Garbage crushing device for constructional engineering

A crushing device and construction engineering technology, which is applied in the field of construction engineering, can solve the problems of operator injury, inconvenient movement of the device, blockage of the feeding hole, etc., and achieve the effects of slowing down the feeding speed, improving the crushing effect, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

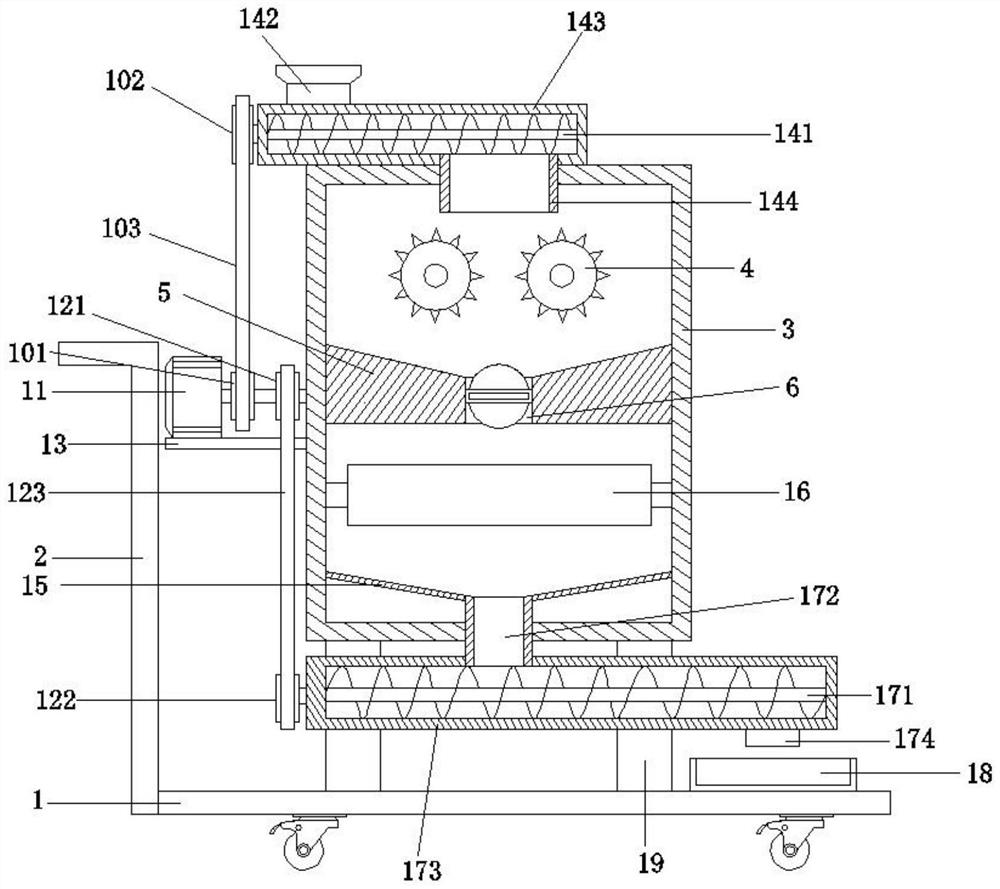

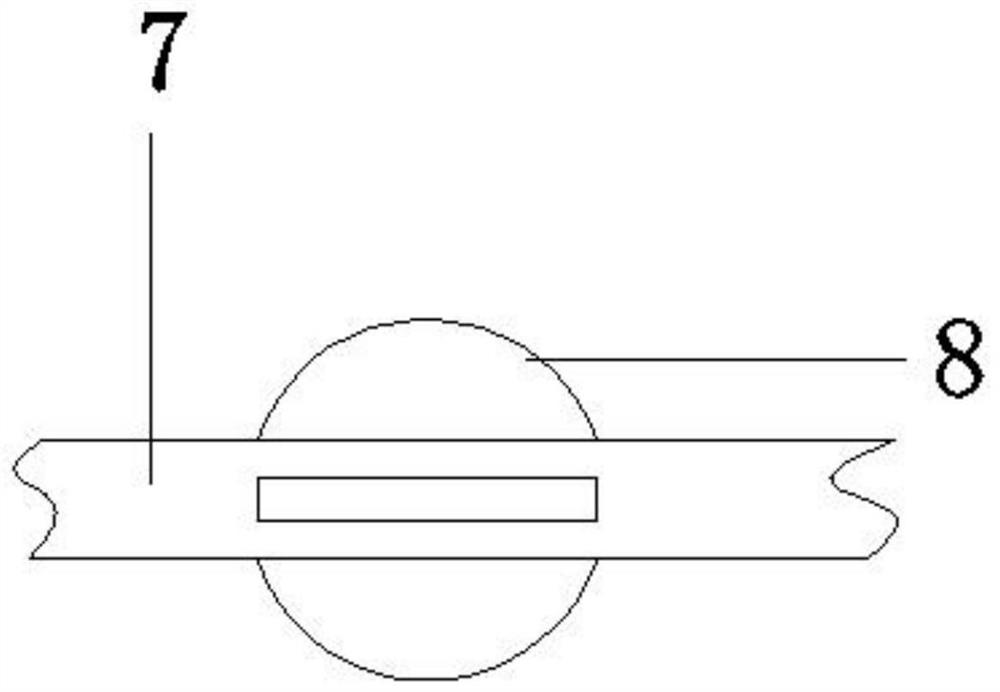

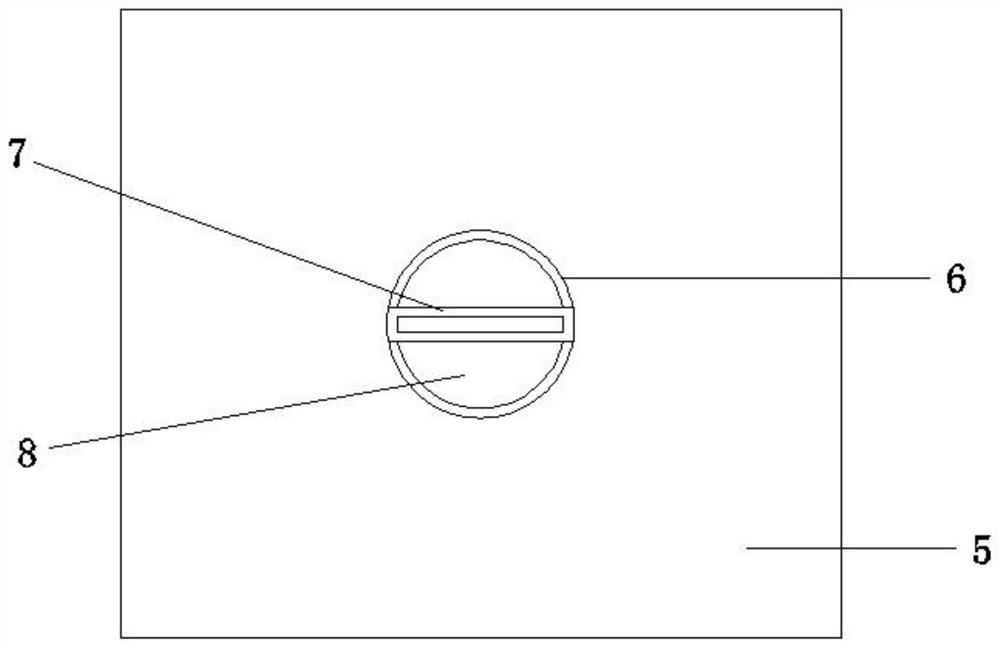

[0030] A rubbish crushing device used in construction projects comprises a base 1 with rollers, and a push handle 2 is fixed on the left end of the base 1 . The upper end of base 1 is all fixed with supporting rod 19 around, and the upper end of supporting rod 19 is fixed with casing 3, and the inside of casing 3 is fixed with pulverizer 4, and pulverizer 4 is prior art. The middle part of casing 3 is fixed with blanking seat 5, and the upper end of blanking seat 5 is arranged as funnel shape, and the middle part of blanking seat 5 is provided with blanking port 6. The internal rotation of the blanking seat 5 is limited by a rotating shaft 7, and the outside of the rotating shaft 7 is evenly provided with several rotating blades 8 inside the blanking port 6. The outer end of the box body 3 is fixed with a rectangular plate 13 , the upper end of the rectangular plate 13 is fixed with a transmission motor 11 , and the output shaft of the transmission motor 11 is connected with t...

Embodiment 2

[0032] The upper and lower sides of the output shaft of the transmission motor 11 are respectively provided with a first transmission mechanism 10 and a second transmission mechanism 12 , the upper end of the box body 3 is provided with a first transmission mechanism 14 , and the lower end of the box body 3 is provided with a second transmission mechanism 17 . The first conveying mechanism 14 is connected with the first transmission mechanism 10 , and the second conveying mechanism 17 is connected with the second transmission mechanism 12 . The first transmission mechanism 10 includes a first driving shaft 101 , a first driven shaft 102 and a first belt 103 . The first driving shaft 101 is sheathed on the outside of the output shaft of the transmission motor 11 , and the first driving shaft 101 is transmission-connected to the first driven shaft 102 through the first belt 103 . The second transmission mechanism 12 includes a second driving shaft 121, a second driven shaft 122 ...

Embodiment 3

[0034] A grinding mechanism 16 is provided inside the box body 3 below the feeding seat 5 , and a round bucket 15 is arranged at the bottom of the box body 3 . The grinding mechanism 16 includes a grinding motor 161 , a gear 162 , a grinding rod 163 and a grinding roller 164 . The symmetrical rotation of the grinding rod 163 is limited to the inside of the box body 3. The grinding roller 164 is set on the outside of the grinding rod 163, the outer end of the grinding rod 163 is set with a gear 162, and the outer end of the grinding rod 163 on either side is fixed with a grinding motor. 161. By providing the grinding mechanism 16, the primary crushed construction waste can be secondary crushed, which improves the crushing effect of the construction waste.

[0035] The working principle of this embodiment is: when in use, start the transmission motor 11, add construction waste to the inside of the first feeding pipe 142, the rotation of the transmission motor 11 drives the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com