Preparation method of inorganic perovskite nanocrystal based on thiocyanate doping

A nanocrystal and inorganic calcium technology is applied in the field of preparation of inorganic perovskite nanocrystals to achieve the effects of uniform morphology, simple method and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

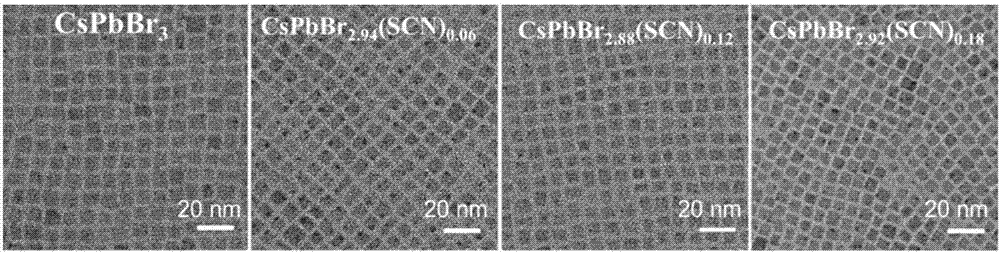

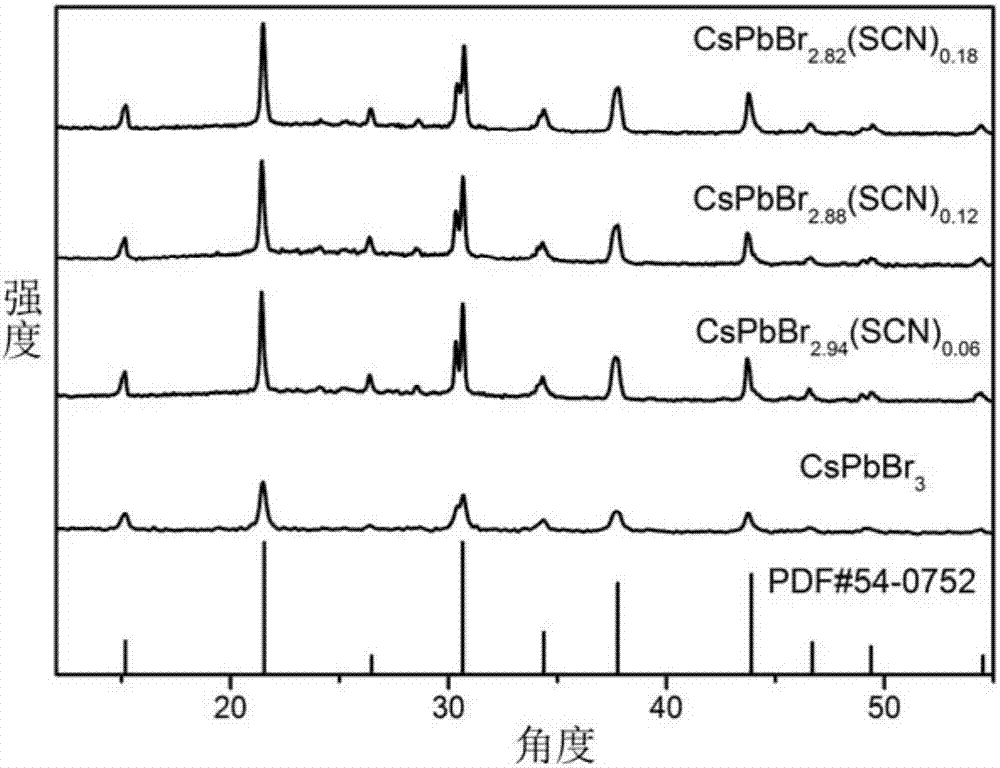

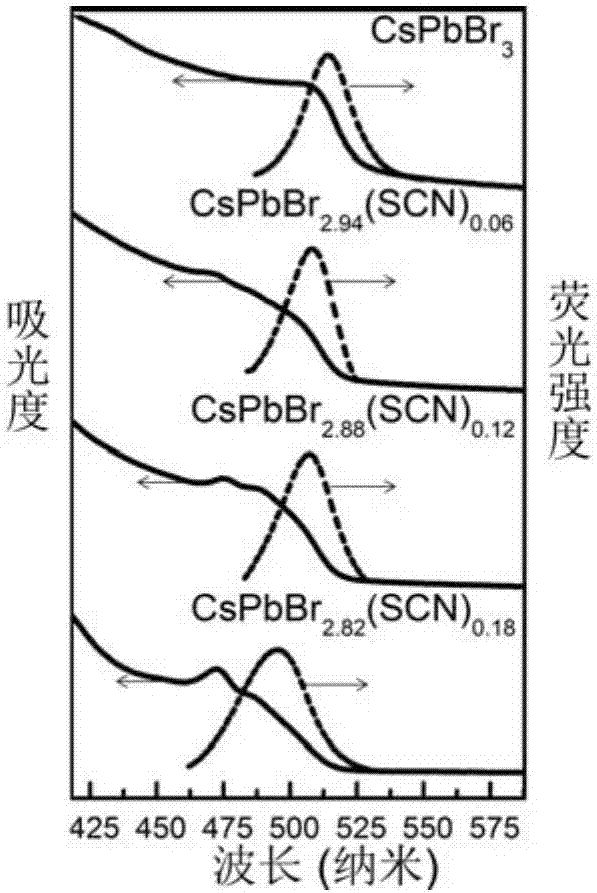

Embodiment 1

[0026] Step 1, 2.5mmol Cs 2 CO 3 Dissolve in 40ml of octadecene and 2.5ml of oleic acid, dry in vacuum at 120°C for 1 hour, pass nitrogen gas, raise the temperature to 150°C to dissolve completely, and form a cesium oleate precursor solution, which is used as a stock solution;

[0027] Step 2, 0.0690g PbBr 2 , 0g Pb(SCN) 2 Mixed with octadecene, first vacuumize the mixed solution, then pass in an inert gas, and then vacuumize again, and cycle for 3 times; finally, heat-preserve and dry at 120°C for 1 hour under vacuum conditions;

[0028] Step 3, feed inert gas nitrogen, add surfactants 0.5ml oleic acid and 0.5ml oleylamine to the mixed solution in step 2 respectively, continue to keep warm to completely dissolve the reactants, and obtain a lead precursor solution;

[0029] Step 4: After heating up to 150°C, take 0.4ml of the cesium oleate precursor solution in step 1 and quickly inject it into the lead precursor solution in step 3 to generate CsPbBr 3 ; Insulate at 150°C ...

example 2

[0032] Adopt the same process of embodiment 1, the difference is that PbBr in step 2) of embodiment 1 2 , Pb(SCN) 2 The quality of the mass was changed to 0.0676g and 0.0012g respectively, and the other conditions were kept the same, and the obtained product was CsPbBr 2.94 (SCN) 0.06 .

example 3

[0034] Adopt the same process of embodiment 1, the difference is that PbBr in step 2) of embodiment 1 2 , Pb(SCN) 2 The quality of the mass was changed to 0.0662g and 0.0024g respectively, and the other conditions were kept the same, and the obtained product was CsPbBr 2.88 (SCN) 0.12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com