Marking device before polishing of electric vehicle body

A marking device, a technology for electric vehicles, applied in grinding/polishing equipment, grinding/polishing hand tools, metal processing equipment, etc., can solve the problems of uneven body surface, affecting process production, time-consuming, etc., to improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

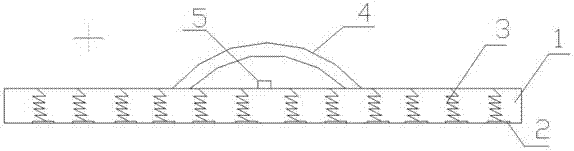

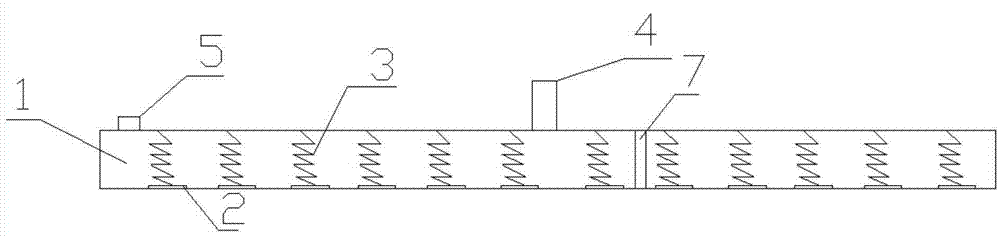

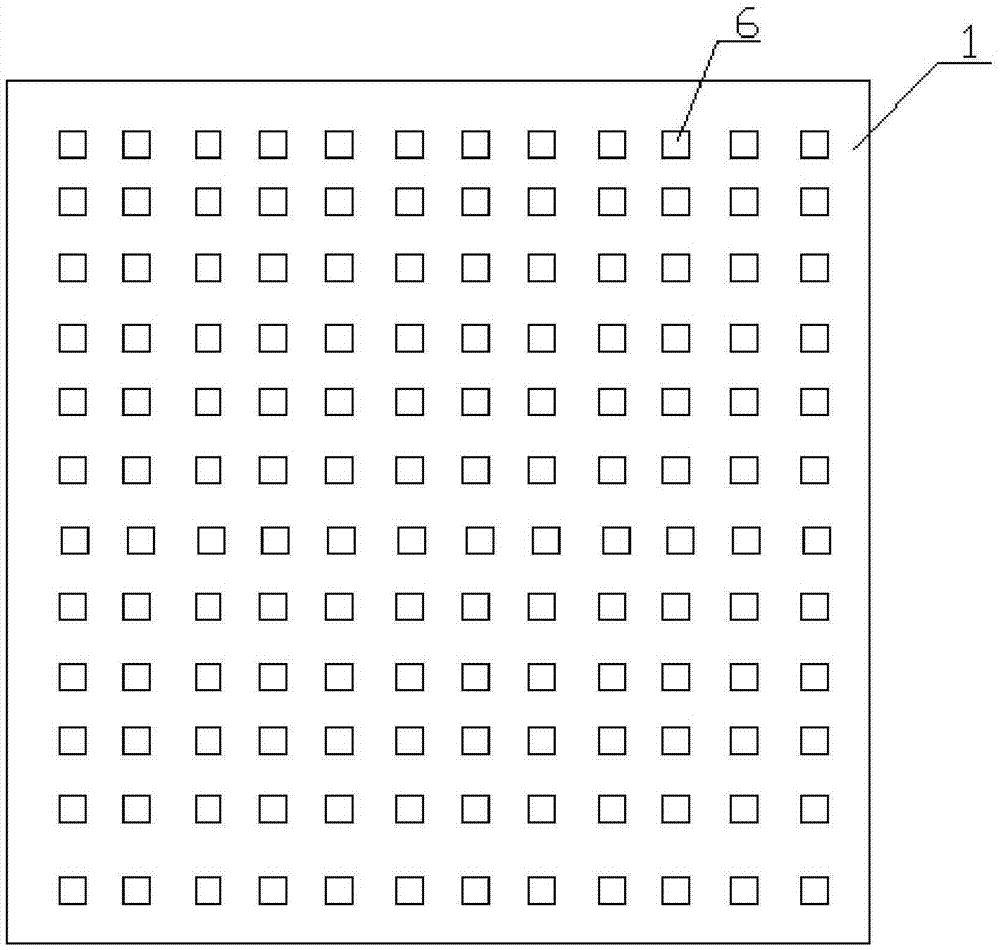

[0012] see figure 1 , figure 2 and image 3 , the technical solution of the present invention is to provide a marking device before the body of an electric vehicle is polished, including a body 1, a spring 3, and a retainer 2. The body 1 is a hollow square structure, and the upper surface of the body 1 is provided with a liquid inlet 5. The body 1 The lower surface of the body is provided with evenly arranged square liquid outlets 6 of 12 times 12, and the inner upper surface of the body 1 corresponding to each liquid outlet 6 is welded with a spring 3; the other end of each spring 3 is welded with a baffle 2 ; The baffle 2 is in close contact with the inner lower surface of the body 1 ; the baffle 2 covers the corresponding liquid outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com