Special fluorescent anti-counterfeit material and preparing method and application thereof

A fluorescence and product technology, applied in luminescent materials, chemical instruments and methods, applications, etc., to achieve the effects of comprehensive implied anti-counterfeiting information, broad application prospects, and stable product fluorescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

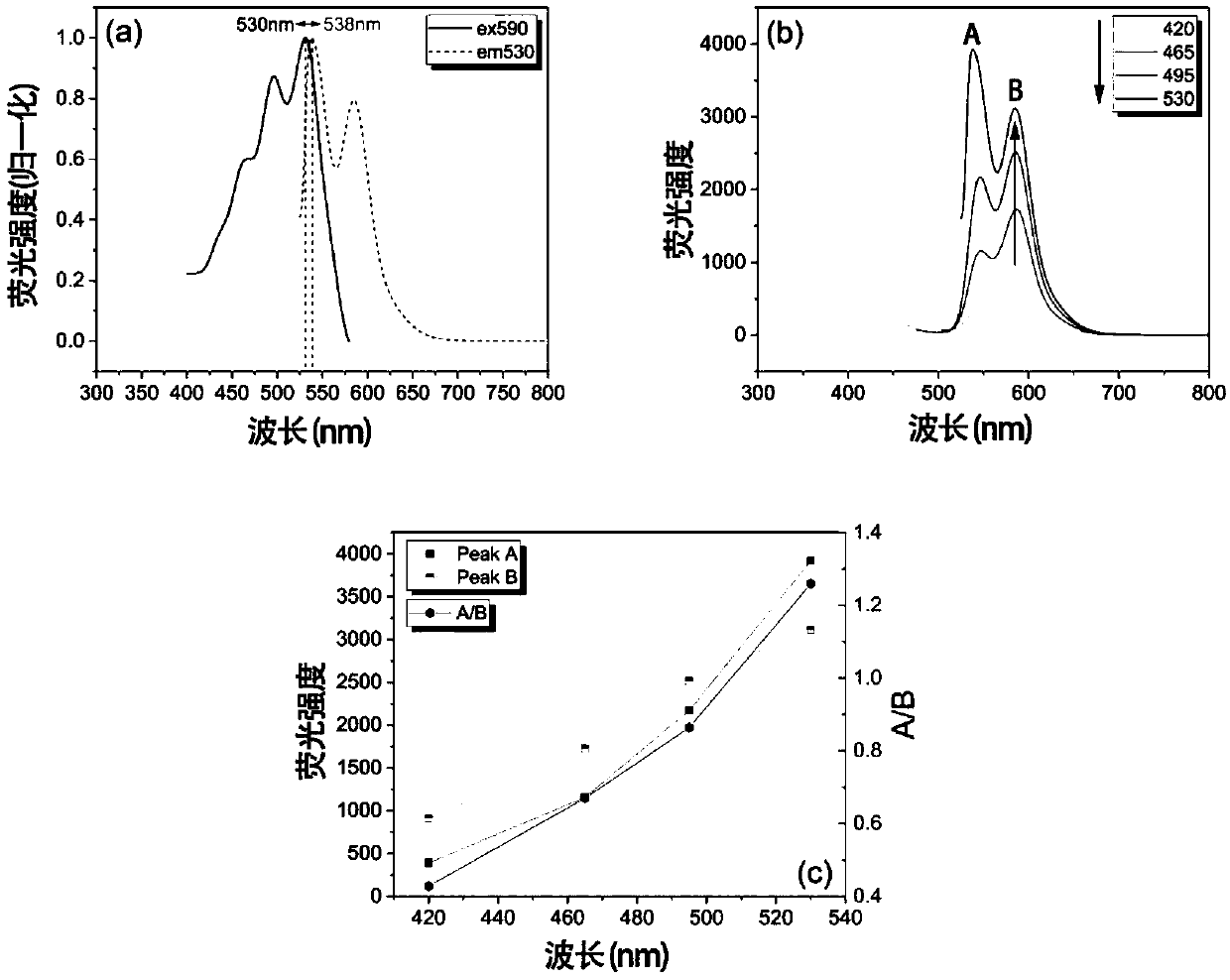

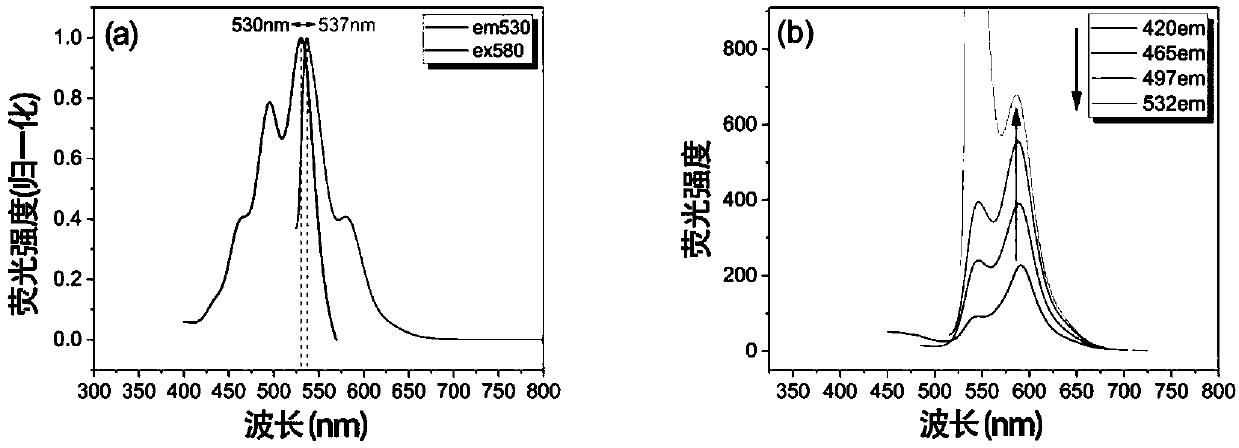

Image

Examples

preparation example Construction

[0055] The present invention provides the preparation method of the compound shown in above-mentioned formula (I), described method comprises the steps:

[0056] 1) 3,4,9,10-perylenetetracarboxylic anhydride, R-NH 2 1. Mix the catalyst into quinoline or imidazole; or without adding quinoline or imidazole, under the protection of argon atmosphere, control the reaction temperature at 120-250°C, and stir for 4-48h;

[0057] 2) During the cooling process, before the mixture obtained from the above reaction is solidified, pour it into the precipitant, stir for 30min-6h, let stand, settle, filter, wash, dry, and finally obtain purified solid powder through silica gel column separation ; Wherein, R is as defined above.

[0058] Preferably, in the synthesis step, according to the different types of reactant organic amines, the catalyst can be diethanolamine or zinc acetate, and the stoichiometric ratio of 3,4,9,10-perylenetetracarboxylic anhydride to the catalyst is 1:0 to 1:5.

[...

preparation example 1

[0064] Preparation Example 1: Synthesis of Compound X6 (R groups are the same, selected from the above-mentioned 2,4,6-trimethylphenyl group with the number 6)

[0065]

[0066] 7.84g (20.0mmol) 3,4,9,10-perylenetetracarboxylic anhydride, 10.00g (74.0mmol) 2,4,6-trimethylaniline and 3.66g (20.0mmol) zinc acetate were miscible in 45.0mL In quinoline, the Schlenk line was used to freeze, vacuumize, and flush with argon three times. Finally, the above mixture was stirred and heated to 230° C. for 4 h under the protection of argon atmosphere to complete the reaction. After cooling, pour the above reactant into about 450mL of 75°C hot water, stir, stand still, precipitate, filter, wash with deionized water, and dry, and the solid sample obtained is separated by silica gel column (dichloromethane / methanol 2%) After purification, 9.40 g of reddish-brown solid powder was obtained, with a yield of 75%.

preparation example 2

[0067] Preparation Example 2: Synthesis of Compound X21 (R groups are the same, selected from the above-mentioned 4-adamantylphenyl group numbered 21)

[0068]

[0069] 3.92g (10mmol) of 3,4,9,10-perylenetetracarboxylic anhydride, 5.68g (25mmol) of 4-adamantyl aniline, and 60.00g (0.88mol) of imidazole were mixed uniformly, and the mixture was vacuum-puffed three times with argon. Under the protection of an argon atmosphere, stir and heat to 140° C. for 4 h to complete the reaction. After cooling, pour it into a mixed solution of 500mL ethanol / water / concentrated hydrochloric acid (volume ratio 25:10:1) while the mixture is still stirring, stir for 4.5h, let stand, settle, filter, wash with deionized water, and dry to obtain Brown solid, the crude product was separated and purified through a silica gel column (dichloromethane / methanol 2%) to obtain 4.21 g of red solid powder with a yield of 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com