Patents

Literature

69 results about "Thiocyanate ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallographic corrosive and alloy macrostructure display method

ActiveCN106637212AWill not cause excessive corrosionDoes not cause insufficient corrosionPreparing sample for investigationGrain boundaryMaterials science

The invention provides a metallographic corrosive and an alloy macrostructure display method. The metallographic corrosive comprises water soluble alkali metal hydroxide, water soluble thiocyanate and water. In the metallographic corrosive, the mole concentration of hydroxide ions is 5 mol / L, and the mole concentration of thiocyanate ions is 0.001-0.011 mol / L. The corrosion rate of grain boundaries and the corrosion rate of crystal grains are matched by adding the thiocyanate to accelerate grain boundary corrosion by means of activity difference between the grain boundaries and the crystal grains, and at this time, the thiocyanate serves as an activator; and meanwhile, the mole concentration of the thiocyanate ions and the mole concentration of the hydroxide ions are matched, so that corrosion to the hydroxyl ions is controlled at a proper degree, insufficient corrosion is avoided, and the phenomenon of excessive corrosion that the aluminum alloy grain boundaries and crystal grains are corroded at the same time is avoided.

Owner:珠海格力绿色再生资源有限公司 +1

Small quality fast extraction method for soil total DNA

InactiveCN1990863AEasy to operateMicrobiological testing/measurementDNA preparationHigh concentrationSoil microbiology

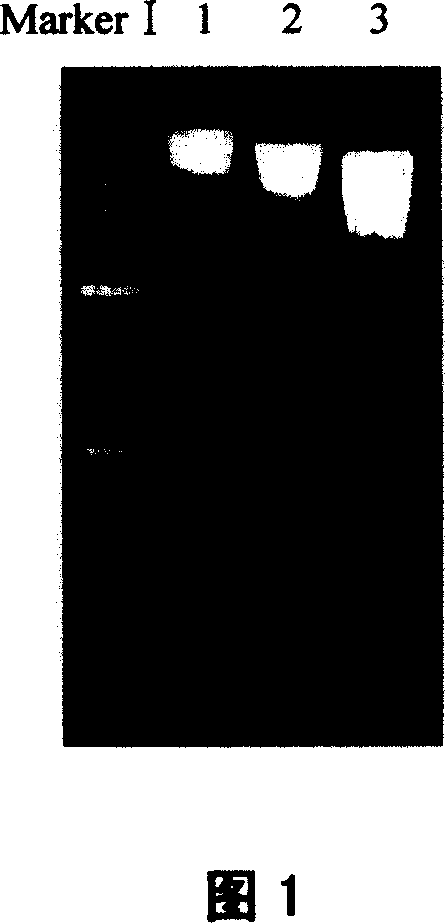

The invention discloses a method for fast extracting the total soil DNA. It takes soil as raw material, shaking with quartz sand and silicon dioxide powder, cracking with cetyltrimethylammonium bromide for DNA releasment, the released DNA can be absorbed by diatomite under weak acid or netural pH condition and high concentration thiocyanate ion, and the DNA will be eluted by low salty buffer solution or deionized water under weak alkaline condition. The extracted DNA with enough purity and amount can be used for PCR and endonuclease reaction. The main steps comprise cell cracking, DNA extraction and DNA purification. The invention is characterized by the simple, fast and easy method, and high purity and low cost extracted DNA. The extracted DNA can be used for kit production. The soil total DNA can be extracted in half hour for microbiological and molecular biological research.

Owner:HUAZHONG AGRI UNIV

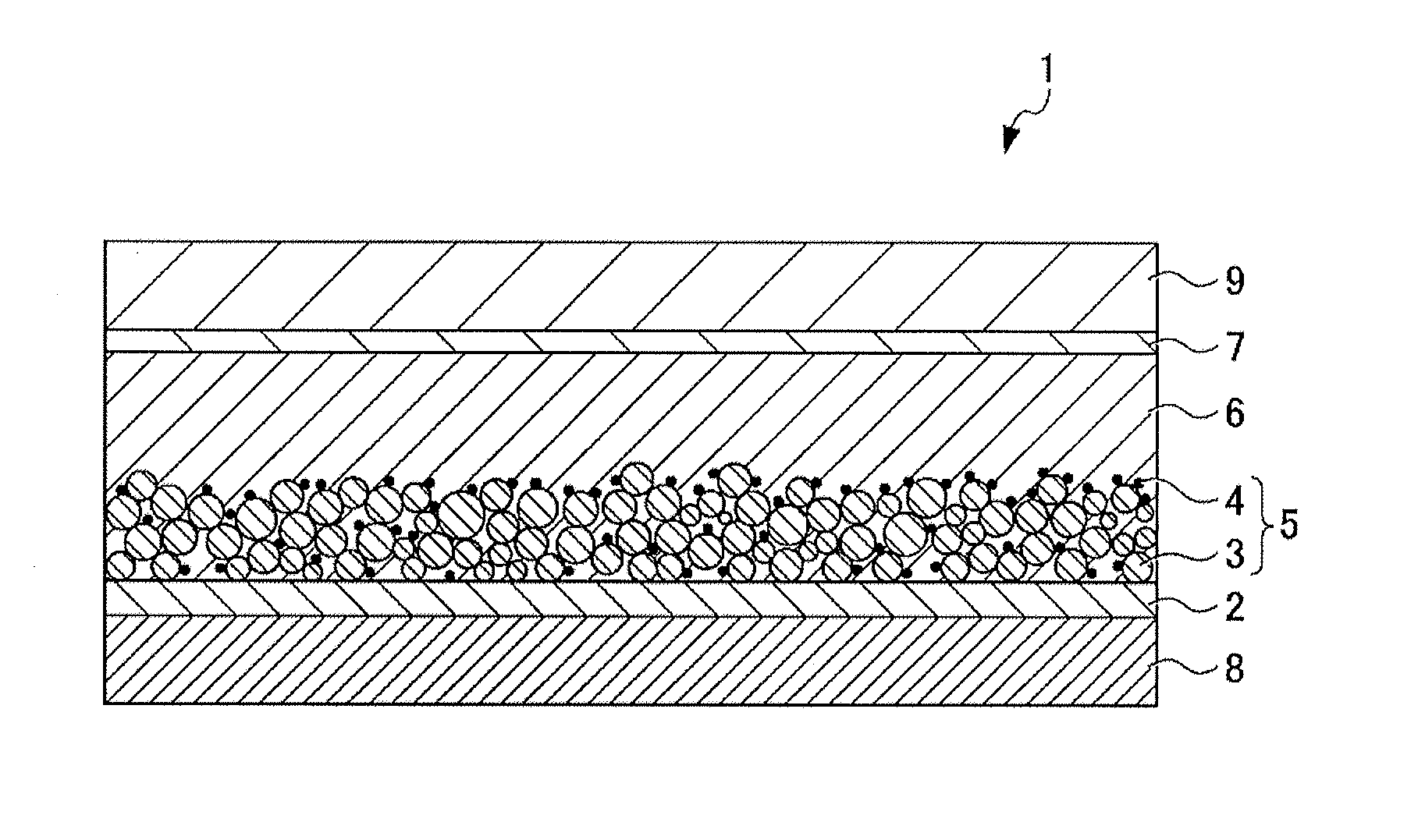

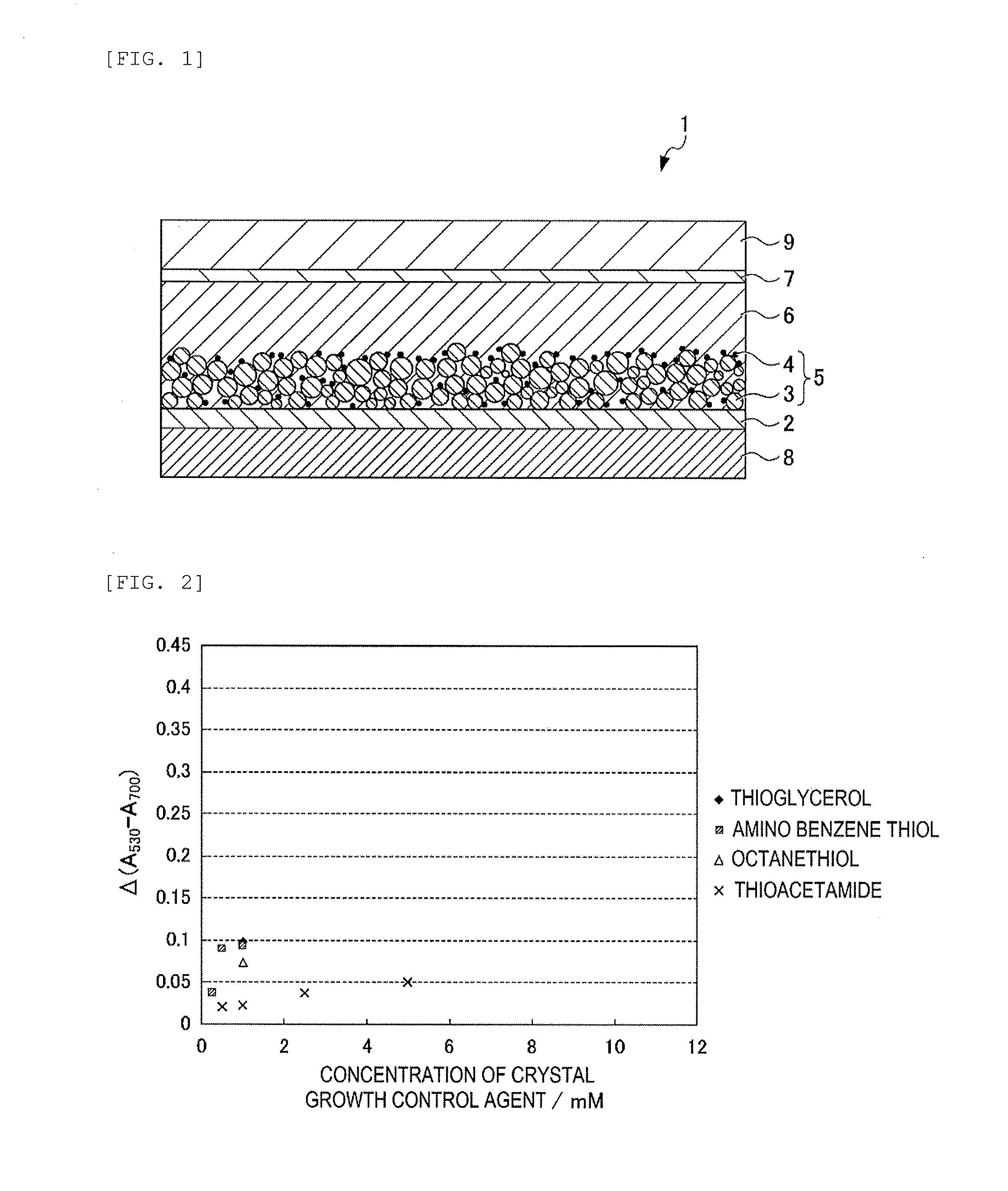

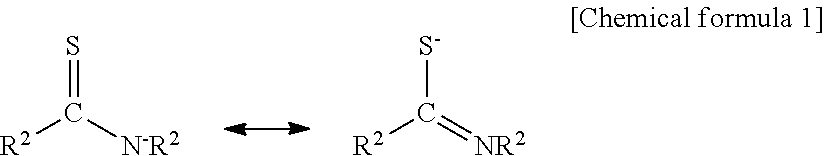

CRYSTAL GROWTH CONTROL AGENT, METHOD FOR FORMING p-TYPE SEMICONDUCTOR MICROPARTICLES OR p-TYPE SEMICONDUCTOR MICROPARTICLE FILM, COMPOSITION FOR FORMING HOLE TRANSPORT LAYER, AND SOLAR CELL

InactiveUS20170018369A1Promote crystallizationLight-sensitive devicesPhotovoltaic energy generationMicroparticleHole transport layer

First, there is provided a crystal growth control agent which is capable of suppressing an increase in a crystal size of a p-type semiconductor, and performing chemical modification on a surface of p-type semiconductor microparticle. Second, there is provided a composition for forming a hole transport layer which is capable of prompting crystallization and fine pulverization of the p-type semiconductor and performing the chemical modification on the surface of the p-type semiconductor microparticle even in the case where an organic salt (an ionic liquid) containing an anion other than the thiocyanate ion is used. According to the present invention, the crystal growth control agent contains at least one of sulfur-containing compounds (except for thiocyanate) selected from the group consisting of a compound, which generates a thiolate anion due to dissociation of a proton or a cation, and a disulfide compound, and controls crystal growth of a p-type semiconductor.

Owner:TOKYO OHKA KOGYO CO LTD

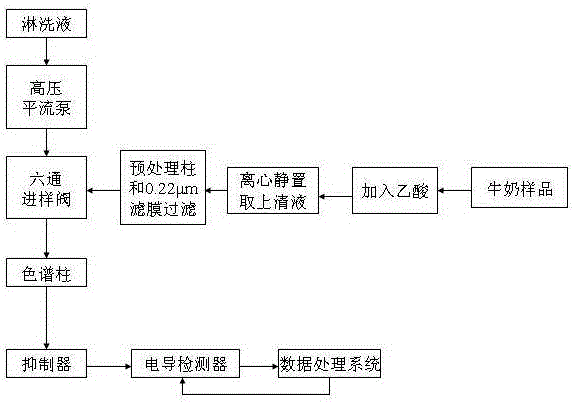

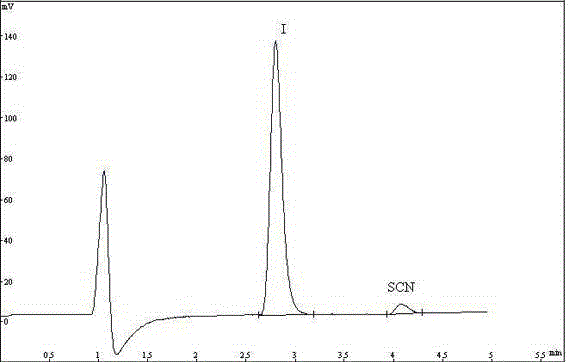

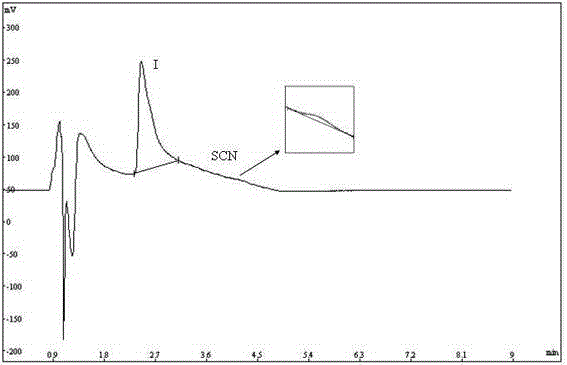

Ion chromatography and voltammetric detection method for quickly determining anions in milk

ActiveCN102749412AShorten detection timeHigh detection sensitivityComponent separationIon chromatographyIon exchange

The invention provides an ion chromatography and voltammetry detection method for quickly detecting anions in milk, which specifically comprises the following step of completing the separation and determination of iodine ions and thiocyanate radical ions within five minutes by using an ion chromatograph with styrene and divinyl benzene copolymer as a filling agent and quaternary amine as an ion exchange functional group, a NaNO3-NaOH elution liquid and a voltammetric detector. The detection repeatability RSD% (n=3) of (I-) and (SCN-) are respectively 1.12% and 1.58%, and the degrees of accuracy (recovery rates) are respectively 98.3% and 93.6%. The separation and determination of (I-) and (SCN-) are completed within five minutes, and the contents are respectively 2.013 mg / L and 0.109 mg / L. The method has high sensitivity and accuracy and short analysis time and can be used for the routine analysis of milk.

Owner:QINGDAO PUREN INSTR

Method for selectively absorbing and separating thiocyanates and thiosulfates in water solution

ActiveCN101857282AEasy to recycleSolve pollutionThiocyanic acidSulfur-trioxide/sulfuric-acidSorbentAbsorption effect

The invention provides a method for selectively absorbing and separating thiocyanates and thiosulfates in water solution. The invention uses the difference absorption effect of the layered bihydroxide mixed metal oxide roasted products (LDO) on the ion absorption quantity of thiosulfate radicals and thiocyanate radicals, the LDO is used as absorbing agents to be placed into the water solution containing thiosulfates and thiosulfates, firstly, the thiosulfates in the solution are absorbed into the LDO, then, the replacement and the purification are carried out, and next, the thiosulfates in the rest solution are separated, so the goal of separating and purifying two salts is reached. The used LDO is obtained through roasting Mg-Al hydrotalcites with the constitutional formula of Mg<1-x>Alx(OH)2(An<->)x / 2.yH2O at 400 to 500 DEG C for 3 to 4 h. The method can be used for treating waste water in the solution containing the thiosulfates and the sulfates for solving the problem of water body and soil pollution by the thiosulfates and the sulfates, and at the same time, the two salts can be perfectly recovered.

Owner:BEIJING UNIV OF CHEM TECH

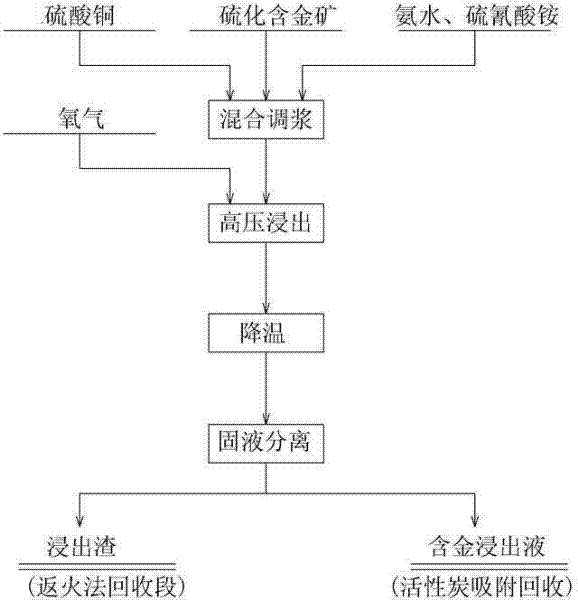

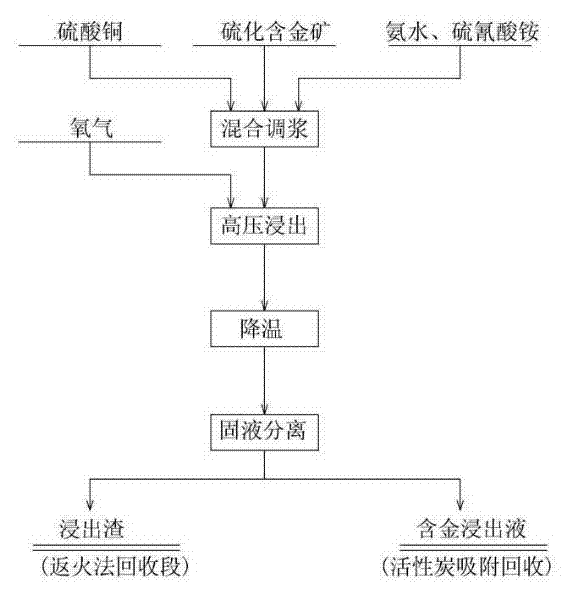

New process for treating vulcanized gold-containing ore

ActiveCN102409171AImprove leaching rateHigh recovery rateProcess efficiency improvementHydrometallurgyMaterials science

The invention relates to a new process for treating vulcanized gold-containing ore and belongs to the field of hydrometallurgy. The process comprises the following steps of: before an experiment, smashing and grinding ore into powder and screening with a 200-mesh sieve; preparing NH4SCN-NH4OH into a leaching aqueous solution, and adding CuSO4; adding the vulcanized gold-containing ore subjected to granulation and screening in a leachate in a proportion of (3-10):1; and continuously introducing oxygen, wherein the temperature is 80-200 DEG C, the oxygen partial pressure is 0.6-2.0MPa, the stirring speed is 300-800r / min, and the reaction time is 1-5 hours. In the oxidation leaching process, the vulcanized ore coated with gold is sufficiently oxidized and decomposed, so that thiocyanate ionscan be well matched with gold ions to enter into a solution, thereby improving the leaching rate and recovery rate of gold; after the leaching process is finished, solid-liquid separation is carried out, thereby realizing the primary separation of metal; and leachate slag is further processed in a back pyrometallurgy recovery section, and the gold-containing leachate is adsorbed by activated carbon and recovered.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Articles having a colored metallic coating and process for their manufacture

InactiveUS6391181B1Duplicating/marking methodsSurface reaction electrolytic coatingZincMetallic coating

An article includes a colored electroplated metallic coating comprising both nickel and zinc, on an underplate of copper, brass, bright nickel or matt nickel, supported on a metallic or plastic substrate, various colors in the electroplated coating being exemplified. The electrolyte contains Ni2+, Zn2+, (NH4)+ and thiocyanate ions in specified concentrations, but no oxidative ion, color variation of the coating being achieved exclusively by variation of current density, time of the electroplating step and current quantity, provided that the current density at the cathode underplate is within the range of 0.01 to 0.5 A / dm2.

Owner:NICKEL RAINBOW LTD

Method for preparing cuprous thiocyanate from coked desulfuration waste liquid

InactiveCN102303875AReduce churnReduce manufacturing costThiocyanic acidSodium thiocyanatePolyacrylamide

The invention discloses a method for preparing cuprous thiocyanate from a coked desulfuration waste liquid. The method comprises the following steps: adding 20-60 kg of activated carbon to 1000 kg of coked desulfuration waste liquid, heating to 80-130 DEG C, keeping stirring for 1-3 hours, and then filtering; adding a copper salt the molar of which is equal to that of thiocyanic acid radical ion to filtrate; and keeping stirring and reacting for 1-3 hours at the temperature of 30-60 DEG C in the SO2 or CO2 atmosphere, adding polyacrylamide (PAM) the mass of which is 0.01% that of cuprous thiocyanate in a reaction liquid and stirring for 8-12 minutes at the stirring speed of 100-500 r / min, filtering, washing 1-3 times with 5wt% sodium hydrogen sulfite hot water, and drying so as to obtain cuprous thiocyanate. By using the method disclosed by the invention, the high-purity cuprous thiocyanate or sodium thiocyanate product is prepared, thus the method has the advantages of low production cost and good environmental protection benefits, social benefits and economic benefits.

Owner:陈琳

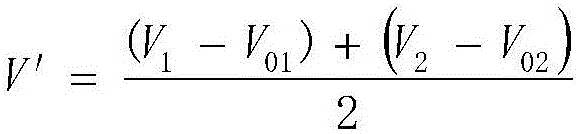

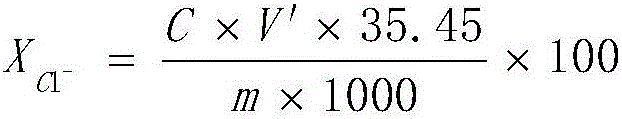

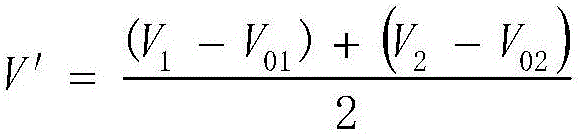

Method for measuring chloride ions in polycarboxylate superplasticizer

ActiveCN106248862AEliminate distractionsImprove accuracyChemical analysis using titrationComponent separationIon chromatographySuperplasticizer

The invention provides a method for measuring chloride ions in a polycarboxylate superplasticizer. The method comprises the following steps: decomposing thiocyanate radicals by using hydrogen peroxide under alkaline conditions, acidifying a test solution, and then measuring the chloride ions by using potentiometric titration, wherein the main reaction equation is as follows: SCN<->+4H2O2+2OH<->=SO4<2->+OCN<->+5H2O; AgCl<+>+AgCl<->=AgCl. By adoption of the method, the interference of the thiocyanate radicals is effectively eliminated, the accuracy of the method is improved, and thus the method has the advantages of small errors and high precision; and compared with the ion chromatography in the GB / T8077-2012, the method has a great advantage of equipment cost, thereby being easier to promote and use.

Owner:安徽海螺材料科技股份有限公司 +1

Electroplating bath, method for manufacturing plated product, and plated product

InactiveUS20190301038A1Reduce colorChromatisationLiquid/solution decomposition chemical coatingElectroplatingThiocyanate ion

An electroplating bath is configured to precipitate a black trivalent chromium layer onto an object to be plated. The electroplating bath includes a nanodiamond and a thiocyanate ion as color enhancers.

Owner:TOYODA GOSEI CO LTD

Method for quickly detecting thiocyanate in liquid milk and detection test paper thereof

InactiveCN101825575ASimple preparation processLow costMaterial analysis by observing effect on chemical indicatorLiquid statePaper based

The invention relates to quick detection test paper for thiocyanate and a preparation method thereof, in particular to quick detection test paper for thiocyanate in liquid milk and a preparation method thereof, which mainly solve the problems of high detection cost, low detection efficiency and long detection period when the thiocyanate content of the liquid milk is detected in the prior art. The method mainly comprises the following steps of: A, preparing the test paper; B, preparing a standard contrast; C, performing detection; and D, judging a result. The test paper is prepared mainly based on the principle that thiocyanate [SCN] is reacted with Fe3+ to generate sanguine [Fe(NCS)(H2O)5]2+ with color difference according to different concentrations. The test paper comprises a test paper base body and detection layers which are arranged on positive and negative surfaces of the test paper base body respectively and contain trivalent iron ions.

Owner:陕西出入境检验检疫局检验检疫技术中心

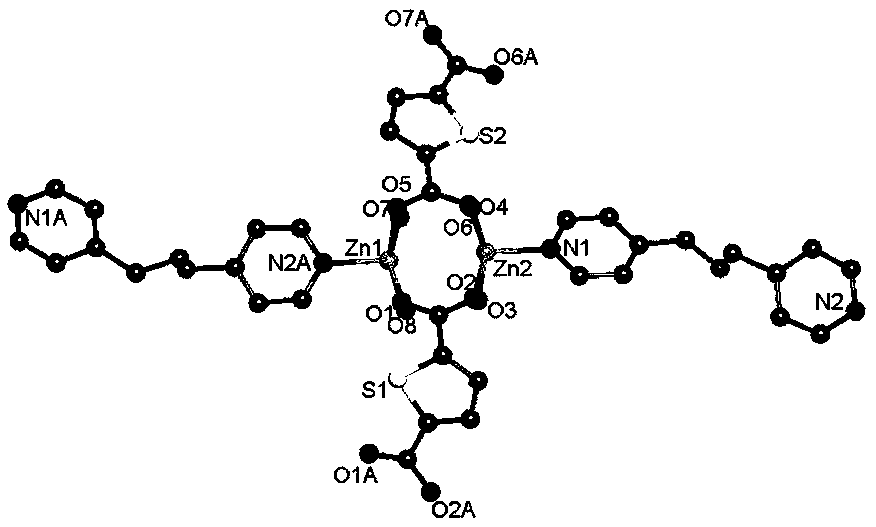

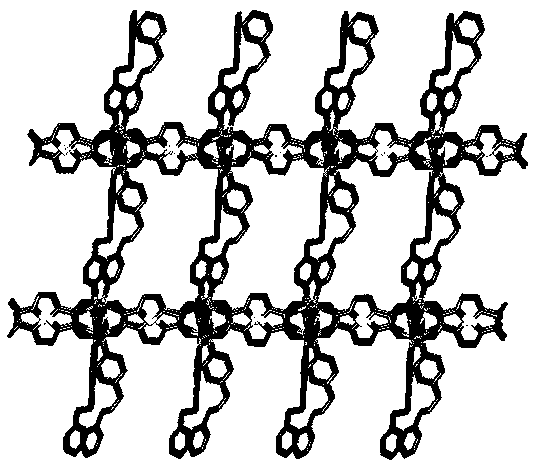

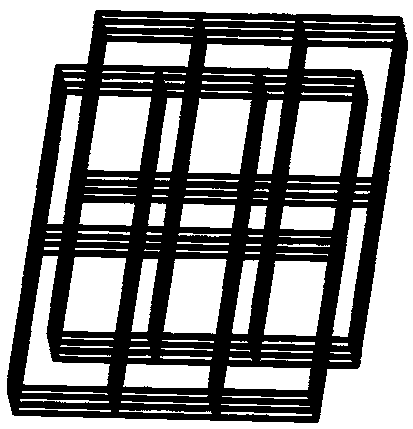

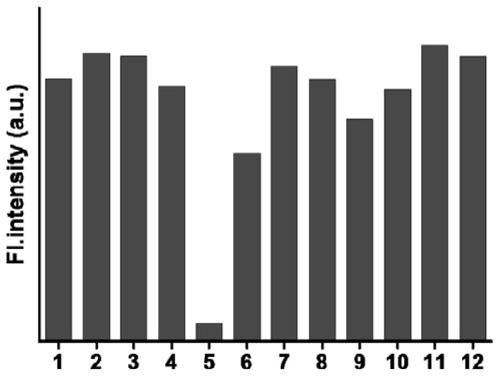

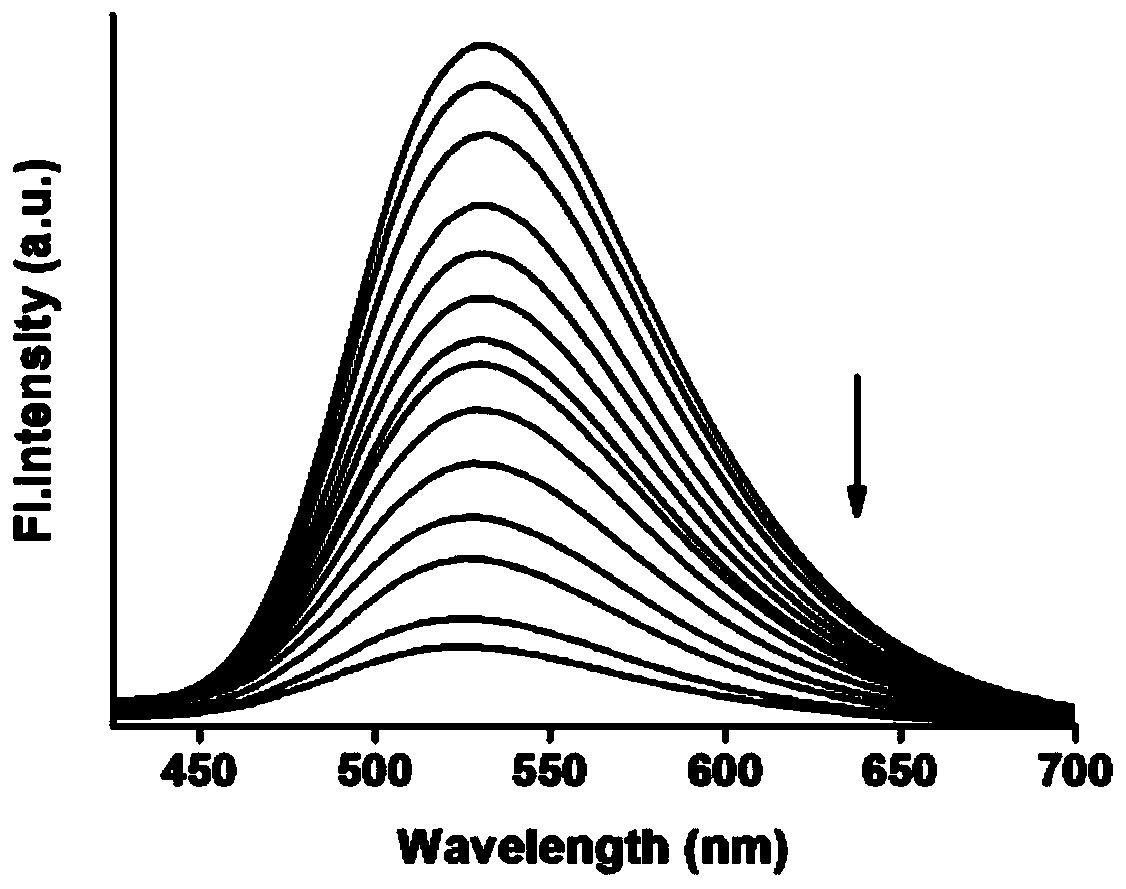

Luminescent metal organic framework material for detecting thiocyanate ions in water and preparation method and application of luminescent metal organic framework material

ActiveCN108587607AAchieving identifiabilityEasy to detectFluorescence/phosphorescenceLuminescent compositionsMetal-organic frameworkCarboxylic acid

The invention relates to a luminescent metal organic framework material for detecting thiocyanate ions in water and a preparation method and application of the luminescent metal organic framework material. The chemical formula of the metal organic framework material is {Zn2(tdc)(bpp)2}n, wherein tdc is polyacid ligand 2,5 thiophene dicarboxylic acid with a V-shaped framework, and bpp is linear nitrogen-containing auxiliary ligand 1,3-di(4-pyridyl)propane. The novel luminescent metal organic framework material which is a compound has the advantages that the compound is prepared by a solvothermal method and has a three-dimensional two-fold penetration structure; the prepared compound is good in thermal stability, high in fluorescence intensity and capable of emitting clear pure-blue light; the fluorescence intensity of the compound gradually weakens along with the increasing of the concentration of the thiocyanate ions, and accordingly the compound can be used as the fluorescent probe for fast and selectively detecting the thiocyanate ions. The preparation method is simple in process, easy to implement and high in crystal purity and yield. A detection method using the compound is simple and high in selectivity.

Owner:SHAANXI UNIV OF SCI & TECH

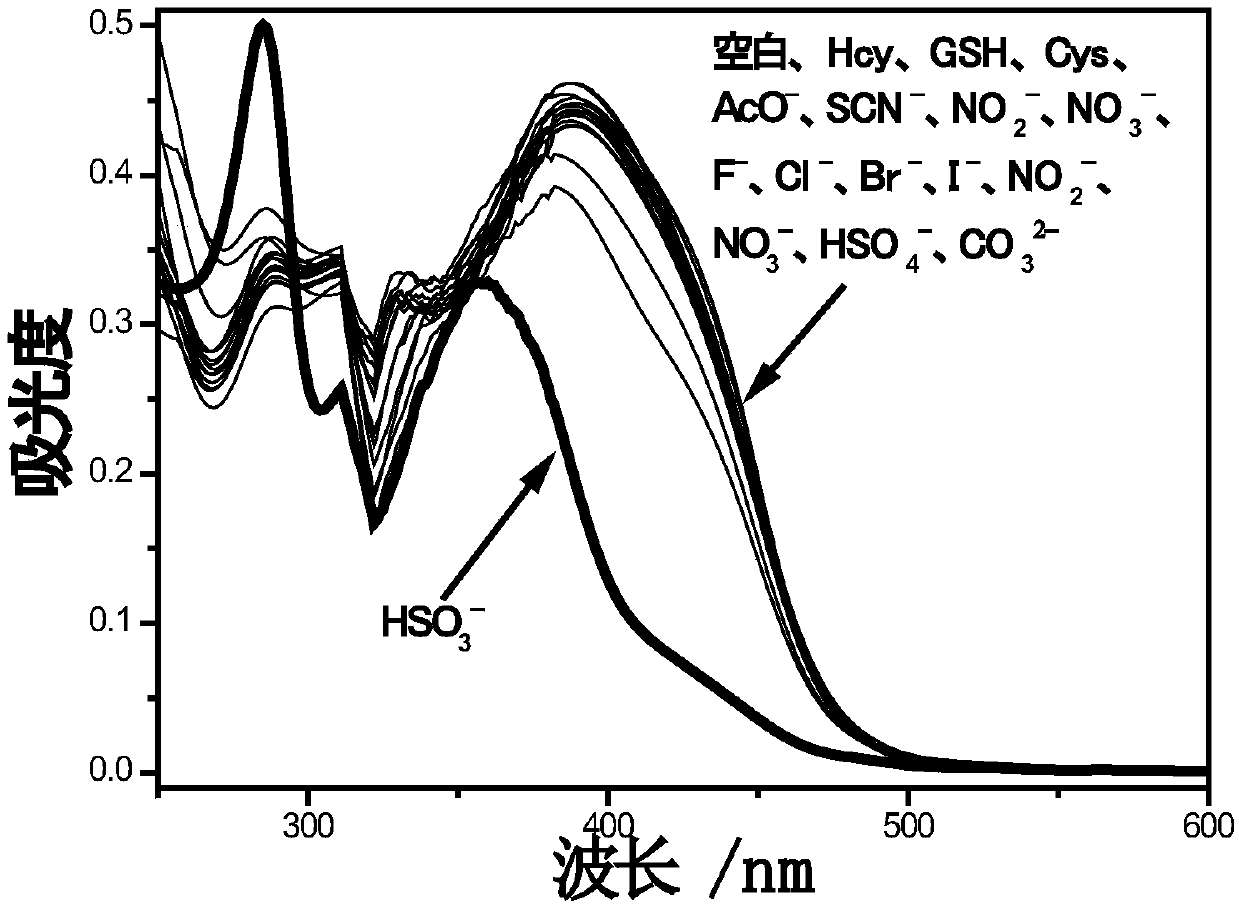

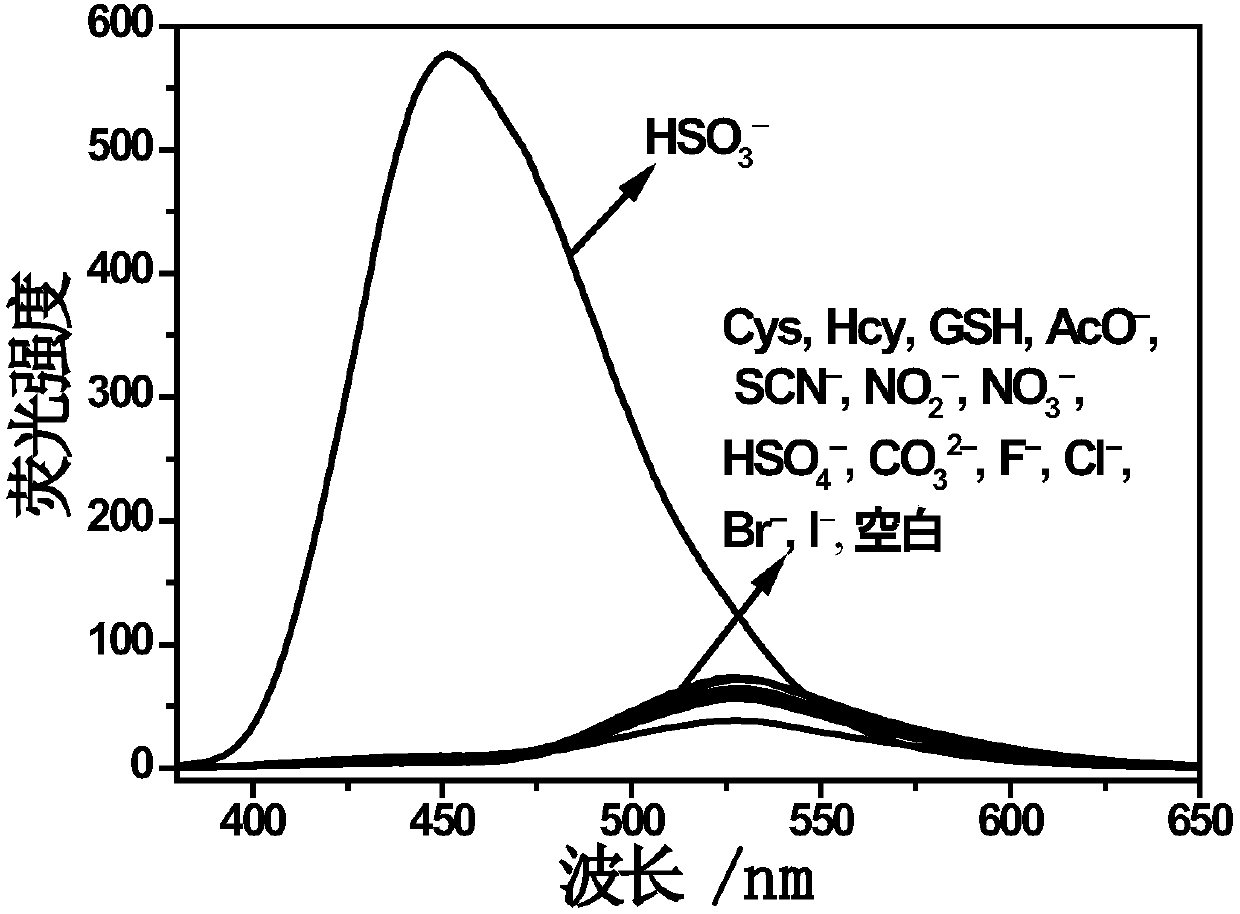

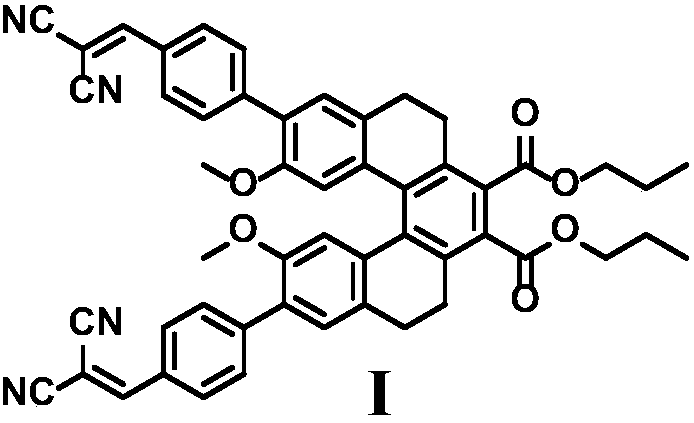

Fluorescence probe for detecting bisulfite and preparation and application

InactiveCN107760298AEasy to synthesizeHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationNitrite ionCysteine thiolate

The invention discloses a fluorescence probe for detecting bisulfate and a preparation method and application of the fluorescence probe for detecting the bisulfate. The molecular formula of the probeis C52H42N4O6, and the structural formula of the probe is as shown in the following formula. The fluorescence probe I prepared by the invention is simple and convenient in synthesis, high in yield andeasy to prepare, and suitable for amplification synthesis and practical production application. The fluorescence probe can use an ultraviolet-visible method and a fluorescence method to detect bisulfite ions, is good in selectivity, fast in detection, and suitable for naked eye detection, and not interfered by anions of acetate ions, thiocyanate ions, nitrite ions, nitrate ions, hydrogensulfate ions, carbonate ions, fluoride ions, chloride ions, bromide ions, iodide ions, cysteine, homocysteine, glutathione and biological mercaptan, can be applied to the field of ion detection as a new probeand has broad application prospects.

Owner:QINGDAO UNIV OF SCI & TECH

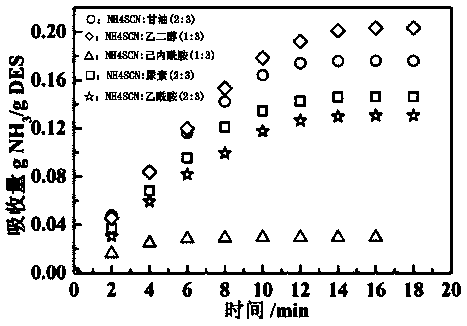

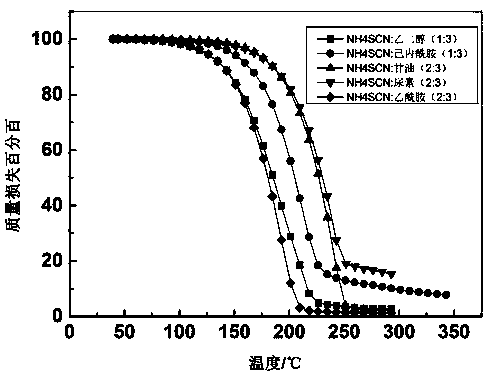

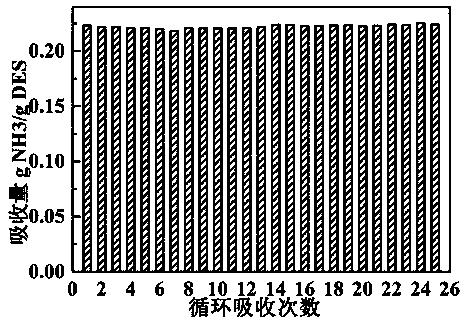

Ammonium thiocyanate base deep-eutectic solvent for absorbing ammonia gas and method for adsorbing same

ActiveCN109260896AFast absorption rateImprove performanceGas treatmentDispersed particle separationGlycerolCaprolactam

The invention discloses an ammonium thiocyanate base deep-eutectic solvent for absorbing ammonia gas and a method for adsorbing the same. The ammonium thiocyanate base deep-eutectic solvent comprisesa hydrogen bond receptor and a hydrogen bond donor. The hydrogen bond receptor is ammonium thiocyanate, and the hydrogen bond donor is a mixtures of more than one or two types of glycerin, 1, 3-propylene glycol, ethylene glycol, ethylene glycol condensation compounds, urea, acetamide and caprolactam. The ammonium thiocyanate base deep-eutectic solvent and the method have the advantages that the ammonium thiocyanate base deep-eutectic solvent is used as an absorbent, and the NH3 absorption capacity can be jointly enhanced mainly under strong interaction between acidic protons on ammonium base cations and NH3 and synergistic effects of thiocyanate ions, hydroxyl on the hydrogen bond donor and the NH3.

Owner:ZHEJIANG UNIV OF TECH

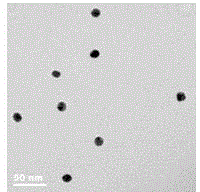

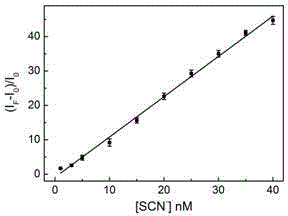

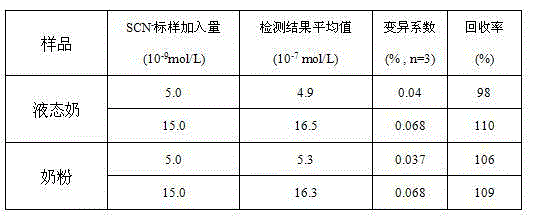

Method for detecting thiocyanate ion based on fluorescence resonance energy transfer

InactiveCN104316501AEasy to detectQuick checkFluorescence/phosphorescenceEnergy transferCompetitive binding

The invention discloses a method for detecting thiocyanate ion in milk based on fluorescence resonance energy transfer. The method comprises the following steps: preparing gold nano solution gel; synthesizing a fluorescein-gold nano complex; detecting the thiocyanate ion and detecting the actual sample. According to the method, the thiocyanate ion is quantitatively detected through fluorescence recovery of a gold nano-fluorescein system caused by competitive binding of the thiocyanate and fluorescein on the surface of the gold nano, the total detection time used by the provided detection method is less than 30 minutes, the thiocyanate ion in the milk can be simply, rapidly and sensitively detected, the method has extremely high sensitivity, the detection limit is 0.09nM, and convenience is provided for research, production and supervision in the future.

Owner:NANCHANG UNIV

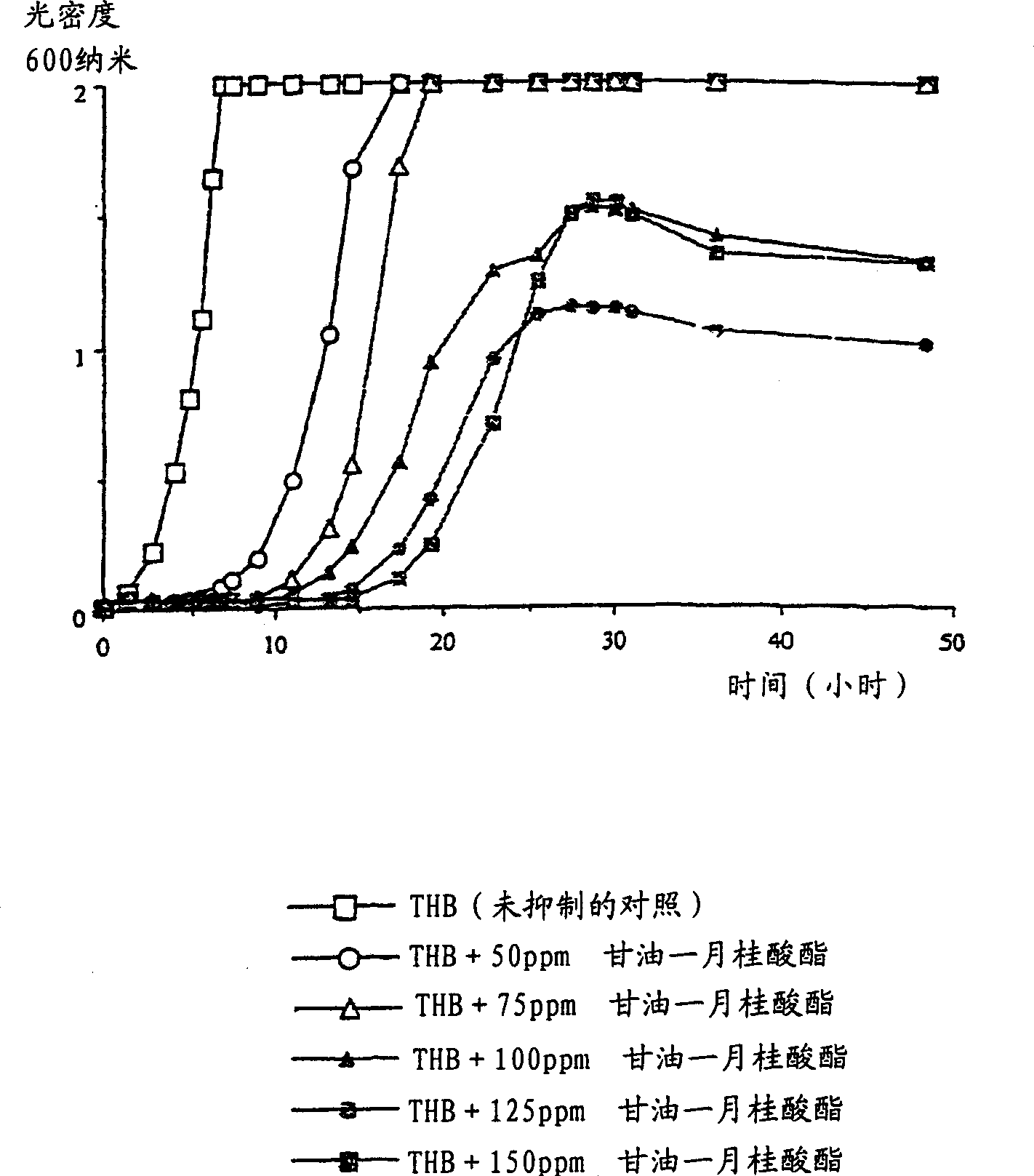

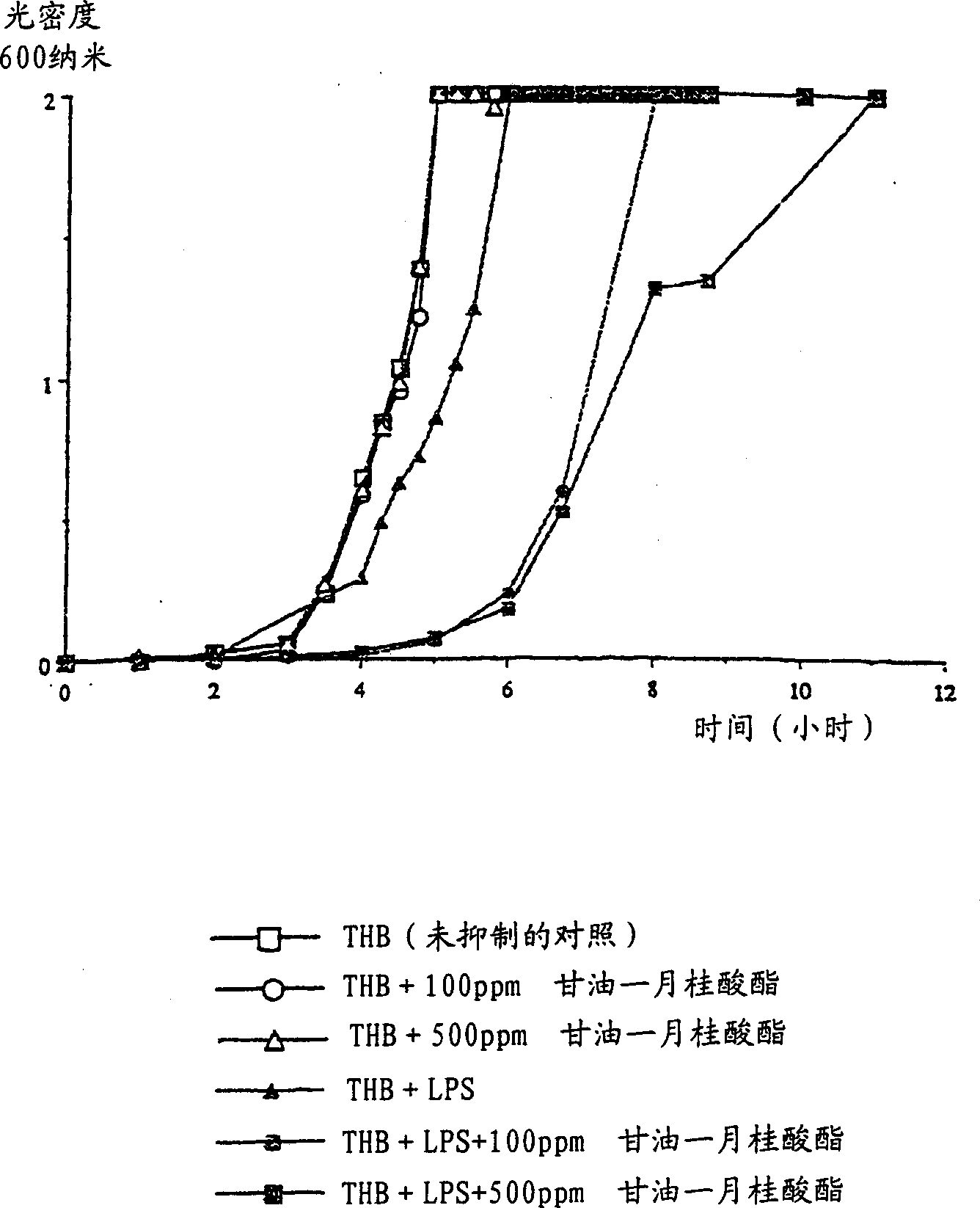

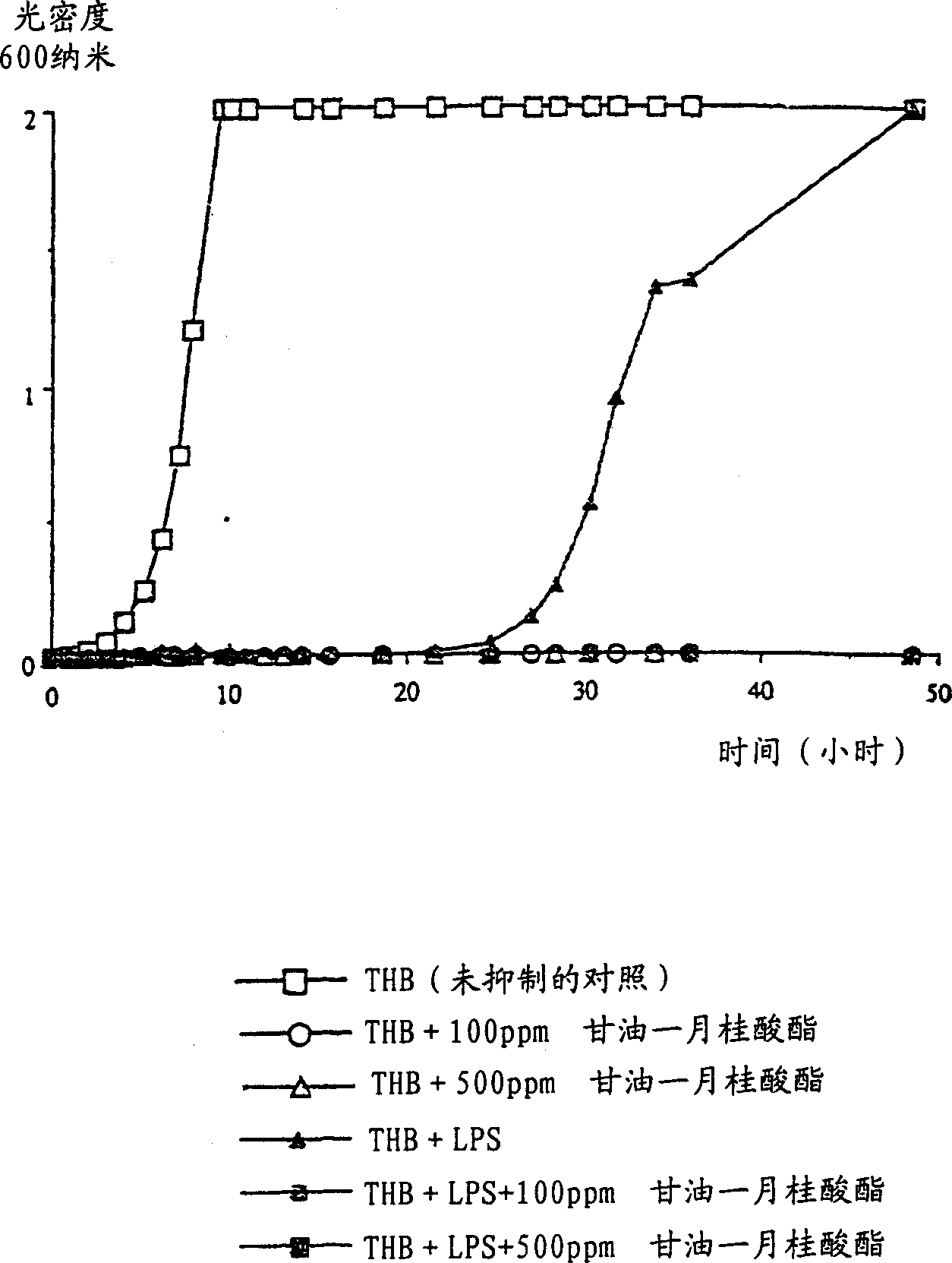

Microbially resistant compositions

Peroxidase systems such as the Lactoperoxidase system (LPS) are combined with antimicrobial fatty acids or fatty acid derivatives to produce a synergistic antimicrobial composition. These compositions are disclosed as being useful for rendering surfaces, and also products such as food or cosmetics, resistant to microbes. A preferred form of the composition contains lactoperoxidase, monolaurin or sodium dodecyl sulphate, a source of peroxide, and thiocyanate ions.

Owner:UNIVERSITY OF OTAGO +1

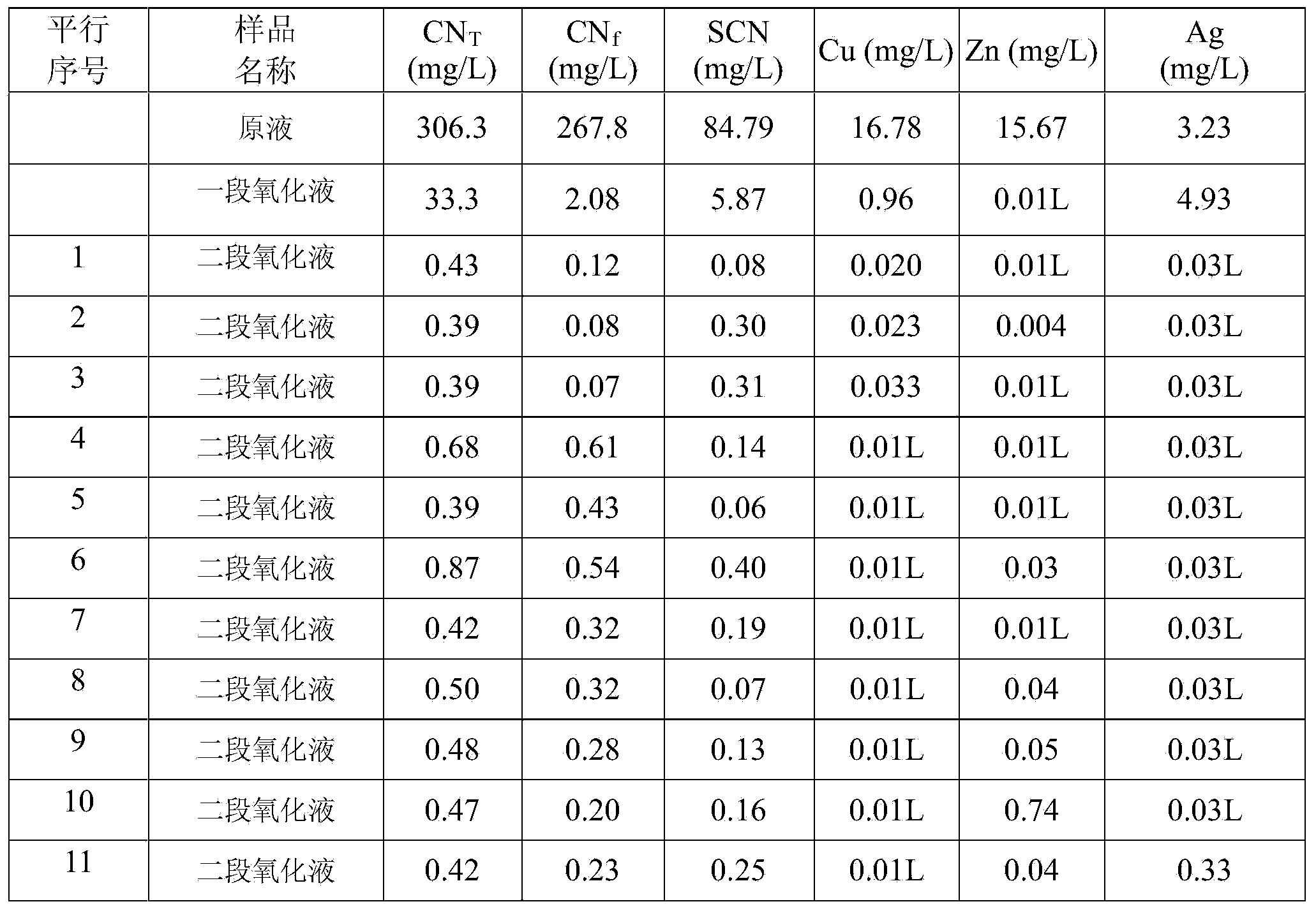

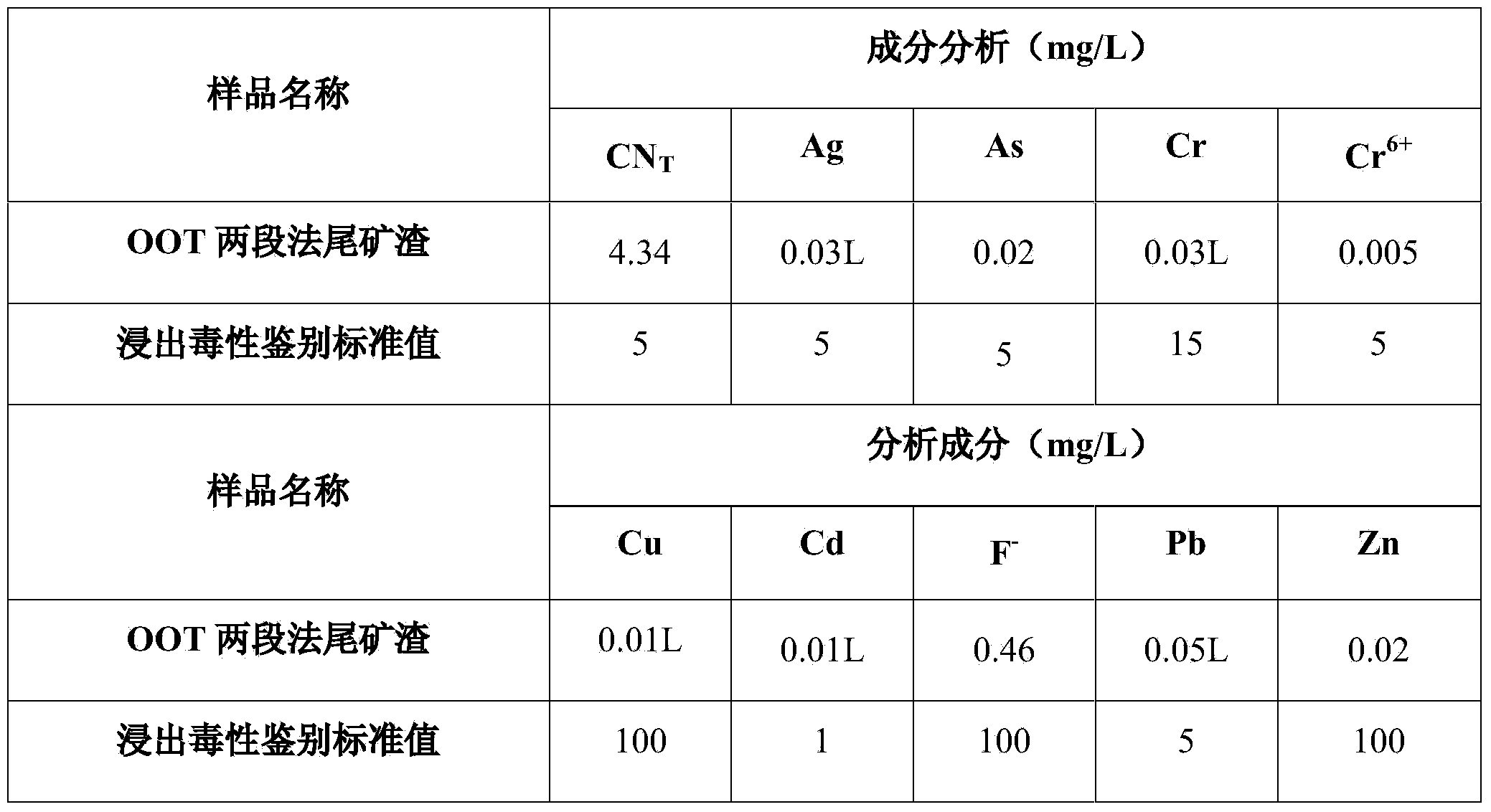

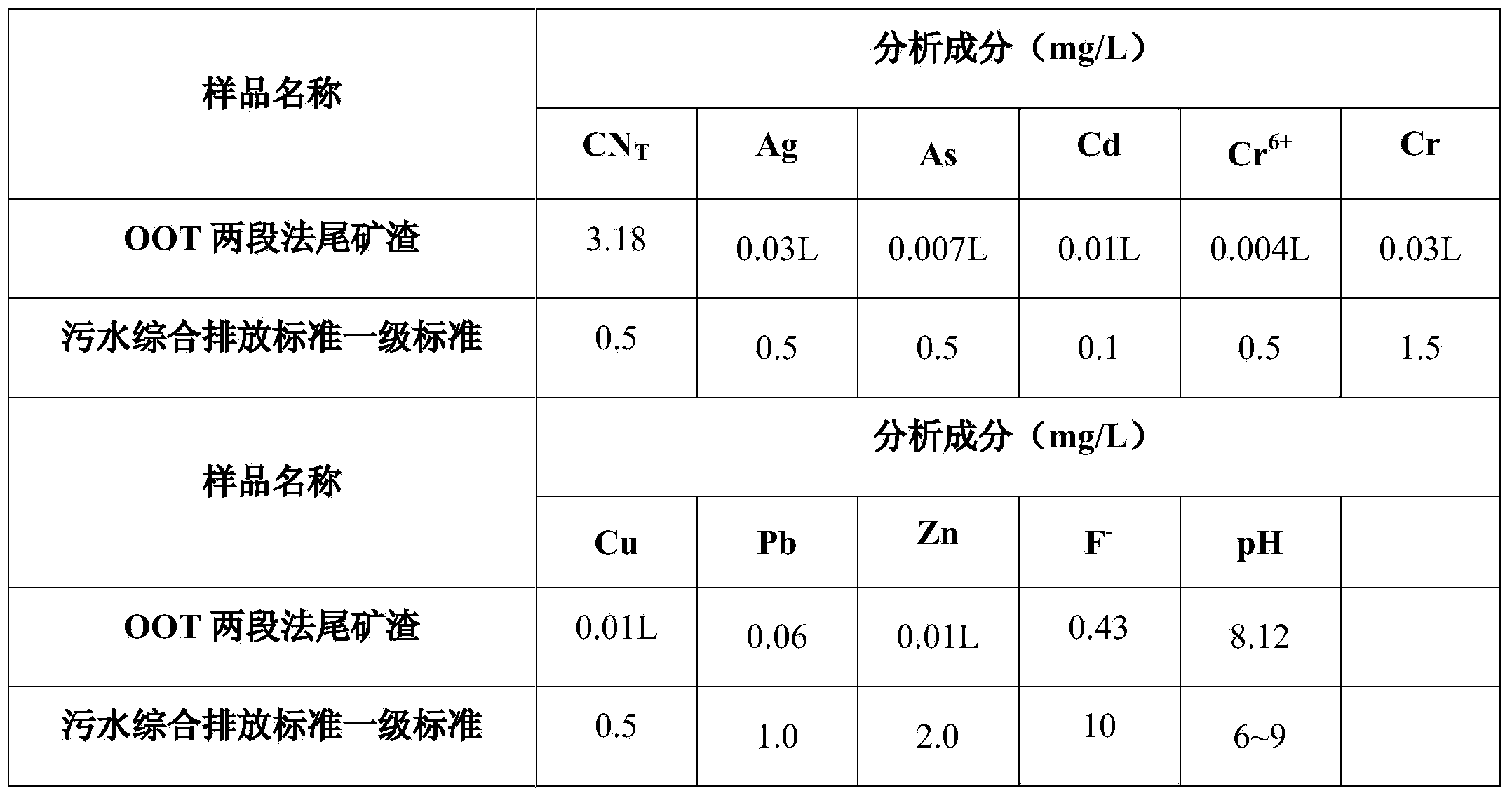

Two-section innocent treatment technology for cyanogens-containing tailing pulp

InactiveCN103523965AReduce loadWith auxiliary oxidationMultistage water/sewage treatmentWater/sewage treatment by neutralisationHigh concentrationOxidative treatment

The invention discloses a two-section innocent treatment technology for cyanogens-containing tailing pulp. The technology comprises a pulp concentration step and an oxidization step, wherein in the pulp concentration step, thickening equipment is used for improving the concentration of the pulp to 50-55 percent; thickened supernate is returned to a site selection technology; high-concentration pulp enters the next treatment procedure; a thickening theory is that solid-liquid separation is performed through gravity sedimentation; in the oxidization step, oxidization is divided into two stages by an OOT oxidization method; in the first stage, sulfuric acid is added to control the pH of the pulp to be 9 to 10, and most releasable cyanides, thiocyanate ions and reductive substances can be removed through oxidization, so that the concentration of the releasable cyanides is smaller than 30 mg / L, and the concentration of the thiocyanate ions is smaller than 10 mg / L; in the second stage, the sulfuric acid is added to adjust the pH of the pulp to be 7 to 8; active carbon is fed in the second oxidization stage to enhance the oxidization effect; due to the adsorption effect of the carbon, gold in part of the tailing pulp can be recycled.

Owner:CHANGCHUN GOLD RES INST

Dark Colored Chromium Based Electrodeposits

An aqueous acidic trivalent chromium electrolyte comprising trivalent chromium ions and a complexing agent for maintaining the trivalent chromium ions in solution is provided in which the aqueous electrolyte comprises additives capable of producing a coating on a substrate having a desired dark hue. The additives typically comprise a dispersion of colloidal silica and an additional additive selected from thiocyanate ions and / or iron ions. The electrolyte is used in a method of producing the desired dark-hued decorative chromium coating on a substrate by electrodeposition.

Owner:MACDERMID ACUMEN INC

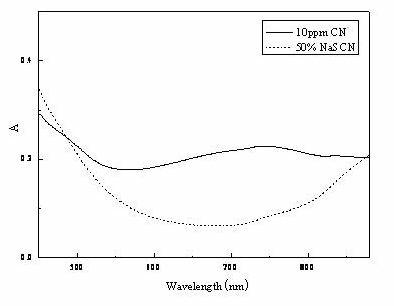

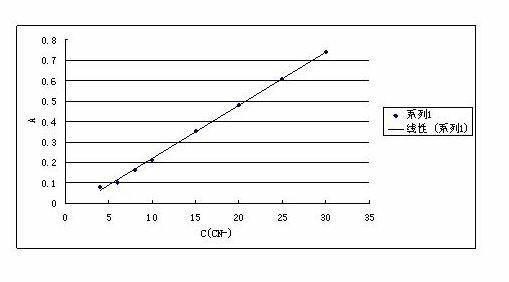

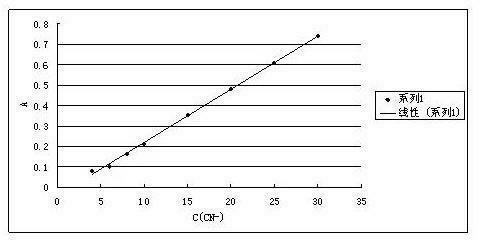

Determination method of cyanogen in thiocyanate

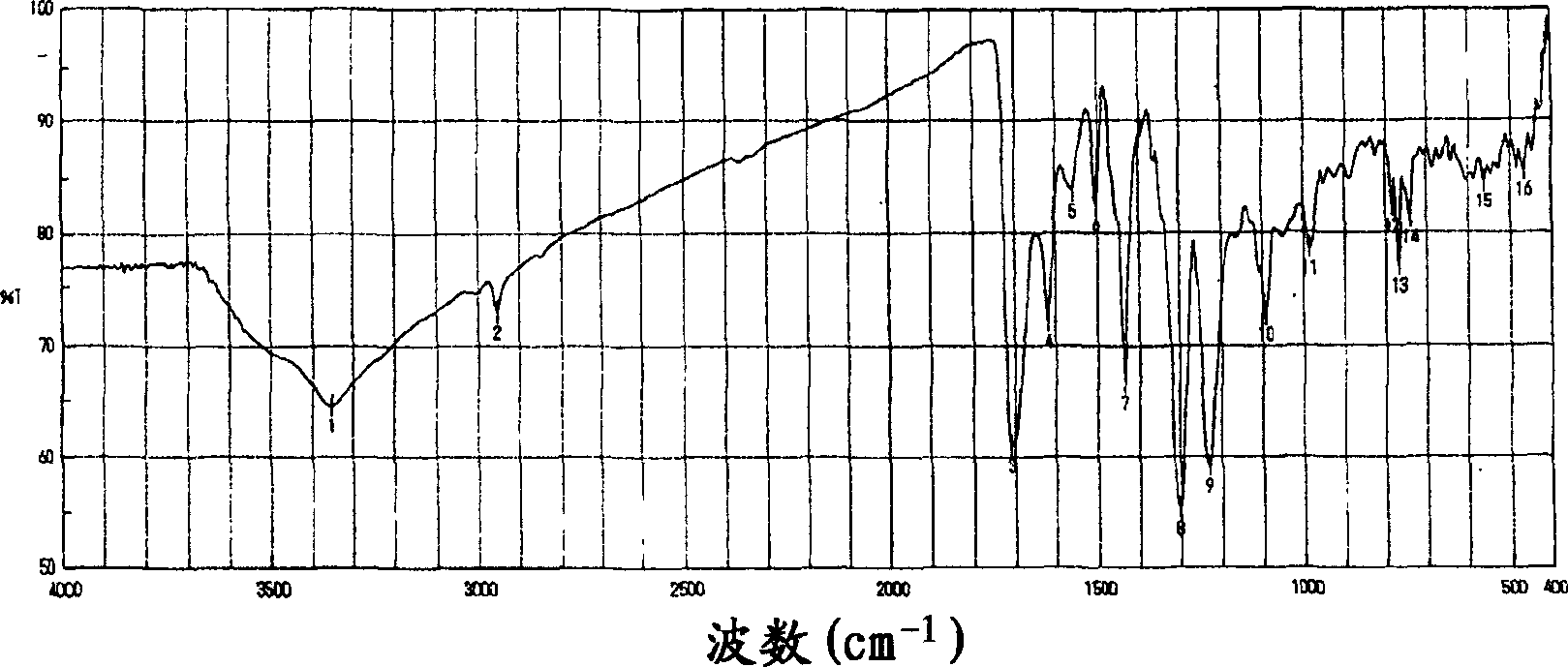

ActiveCN102539352AAvoid interferenceThe measurement results are accurate and reliableColor/spectral properties measurementsSodium thiocyanateRelative standard deviation

The invention discloses a determination method of cyanogen in thiocyanate, belonging to the field of chemical analysis. The method is characterized by adding a ferrous sulfate saturated solution in a thiocyanate solution to convert cyanogen into Prussian blue for coloration, and determining the absorbance of the Prussian blue at the wavelength of 700nm, wherein thiocyanate ions are nearly not absorbed within the wavelength range under the same processing condition, and the interference of thiocyanate is avoided. Through the method, favorable linearity is formed within the cyanogen content range of 4-30ppm, the linear regression equation is obtained as follows: Y=0.0261X-0.0433, and the related coefficient r is 0.9993. According to the method, under the existence of sodium thiocyanate withthe concentration of 50%, the relative standard deviation is 2.03%, the standard recovery rate is 98.8%-105.7%, and the minimum quantitative detection limit is 2.04ppm. The method is simple, is high in flexibility, is good in stability, and is low in detection expense, and the used reagents are safe and non-toxic.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Dark Colored Chromium Based Electrodeposits

An aqueous acidic trivalent chromium electrolyte comprising trivalent chromium ions and a complexing agent for maintaining the trivalent chromium ions in solution is provided in which the aqueous electrolyte comprises additives capable of producing a coating on a substrate having a desired dark hue. The additives typically comprise a dispersion of colloidal silica and an additional additive selected from thiocyanate ions and / or iron ions. The electrolyte is used in a method of producing the desired dark-hued decorative chromium coating on a substrate by electrodeposition.

Owner:MACDERMID INC

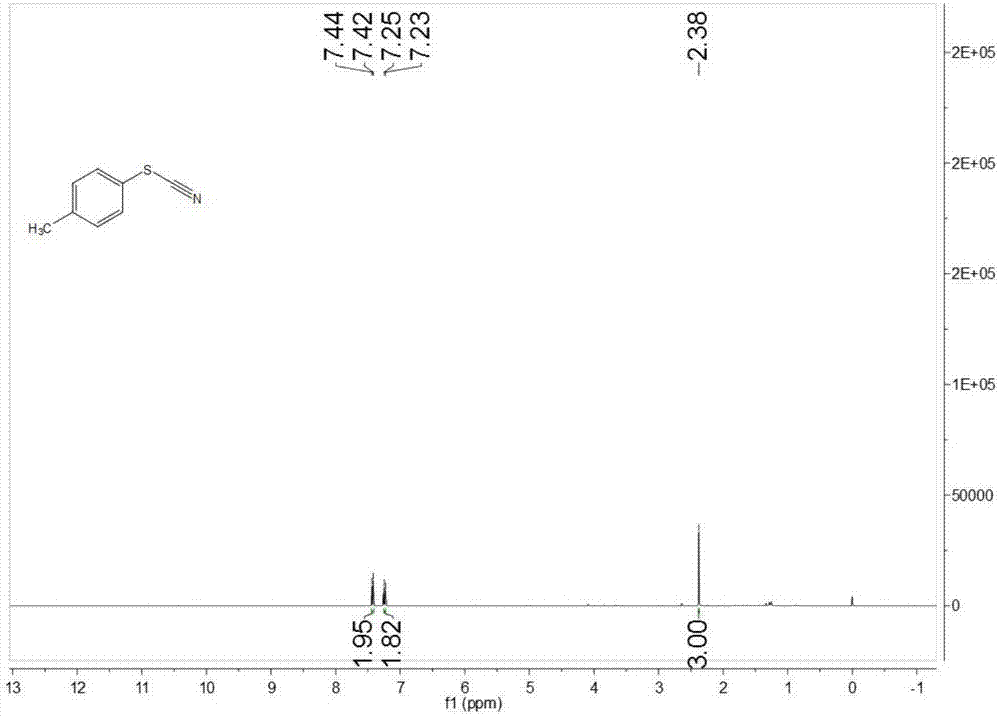

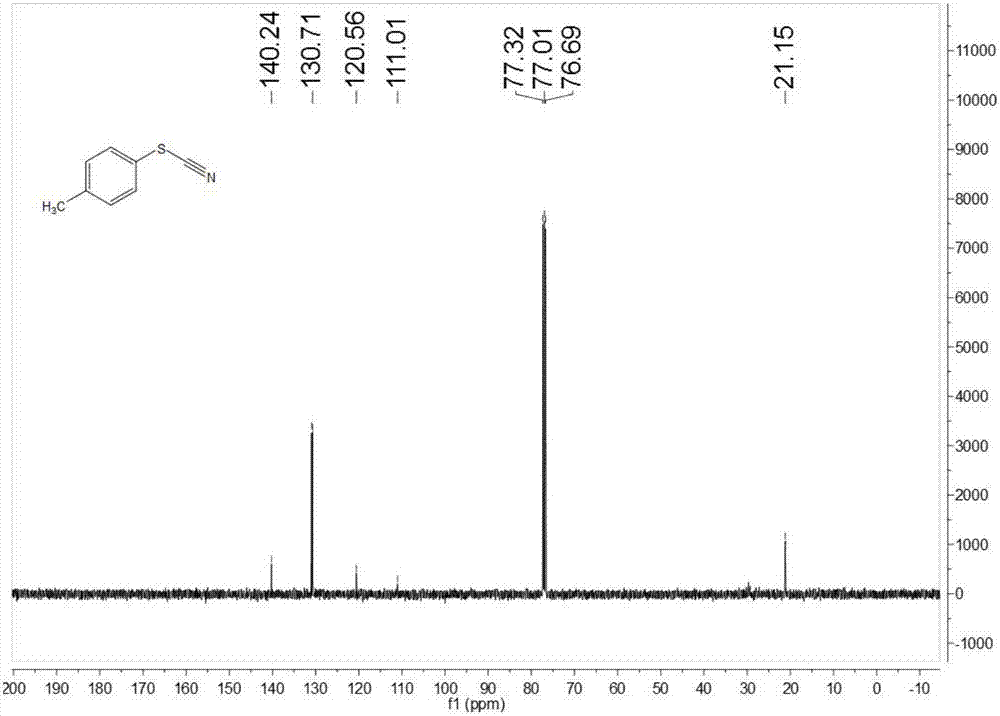

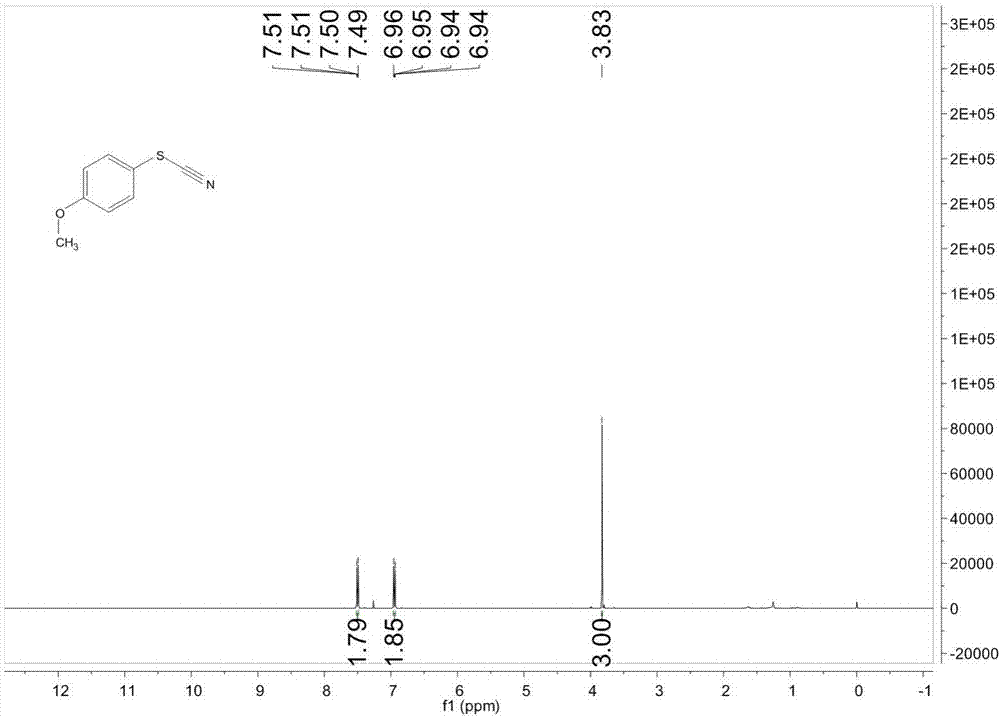

Preparation method for thiocyanide compound

ActiveCN108002969AActivity performance impactHigh purityFunctional group formation/introductionRose bengalHydroxyl radical

The invention discloses a preparation method for a thiocyanide compound. The preparation method comprises the following steps: taking a sulfhydryl compound, thiocyanate as raw materials, taking rose-bengal, eosine Y or eosin B as a catalyst, performing illumination, generating a thiocyanide compound after the illumination reaction. According to the preparation method provided by the invention, thiocyanide is decomposed into thiocyanate ions; the sulfhydryl compound generates sulfhydryl radical under the action of light and the catalyst, and the sulfhydryl radical is used for attacking carbon atoms in thiocyanate ions to obtain a intermediate; sulfide is removed from the intermediate to obtain the thiocyanide compound. The rose-bengal, the eosine Y or the eosin B used by the method containno heavy metal ion, and the adverse effect on the performance of the thiocyanide compound by the heavy metal ion residue is avoided; in addition, the catalyst is easily removed, so that a favorable condition is provided for the preparation of the thiocyanide compound with higher purity.

Owner:GANNAN NORMAL UNIV

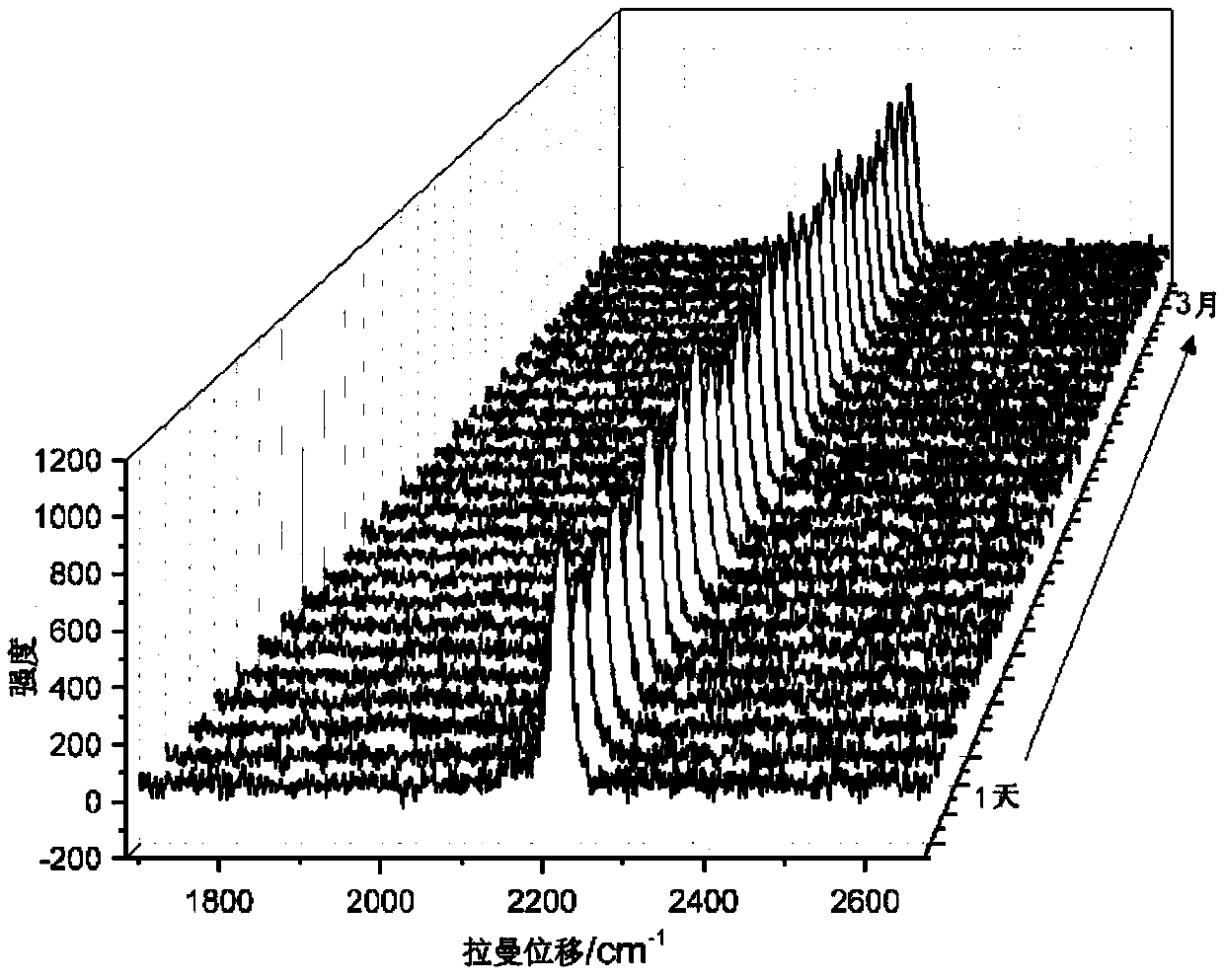

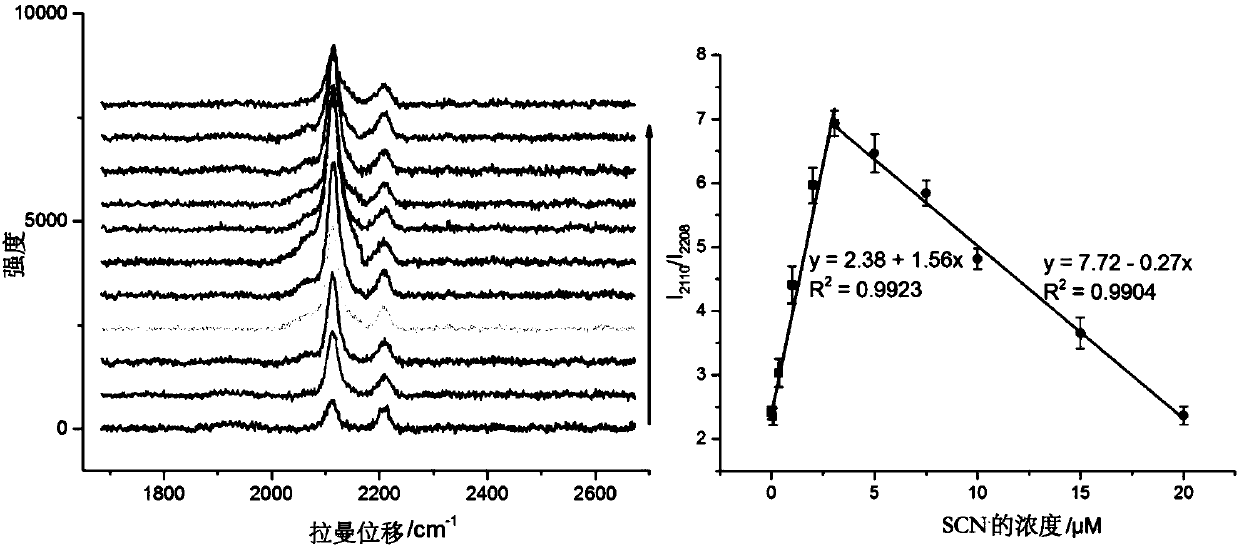

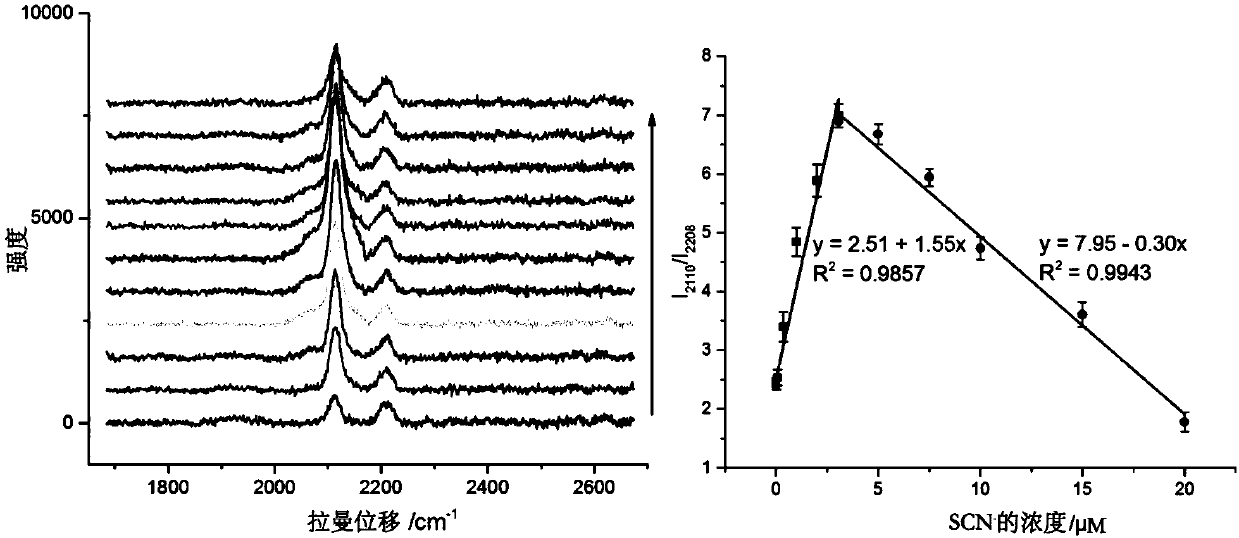

Novel method for determining thiocyanate ion content of actual sample

ActiveCN108037108AAvoid interferenceGood optical stabilityRaman scatteringSignalling moleculesUltimate tensile strength

The invention discloses a novel method for determining the thiocyanate ion content of an actual sample. The method comprises the following steps: using a signal molecule with the Raman scattering peakof 2208 cm<-1> wave number, selecting gold with appropriate size as a reinforcement substrate of a Raman signal, self-assembling the signal molecule onto the surface of the reinforcement substrate, and then selecting silver with a relatively good SERS effect as an enveloping shell layer for probe encapsulation; comparing the characteristic peak intensity of thiocyanate ions at 2110 cm<-1> with the characteristic peak intensity of the signal molecule at 2208 cm<-1>, and drawing a standard working curve according to the molar concentration and the peak intensity ratio of the thiocyanate ions; mixing an SERS nanoprobe and a solution to be detected, standing for 5 minutes, adding CTAB into the mixed solution after the solution to be detected and the SERS nanoprobe are dispersed in a balancedway, measuring the characteristic peak intensity ratio of the thiocyanate to the signal molecule by using a Raman spectrometer 5 minutes later, and substituting the intensity ratio into the drawn standard working curve to determine the thiocyanate content of the actual sample.

Owner:WUHAN UNIV

Preparation method of organic modified bentonite for adsorbing thiocyanate ions

InactiveCN104028212ALow costHigh adsorption rateOther chemical processesWater/sewage treatment by sorptionSodium BentoniteSlag

The invention discloses a preparation method of organic modified bentonite for adsorbing thiocyanate ions. According to the technical scheme, the organic modified bentonite comprises 50-70 percent of sodium bentonite, 20-38 percent of hexadecyl trimethyl ammonium bromide and 1-16 percent of tetramethyl ammonium chloride. The preparation method comprises the following steps: weighing hexadecyl trimethyl ammonium bromide and tetramethylammonium chloride according to a formula ratio and dissolving in 200 ml of distilled water, and stirring at a temperature of 16 DEG C for 30min to prepare a solution A; weighing sodium bentonite according to the formula ratio and adding sodium bentonite in the solution A, and continuing stirring at a rotating speed of 160 r / min for 1 h to prepare a solution B; and filtering the solution B, then repeatedly washing the obtained filter slag by using the distilled water until no bromide ion or chorine ion exists, performing vacuum filtration to obtain a filter cake, drying the filter cake at a temperature of 75 DEG C for 24 h, and grinding the obtained solid into powder with a particle size of not more than 100 microns. The preparation method has the following beneficial effects that the bentonite which is abundant in the nature is used as a raw material and is low in cost, and the bentonite which is organically modified can be widely applied to the adsorption and the treatment of toxic inorganic matters in industrial wastewater such as electroplating, coking, metal smelting, pesticide and dyeing.

Owner:JIANGSU WAN QI BIOLOGICAL TECH

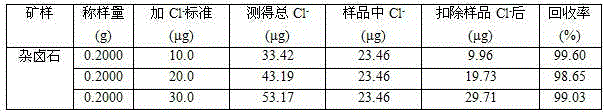

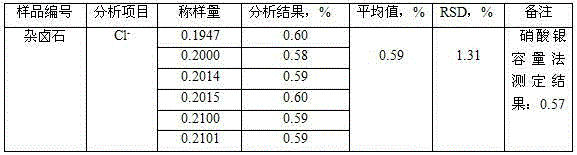

Method for determining chloride ion content in polyhalite

InactiveCN104807767AThe measurement results are accurate and reliableWide applicabilityColor/spectral properties measurementsIon contentTest sample

The invention discloses an analysis method for chloride ion content in polyhalite. The method comprises the following steps: dissolving a polyhalite test sample with acid; reacting chloride ions with mercuric thiocyanate in an acid medium to displace thiocyanate ions out; generating a red complex with iron III ions in ferric salt added into a solution; measuring the light absorption value of the complex in a test solution at the 460-nanometer position of a spectrophotometer in order to calculate the content of chloride ions in the polyhalite. For the content determination of chloride ions less than 1 percent in the polyhalite, the method is simple, convenient, reasonable, rapid and accurate; moreover, results are stable, and the precision is high.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

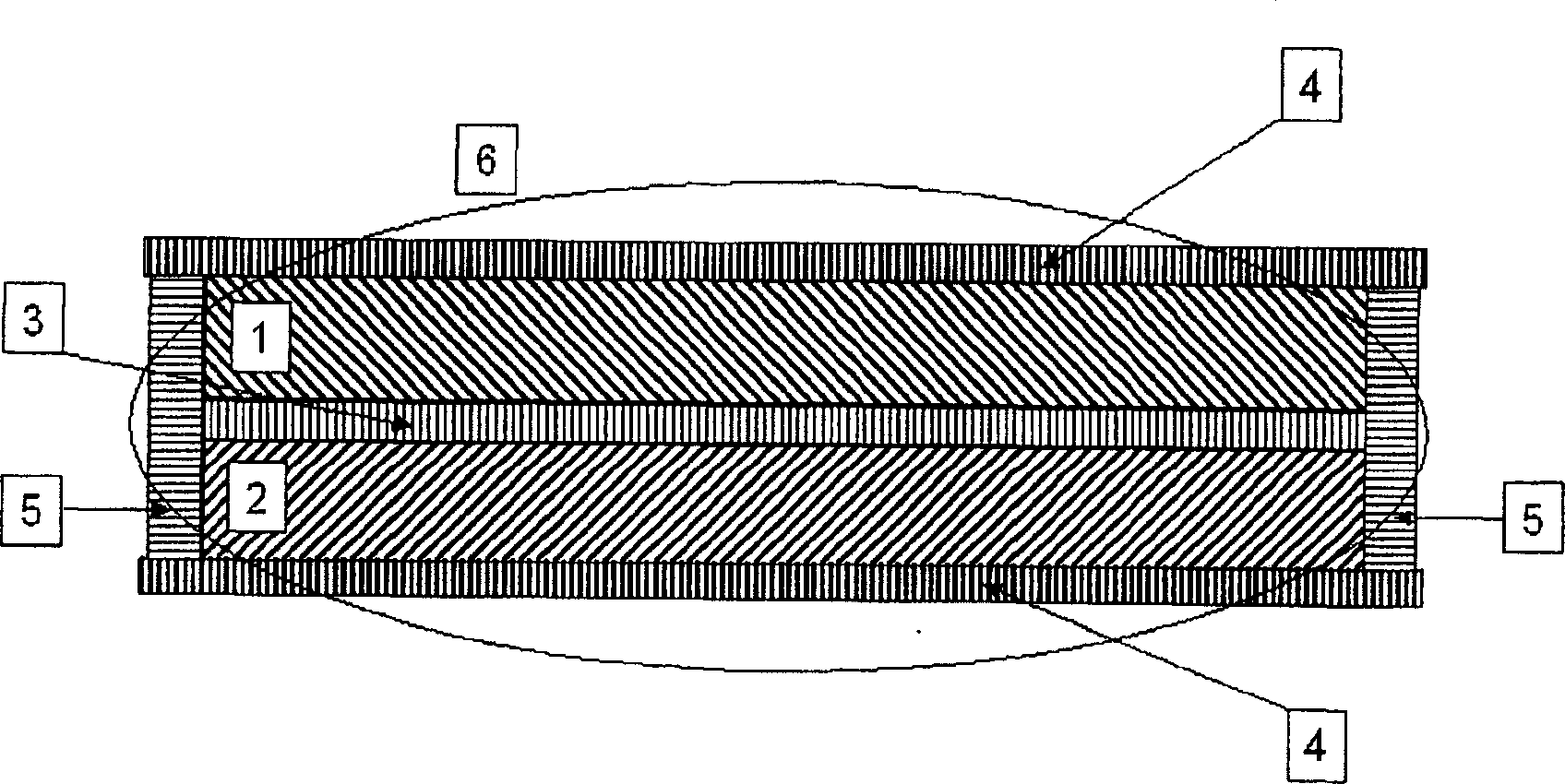

Preparation method of inorganic perovskite nanocrystal based on thiocyanate doping

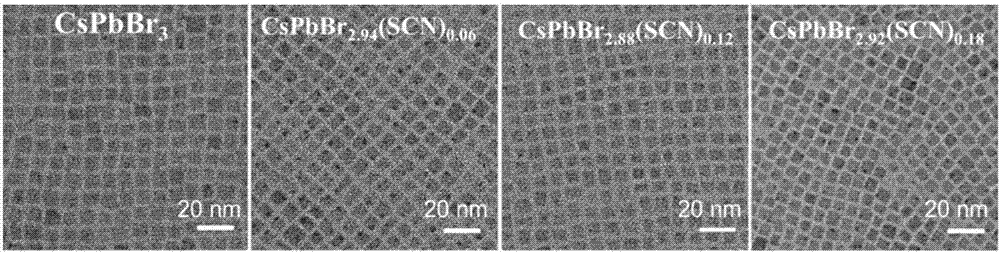

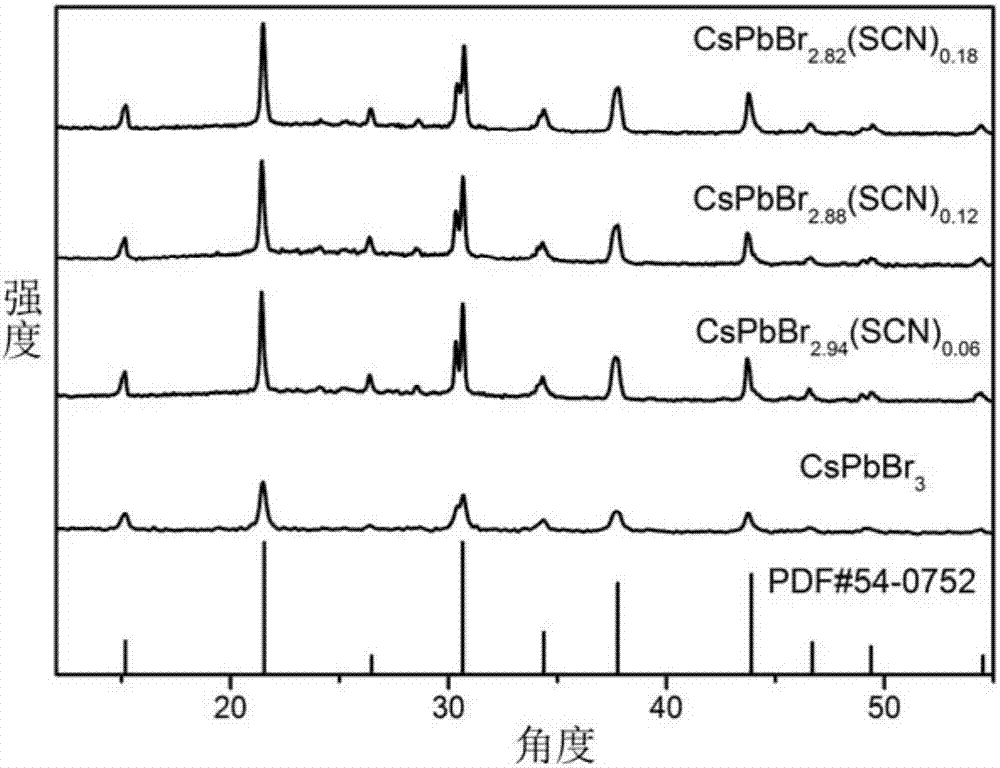

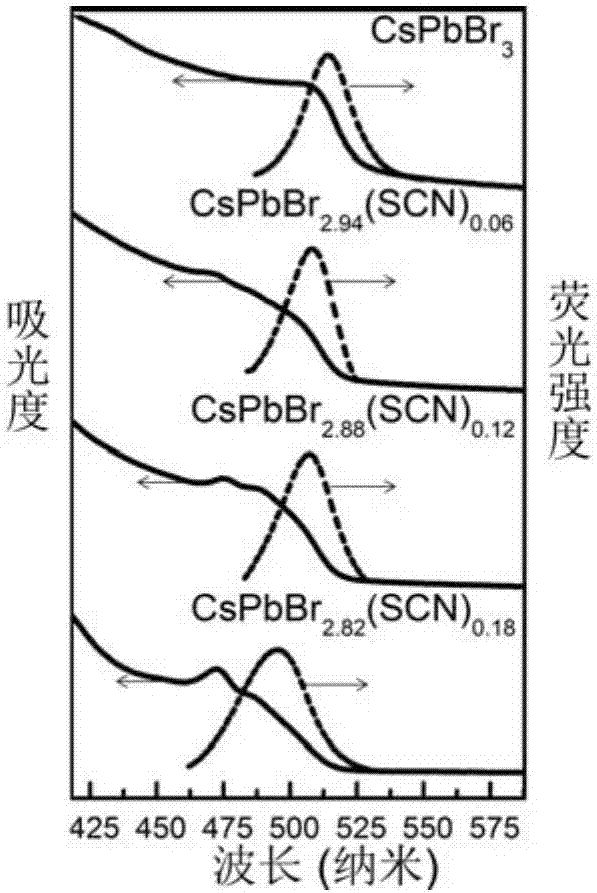

InactiveCN106929920AGood dispersionImprove stabilityPolycrystalline material growthFrom normal temperature solutionsIce waterSynthesis methods

The invention provides a preparation method of a CsPbBr3-x(SCN)x (x is equal to 0, 0.06, 0.12 and 0.18) inorganic perovskite nanocrystal based on thiocyanate doping.The method comprises the steps of mixing PbBr2 and Pb(SCN)2 with a reaction solvent octadecene, a surfactant oleic acid and oleylamine till complete dissolution under an inert gas shielding condition, heating a mixed solution to a reaction temperature, quickly injecting a cesium precursor, allowing a system to start reaction to generate a perovskite structure, gradually forming a CsPbBr3-x(SCN)x nanocrystal with the proceeding of the reaction, quickly cooling a product in an ice water bath after the reaction is finished, and obtaining the final CsPbBr3-x(SCN)x inorganic perovskite nanocrystal.According to the method, a hot injection synthesis method is adopted; a thiocyanate ion is doped to different extents; and micro regulation of an optical property of inorganic perovskite is achieved on the premise of not changing morphology and a crystal structure of the perovskite.The synthesized perovskite nanocrystal is better in monodispersity and stability and uniform in morphology and has profound significance for constructing a high-performance full-solution photoelectric device.

Owner:SOUTHEAST UNIV

Dark colored chromium based electrodeposits

An aqueous acidic trivalent chromium electrolyte comprising trivalent chromium ions and a complexing agent for maintaining the trivalent chromium ions in solution is provided in which the aqueous electrolyte comprises additives capable of producing a coating on a substrate having a desired dark hue. The additives typically comprise a dispersion of colloidal silica and an additional additive selected from thiocyanate ions and / or iron ions. The electrolyte is used in a method of producing the desired dark-hued decorative chromium coating on a substrate by electrodeposition.

Owner:MACDERMID ACUMEN INC

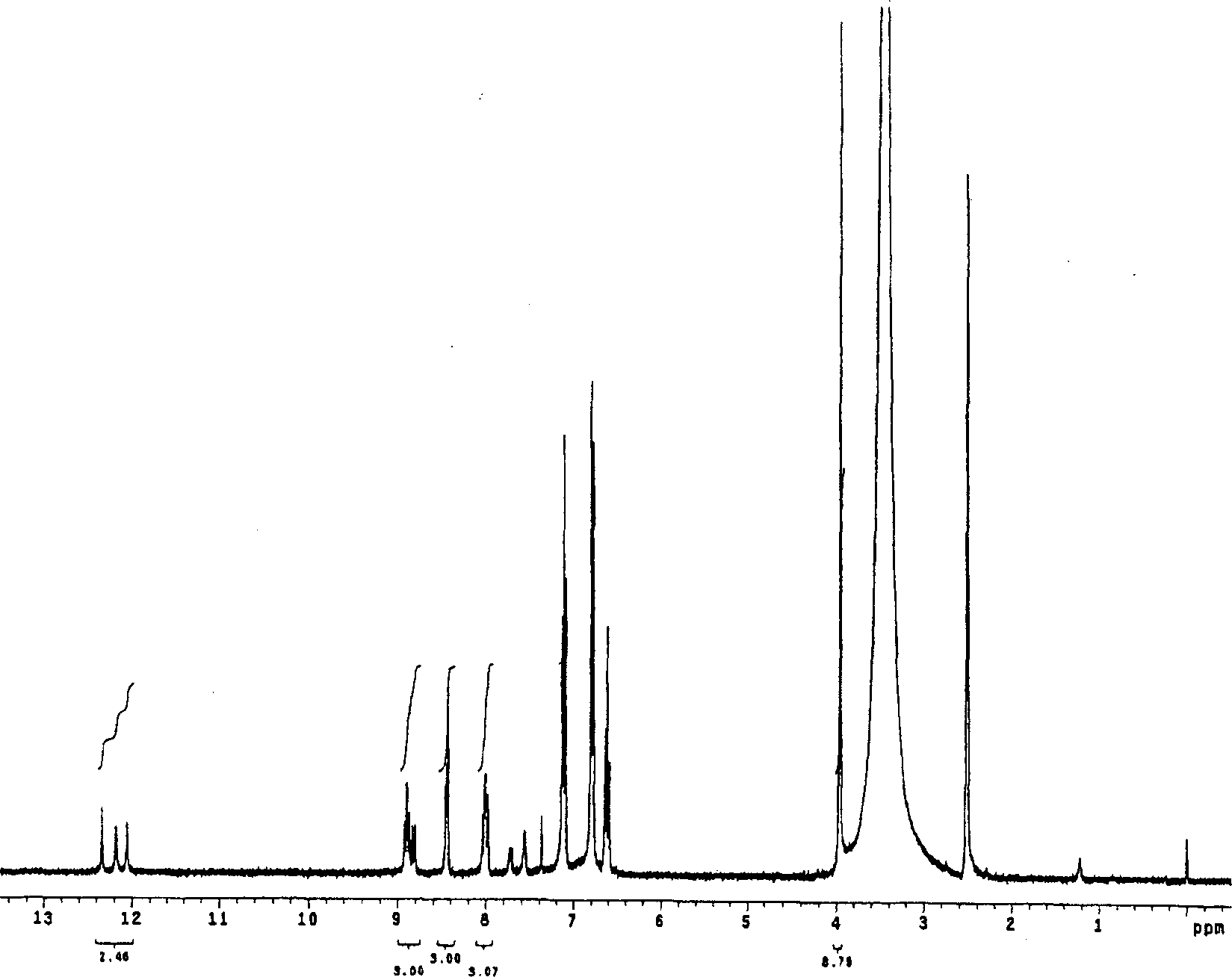

Organosilicon polymer fluorescent probe for detecting thiocyanate ion, and synthesis and application thereof

InactiveCN109705292ARealize identificationFluorescence/phosphorescenceLuminescent compositionsOrganosiliconThiocyanate ion

The invention provides an organosilicon polymer fluorescent probe for detecting a thiocyanate ion, wherein the structural formula is represented as the specification. The fluorescent probe is synthesized from raw materials including: bisphenol fluorene, MMNH2, formaldehyde, 4-bromo-1,8-naphthyl anhydride, sodium methyl mercaptide, etc. The method employs accessible raw materials, is simple in synthetic steps and high in yield. The fluorescent probe can emit fluorescence of thiomethyl naphthalimide; when the thiocyanate ion is added, the probe can specifically recognize the thiocyanate ion, wherein the thiomethyl group in the probe is oxidized into a dithio bond, and the fluorescence is dimmed. The detection conditions are that excitation wavelength is 405 nm and detection wavelength is 530nm.

Owner:UNIV OF JINAN

Treatment method of thiourea feed liquid

ActiveCN110759838AEfficient removalReduce the content of thiocyanate ionOrganic chemistryThioureaPhysical chemistry

The invention provides a treatment method of thiourea feed liquid. The treatment method comprises the following steps that a resin column is filled with SH-type anion resin, the resin is used for conducting ion exchange with the thiourea feed liquid, and the treated thiourea feed liquid is obtained. Compared with the prior art, according to the provided treatment method, a specific kind of ion exchange resin is selected to conduct the ion exchange for the thiourea feed liquid, thus thiocyanate ions enter into the resin, meanwhile HS<-> ions are displaced, in the process of thiourea production,HS<-> participates in the reaction, thus the thiocyanate ions in the thiourea feed liquid can be effectively removed without damaging the thiourea feed liquid and affecting the recycling use of the thiourea feed liquid, the content of the thiocyanate ions in a thiourea product is further significantly decreased, and the product quality is improved. The experimental result shows that the thiocyanate content in the treated thiourea feed solution obtained by the provided treatment method does not exceed 1.33%, the thiocyanate content in the obtained thiourea product does not exceed 0.013%, and the requirements of the product quality standard are met.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Indolecarboxylic ester trimer and electrochemical cell using the same

InactiveCN1660853AIncrease capacityExcellent cycle characteristicsOrganic chemistryCell electrodesHydrogen SulfatePropanoic acid

The present invention provides a novel indole carboxylic ester trimer which is characterized by being represented by the following general formula (1): wherein R represents a straight or branched chain alkyl group having 1-6 carbon atoms; n is an integer of 1-4; Xa- represents at least one anion selected from a group of anions having a valency of 1-3 consisting of chloride ion, bromide ion, iodide ion, fluoride ion, nitrate ion, sulfate ion, hydrogen sulfate ion, phosphate ion, borofluoride ion, perchlorate ion, thiocyanate ion, acetic acid ion, propionic acid ion, methanesulfonic acid ion, p-toluenesulfonic acid ion, trifluoroacetic acid ion and trifluoromethanesulfonic acid ion; a represents the ionic valence number of X and is an integer of 1-3; and m is 0-0.5.

Owner:TOKIN CORP

Method for removing thiocyanate ions from water

InactiveCN103214054AQuick removalApplicable to a wide range of concentrationsOther chemical processesWater/sewage treatment by sorptionIndustrial waste waterSodium Bentonite

Belonging to the technical field of environmental engineering, the invention relates to a method for removing thiocyanate ions from water. The method is characterized by making use of long and short carbon chain cationic surfactants to modify bentonite to prepare a modified bentonite composite material, thereby removing thiocyanate ions from a water solution. Specifically, the steps include: (1) using long and short carbon chain cationic surfactants to modify sodium bentonite; (2) utilizing modified organic bentonite to adsorb thiocyanate ions from the water solution; and (3) testing the removal rate of thiocyanate ions. The organic bentonite obtained by the method has good stability, and has the characteristics of rapidity, high efficiency, simplicity, wide pH application range, low cost and the like in terms of adsorbing thiocyanate ions in the water solution, thus being widely applicable in treatment of industrial wastewater containing thiocyanate ions.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com