Determination method of cyanogen in thiocyanate

A determination method and thiocyanate technology, applied in the field of chemical analysis, can solve the problem of not measuring cyanide content, etc., and achieve the effects of reliable measurement results, no environmental pollution, and sensitive response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] 1. Reagents and instruments used: Potassium cyanide standard sample (provided by Henan Provincial Analysis and Testing Center); reagent sodium thiocyanate (commercially available, analytically pure); industrial sodium thiocyanate (commercially available); heptahydrate sulfurous acid Iron (analytical pure). UV1800 spectrophotometer.

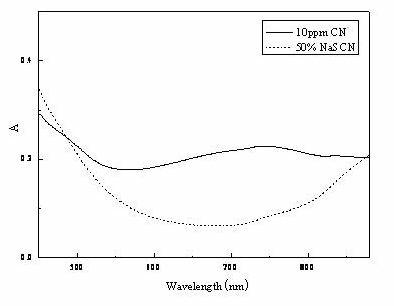

[0021] Both the reagent sodium thiocyanate and the industrial sodium thiocyanate are prepared as 10% and 50% solutions by mass percentage;

[0022] Mixed sample: 50% sodium thiocyanate solution containing 8 μg / mL cyanide.

[0023] Ferrous sulfate heptahydrate was prepared as a saturated ferrous sulfate solution with deionized water, and set aside.

[0024] 2. Method:

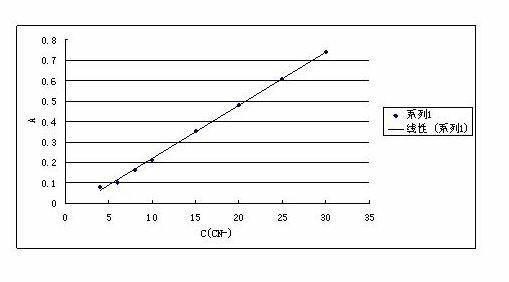

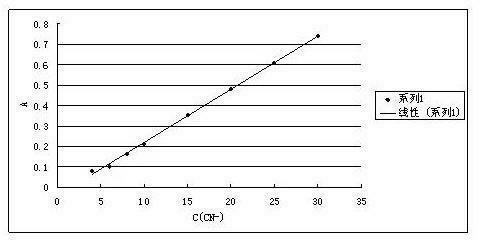

[0025] Accurately weigh 0.25 g of potassium cyanide in a 100 mL volumetric flask, dissolve it with deionized water and make up to the mark to prepare a standard stock solution with a concentration of 2.5 mg / mL. Prepare the standard stock solution with deionized water so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com