Wear-resistant corrosion-resistant powder paint for aluminum alloy template and preparation process thereof

A technology of aluminum alloy formwork and powder coating, which is applied in the field of coatings and can solve problems such as paint film damage, general wear resistance, and reduced service life of aluminum alloy formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

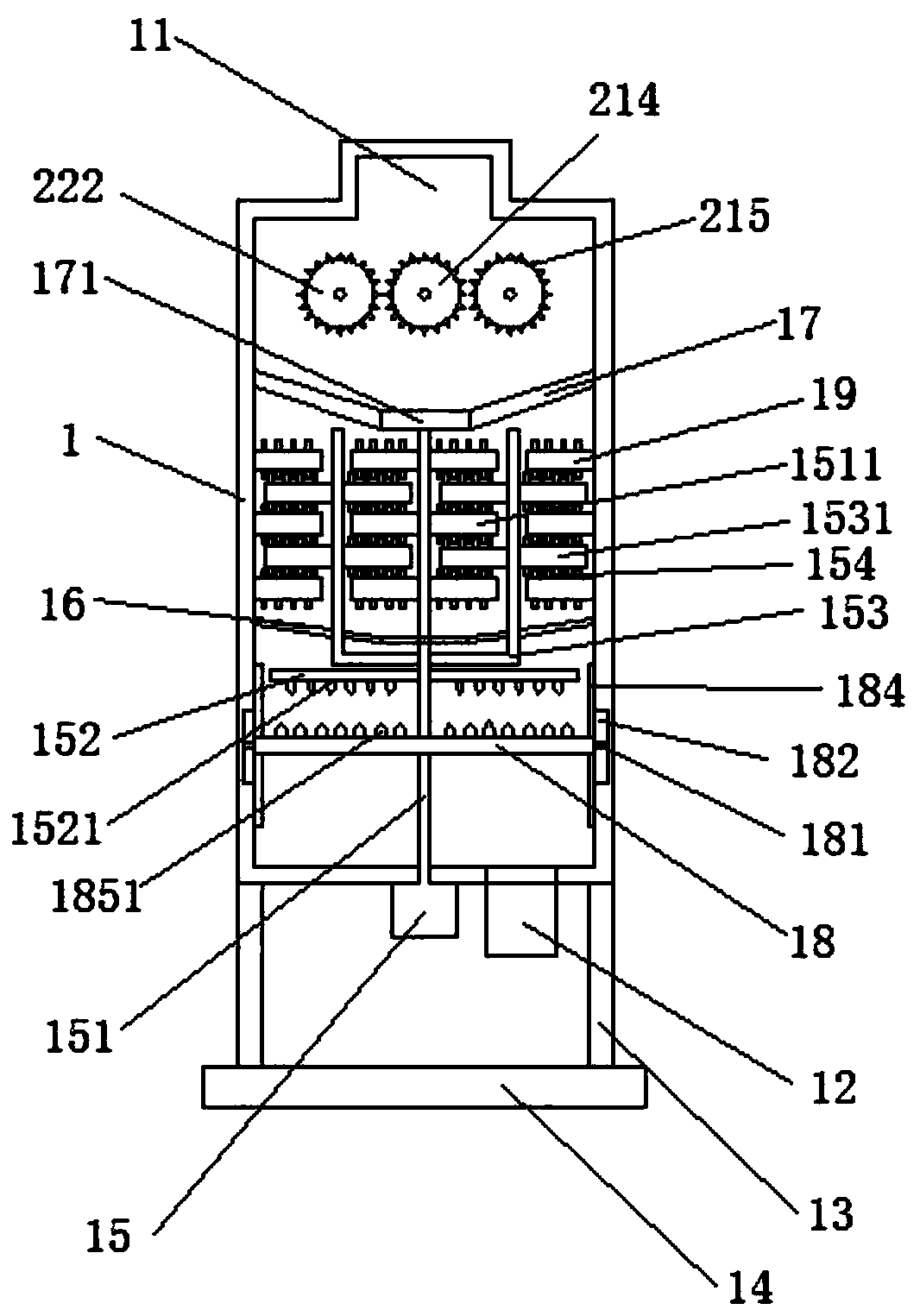

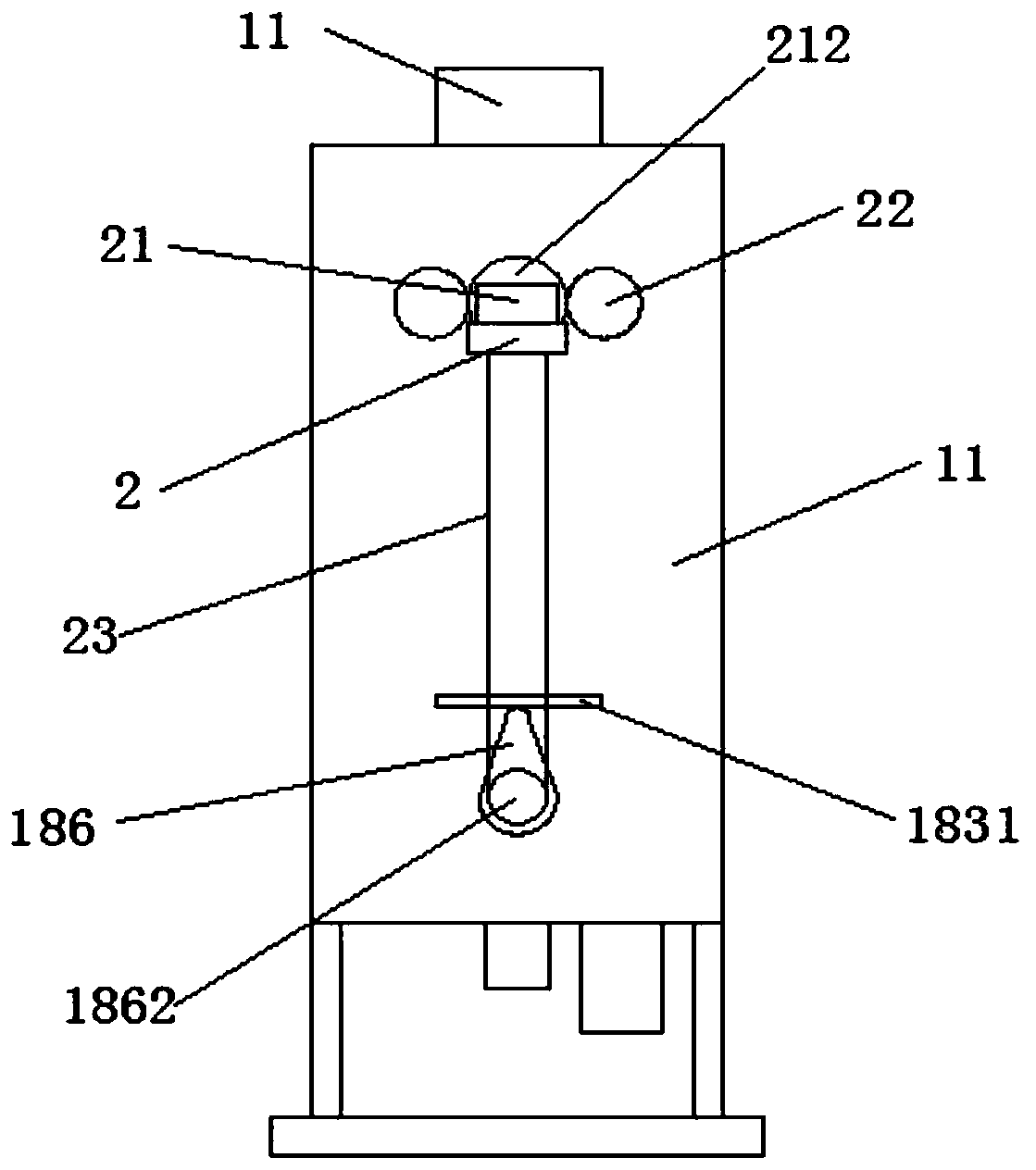

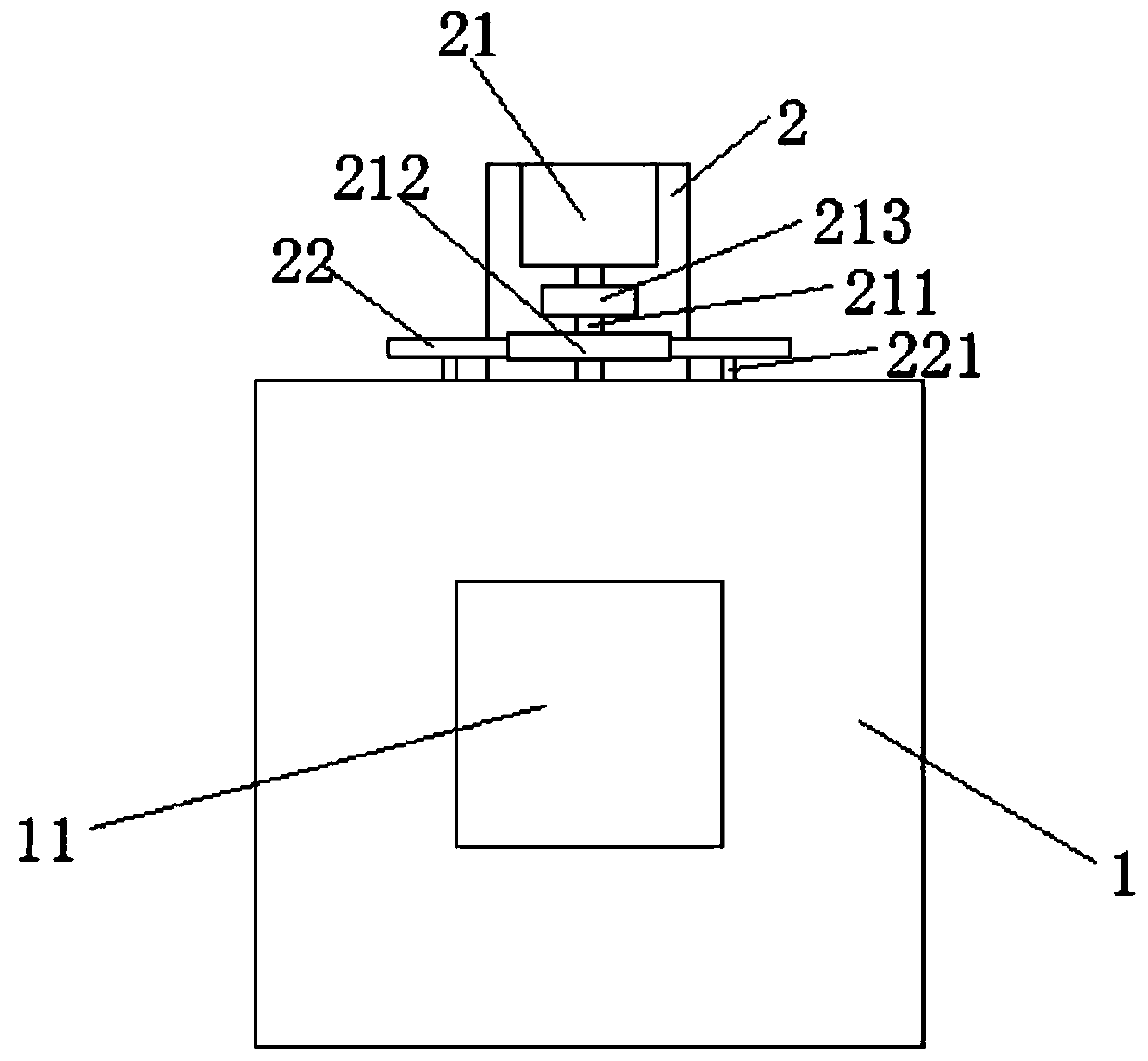

Image

Examples

Embodiment 1

[0055] A wear-resistant and anti-corrosion aluminum alloy template powder coating is made of the following raw materials in parts by weight: 20 parts of polyvinylidene chloride, 1.5 parts of titanium dioxide powder, 1.5 parts of silicon dioxide powder, 3 parts of stearic acid, 4 parts of reinforcing agent, 1.6 parts of silicone oil, 2 parts of polyethylene wax;

[0056] The preparation steps of this powder coating are as follows:

[0057] Step S1: Weigh the raw materials according to the above weight parts, add polyvinylidene chloride, titanium dioxide powder, silicon dioxide powder, stearic acid, and reinforcing agent into the dryer, and carry out the drying process at a temperature of 100°C. Dry for 10 minutes to obtain dried raw materials;

[0058] Step S2: Add the dried polyvinylidene chloride, titanium dioxide powder, silicon dioxide powder, stearic acid, reinforcing agent, silicone oil, and polyethylene wax into a high-speed mixer, and carry out at a speed of 500r / min. ...

Embodiment 2

[0069] A wear-resistant and anti-corrosion aluminum alloy template powder coating is made of the following raw materials in parts by weight: 23 parts of polyvinylidene chloride, 3 parts of titanium dioxide powder, 3 parts of silicon dioxide powder, 4 parts of stearic acid, 6 parts of reinforcing agent, 1.8 parts of silicone oil, 3 parts of polyethylene wax;

[0070] The preparation steps of this powder coating are as follows:

[0071] Step S1: Weigh the raw materials according to the above weight parts, add polyvinylidene chloride, titanium dioxide powder, silicon dioxide powder, stearic acid, and reinforcing agent into the dryer, and carry out the drying process at a temperature of 105°C. Dry for 13 minutes to obtain dried raw materials;

[0072] Step S2: Add the dried polyvinylidene chloride, titanium dioxide powder, silicon dioxide powder, stearic acid, reinforcing agent, silicone oil, and polyethylene wax into a high-speed mixer, and carry out at a speed of 650r / min. mix...

Embodiment 3

[0076] A wear-resistant and anti-corrosion aluminum alloy template powder coating is made of the following raw materials in parts by weight: 25 parts of polyvinylidene chloride, 4 parts of titanium dioxide powder, 4 parts of silicon dioxide powder, 5 parts of stearic acid, 8 parts of reinforcing agent, 2 parts of silicone oil, 4.5 parts of polyethylene wax;

[0077] The preparation steps of this powder coating are as follows:

[0078] Step S1: Weigh the raw materials according to the above weight parts, add polyvinylidene chloride, titanium dioxide powder, silicon dioxide powder, stearic acid, and reinforcing agent into the dryer, and carry out the drying process at a temperature of 110°C. Dry for 15 minutes to obtain dried raw materials;

[0079] Step S2: Add the dried polyvinylidene chloride, titanium dioxide powder, silicon dioxide powder, stearic acid, reinforcing agent, silicone oil, and polyethylene wax into a high-speed mixer, and carry out at a speed of 800r / min. mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com