Mine stone crushing and dust removing equipment

A technology for dust removal equipment and stone materials, which is applied in the fields of dust removal, separation method, grain processing, etc., can solve the problems of difficult popularization and application, difficult to control the ore feeding rate, unfavorable ore crushing, etc., and achieves the effect of increasing the feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

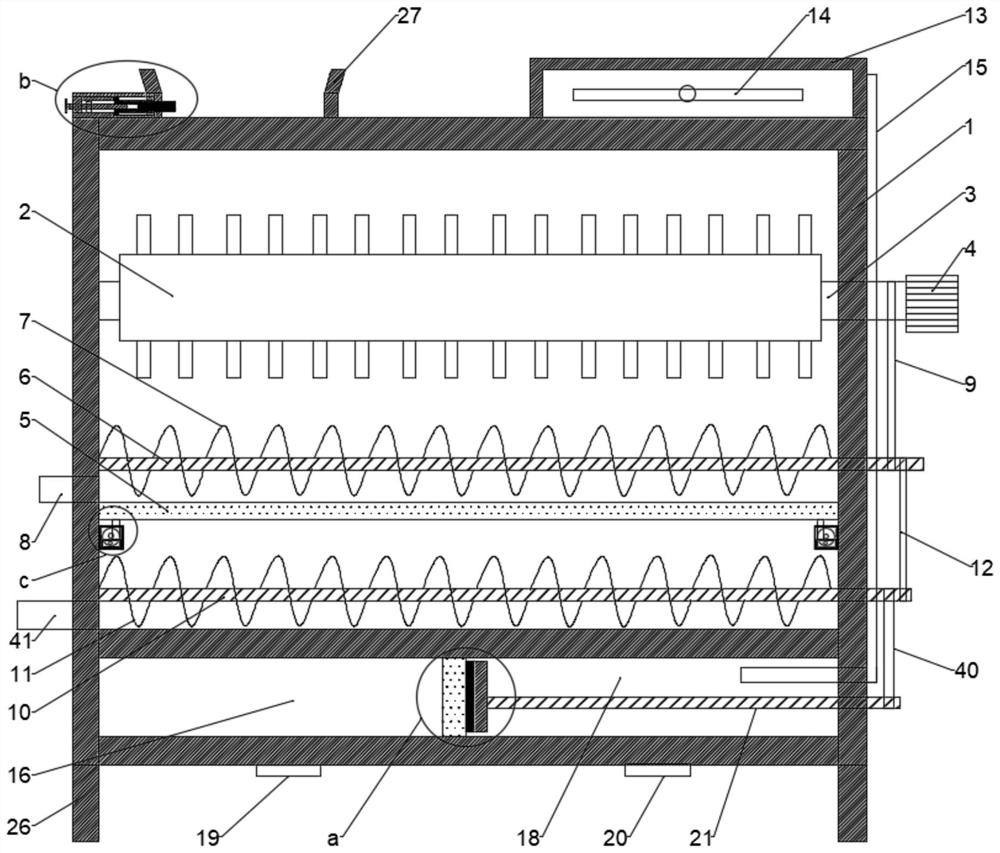

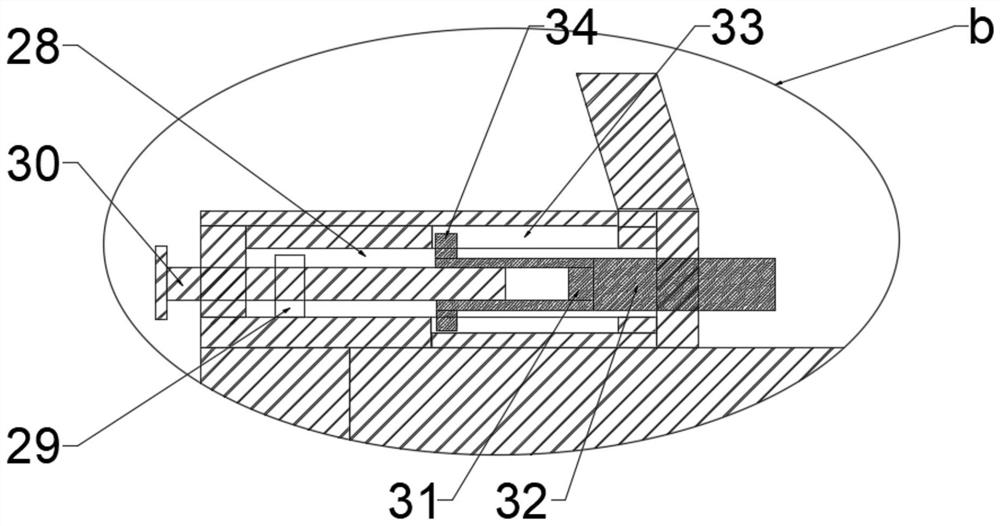

[0028] see Figure 1 ~ Figure 4 , a mining stone crushing and dust removal equipment, including a body 1, a crushing roller 2, a rotating shaft 3, a first motor 4, a filter screen 5, a first transmission rod 6, a first screw blade 7, a first discharge port 8, a first A belt 9, a second transmission rod 10, a second spiral blade 11, a second belt 12, a fan box 13, a fan 14, a conduit 15, a placement box 16, a connecting column 17, a dust box 18, an air outlet 19, an outlet Dust valve 20, column 26, feed port 27, groove 28, fixed plate 29, threaded rod 30, movable rod 31, baffle plate 32, first chute 33, slider 34, fixed frame 35, second motor 36 , the second chute 37 and the connection frame 38.

[0029] The inside of the body 1 is provided with a crushing roller 2, and the outside of the body 1 is provided with a first motor 4, the output end of the first motor 4 is connected with a rotating shaft 3, and the outer end of the rotating shaft 3 is connected with a crushing rolle...

Embodiment 2

[0040] see Figure 1 ~ Figure 4 , a mining rock crushing and dedusting equipment, comprising a body 1, a crushing roller 2 is arranged inside the body 1, a first motor 4 is arranged outside the body 1, a rotating shaft 3 is connected to the output end of the first motor 4, and the rotating shaft 3 The outer end of the crushing roller 2 is connected with the crushing roller 2, and the crushing roller 2, the rotating shaft 3 and the first motor 4 respectively have two, which are convenient for crushing the stone. During use, add stone to be crushed in the body 1 through the feed port 27, turn on the first motor 4, the output end of the first motor 4 drives the rotating shaft 3 to rotate, and the rotating shaft 3 drives the crushing roller 2 to rotate, and the stone is crushed.

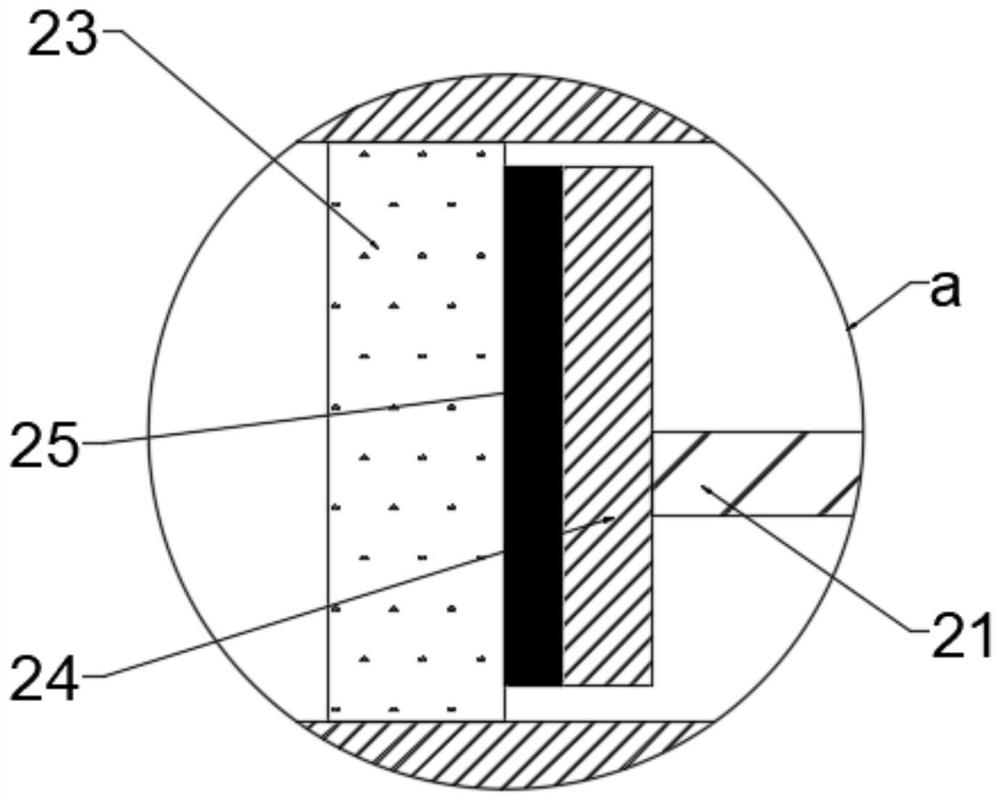

[0041] Different from Embodiment 1, the inside of the dust box 18 is provided with a rotating rod 21, the second transmission rod 10 is connected to the rotating rod 21 through the third belt 40, the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com