Copper plate card and preparation method thereof

A technology for copper plate cards and primer coatings, applied in the directions of adding inorganic compounds, adding water repellents, adding reinforcing agents, etc., can solve the problem that paper is difficult to meet customer requirements, and achieve the effect of excellent performance, good folding resistance and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

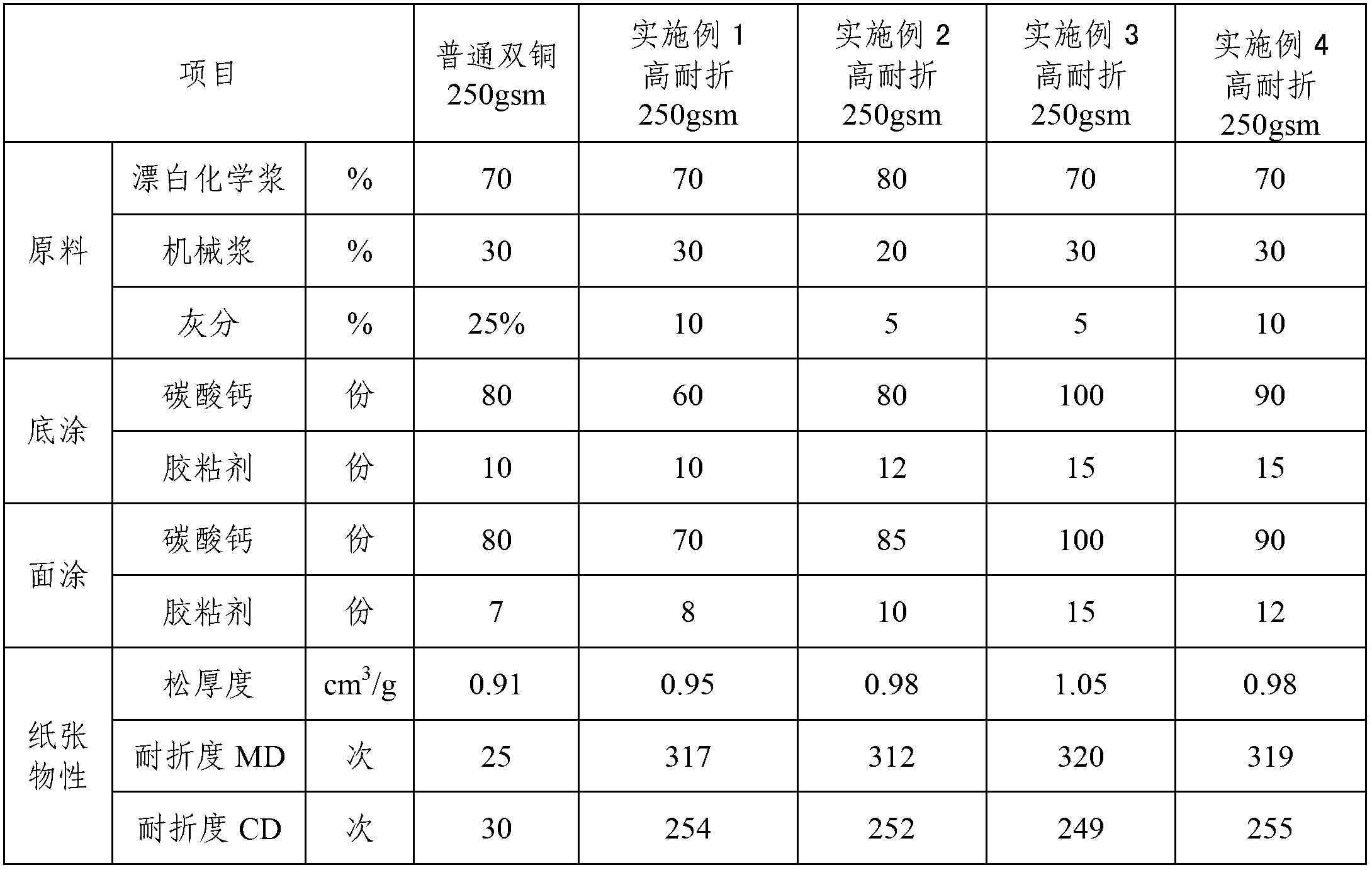

Embodiment 1

[0024] The proportion of pulp is softwood pulp (NBKP, purchased from Jinguang APP Group) 20%, hardwood pulp (LBKP, purchased from Jinguang APP Group) 50%, chemical thermomechanical pulp (BCTMP, purchased from Canada Meadow Lake pulp mill) )30%. The base paper layer uses more softwood pulp (NBKP), which can meet the base paper with higher folding resistance requirements. According to the calculation of 1 ton of paper per 0.9 tons of pulp, the raw materials are dispersed and refined in proportion, and wet-end chemicals (alkyl ketene dimer 7kg / t, alkenyl succinic anhydride 1.0kg / t, positive starch 10kg / t, polyacrylamide ternary retention system, fluorescent whitening agent 2kg / t, polyaluminum chloride 0.7kg / t), sizing, dehydration, front drying, surface sizing, post drying, curling into paper, and making base paper .

[0025] The dust point of base paper is controlled below 0-5ppm to meet the basic requirements for the appearance of high-grade paper in the international market...

Embodiment 2

[0033] The proportion of pulp is 30% of softwood pulp (NBKP), 50% of hardwood pulp (LBKP), and 20% of chemithermomechanical pulp (BCTMP). According to the calculation of 1 ton of paper per 0.95 tons of pulp, the raw materials are dispersed, refined, and wet-end chemicals are added in proportion (5 kg / t of alkyl ketene dimer, 08 kg / t of alkenyl succinic anhydride, 8 kg / t of positive starch) t, polyacrylamide ternary retention system, polyaluminum chloride 0.5kg / t), sizing, dehydration, pre-drying, surface sizing, post-drying, curling into paper, and making base paper.

[0034]The dust point of base paper is controlled below 0-5ppm to meet the basic requirements for the appearance of high-grade paper in the international market. The paper weight of the base paper is 100-200gsm, the ash content of the base paper is controlled at 5% or less, and a three-way retention system (cationic polyacrylamide 0.2kg / t, anionic polyacrylamide 0.2kg / t, weak anionic polyacrylamide 2.0 kg / t), th...

Embodiment 3

[0039] The proportion of pulp is 25% of softwood pulp (NBKP), 45% of hardwood pulp (LBKP), and 30% of chemical thermomechanical pulp (BCTMP). According to the calculation of 1 ton of paper per 0.95 tons of pulp, the raw materials are dispersed, refined, and wet-end chemicals are added in proportion (10kg / t of alkyl ketene dimer, 1.2kg / t of alkenyl succinic anhydride, 12kg of positive starch / t, polyacrylamide ternary retention system, fluorescent whitening agent 5kg / t, polyaluminum chloride 1kg / t), sizing, dehydration, pre-drying, surface sizing, post-drying, curling into paper, and make base paper.

[0040] The dust point of base paper is controlled below 0-5ppm to meet the basic requirements for the appearance of high-grade paper in the international market. The grammage of base paper is 100-300gsm, the ash content of base paper is controlled at 5% or less, and a ternary retention system (cationic polyacrylamide 0.2kg / t, anionic polyacrylamide 0.2kg / t, weak anionic polyacryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com