New process for treating vulcanized gold-containing ore

A new process and technology for gold ore, applied in the new process field of treating sulfide gold-bearing ores, can solve the problems of high consumption of chemical liquid and high production cost, achieve high leaching rate and recovery rate, low environmental pollution and simple equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

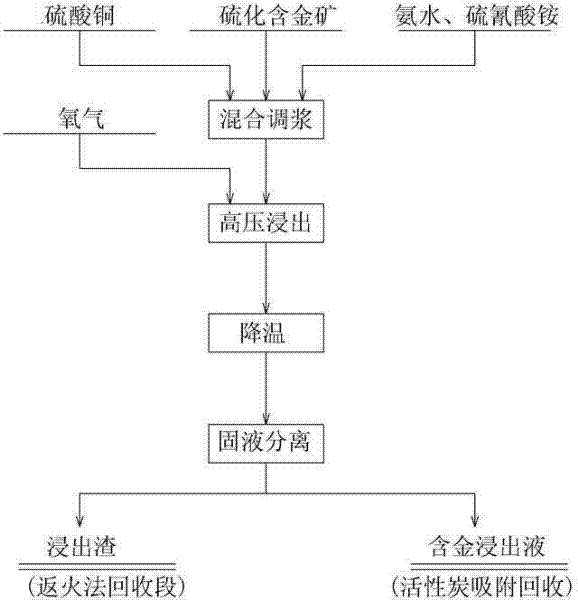

Image

Examples

Embodiment 1

[0016] The composition of a sulfide gold-bearing ore is as follows: Pb: 0.38%, Cu: 0.37%, Fe: 34.92%, S: 32.77%, SiO 2 : 13.07%, Ag: 0.0049%, Zn: 0.58%, Sb: 0.71%, Au: 0.0024%, As: 7.65%. Example process such as figure 1 As shown, the following steps are taken in order of implementation:

[0017] ① Crushing and grinding: crush and grind the massive sulfide gold-bearing ore to a particle size of 200 mesh, and sieve;

[0018] ②High pressure leaching: NH 4 SCN and NH 4 OH is configured as a leaching solution, and CuSO is added 4 ; In solution: NH 4 SCN 2mol / L, NH 4 OH 1 mol / L, CuSO 4 3 g / L; then add the sulfidized gold-containing ore after grinding and sieving into the leaching solution at a liquid-solid ratio of 5:1, and then send it to an autoclave for high-pressure leaching. The leaching conditions are: temperature 180°C , continue to feed oxygen, the oxygen partial pressure is 0.8MPa, the stirring speed is 800r / min, and the reaction time is 2 hours;

[0019] ③Liquid...

Embodiment 2

[0022] The composition of a sulfide gold-bearing ore is as follows: Pb: 0.42%, Cu: 0.50%, Fe: 33.76%, S: 30.28%, SiO 2 : 14.56%, Ag: 0.0043%, Zn: 0.55%, Sb: 0.65%, Au: 0.00246%, As: 7.80%. Take the following steps in order to implement:

[0023] ① Crushing and grinding: crush and grind the massive sulfide gold-bearing ore to a particle size of 100 mesh, and sieve;

[0024] ②High pressure leaching: NH 4 SCN and NH 4 OH is configured as a leaching solution, and CuSO is added 4 ; In solution: NH 4 SCN 4mol / L, NH 4 OH 5 mol / L, CuSO 4 2 g / L; then add the sulfidized gold-containing ore after grinding and sieving into the leaching solution at a liquid-solid ratio of 3:1, and then send it to an autoclave for high-pressure leaching. The leaching conditions are as follows: the temperature is 200°C , continue to feed oxygen, the oxygen partial pressure is 0.6MPa, the stirring speed is 300r / min, and the reaction time is 5 hours;

[0025] ③Liquid-solid separation: After the leachi...

Embodiment 3

[0028] The composition of a sulfide gold-bearing ore is as follows: Pb: 0.40%, Cu: 0.55%, Fe: 35.35%, S: 33.39%, SiO 2 : 16.46%, Ag: 0.0037%, Zn: 0.53%, Sb: 0.72%, Au: 0.00248%, As: 7.70%. Take the following steps in order to implement:

[0029] ① Crushing and grinding: crush and grind the massive sulfide gold-bearing ore to a particle size of 150 mesh, and sieve;

[0030] ②High pressure leaching: NH 4 SCN and NH 4 OH is configured as a leaching solution, and CuSO is added 4 ; In solution: NH 4 SCN 0.5mol / L, NH 4 OH 6 mol / L, CuSO 4 1 g / L; then add the sulfidized gold-containing ore after grinding and sieving into the leaching solution at a liquid-solid ratio of 10:1, and then send it to an autoclave for high-pressure leaching. The leaching conditions are: temperature 80°C , continue to feed oxygen, the oxygen partial pressure is 2.0MPa, the stirring speed is 600r / min, and the reaction time is 1 hour;

[0031] ③Liquid-solid separation: After the leaching process is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com