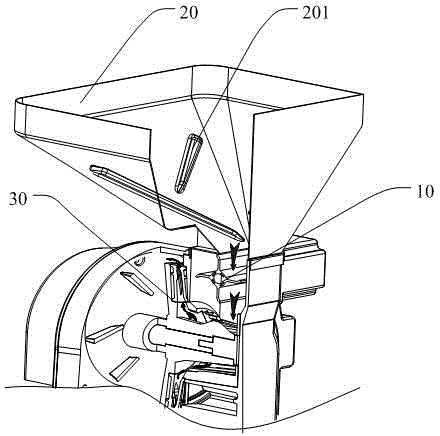

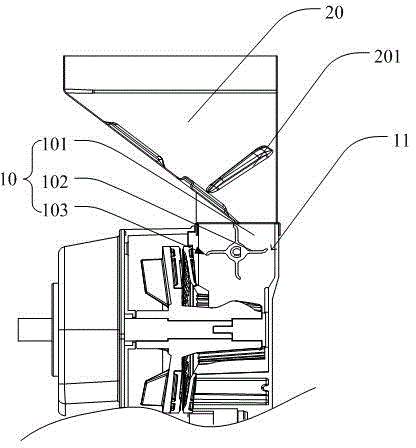

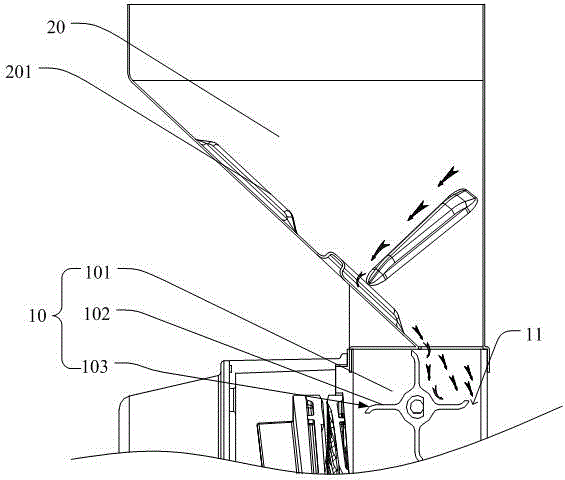

Pulverizer and discharging method thereof

A technology of milling machine and hopper, which is applied in the field of milling machine and its feeding, which can solve the problems of burnt lumps, slow feeding speed, unbalanced nutrition powder, etc. no loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention provides a pulverizer and a feeding method thereof. The feeding speed of raw materials with large specific gravity and small particles can be controlled by intermittent feeding of the intermittent feeding mechanism every preset time. The intermittent feeding can be used All kinds of raw materials are mixed evenly during the feeding process and then enter the grinding mechanism for grinding, so that the nutritional balance of the nutritional powder will not be stratified. Moreover, the present invention makes the working load of the grinding mechanism uniform by means of intermittent feeding, so that the grinding mechanism will not be overloaded, and the food materials are prevented from blocking the feeding opening. At the same time, because the grinding mechanism will not be overloaded, it is not easy to generate high temperature during the grinding process, so that the sugar material will not be burnt, and the powder will be discharged smoothly, ensuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com