Treatment method and system of wastewater

A treatment method and wastewater technology, applied in water/sewage treatment, biological water/sewage treatment, reduced water/sewage treatment, etc., can solve the problems of reducing biological toxicity of wastewater, high cyanide ion and thiocyanate ion concentration, and achieve The effect of stabilizing the water quality of wastewater, stabilizing water quality, and ensuring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

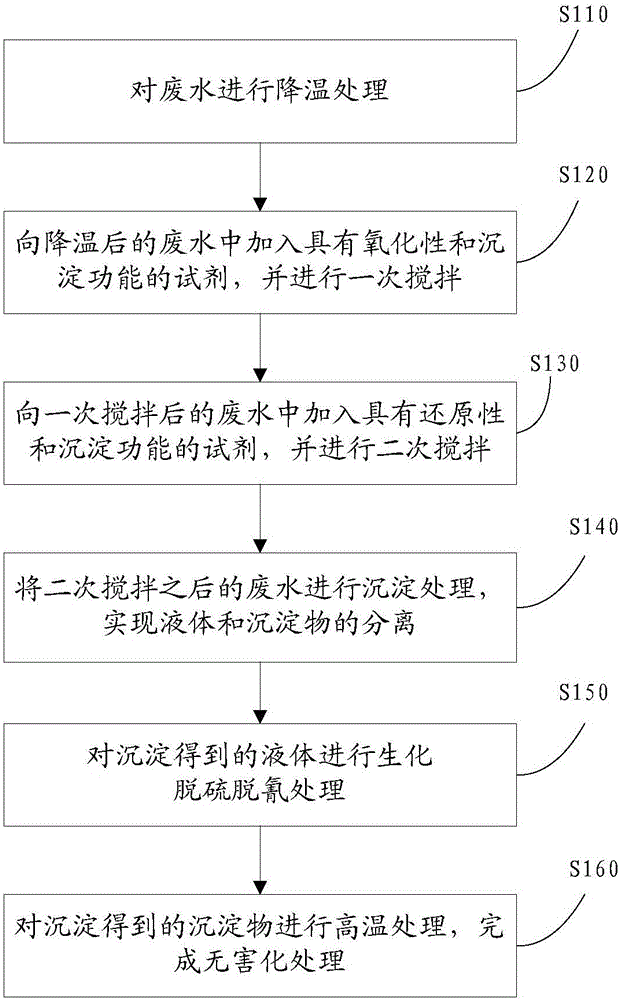

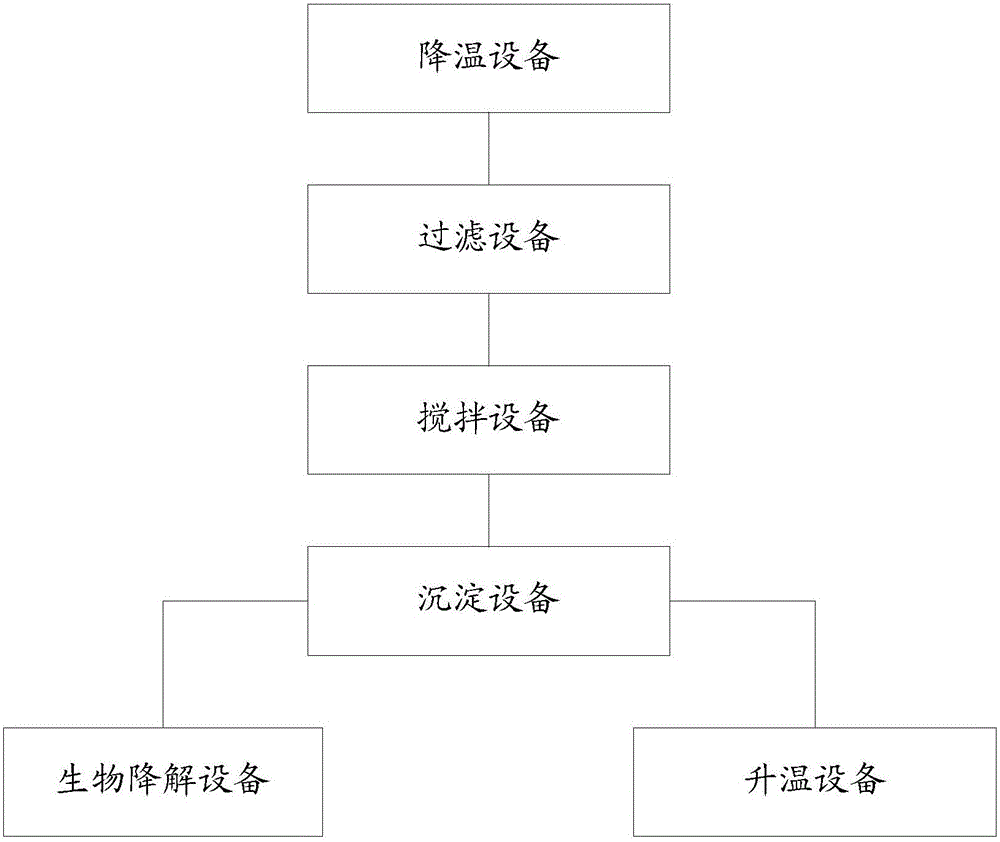

[0049] The process of treating distilled ammonia wastewater through the system provided by the embodiment of the present invention (wherein, the reagent with oxidizing and precipitation functions is Ca(ClO) 2 , The reagent with reducing and precipitation function is FeSO 4 )include:

[0050] 1. The wastewater after ammonia distillation is cooled to below 35°C by two heat exchangers. The two media of the heat exchanger are circulating water and ammonia wastewater.

[0051] 2. Filter the waste water treated in process 1 through a paper bag filter, and the filter aperture of the paper bag is selected to be 0.1-0.5mm.

[0052] 3. Put 0.1mm diameter Ca(ClO) into the wastewater treated by process 2 in the mixing and mixing tank according to the solid-liquid ratio of 1:200-1:300 2 , The stirring speed of the stirrer is 20-80r / min, and the stirring time is 20-30min.

[0053] 4. In the same mixing tank, the FeSO put in the wastewater after treatment in process 3 according to the liquid-to-liqui...

Embodiment 2

[0058] The process of treating distilled ammonia wastewater through the system provided by the embodiment of the present invention (wherein, the reagent with oxidizing and precipitation functions is Mg 2 ClO(OH) 3 ﹒ H 2 O, the reagent with reducing and precipitation function is FeCl 2 )include:

[0059] 1. The wastewater after ammonia distillation is cooled to below 35°C by two heat exchangers. The two media of the heat exchanger are circulating water and ammonia wastewater.

[0060] 2. Filter the waste water treated in process 1 through a paper bag filter, and the filter aperture of the paper bag is selected to be 0.1-0.5mm.

[0061] 3. Put Mg with a particle size of 0.1mm into the wastewater treated in process 2 according to the solid-liquid ratio of 1:250-1:350 in the mixing tank 2 ClO(OH) 3 ﹒ H 2 O, the stirring speed of the stirrer is 30-65r / min, and the stirring time is 20-30min.

[0062] 4. In the same mixing tank, the FeCl added to the wastewater after treatment in process 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com