CO2 Absorbents for Post Combustion Capture

A carbon dioxide and absorbent technology, applied in chemical instruments and methods, dispersed particle separation, air quality improvement, etc., to achieve the effects of reducing solution loss, fast absorption rate, and reducing energy consumption for regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

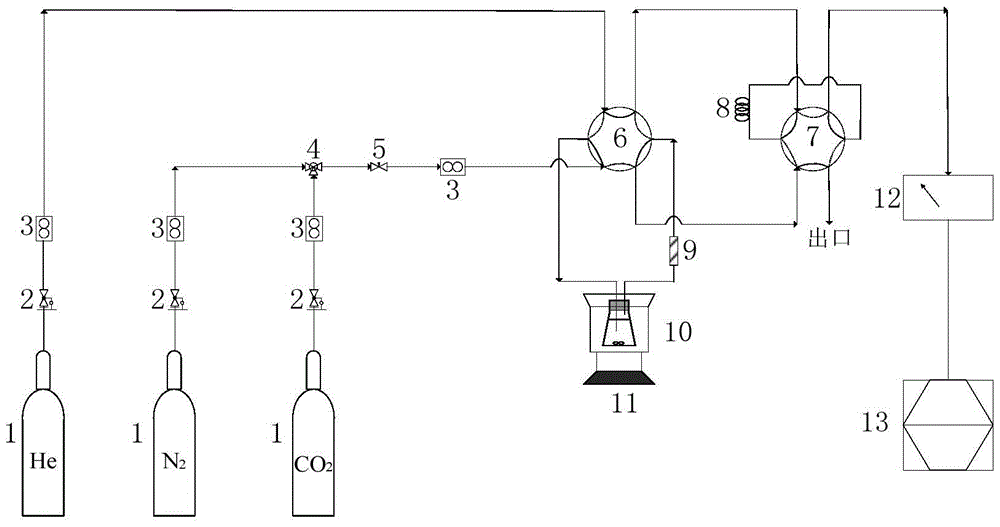

[0020] The components and mass fractions of sample A are: polyethyleneimine 15%, molecular weight 350, tetraethylenepentamine 5%, ethanolamine 5%, sodium sulfite 0.02%, sodium molybdate 0.02%, and the rest is water; the group of sample B The mass fractions are: polyethyleneimine 20%, molecular weight 350, N-methyldiethanolamine 5%, ethanolamine 5%, sodium sulfite 0.02%, sodium molybdate 0.02%, and the rest are water; the components of sample C and The mass fraction is: polyethyleneimine 25%, molecular weight 350, diethanolamine 5%, ethanolamine 5%, sodium sulfite 0.02%, sodium molybdate 0.02%, and the rest is water; the absorption capacity and Absorption rate, the test device such as figure 1 As shown, in a glass reactor placed in a constant temperature water bath at 45°C, 100mL of absorbent solution was added, and the volume composition was 14% CO at a flow rate of 1L / min under 1 atmosphere. 2 , 86%N 2 mixed gas, while the absorption liquid was slowly stirred at a constant ...

Embodiment 2

[0024] Select sample B as the absorption liquid, and conduct the test on a 2,000-ton / year carbon dioxide capture test platform, and introduce a part of the flue gas from a 3MW thermal test platform into the capture system. The generated flue gas, the top of the desulfurization washing tower, the top of the absorption tower and the outlet of the regenerated gas-liquid separator of the capture test bench are sampled and analyzed. The flue gas of the 3MW boiler is analyzed by the flue gas analyzer, and the gas sample of the capture test bench is analyzed by the gas chromatograph. The composition of the flue gas and the analysis results of the gas samples from the capture test bench are shown in Table 2. It can be seen from Table 2 that the concentration of carbon dioxide in the flue gas is 11.92%. After being absorbed by the absorption tower, the CO in the flue gas 2 It is reduced to 0.5%, and the removal rate of the absorption tower exceeds 95%. CO in the gas phase of the rege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com