Anti-counterfeiting structure of bottle cap

A technology of bottle caps and anti-counterfeiting rings, which is applied in the field of bottle caps, can solve problems such as not easy to imitate, and achieve the effect of not easy to slide, high friction, and anti-counterfeiting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

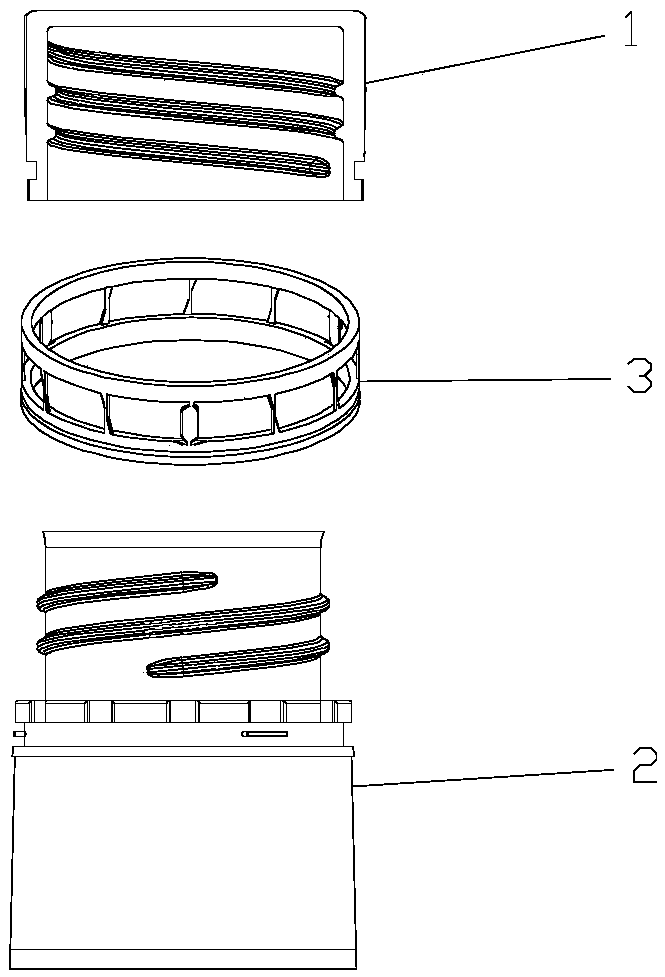

[0027] Below in conjunction with accompanying drawing, the specific mode of the present invention is explained, and the implementation direction of the present invention is with figure 1 The direction of is standard.

[0028] Such as figure 1 As shown, the anti-counterfeiting structure of a bottle cap of the present invention includes a loam cake 1, a base 2 and an anti-counterfeiting ring 3, wherein:

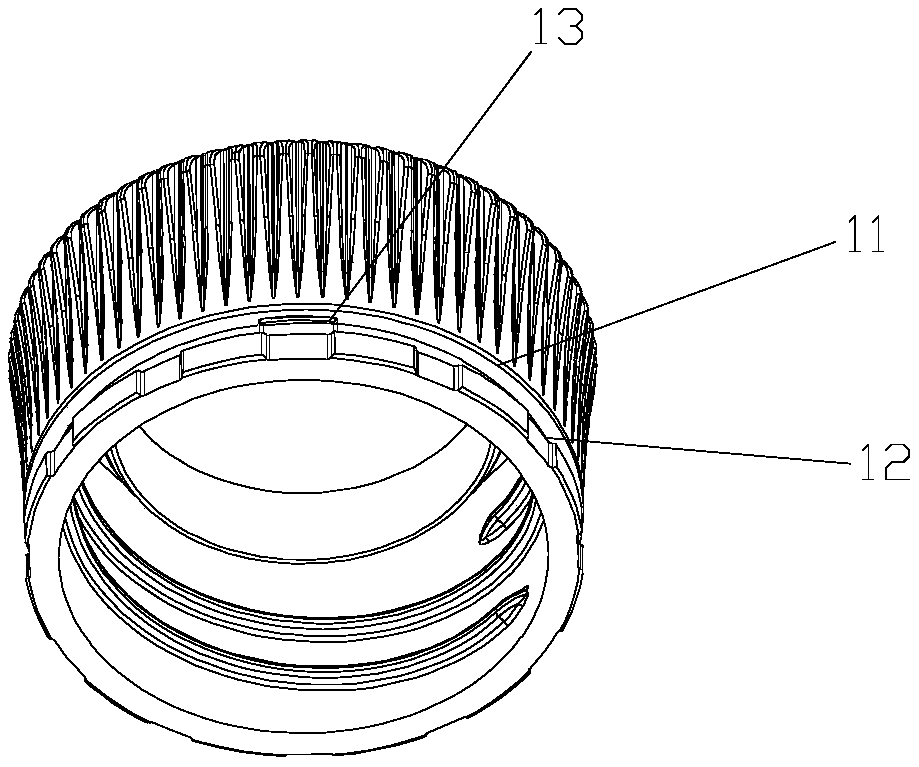

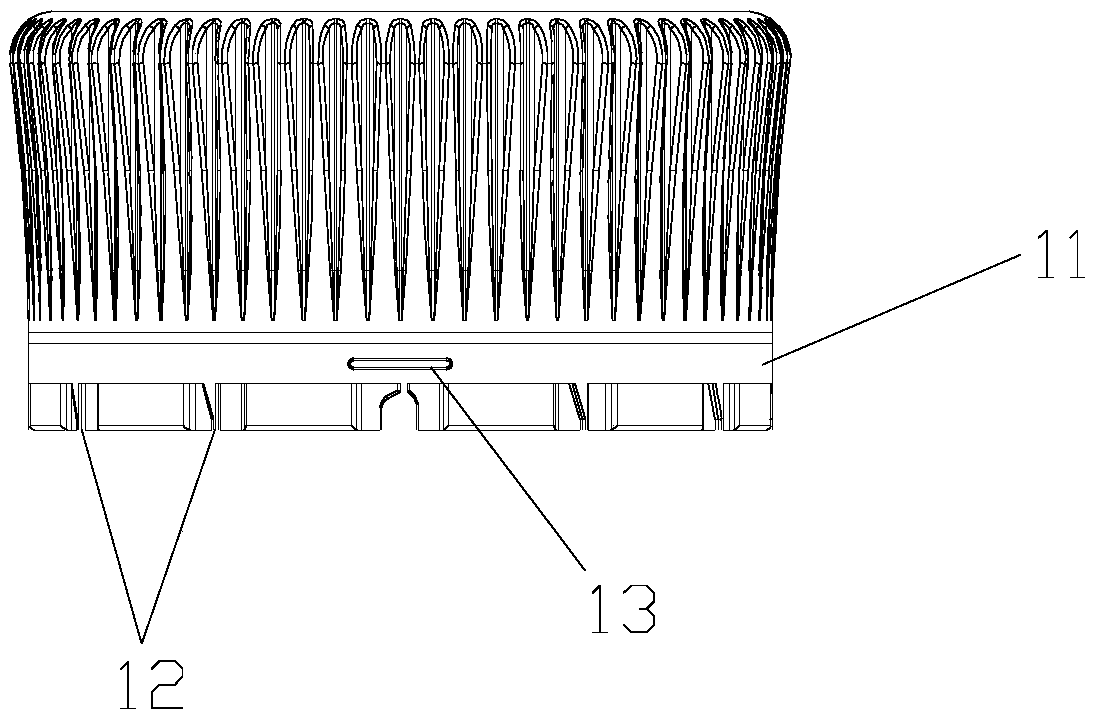

[0029] The loam cake 1 is used to cooperate with the base 2 to realize the sealing of the bottle body 4. The inner wall of the loam cake 1 is provided with threads, and the bottom of the outer wall of the loam cake 1 is provided with a first anti-counterfeiting injection groove 11 along its circumference. A plurality of strip-shaped upper protrusions 13 are arranged at equal intervals in the interior of the housing 11. The bottom end (below the first anti-counterfeiting injection molding groove 11) of loam cake 1 outer wall is longitudinally provided with several upper passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com