Feeding apparatus

A feeding device and feeding technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of fast feeding speed, inability to bend, affect bending effect, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

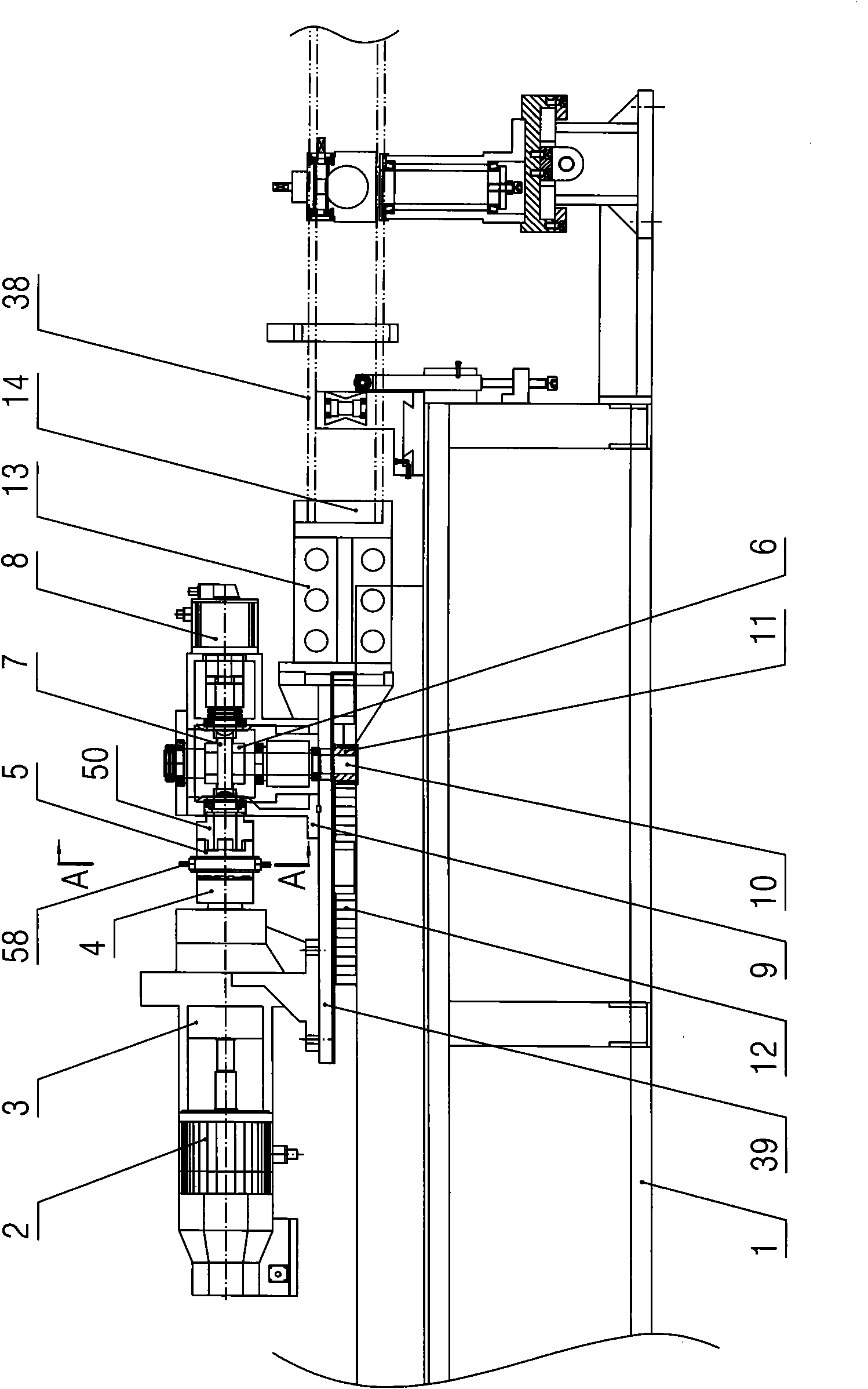

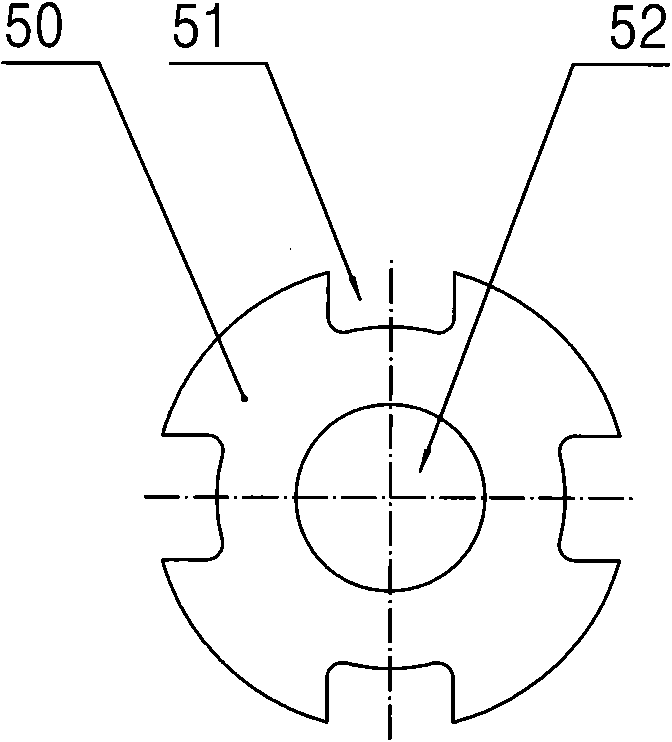

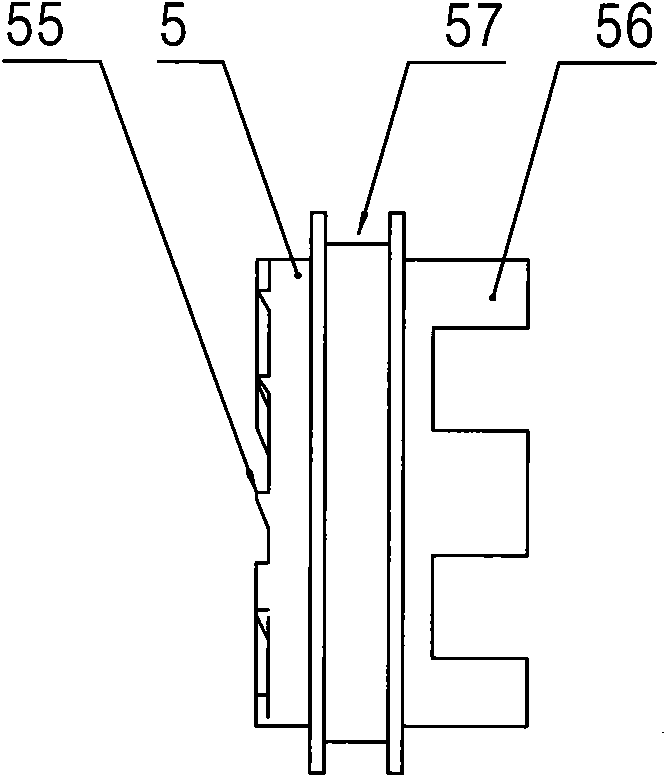

[0017] Such as figure 1 As shown, the feeding device of the present invention includes: a pair of parallel guide rails 40 arranged on the fuselage 1 and a feeding bottom plate 39 movably arranged on the pair of guide rails 40 through a slider 41—see Figure 5 As shown, the feeding bottom plate 39 is provided with a worm gear box 9, a feed motor 2 positioned at one side of the worm gear box 9, a feed reducer 3 and a reset motor 8 positioned at the other side of the worm gear box 9, and the output of the feed motor 2 The shaft is connected with the input shaft of the feed reducer 3, and the worm gear 6 is provided with the transmission shaft 10 in the vertical direction in the worm gear box 9. It meshes with the rack 12 arranged on the fuselage 1, and a horizontal worm 7 matched with the worm wheel 6 is also pierced in the worm gear box 9. A cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com