Novel cloth filtering tank

A filter cloth filter, a new type of technology, applied in the direction of moving filter element filters, filtration separation, separation methods, etc., can solve the problems of large operating resistance and high energy consumption of rotary disc filters, and reduce working energy consumption and operating costs. , good filtration effect, uniform water inlet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

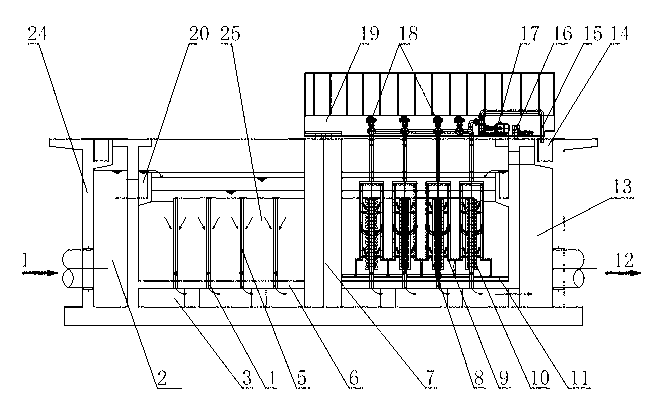

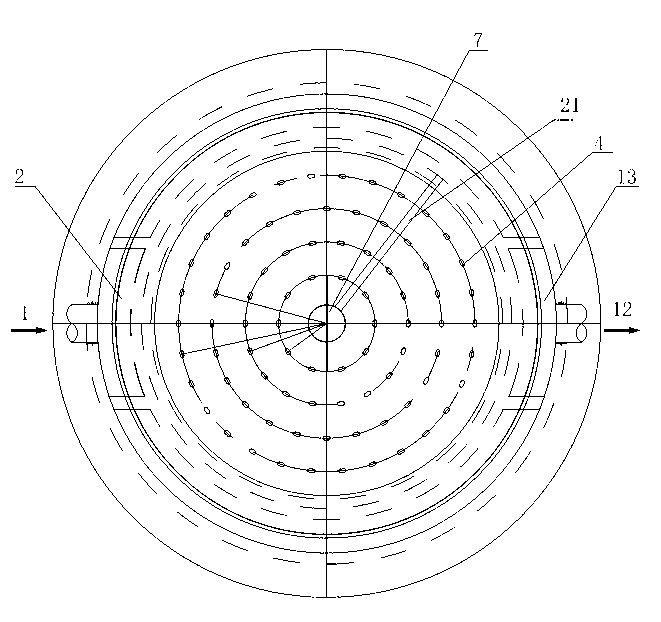

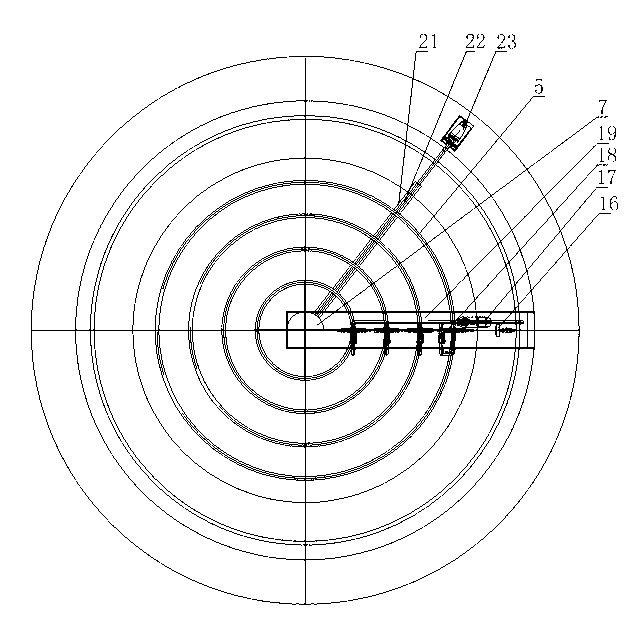

[0019] Such as Figure 1 to Figure 3 As shown, the novel filter cloth filter tank of the present invention is composed of three parts: a tank body 24, a filter ring 5 and a backwashing device. The center of the circular pool body 24 is provided with a central pier 7, and the bottom of the pool is an interlayer structure. The partition board 6 divides the pool body 24 into the upper sewage chamber 25 and the bottom clean water chamber 3. The radiation divergence on the partition board 6 is evenly distributed with a number of through holes. The outlet hole 4 of dividing plate 6 thickness (referring to figure 2 ), the front of the clapboard 6 is provided with a sunken sludge collecting ditch 21 along the radial direction, and the bottom of the sludge collecting ditch 21 is provided with a sludge suction pipe 22, and the sludge suction pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com