A method and system for producing video clips

A technology of video clips and acquisition methods, applied in the field of production video clip acquisition, can solve problems such as difficulty in finding the real cause of defective products and inability to know implementation details.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

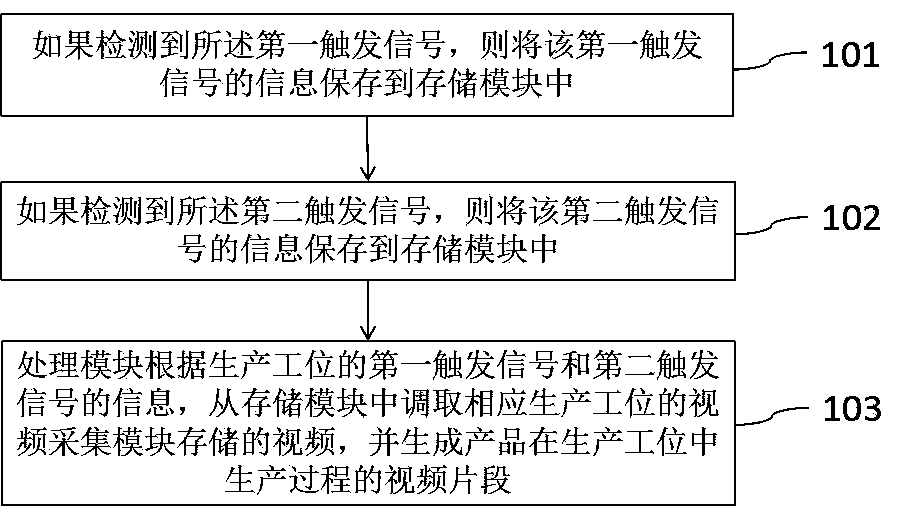

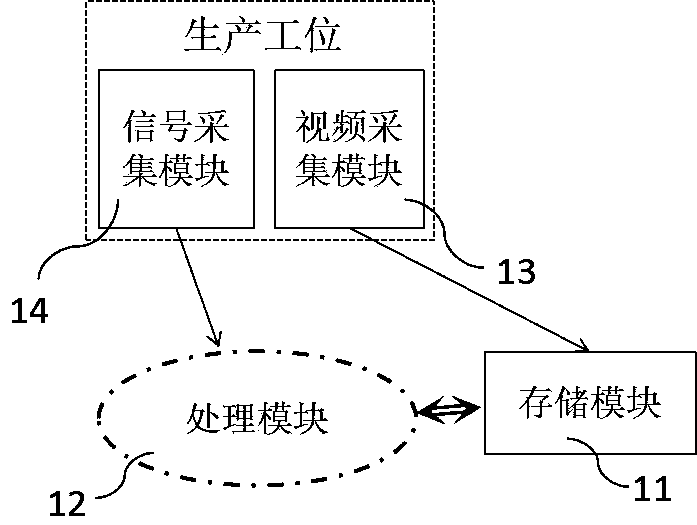

[0049] A production video segment acquisition method (such as figure 1 ), a video capture module (13) is installed in the production station, and the video captured by the video capture module (13) will be stored in the storage module (11). The method at least includes the following steps:

[0050] Step 101, if the first trigger signal is detected, save the information of the first trigger signal into the storage module;

[0051] In a specific implementation, the first trigger signal may be sent by a sensor at the entrance of the equipment in the processing station, such as a photoelectric sensor or a pressure sensor, and when it senses that the product arrives at the entrance of the equipment, the first trigger signal is sent to the processing module (12) The first trigger signal can also be the trigger signal sent when the barcode scanner in the detection station scans the barcode, for example, the inspector scans the barcode of the product before product detection, and at t...

Embodiment 2

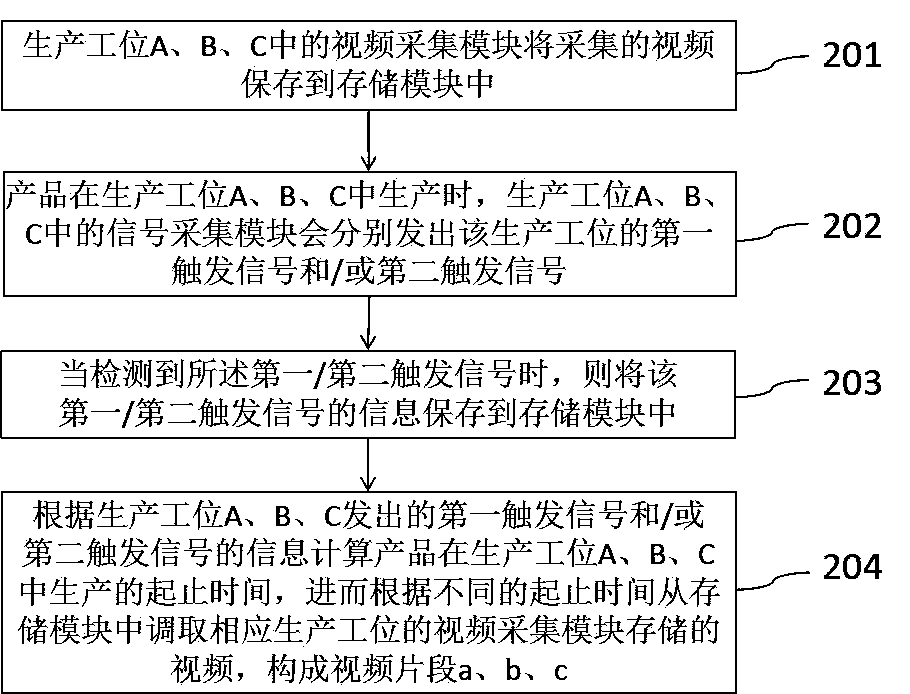

[0062] A production video segment acquisition method and system (such as figure 2 ), the method at least includes the following steps:

[0063] Step 201, the video capture modules in the production stations A, B, and C save the captured video in the storage module;

[0064] In specific implementation, the production station A can be a raw material processing station, where a video capture module A is installed, the production station B can be a product assembly station, where a video capture module B is installed, and the production station C can be a product packaging Work station, wherein video capture module C is installed; Video capture module A, B, C save the video that collects in the storage module (11) uninterruptedly;

[0065] Further improvement, according to the specific settings of the factory, the production stations A, B, and C can also be raw material processing stations, product processing stations, product assembly stations, product testing stations, product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com