Two-section innocent treatment technology for cyanogens-containing tailing pulp

A technology of harmless treatment and two-stage method, which is applied in the direction of oxidized water/sewage treatment, multi-stage water/sewage treatment, adsorbed water/sewage treatment, etc., which can solve the problems of high electricity price, non-drinkable, large investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

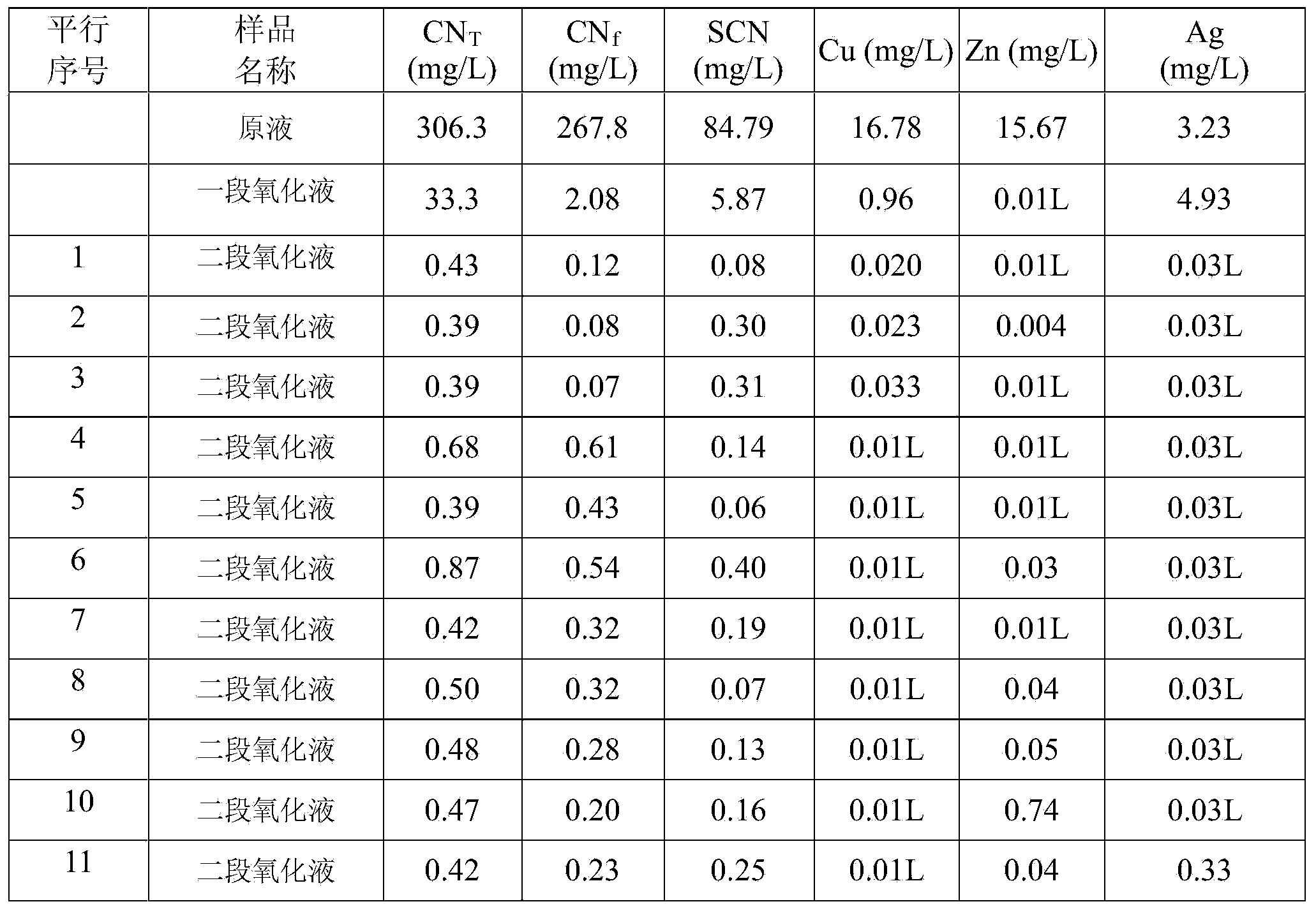

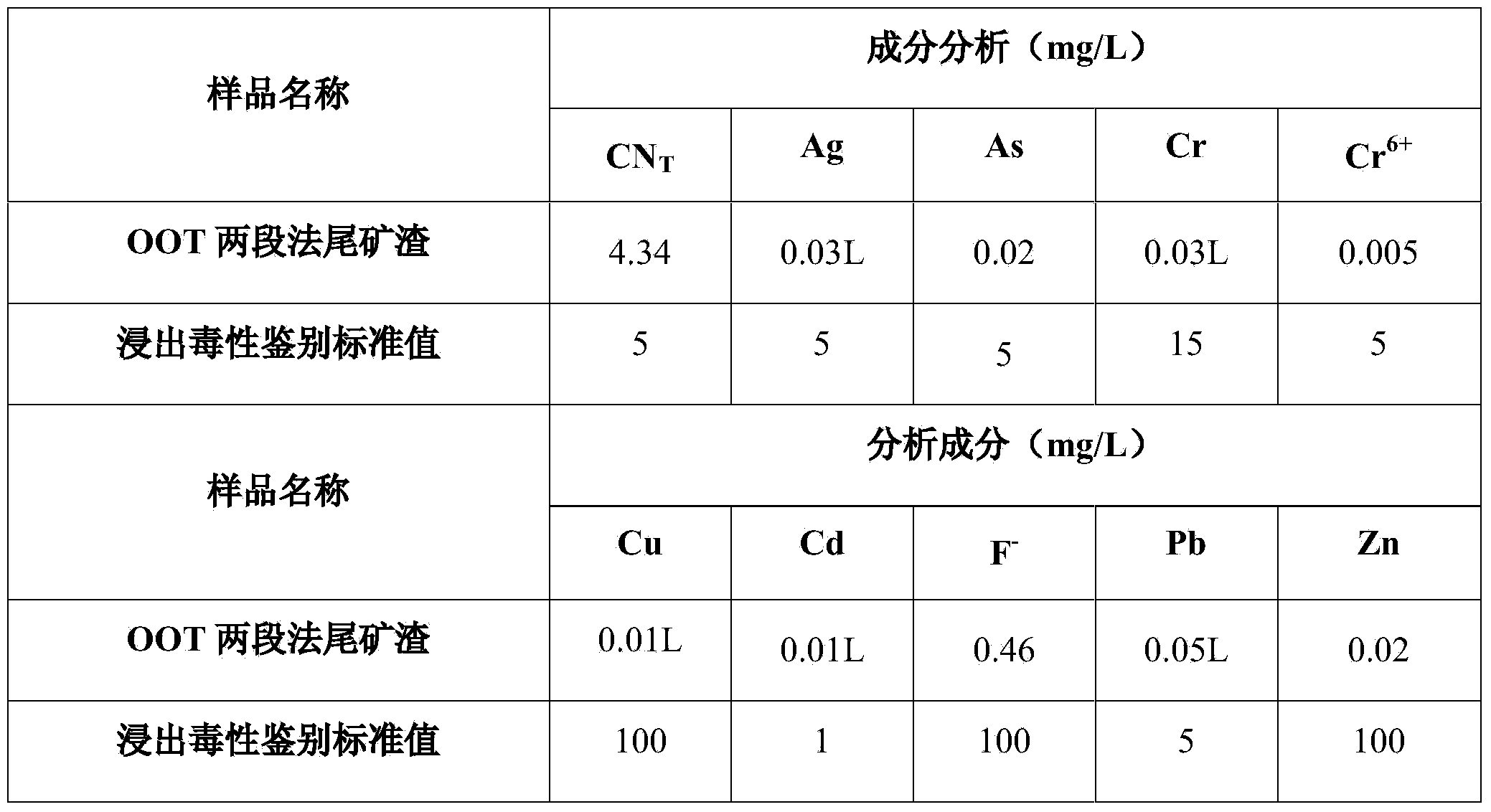

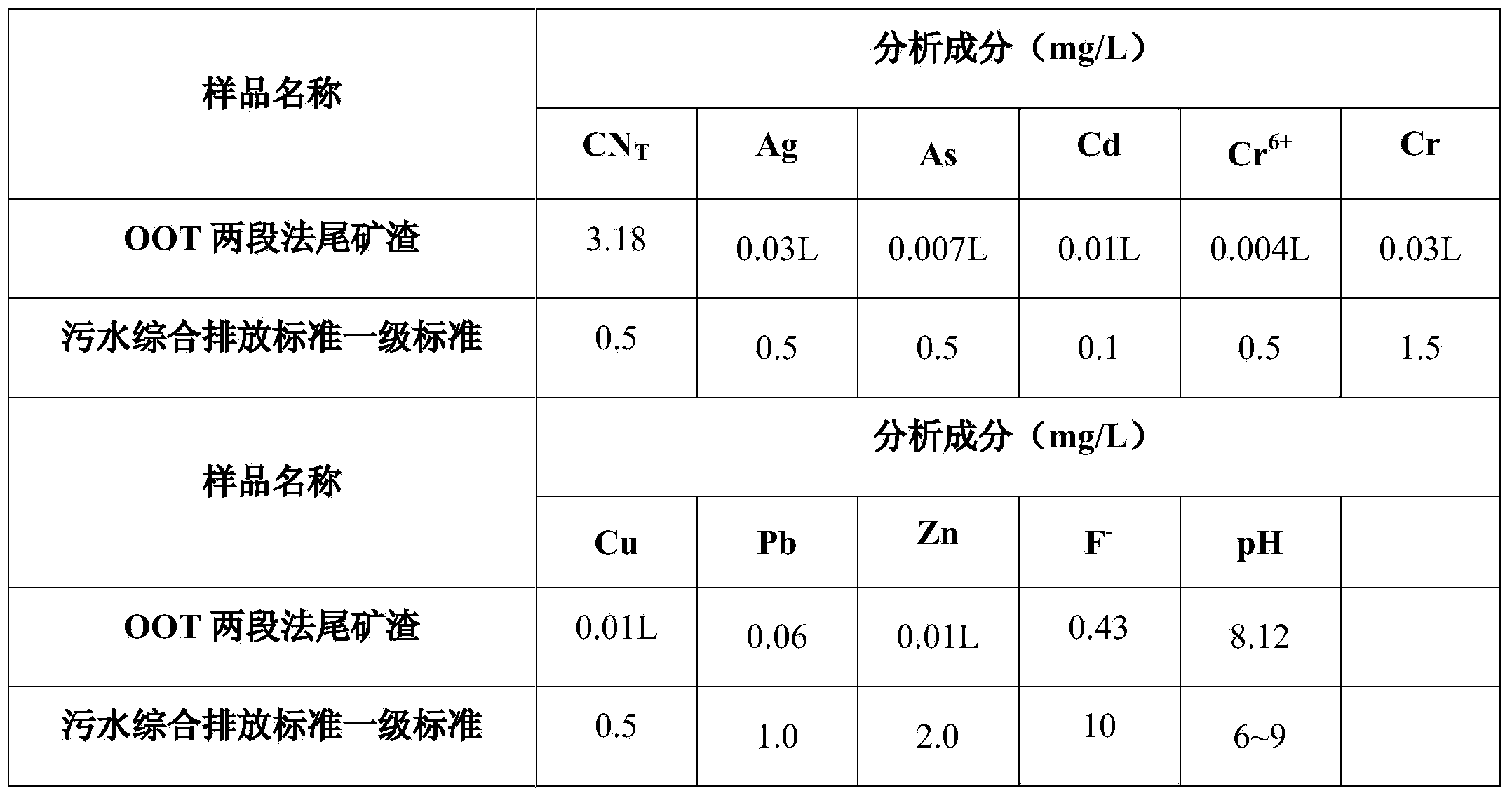

[0071] Adopt the technical process of the present invention to carry out " ore pulp concentration+OOT two-stage method " processing test to the cyanide-containing tailings slurry output in the actual production process of a gold mine, the processing capacity is 10L / h, and the cyanide-containing tailings slurry treatment results are shown in Table 1, containing The toxic leaching results of cyanide tailings pulp are shown in Table 2 and Table 3.

[0072] Table 1 Water quality results after treatment of cyanide-containing tailings slurry Unit: mg / L

[0073]

[0074] Table 2 Overturning oscillation method Unit: mg / L

[0075]

[0076] Table 3 Horizontal oscillation method Unit: mg / L

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com