Respective recovery method for rare earth concentrate multi-stage baking tail gases, and device thereof

A rare earth concentrate and recovery method technology, which is applied in the field of separate recovery of roasting tail gas, multi-stage roasting of mixed rare earth concentrate concentrated sulfuric acid, and separate recovery of rare earth concentrate multi-stage roasting tail gas, can solve the complex process of rare earth roasting tail gas, Difficulty in recovering hydrofluoric acid and other problems to achieve the effect of saving process water and simplifying the concentration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The multistage roasting of embodiment 1 rare earth concentrate

[0075] The method described in Chinese patent CN102031363A is used for multi-stage roasting of rare earth concentrate.

[0076] The mixed rare earth concentrate raw material whose composition is shown in Table 1 below adopts a multi-stage (taking two stages as an example) serial rotary roasting method.

[0077] Table 1: Mixed rare earth concentrate raw material composition: (the unit of numerical value in the table is weight percent)

[0078] components

REO

CaO

Fe

THO 2

BaO

F

P 2 o 5

content

51.2

9.16

6.55

0.17

3.82

7.43

9.27

[0079] Mix the rare earth concentrate and concentrated sulfuric acid according to the ratio of mineral acid (dry ore: pure sulfuric acid) at 1:1.3; first-stage roasting: roast the mixed material at 400-480°C in a closed rotary kiln; second-stage roasting: put the above The mixed material after the...

Embodiment 2

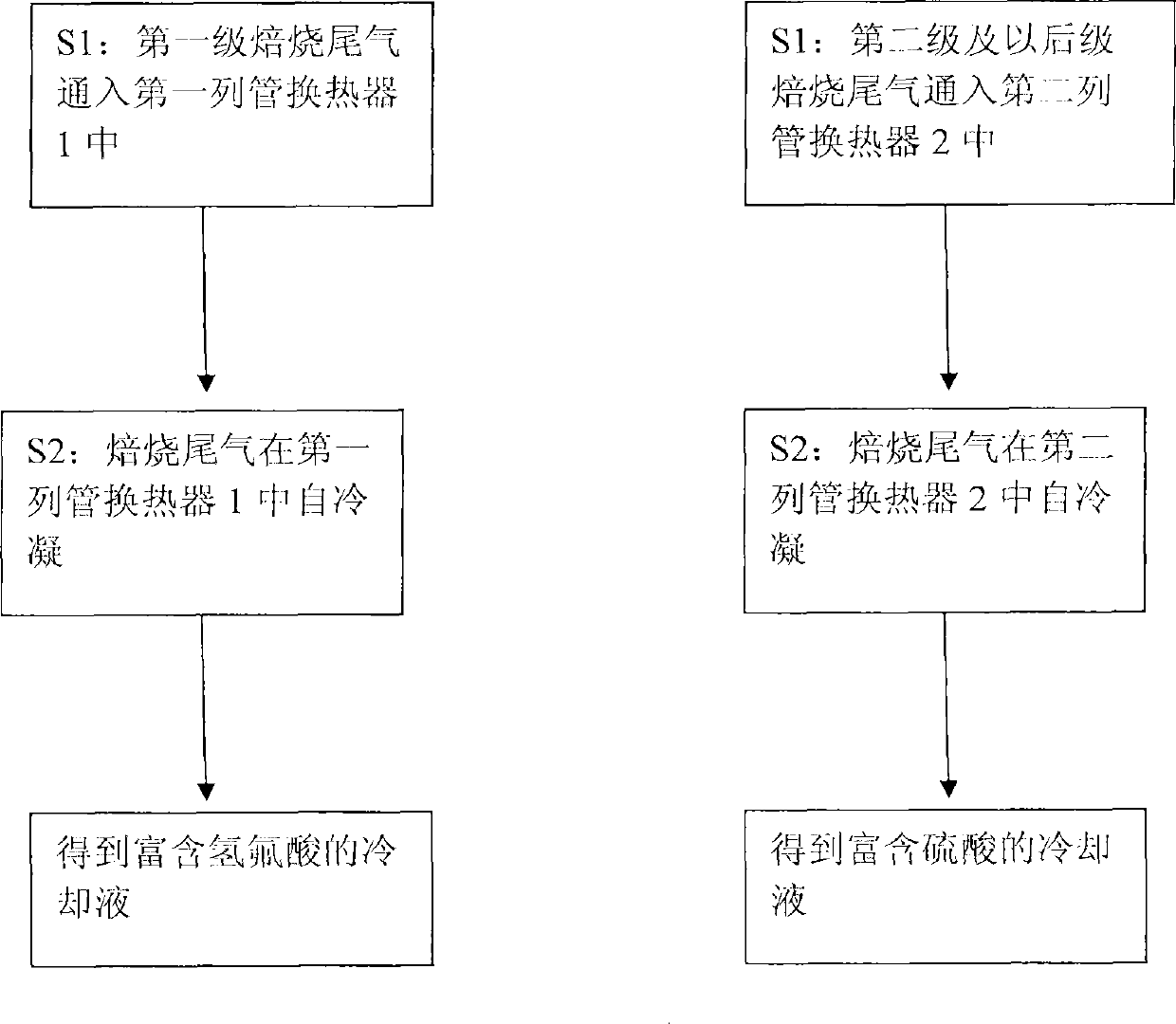

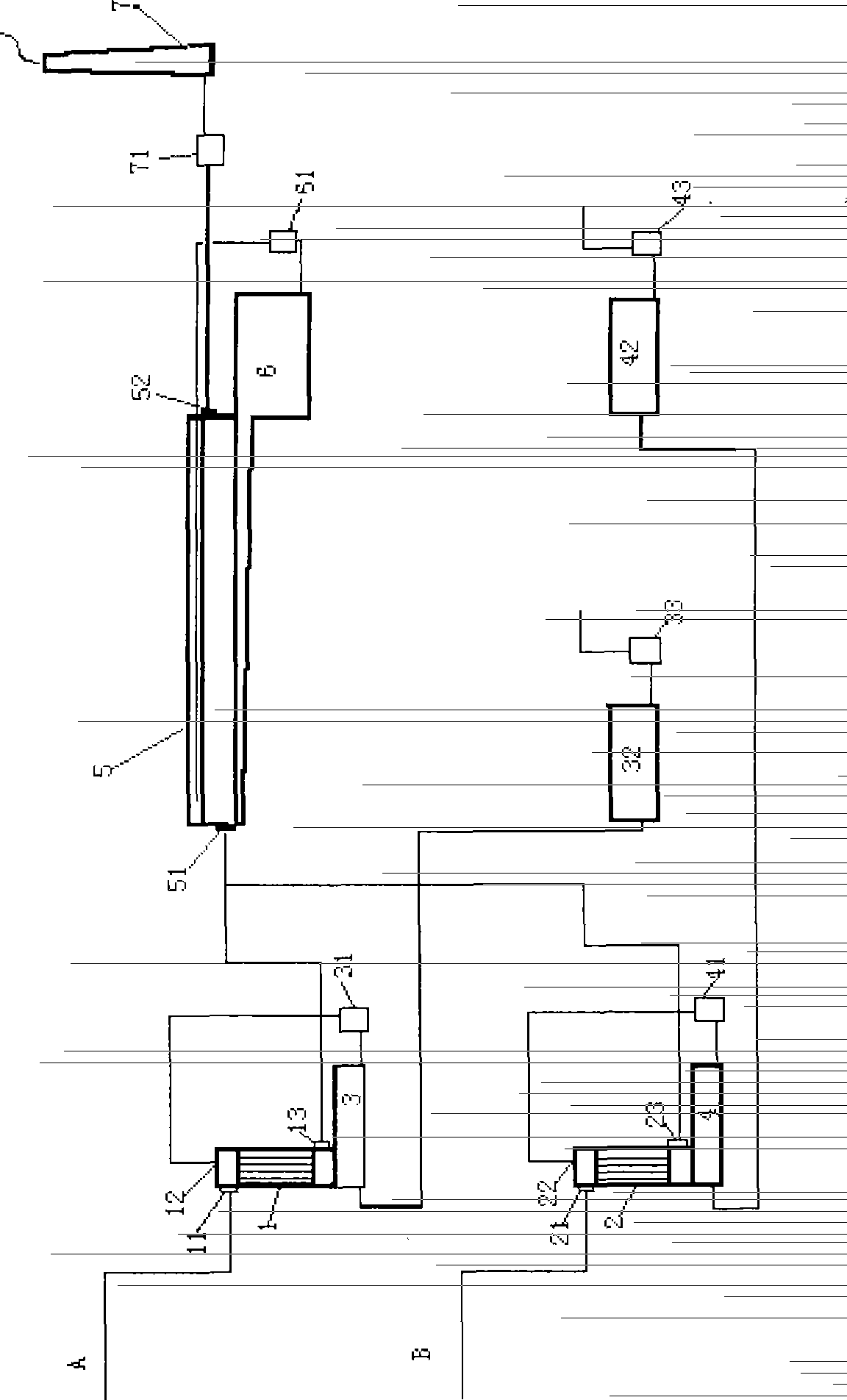

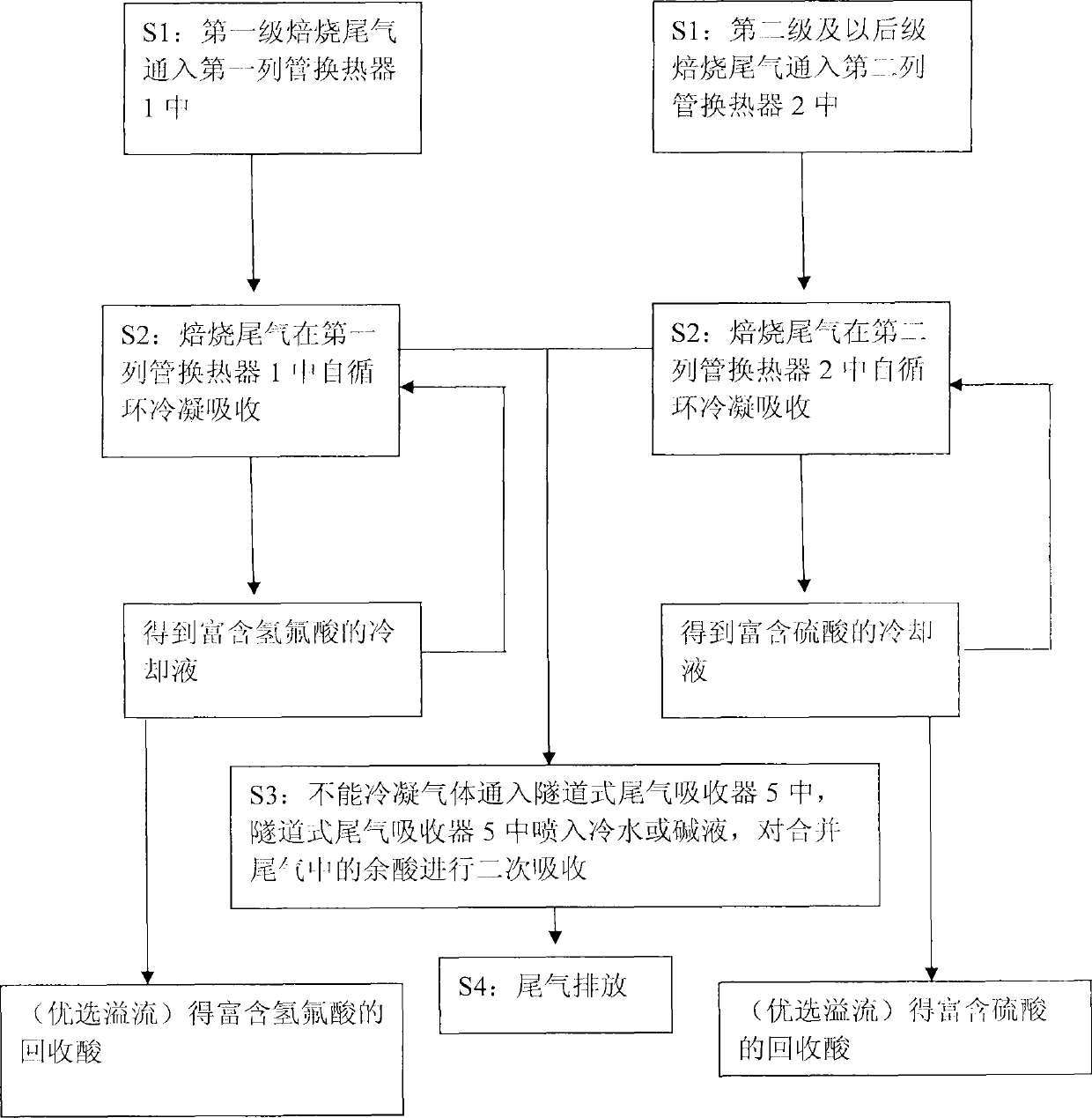

[0083] Embodiment 2 multi-stage roasting tail gas recovery and treatment respectively

[0084] This embodiment adopts as figure 2 The device shown is processed. When the concentrate roasting capacity is 20 tons / hour, the implementation plan for the separate recovery and treatment of multi-stage roasting tail gas is as follows: the first tube heat exchanger 1 and the second tube heat exchanger 2 are both graphite tube heat exchangers. It is about 21000 cubic meters per hour that strong induced draft fan 71 is set to air volume, and wind pressure is 3000 Pa, and motor is 30 kilowatts. The first-stage discharge in Example 1 is introduced into the inner side of the first tube heat exchanger 1 . The outside of the tubes of the first tube heat exchanger 1 is fed with circulating cooling water, and the first-stage discharge is condensed and collected in the first circulating acid pool 3 . The first acid-resistant pump 31 is set to a flow rate of about 50 cubic meters per hour, a ...

Embodiment 3

[0090] This embodiment adopts as Figure 4 The device shown is processed. The treatment method of this embodiment is basically the same as that of Embodiment 2, except that the first-stage discharge is collected in the first acid storage pool 14 after being condensed, and the condensate automatically overflows to the first circulating acid pool 3 as time goes by. After the second-stage discharge is condensed, it is collected in the second acid storage pool 24, and the condensate automatically overflows to the second circulating acid pool 4 as time goes by.

[0091] For each treatment of 1000g of dry ore, condensed absorption solution containing hydrofluoric acid recovered through self-circulation condensation absorption: 350g, analyzed by conventional means, the fluorine-containing acid is calculated as 71g, and the fluorine-containing acid in the condensed absorption solution is expressed as hydrofluoric acid Calculated weight percent concentration: 20.29%. The components o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com