Ammonium thiocyanate base deep-eutectic solvent for absorbing ammonia gas and method for adsorbing same

A low eutectic solvent, ammonium thiocyanate technology, applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve the problems of slow absorption rate, high viscosity of deep eutectic solvent, insufficient absorption capacity, etc. Volume increase, viscosity reduction, excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Ammonium thiocyanate-based deep eutectic solvent was prepared, using ammonium thiocyanate as hydrogen bond acceptor and glycerol as hydrogen bond donor. Weigh 6.00 g of ammonium thiocyanate and place it in a 50 ml Erlenmeyer flask, add 10.88 g of glycerin, and stir magnetically until a homogeneous transparent solution is obtained in a constant temperature water bath at 80°C (stirring time is about 2 hours); then cool to room temperature, and 16.88g of deep eutectic solvent was obtained, wherein the mass ratio of hydrogen bond donor to hydrogen bond acceptor was 1.813:1, and the molar ratio was 2:3.

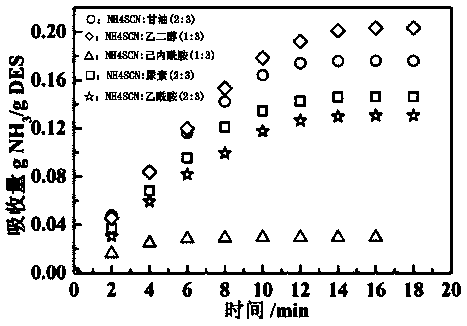

[0021] Take 3.00 g of the above-prepared deep eutectic solvent, put it into a self-made bubble absorber (inner diameter 12mm, length 120mm), control the absorption temperature at 20°C, and pass it into the bubble absorber at a rate of 60mL / min 0.1MPa ammonia gas (that is, pure ammonia gas), the deep eutectic solvent will absorb the ammonia gas, and measure the absorption by...

Embodiment 2

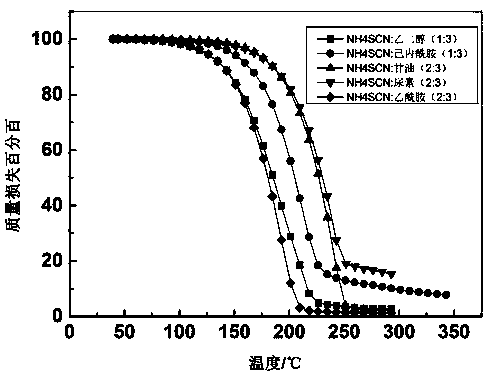

[0023] The process of preparing ammonium thiocyanate-based deep eutectic solvent repeats Example 1, but is different from Example 1: change the type of hydrogen bond donor, and change the molar ratio of ammonium thiocyanate and hydrogen bond donor, prepare The obtained deep eutectic solvent is recorded as DES, and the composition of DES is shown in Table 1 and Table 2.

[0024] The steps of the method for adsorbing ammonia by the deep eutectic solvent prepared above were repeated in Example 1, but the difference from Example 1 was that the absorption temperature was replaced by 40° C., and the absorption results are shown in Table 1. The steps of the method for adsorbing ammonia by the deep eutectic solvent prepared above were repeated in Example 1, but the difference from Example 1 was that the absorption temperature was replaced by 10° C., and the absorption results are shown in Table 2.

[0025] Table 1 Ammonia absorption results of DES formed by different hydrogen bond don...

Embodiment 3

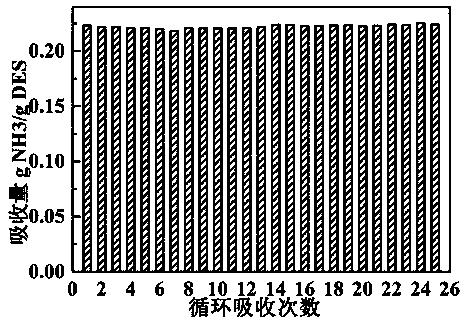

[0033] Ammonium thiocyanate-based deep eutectic solvent, its composition and preparation method repeat embodiment 1, promptly with NH 4 SCN-glycerol as absorbent, NH 4 The molar ratio of SCN to glycerin was 2:3, and the deep eutectic solvent was prepared according to the method of Example 1.

[0034] The method steps of the deep eutectic solvent adsorption ammonia of above-mentioned preparation repeats embodiment 1, but is different from embodiment 1: change the partial pressure of absorption temperature and ammonia, when the partial pressure of ammonia is lower than 1bar, the waiting to be fed into The adsorbed gas is nitrogen containing ammonia (that is, a mixed gas of ammonia and nitrogen is fed, and the total pressure of ammonia and nitrogen is 1 bar). The absorption results are shown in Table 3. It can be seen from Table 3 that the higher the concentration of ammonia, the shorter the absorption time, and the greater the ammonia absorption capacity when the adsorption is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com