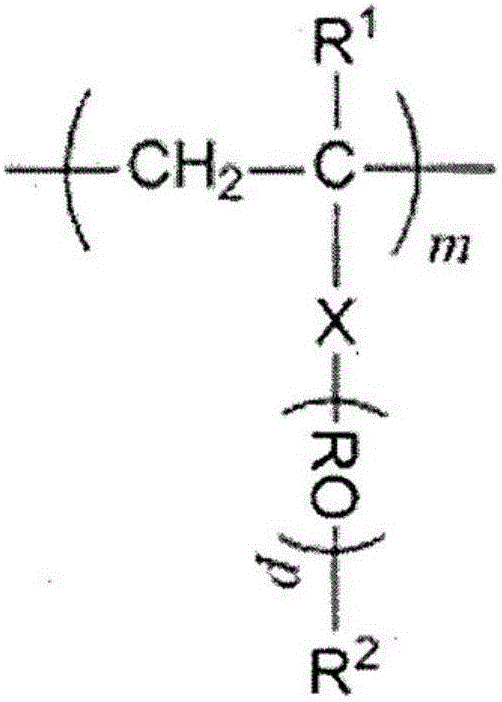

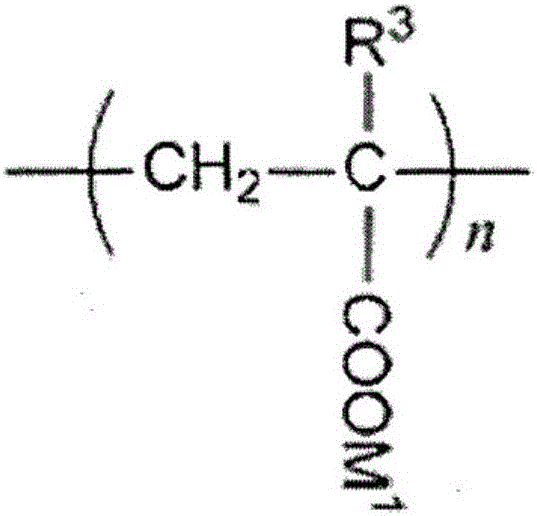

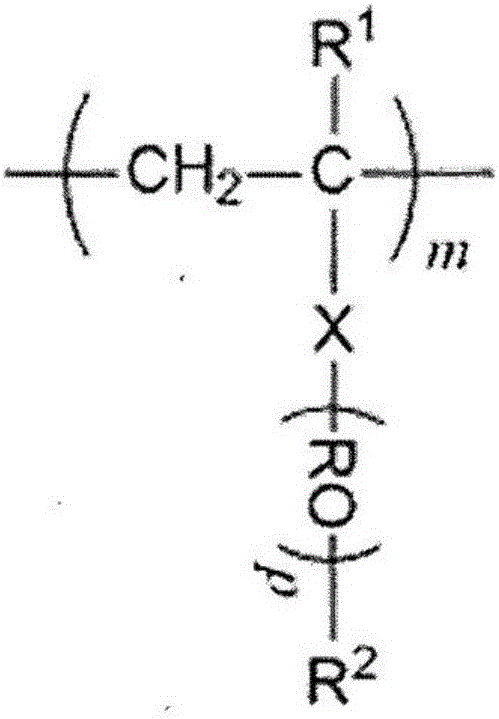

Method for preparing super-absorbent resin and super-absorbent resin prepared thereby

一种超吸收性、聚合物的技术,应用在吸收垫、医药科学、绷带等方向,能够解决离心保留容量吸收度减小等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0088] 400 parts by weight of ion-exchanged water was added to a 3L four-necked flask reactor equipped with a stirrer, a thermometer, a nitrogen gas supplier, and a circulating condenser, nitrogen gas was supplied into the reactor while stirring, and the reactor was heated under a nitrogen atmosphere to 75°C.

[0089] Subsequently, 2 parts by weight of ammonium persulfate was added to the reactor and the resulting solution was completely dissolved. Then, by making 600 parts by weight of methoxypolyethylene glycol monomethacrylate (the average number of moles of ethylene oxide (EO) added: about 50 moles), 96.6 parts by weight of methacrylic acid and 190 parts by weight of water The monomer aqueous solution prepared by mixing, the mixed solution of 5 parts by weight of 3-mercaptopropionic acid and 5 parts by weight of water, and 150 parts by weight of 3% by weight ammonium persulfate aqueous solution were continuously added to the reactor at a uniform speed within 4 hours. Imme...

preparation example 2

[0093] Polycarboxylate copolymer (weight-average molecular weight: 40,000) was prepared in the same manner as in Preparation Example 1, except that after completing the polymerization reaction as in Preparation Example 1, it was passed through 30% by weight of triethanolamine aqueous solution and about 1 hour.

preparation example 3

[0095] A polycarboxylic acid-based copolymer (weight average molecular weight: 40,000) was prepared in the same manner as in Preparation Example 2 except that it was neutralized with an aqueous sodium hydroxide solution instead of an aqueous solution of triethanolamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com