Recessive antifalsification paper and preparation method thereof

An anti-counterfeiting paper and concealment technology, which is applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of anti-counterfeiting paper being forged by lawless elements and cannot effectively play an anti-counterfeiting role, and achieve the goal of increasing anti-counterfeiting measures and improving anti-counterfeiting effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

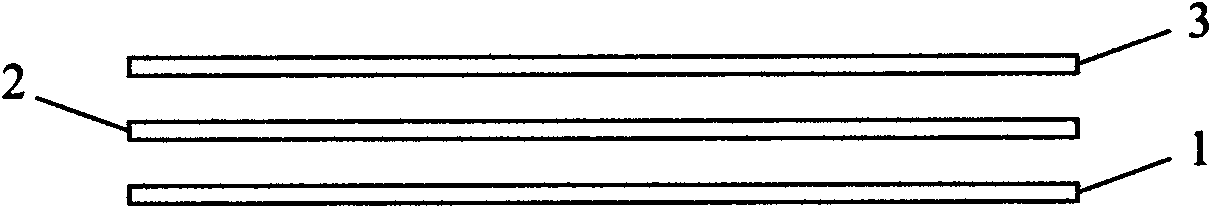

[0034] see figure 1 , as shown in the figure, a covert anti-counterfeiting paper includes a base material layer 1 with a visible ink layer 2 on the base material layer 1 and a covert ink layer 3 on the covert ink layer 2 . The substrate layer is coated paper layer, offset layer or bond paper layer. The hidden ink layer is a hidden logo pattern layer, and the hidden logo pattern layer is a hidden two-dimensional code layer or a hidden pattern layer. The recessive ink contains a reaction reagent capable of reacting with dilute nitric acid with a molar concentration of 30-35% to turn black, and the reaction reagent accounts for 10-20% by volume of the recessive ink. The reaction reagent is 3-cyclohexylmethylamino-6-methyl-7-anilinofluorane synthesized by reacting diphenylcopper derivatives with 2-methyl-4-methoxydiphenylamine.

Embodiment 2

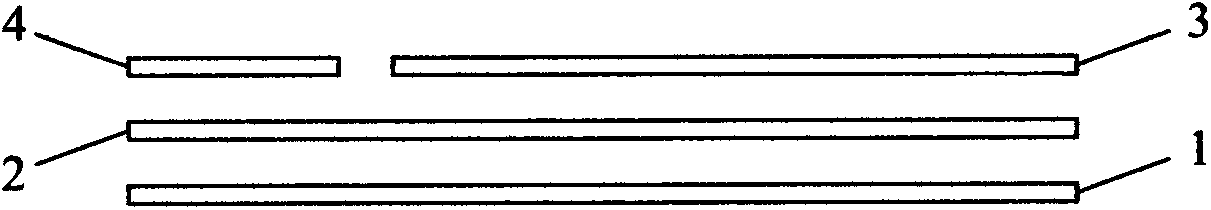

[0036] see figure 2 , as shown in the figure, a covert anti-counterfeiting paper includes a base material layer 1 with a visible ink layer 2 on the base material layer 1 and a covert ink layer 3 on the covert ink layer 2 . The overt ink layer 2 also has a refraction anti-counterfeiting layer 4 printed with refraction ink. The refraction ink is UV refraction ink. The substrate layer is coated paper layer, offset layer or bond paper layer. The hidden ink layer is a hidden logo pattern layer, and the hidden logo pattern layer is a hidden two-dimensional code layer or a hidden pattern layer. The recessive ink contains a reaction reagent capable of reacting with dilute nitric acid with a molar concentration of 30-35% to turn black, and the reaction reagent accounts for 10-20% by volume of the recessive ink. The reaction reagent is 3-cyclohexylmethylamino-6-methyl-7-anilinofluorane synthesized by reacting diphenylcopper derivatives with 2-methyl-4-methoxydiphenylamine.

Embodiment 3

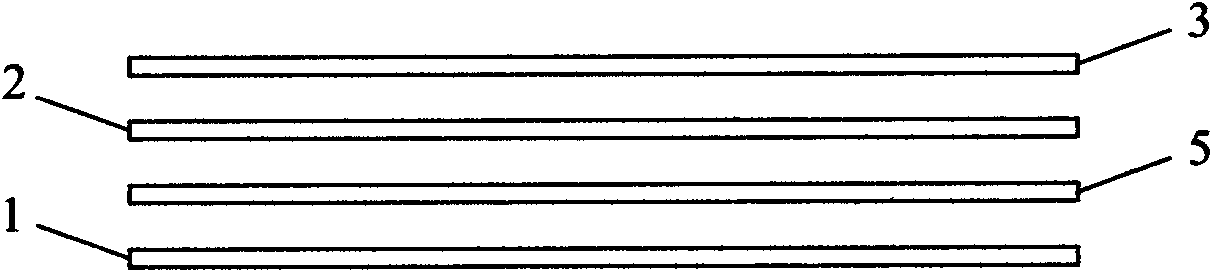

[0038] see image 3 , as shown in the figure, a covert anti-counterfeiting paper includes a base material layer 1 with a visible ink layer 2 on the base material layer 1 and a covert ink layer 3 on the covert ink layer 2 . There is a watermark pattern layer 5 between the substrate layer 1 and the visible ink layer 2 . The substrate layer is coated paper layer, offset layer or bond paper layer. The hidden ink layer is a hidden logo pattern layer, and the hidden logo pattern layer is a hidden two-dimensional code layer or a hidden pattern layer. The recessive ink contains a reaction reagent capable of reacting with dilute nitric acid with a molar concentration of 30-35% to turn black, and the reaction reagent accounts for 10-20% by volume of the recessive ink. The reaction reagent is 3-cyclohexylmethylamino-6-methyl-7-anilinofluorane synthesized by reacting diphenylcopper derivatives with 2-methyl-4-methoxydiphenylamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com