Double-cone ring

A cone-ring and ring-shaped technology, which is applied in the field of synchronizer accessories and double-cone rings, can solve the problems of low friction coefficient between the outer peripheral surface and the inner peripheral surface, it is difficult to ensure the effective contact area, and the wear debris is not easy to discharge, etc., to achieve effective contact The effect of large area, light weight and smooth debris discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

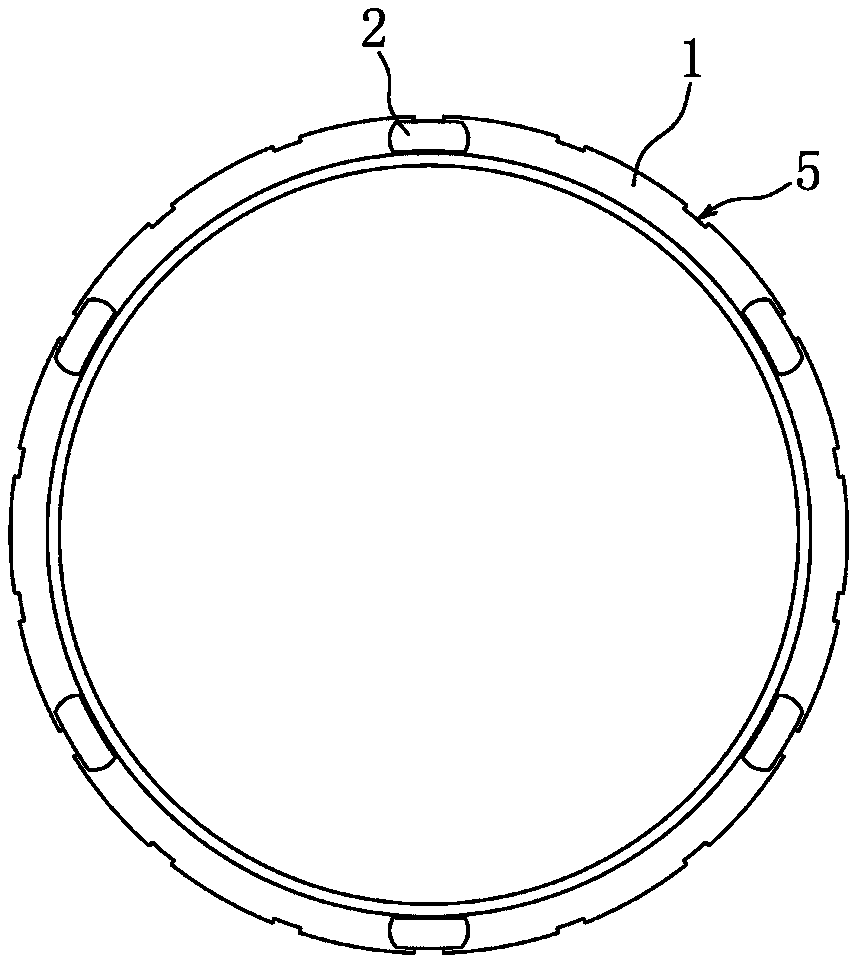

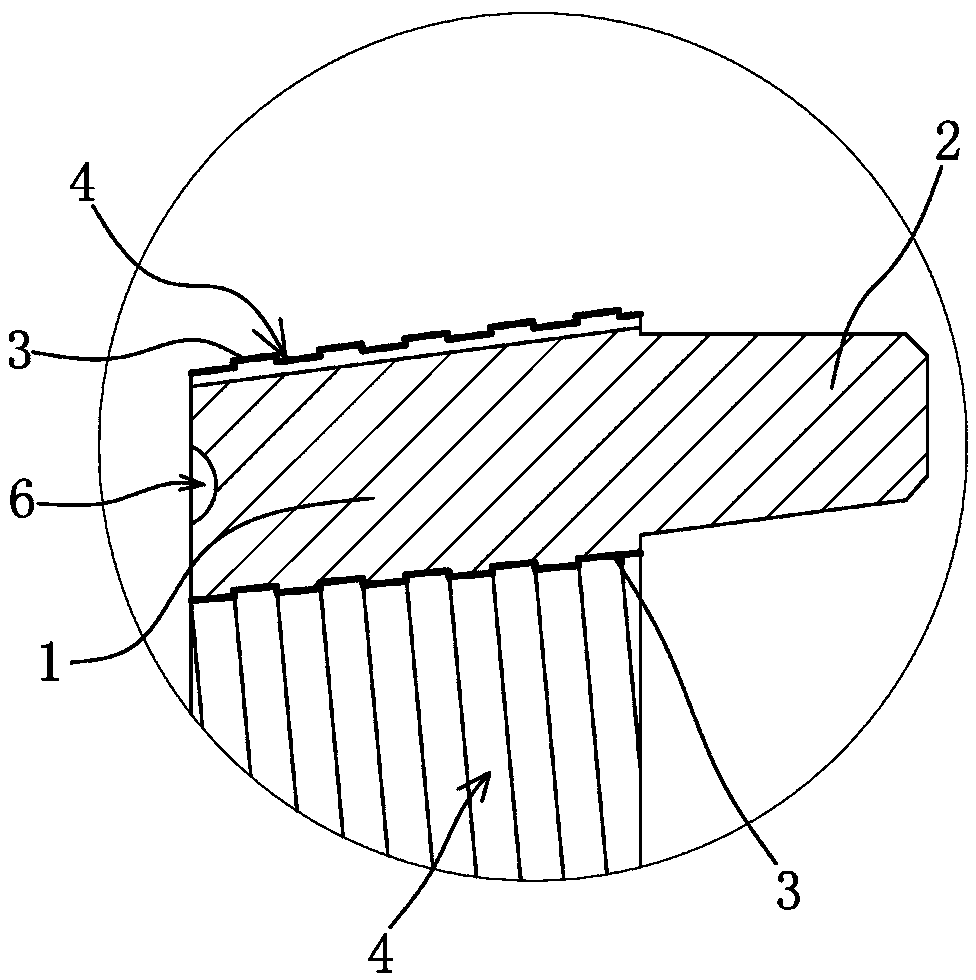

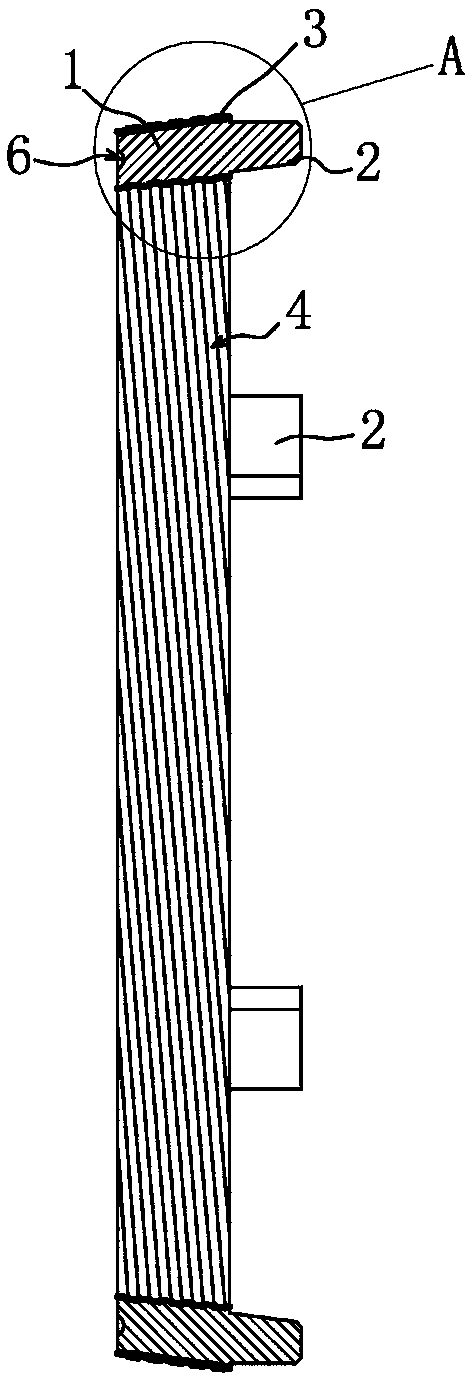

[0018] Such as figure 1 , figure 2 and image 3 As shown, the double cone ring includes a ring-shaped body 1, the outer and inner peripheral surfaces of the body 1 are conical, and on the axial section of the body 1, the outer peripheral surface of the body 1 is parallel to the inner periphery of the body 1 The side of the main body 1 with a large outer diameter has several axially extending and evenly distributed circumferentially protruding bumps 2, and the number of protruding bumps 2 in this embodiment is six. Both the outer peripheral surface and the inner peripheral surface of the main body 1 are attached with a molybdenum surface layer 3 formed by spraying molybdenum wire.

[0019] In further detail, the outer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com