Colorful anti-forgery ink for high temperature sintering toughened glass and microcrystalline glass and use method thereof

A technology of high-temperature sintering and glass ink, which is applied in inks, applications, household appliances, etc., can solve the problems of uneven product quality, easy peeling off of printed marks, and inability to achieve anti-counterfeiting, and achieve good anti-counterfeiting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

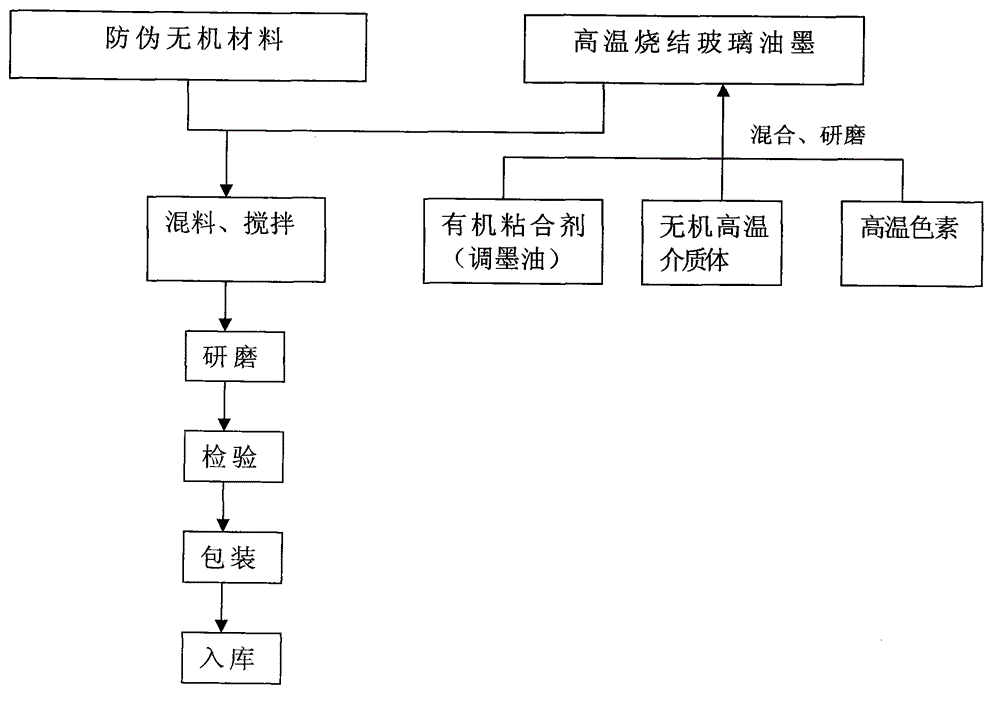

[0020] Such as figure 1 As shown, take 10%-30% of organic binder, 30%-80% of inorganic high-temperature medium and 0%-40% of high-temperature pigment for mixing and grinding to make high-temperature sintered glass ink; then take anti-counterfeiting inorganic 20-50% of the material, mixed and stirred evenly, then ground, packaged and put into storage after passing the inspection, as the finished high-temperature sintered anti-counterfeiting glass ink.

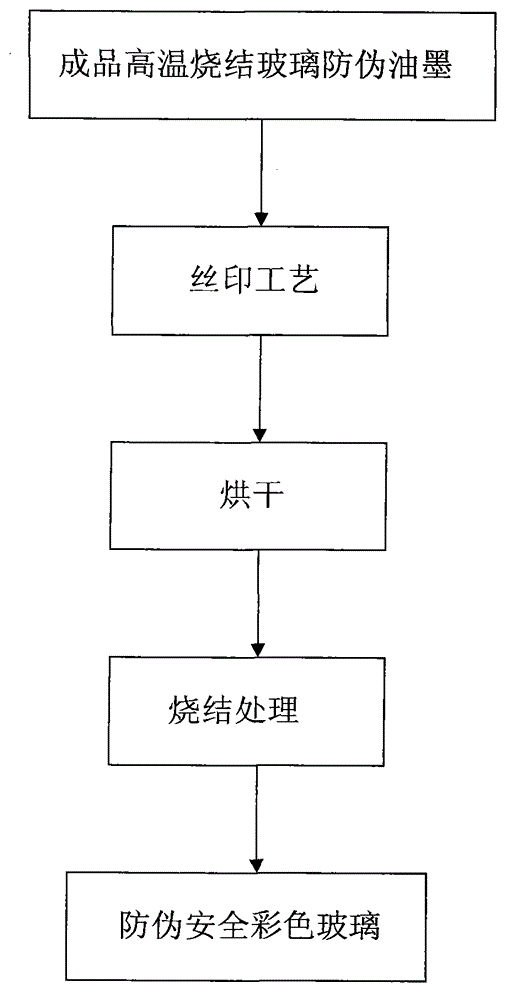

[0021] Such as figure 2 As shown, take figure 1 The finished high-temperature sintered anti-counterfeiting glass ink is uniformly printed on the glass surface with an 80-350 mesh screen printing process, dried at a temperature of 150-200°C for about 3-5 minutes, and then the glass is put into a high-temperature furnace. 530-750°C, the time is 2-10 minutes. Carry out sintering treatment. During the treatment process, the binder of the organic part in the high-temperature anti-counterfeiting ink is burned away, leaving the ino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com