Concrete spouting device

A concrete and cylinder technology, which is applied in the field of concrete pouring devices, can solve the problem of inability to adjust the size of the opening of the discharge port, and achieve the effects of reducing concrete dripping, slowing down the speed of feeding, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

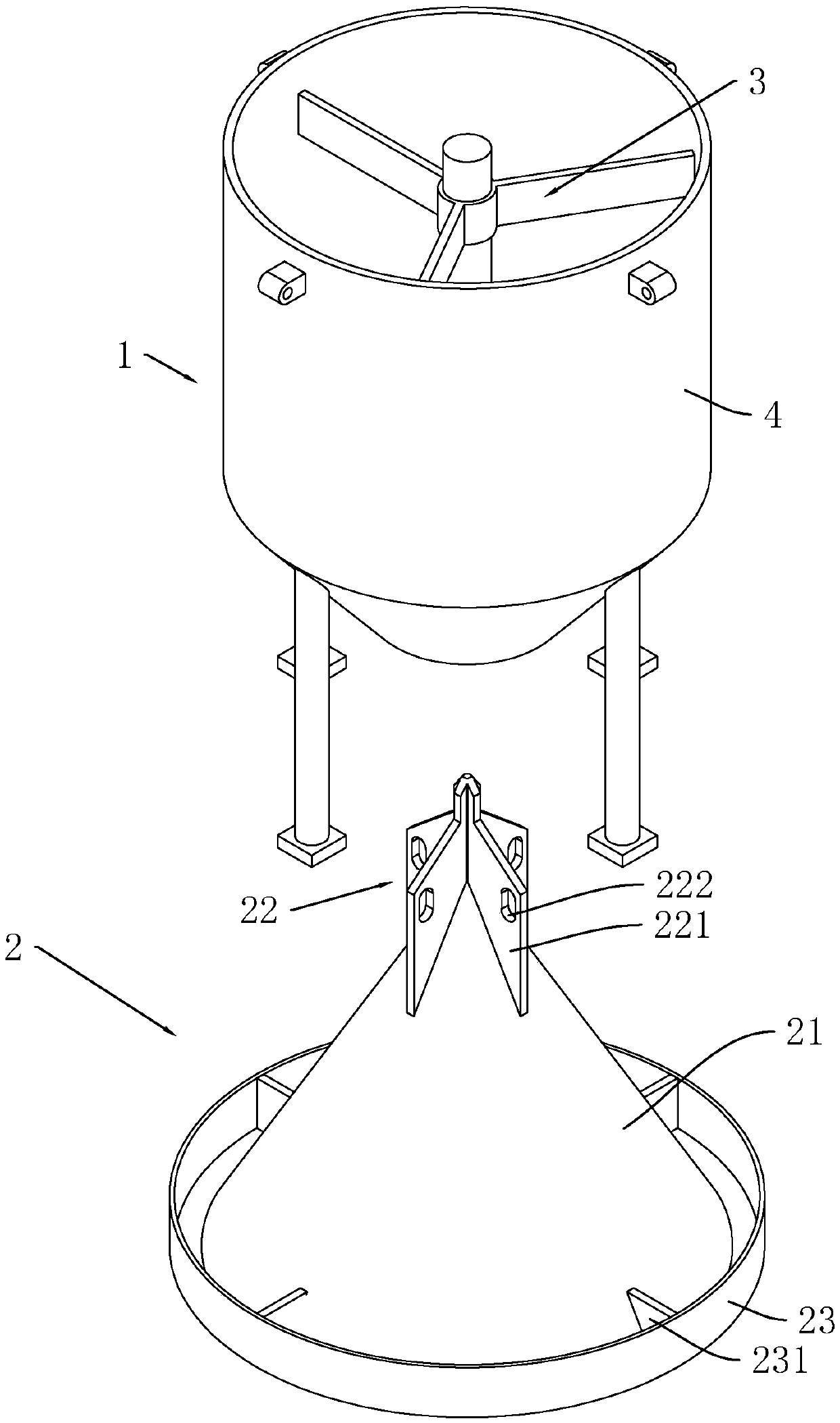

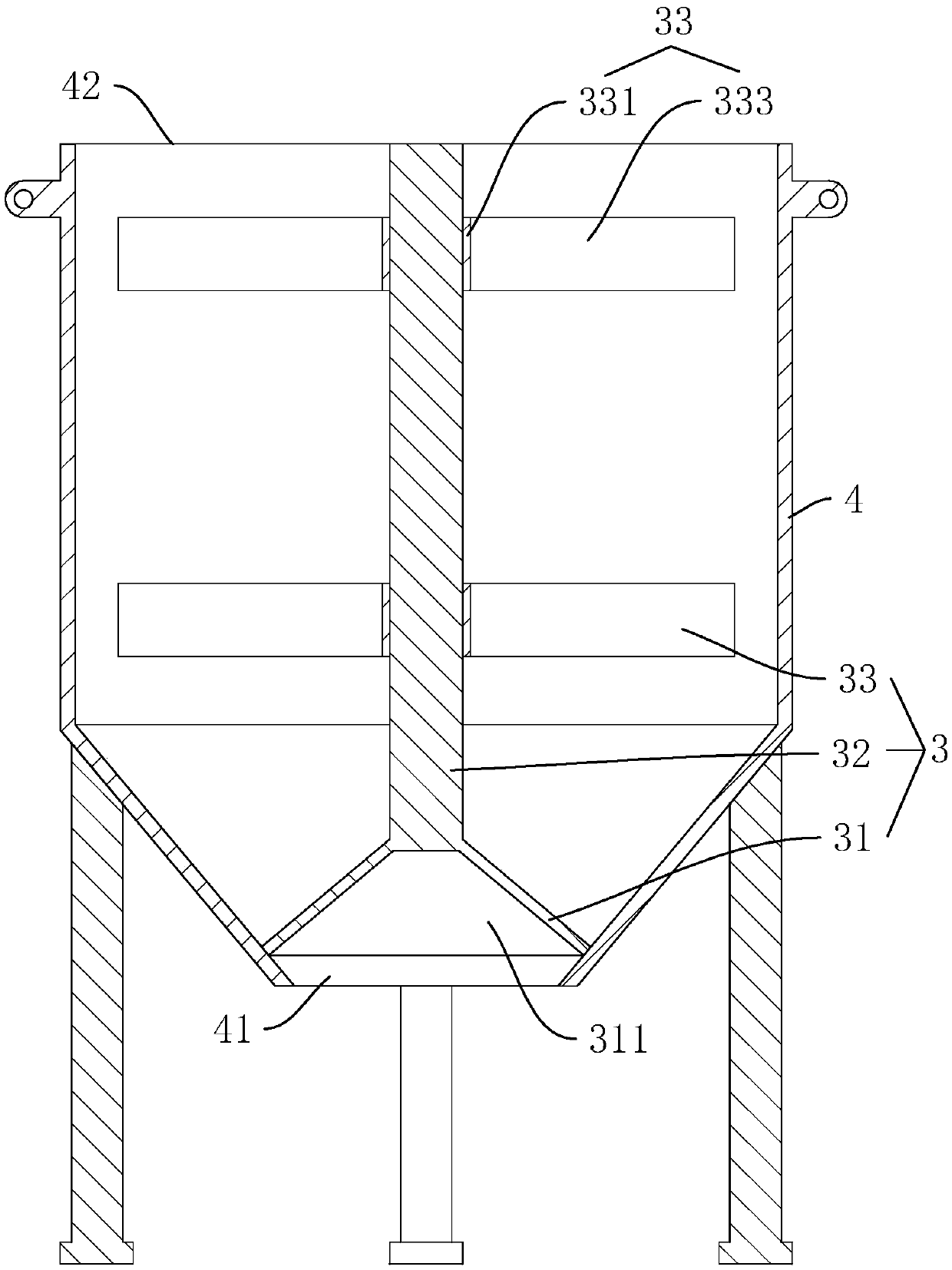

[0031] Embodiment 1: a kind of concrete pouring device, such as figure 1 As shown, it includes a material barrel 1 and a feeding cone 2. The lower material cone 2 is placed on the inner mold of the vertical vibrating steel mold, and the material barrel 1 is moved to the top of the lower material cone 2, and then the concrete in the material barrel 1 is unloaded. On the feeding cone 2. Concrete flows into the annular mold cavity along the conical surface of the feeding cone 2 .

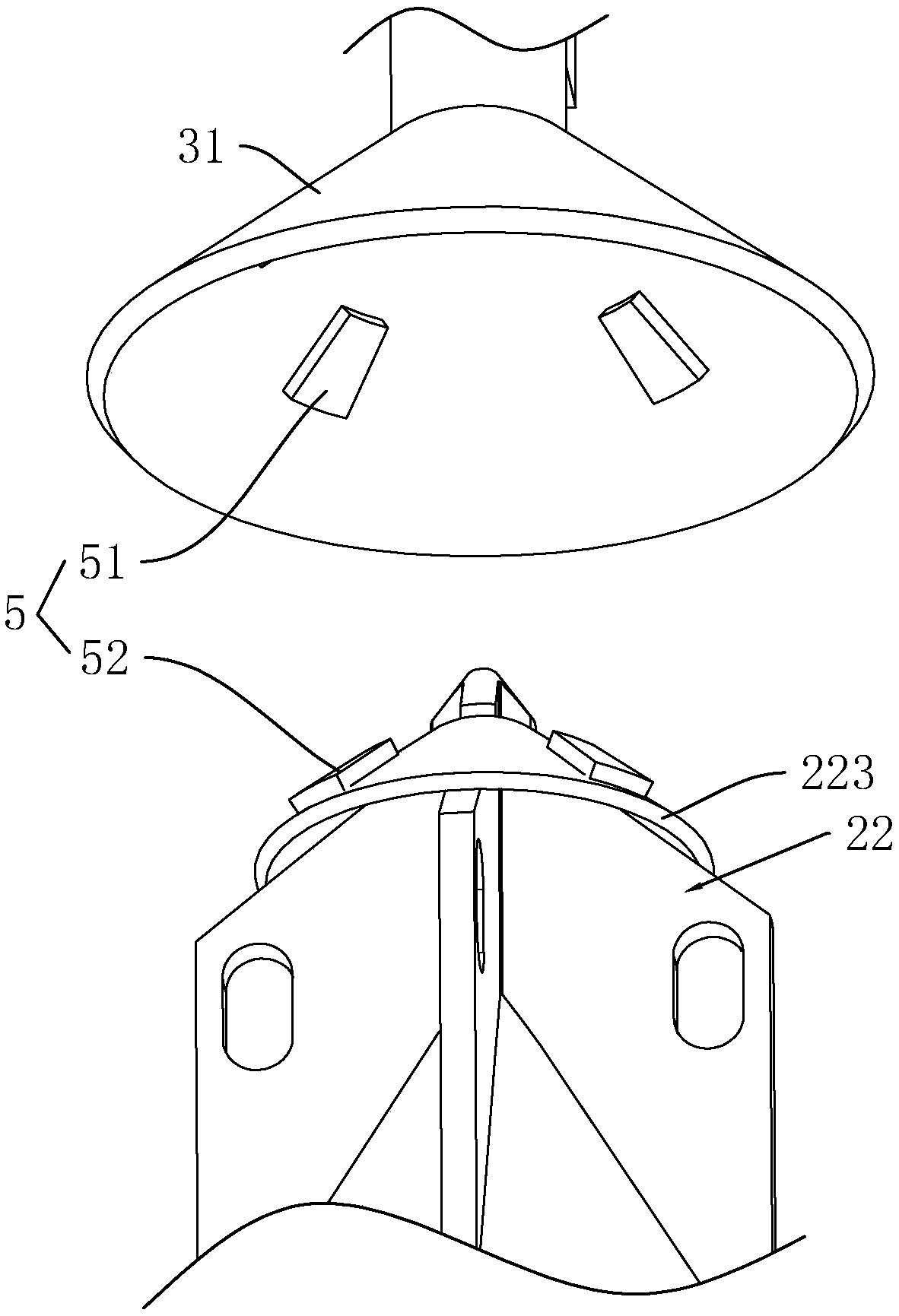

[0032] Such as figure 1 The blanking cone 2 includes a cone portion 21 and a tip portion 22 , the center axis of the tip portion 22 is coaxially arranged with the center axis of the cone portion 21 . The cone portion 21 is hollow cone, and the tip portion 22 is located at the upper end of the cone portion 21 . The tip part 22 includes four circumferential ribs 221 vertically welded to the cone 21. The end face of the rib 221 away from the cone 21 is inclined, and the end face away from the central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com