Coal slime classified concentration device

A technology for concentrating device and coal slime water, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of increasing capital construction and production costs, vicious circle, shortening the service life of filter cloth, etc., and reduce the impact of settlement effect. , The effect of simplifying the two-stage concentration process and reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the example in the accompanying drawings:

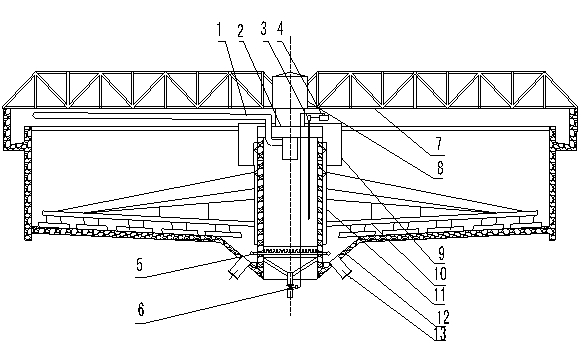

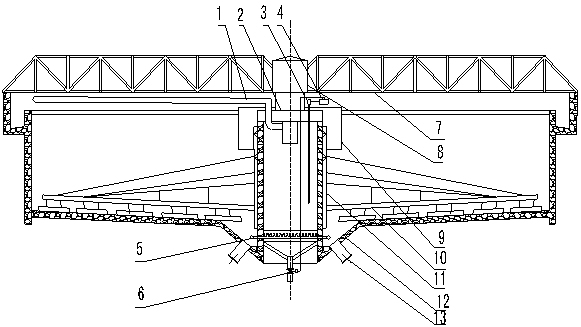

[0009] Such as figure 1 As shown, the coal slime water graded concentration device of the present invention is mainly composed of a feed cylinder 1, a liquid-solid fluidized bed cylinder body 2, a concentration sensor 3, a controller 4, a fluid distributor 5, an underflow discharge valve 6, a transmission device 8, The guide cylinder 9, the turret 11 and the pool body 12 constitute. The liquid-solid fluidized bed cylinder 2 is set at the center of the pool body 12, the upper part of the liquid-solid fluidized bed cylinder 2 is installed with a guide tube 9, and the feeding cylinder 1 is installed at the upper center of the liquid-solid fluidized bed cylinder 2 , the external feed pipe is connected with the feed cylinder 1 tangentially. The top of the pool body 12 is provided with a bridge frame 7, the bottom of the pool body 12 is provided with a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com