Heat-sensitive label and preparation method thereof

A label and heat-sensitive technology, applied in the field of labels, can solve the problems of easy removal, poor reliability, and inability to play an anti-counterfeiting role

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

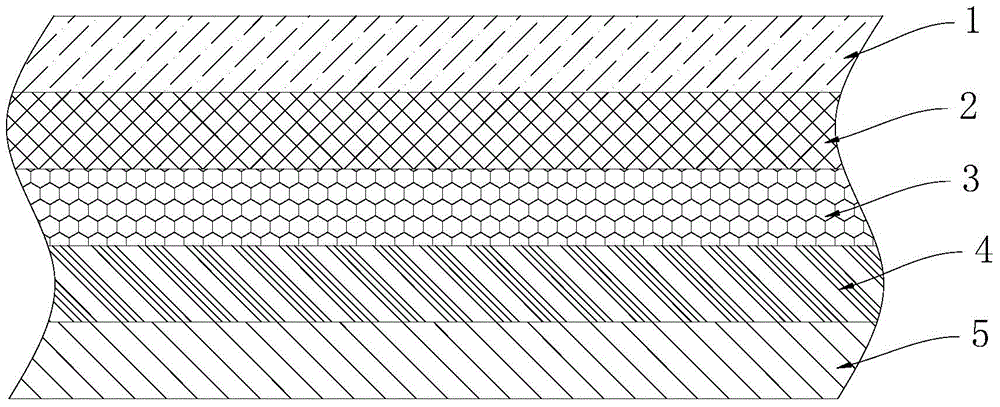

[0018] This embodiment discloses a thermal label, such as figure 1 As shown, it includes a thermal paper 1, the side of the thermal paper 1 facing away from its heat-sensitive coating is coated with an isolation layer 2, and an ink layer of a preset graphic is printed on the isolation layer 2 3. A glue layer 4 is coated on the ink layer 3 , and a release paper 5 is pasted on the glue layer 4 . Among them, the thermal paper 1 is a primary and three-proof thermal paper with a thickness of 30 μm to 300 μm. The thermal paper 1 includes a thermal coating layer, a coated base paper, and a resin layer stacked sequentially from top to bottom. The resin layer Including but not limited to PP, PE, PET, PVA or other resins.

[0019] When the above thermal label is in use, the release paper 5 is first removed, and then the glue layer 4 side of the thermal label is pasted on the product, wherein the thermal paper 1 is located on the surface layer, and when the thermal coating is heated Di...

Embodiment 2

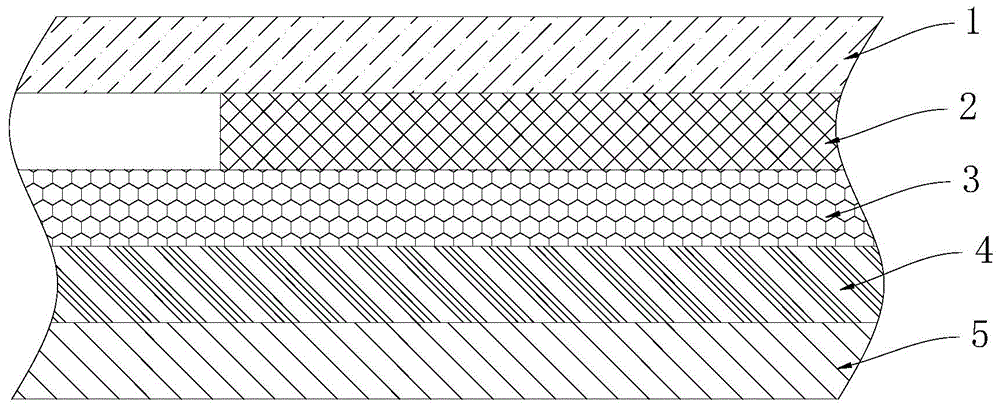

[0024] Such as figure 2 As shown, the thermal label in this embodiment includes thermal paper 1, isolation layer 2, ink layer 3, glue layer 4 and release paper 5. The difference between this embodiment and Embodiment 1 is that the The isolation layer 2 is a partial isolation layer covering the preset position of the thermal paper 1 .

[0025] The heat-sensitive label of above-mentioned structure, its preparation method comprises the following steps:

[0026] Step S1, using a coating device to coat a release layer 2 on the side of the thermal paper 1 facing away from the thermal coating;

[0027] Step S2, using the printing equipment to print the ink layer 3 of the preset image and text on the isolation layer 2;

[0028] Step S3, coating the glue layer 4 on the ink layer 3;

[0029] In step S4, attach the release paper 5 to the glue layer 4, and then print images and texts on the front side of the thermal paper 1 and die-cut to obtain a finished thermal label.

[0030] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com