Metallographic corrosive and alloy macrostructure display method

A display method and etchant technology, which is applied in the field of metallographic etchant and alloy macrostructure display, and can solve the problems such as unsatisfactory corrosion effect of 3 series aluminum alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] At room temperature, pour sodium hydroxide and potassium thiocyanate into a beaker filled with distilled water. The dosage of each substance is shown in Table 1. Stir with a glass rod until the solute is completely dissolved, and let it stand for 2 minutes to form a metallographic etchant. .

[0039]The SAPA 3-series long-life aluminum alloy tube samples used for air-conditioning heat exchangers were intercepted for grinding and polishing. The grinding and polishing treatment specifically includes: sequentially using 100 mesh, 400 mesh, and 800 mesh water sandpaper to polish the surface to be corroded step by step, adding water to wet the sample during the polishing process, and grinding time for each level of sandpaper for 3 to 5 minutes, so as to obtain a flat and smooth surface. Smoother finish. When grinding, the sandpaper is placed on the pre-grinder, and the pre-grinder drives the sandpaper to rotate at a speed of 500-1000r / min. The pre-grinder continuously wets...

Embodiment 2 to 6、 comparative example 1 to 3

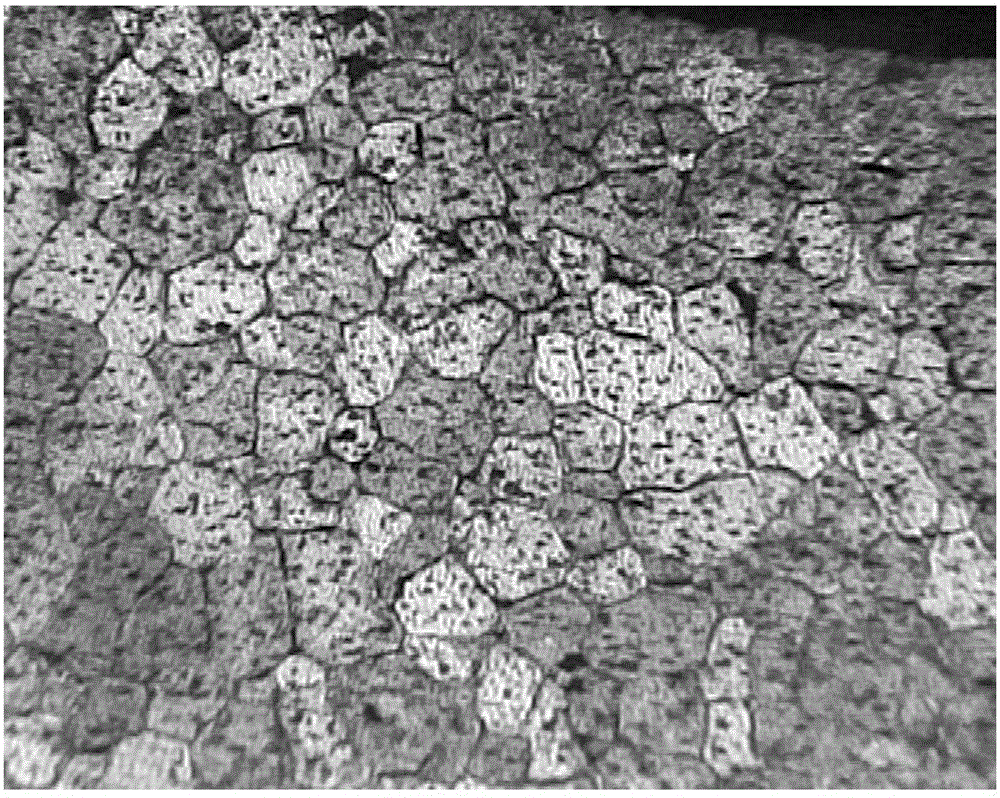

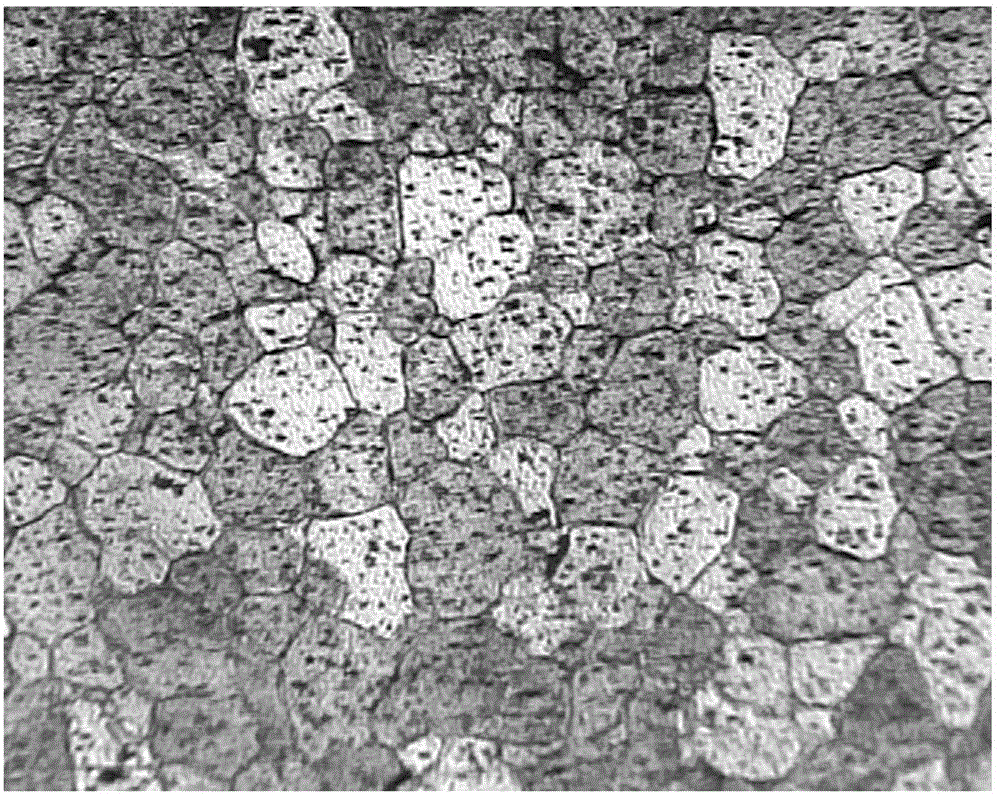

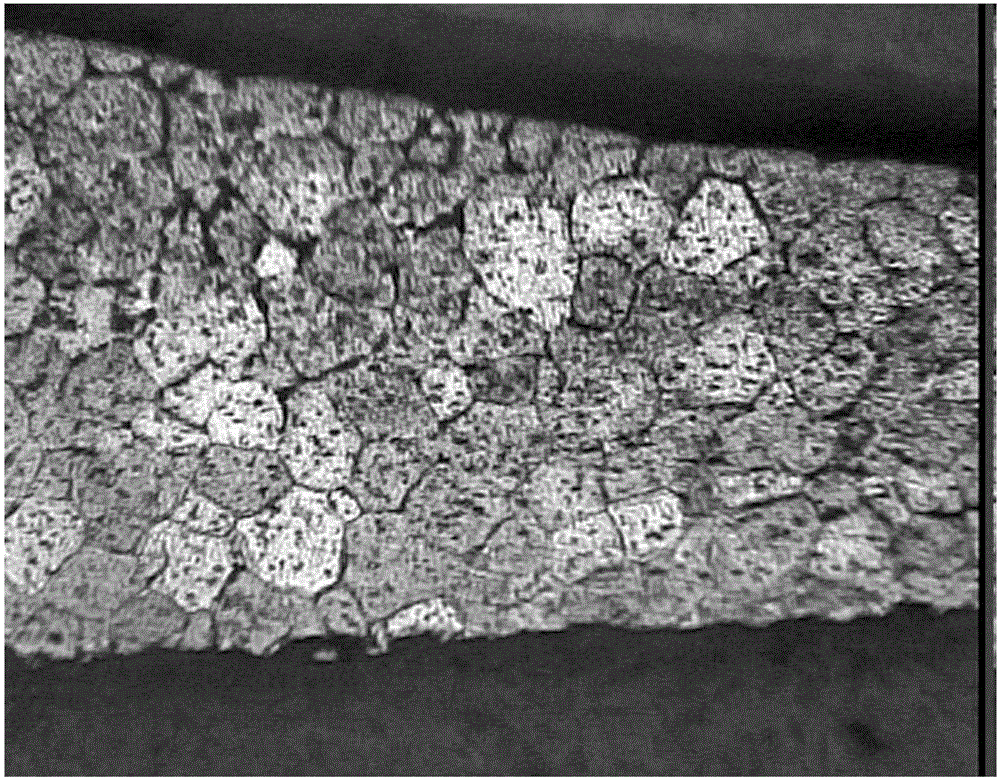

[0043] The composition of metallographic etchant is shown in Table 1, and others are identical with embodiment 1, and wherein, the observation result of embodiment 2 sees figure 2 , the observation result of embodiment 3 sees image 3 , see the observation results of Comparative Example 1 Figure 4 , see the observation results of Comparative Example 2 Figure 5 , see the observation result of comparative example 3 Image 6 , the magnification is 400 times, and the observation results of embodiment 3, embodiment 4 and embodiment 5 are basically the same, the observation results of embodiment 6 and embodiment 2 are basically the same, the observation results of embodiment 7 are between comparative example 3 Compared with Example 3, but the macrostructure of the 3-series aluminum alloy cannot be well judged.

Embodiment 7

[0045] The composition of the metallographic etchant is the same as in Example 1, except that the sample is taken out after 20s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com